Sub-Zero Technology: A World of Cold Possibilities

Sub zero technology – Sub-zero technology, the science of manipulating matter at extremely low temperatures, opens up a world of possibilities across diverse fields. From the cutting edge of scientific […]

Sub zero technology – Sub-zero technology, the science of manipulating matter at extremely low temperatures, opens up a world of possibilities across diverse fields. From the cutting edge of scientific research to the heart of industrial processes, the ability to harness the power of cold has revolutionized our understanding and manipulation of the physical world.

The realm of sub-zero technology encompasses a wide range of applications, including cryogenics, which involves cooling substances to extremely low temperatures, often close to absolute zero (-273.15 °C or -459.67 °F). This process unlocks unique properties in materials, allowing for advancements in fields like medicine, aerospace, and energy.

Sub-Zero Technology

Sub-zero technology refers to any technology that operates at extremely low temperatures, typically below -150°C (-238°F). This technology is used in various applications, including scientific research, medical treatments, and industrial processes.

Applications of Sub-Zero Technology

Sub-zero technology has numerous applications across various fields. Here are some of the most notable:

- Cryogenic Preservation: This is a key application of sub-zero technology. It involves freezing biological samples, such as cells, tissues, and organs, at extremely low temperatures to preserve their structure and function for extended periods. This technology is crucial for medical research, organ transplantation, and the development of new drugs and therapies.

- Cryogenic Engineering: Sub-zero temperatures are used in various engineering applications, such as cryogenic fuel storage for rockets and spacecraft, the production of liquefied gases (like oxygen and nitrogen), and the development of high-temperature superconducting materials.

- Cryosurgery: This medical procedure utilizes sub-zero temperatures to destroy abnormal tissues, such as tumors or warts. Cryosurgery is a minimally invasive technique that offers several advantages, including reduced pain and faster recovery times.

- Food Preservation: Sub-zero temperatures are widely used to preserve food products, extending their shelf life and preventing spoilage. This technology is employed in various methods, including freezing, blast freezing, and cryogenic freezing.

- Materials Science: Sub-zero temperatures are used in materials science research to study the behavior of materials at extreme conditions. This knowledge is crucial for developing new materials with enhanced properties, such as high strength and durability.

Advantages and Limitations of Sub-Zero Technology

Sub-zero technology offers numerous advantages in various applications, but it also comes with certain limitations.

Advantages

- Enhanced Preservation: Sub-zero temperatures effectively slow down or completely halt biological processes, allowing for the long-term preservation of cells, tissues, and organs. This is particularly crucial for medical research and organ transplantation.

- Improved Efficiency: Sub-zero temperatures can significantly improve the efficiency of certain industrial processes, such as the production of liquefied gases and the development of superconducting materials.

- Minimally Invasive Procedures: Cryosurgery offers a minimally invasive approach to treating various medical conditions, reducing pain and recovery time compared to traditional surgical methods.

- Extended Shelf Life: Sub-zero temperatures are highly effective in preserving food products, extending their shelf life and reducing spoilage, which is essential for food security and distribution.

- Advanced Research: Sub-zero temperatures provide unique opportunities for studying materials and biological systems at extreme conditions, leading to the development of new materials and technologies.

Limitations

- High Energy Consumption: Maintaining sub-zero temperatures requires significant energy consumption, which can be a major concern in terms of cost and environmental impact.

- Cryogenic Damage: Freezing biological samples at sub-zero temperatures can sometimes lead to damage, especially if the process is not carefully controlled. This is a major concern for cryogenic preservation and cryosurgery.

- Cost-Effectiveness: The equipment and infrastructure required for sub-zero technology can be expensive, making it less accessible for certain applications, particularly in developing countries.

- Safety Concerns: Working with sub-zero temperatures poses certain safety risks, including frostbite and the potential for explosions due to the rapid expansion of gases at low temperatures.

- Limited Applicability: Sub-zero technology is not suitable for all applications, and its effectiveness can vary depending on the specific process or material being used.

Cryogenics and Sub-Zero Temperatures

Cryogenics is the study and application of extremely low temperatures, typically below -150°C (-238°F). It encompasses various scientific and engineering disciplines, including physics, chemistry, and materials science. Cryogenics plays a crucial role in sub-zero technology, enabling advancements in diverse fields like medicine, energy, and manufacturing.

Cryogenic Cooling Methods, Sub zero technology

Cryogenic cooling methods are essential for achieving and maintaining extremely low temperatures. These methods utilize various principles to extract heat from a system, leading to significant temperature reductions.

