Thermocouple Technology: Measuring Temperature with Precision

Thermocouple technology, a cornerstone of temperature measurement, harnesses the Seebeck effect to convert heat into electrical signals. This remarkable phenomenon, discovered in the 19th century, has revolutionized industries ranging from […]

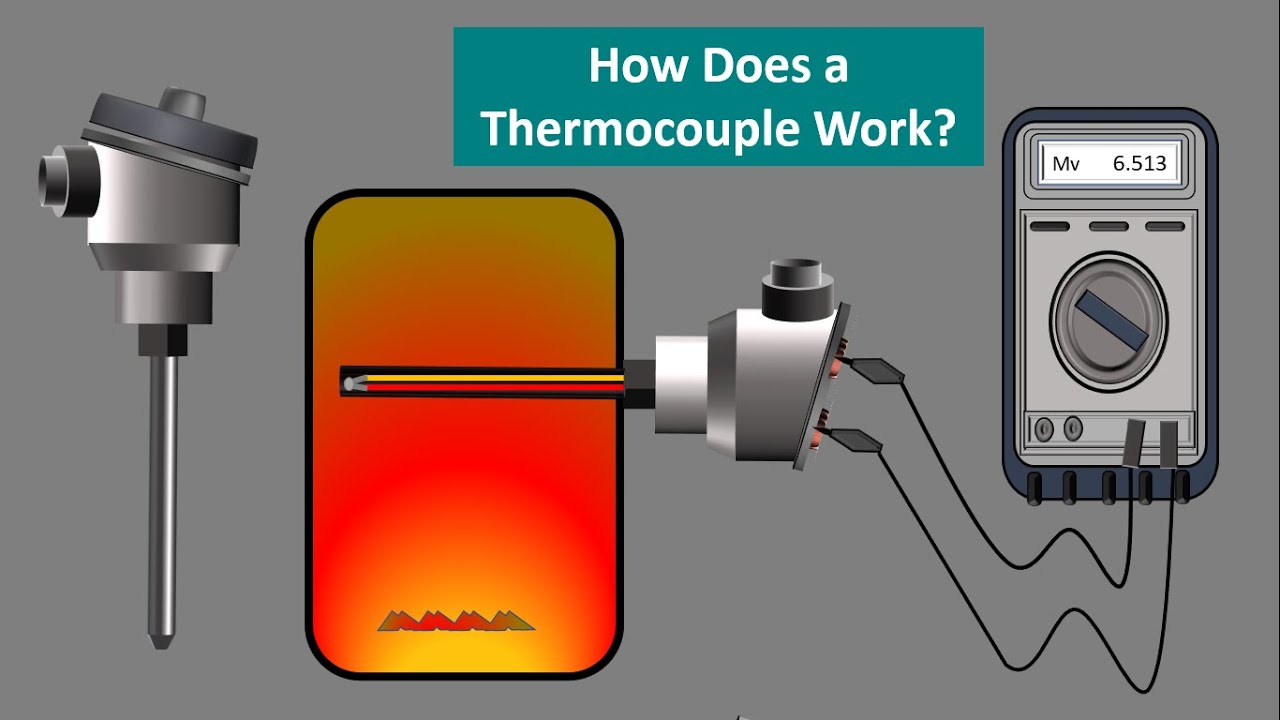

Thermocouple technology, a cornerstone of temperature measurement, harnesses the Seebeck effect to convert heat into electrical signals. This remarkable phenomenon, discovered in the 19th century, has revolutionized industries ranging from manufacturing and research to aerospace and beyond. Thermocouples, essentially junctions of dissimilar metals, generate a voltage proportional to the temperature difference between their ends. This voltage, measured by a specialized instrument, provides a precise reading of the temperature being monitored.

The simplicity and versatility of thermocouple technology make it a vital tool in numerous applications. From monitoring furnace temperatures in manufacturing to measuring the heat generated by aircraft engines, thermocouples offer a reliable and cost-effective solution for accurate temperature measurement. Their ability to withstand harsh environments, such as high temperatures and pressures, further enhances their value across diverse industries.

Thermocouple Applications

Thermocouples are widely used in various industries for measuring temperature, due to their versatility, accuracy, and wide temperature range. Their ability to provide accurate temperature readings across a wide range of applications makes them indispensable in diverse fields.

Thermocouple Applications in Different Industries, Thermocouple technology

Thermocouples are used in a wide range of applications across different industries, each with its unique requirements and temperature ranges. The table below showcases various applications of thermocouples in different industries, including the thermocouple type and the temperature range:

| Industry | Application | Thermocouple Type | Temperature Range (°C) |

|---|---|---|---|

| Manufacturing | Monitoring furnace temperatures in steel mills | Type K | -200 to 1372 |

| Manufacturing | Measuring the temperature of plastic molding machines | Type J | -213 to 760 |

| Research | Temperature measurements in scientific experiments | Type E | -270 to 900 |

| Aerospace | Monitoring engine temperatures in aircraft | Type N | -270 to 1260 |

| Automotive | Measuring engine coolant temperature | Type K | -200 to 1372 |

| Food Processing | Monitoring the temperature of ovens and food processing equipment | Type T | -200 to 370 |

| Medical | Measuring body temperature in medical devices | Type T | -200 to 370 |

Concluding Remarks: Thermocouple Technology

Thermocouple technology, with its unwavering precision and adaptability, continues to evolve. Advancements in materials and design have led to the development of nanothermocouples, capable of measuring temperatures at the nanoscale. These innovations hold immense potential for applications in microelectronics, medicine, and even the exploration of outer space. As technology progresses, thermocouples will undoubtedly play an increasingly vital role in shaping the future of temperature measurement and control.

Thermocouple technology, with its ability to measure temperature with precision, finds applications in various industries. From monitoring industrial processes to controlling the temperature of delicate scientific experiments, thermocouples play a vital role. Streamcast technologies, a company specializing in digital video solutions , can benefit from thermocouple technology by incorporating it into their systems for monitoring equipment temperature and ensuring optimal performance.

This integration can enhance the reliability and longevity of their products, further solidifying their position in the digital video market.