The most common cryogenic cooling methods include:

- Vapor-Compression Refrigeration: This method utilizes a refrigerant, typically a gas, to absorb heat from the system and release it to the environment. The refrigerant undergoes a cycle of compression, condensation, expansion, and evaporation, leading to cooling. This method is widely used in refrigerators, air conditioners, and other applications.

- Gas Liquefaction: This method involves converting a gas into a liquid by cooling it to its boiling point. This process releases significant amounts of heat, which is then removed to maintain the liquid state. Liquefied gases like nitrogen, oxygen, and helium are commonly used in cryogenic applications.

- Adiabatic Demagnetization Refrigeration: This method utilizes the magnetic properties of certain materials to achieve extremely low temperatures. When a magnetic field is applied to a paramagnetic material, its temperature increases. When the field is removed, the material cools down. This process can reach temperatures close to absolute zero.

- Pulse Tube Refrigeration: This method uses a pulse of compressed gas to transfer heat from the system to a heat sink. The gas undergoes cycles of compression, expansion, and heat exchange, leading to cooling. Pulse tube refrigerators are highly efficient and reliable, making them suitable for various applications.

Challenges of Maintaining Extremely Low Temperatures

Maintaining extremely low temperatures poses significant challenges due to the inherent properties of matter at such low temperatures. The following challenges are commonly encountered:

- Heat Transfer: Heat transfer becomes more efficient at lower temperatures, making it challenging to prevent external heat from entering the cryogenic system. This can lead to temperature fluctuations and potential loss of cryogenic properties.

- Material Properties: Many materials undergo significant changes in their physical properties at extremely low temperatures. For example, metals become brittle, and some materials become superconducting. These changes must be carefully considered when designing cryogenic systems.

- Vacuum Requirements: Cryogenic systems often require high vacuum levels to minimize heat transfer through conduction and convection. Maintaining a vacuum environment adds complexity and requires specialized equipment.

- Safety Considerations: Working with cryogenic fluids poses safety risks due to their extreme temperatures and potential for rapid expansion. Proper safety protocols and equipment are essential to prevent accidents.

Applications of Cryogenics

Cryogenics has a wide range of applications across various industries. Some of the most notable applications include:

- Medicine: Cryogenics is used in medical imaging, such as magnetic resonance imaging (MRI), and in cryosurgery, where extremely low temperatures are used to destroy diseased tissue.

- Energy: Cryogenics is used in the production and storage of liquefied natural gas (LNG), which is a clean and efficient energy source.

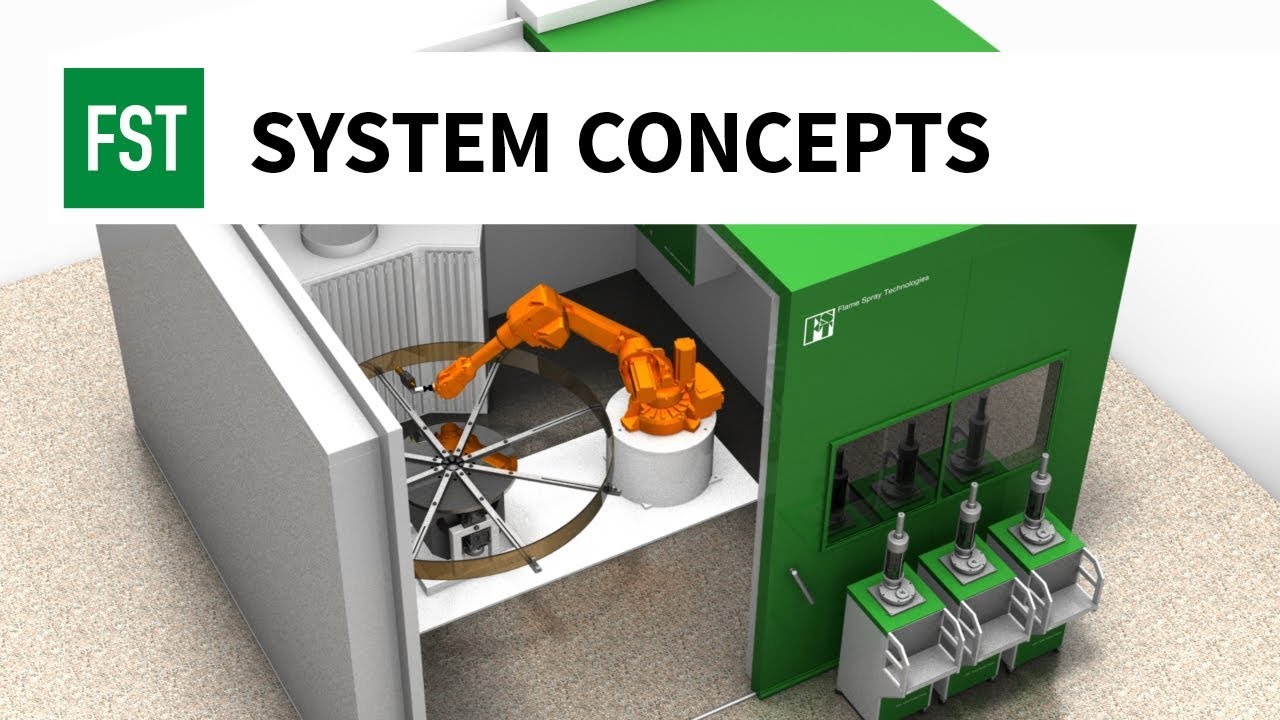

- Manufacturing: Cryogenics is used in various manufacturing processes, such as metal processing, where low temperatures can improve material properties.

- Research: Cryogenics is essential for scientific research, enabling the study of matter at extremely low temperatures and the development of new technologies.

Sub-Zero Technology in Industry: Sub Zero Technology

Sub-zero technology, the manipulation of temperatures below freezing, has revolutionized various industries, leading to significant advancements in manufacturing processes and product quality. This technology, utilizing the principles of cryogenics, offers unique advantages in areas such as material properties, machining precision, and overall efficiency.

Cryogenic Machining

Cryogenic machining involves using tools and materials cooled to sub-zero temperatures during the machining process. This technique offers several benefits:

- Enhanced Tool Life: Cooling the cutting tools to cryogenic temperatures increases their hardness and wear resistance, extending their lifespan and reducing tool replacement costs. This is especially crucial for machining hard-to-cut materials.

- Improved Surface Finish: Cryogenic machining results in a smoother and more precise surface finish, reducing the need for post-machining operations like grinding or polishing. This leads to improved product quality and reduced manufacturing time.

- Increased Material Removal Rate: Cryogenic cooling enhances the cutting edge’s sharpness, allowing for higher cutting speeds and faster material removal rates. This increases productivity and reduces overall manufacturing time.

Cryogenic Treatment

Cryogenic treatment involves exposing materials to extremely low temperatures, typically between -196°C (-320°F) and -253°C (-423°F), for a specific period. This process alters the material’s microstructure, leading to several improvements:

- Increased Strength and Hardness: Cryogenic treatment significantly enhances the material’s tensile strength, yield strength, and hardness, improving its resistance to wear, fatigue, and fracture.

- Reduced Residual Stresses: Cryogenic treatment can effectively reduce internal stresses that arise during manufacturing processes. This minimizes the risk of cracking and improves the material’s overall performance and durability.

- Enhanced Machinability: Cryogenic treatment can improve the machinability of certain materials, allowing for more efficient cutting and shaping processes. This leads to faster production cycles and reduced manufacturing costs.

Industries Utilizing Sub-Zero Technology

Sub-zero technology finds widespread applications in various industries, significantly impacting their manufacturing processes and product quality:

- Aerospace: Cryogenic machining and treatment are crucial in the aerospace industry, where high-performance materials like titanium and aluminum alloys are used for aircraft components. These processes ensure the components meet stringent strength, fatigue, and wear resistance requirements.

- Medical: Sub-zero technology plays a vital role in the medical industry, where precision and sterility are paramount. Cryogenic machining is used to manufacture surgical instruments and implants, while cryogenic treatment enhances the properties of medical devices and implants.

- Energy: Sub-zero technology is utilized in the energy sector for applications such as cryogenic storage of natural gas, liquefaction of natural gas, and cryogenic processing of fuels. These processes enhance energy efficiency and reduce environmental impact.

Case Studies

- Boeing: Boeing utilizes cryogenic treatment for aircraft components, resulting in improved fatigue resistance and extended service life. This has significantly reduced maintenance costs and increased aircraft safety.

- General Electric: General Electric employs cryogenic machining for manufacturing turbine blades, leading to improved surface finish and reduced wear, resulting in increased efficiency and extended service life.

- ExxonMobil: ExxonMobil uses cryogenic technology for liquefied natural gas (LNG) storage and transportation, ensuring efficient and safe handling of this valuable energy resource.

Sub-Zero Technology in Research and Development

Sub-zero technology, the manipulation of extremely low temperatures, plays a pivotal role in scientific research, enabling advancements in various fields like materials science, physics, and biology. By creating environments far below freezing, researchers can unlock unique properties of matter and explore phenomena not observable at ambient temperatures.

Materials Science

Sub-zero temperatures significantly impact the properties of materials.

- Cryogenic processing, involving extreme cold, can enhance material strength, ductility, and toughness. For instance, cryogenic treatment of steel can improve its hardness and wear resistance, making it ideal for tools and machinery.

- Cryogenic grinding, a precise machining process, utilizes sub-zero temperatures to minimize heat generation and improve surface finish, leading to enhanced performance in precision components.

- Cryogenic deposition, a technique used to deposit thin films at low temperatures, allows for the fabrication of materials with unique electrical, optical, and magnetic properties. This method is crucial in developing advanced electronic devices and optical coatings.

Physics

Sub-zero temperatures are essential for exploring fundamental physics principles.

- Superconductivity, a state where materials exhibit zero electrical resistance, occurs at extremely low temperatures. Research in this field has led to the development of superconducting magnets used in magnetic resonance imaging (MRI) and high-speed trains.

- Quantum mechanics, the study of matter at the atomic and subatomic levels, relies heavily on sub-zero temperatures to observe and manipulate quantum phenomena. This research has paved the way for advancements in quantum computing and precision measurements.

- Bose-Einstein condensate (BEC), a state of matter where atoms behave like waves, is achieved at extremely low temperatures. Studying BECs allows researchers to investigate fundamental properties of matter and explore applications in precision sensors and atomic clocks.

Biology

Sub-zero temperatures play a crucial role in biological research, particularly in fields like cryopreservation and cryobiology.

- Cryopreservation, the process of preserving biological materials at low temperatures, allows for long-term storage of cells, tissues, and organs. This technology is vital for preserving genetic material, developing new therapies, and enabling organ transplantation.

- Cryobiology, the study of the effects of low temperatures on living organisms, explores the mechanisms of cryoprotection and the potential for cryosurgery. Research in this field aims to develop novel techniques for cryopreservation and therapeutic applications.

- Cryo-electron microscopy (cryo-EM), a powerful imaging technique, utilizes sub-zero temperatures to preserve the structure of biological samples. This technique has revolutionized our understanding of protein structures and their functions, leading to breakthroughs in drug discovery and disease research.

Hypothetical Research Project

A hypothetical research project utilizing sub-zero technology could focus on developing novel cryoprotectants for preserving human organs for transplantation.

- Objective: To create a cryoprotectant solution that effectively protects organs from damage during freezing and thawing, enabling longer-term storage and increasing the availability of organs for transplantation.

- Methodology: Researchers would use sub-zero technology to test the effectiveness of various cryoprotectant solutions on different organ types. They would analyze the impact of different freezing and thawing protocols on organ viability and function.

- Potential Benefits: Successful development of this technology could significantly reduce the organ shortage, increase the success rate of organ transplantation, and ultimately save lives.

Future Trends and Innovations in Sub-Zero Technology

Sub-zero technology, involving the study and application of extremely low temperatures, is a rapidly evolving field with immense potential to revolutionize various industries and aspects of our lives. The continuous development of cryogenic cooling systems and materials, alongside the exploration of new applications, is shaping the future of this technology.

Advancements in Cryogenic Cooling Systems and Materials

Advancements in cryogenic cooling systems and materials are crucial for the progress of sub-zero technology. These advancements are driving the development of more efficient, cost-effective, and compact cooling systems, enabling wider applications in various sectors.

- High-Temperature Superconductors: These materials exhibit zero electrical resistance at relatively higher temperatures compared to conventional superconductors, paving the way for more efficient and compact cryogenic systems. The development of high-temperature superconductors is a significant advancement in cryogenic technology, with applications in magnetic resonance imaging (MRI), high-speed trains, and energy transmission.

- Magnetic Refrigeration: This technology utilizes magnetic fields to cool substances, offering a more environmentally friendly alternative to traditional vapor-compression refrigeration. Magnetic refrigeration has the potential to replace traditional refrigeration systems in various applications, including food storage and industrial processes.

- Pulse Tube Refrigeration: This type of cryocooler operates without any moving parts, making it highly reliable and efficient. Pulse tube refrigeration systems are used in applications requiring low vibration, such as scientific instruments and medical devices.

Applications of Sub-Zero Technology in Future Technologies

Sub-zero technology is poised to play a critical role in the development of future technologies, particularly in areas like quantum computing and energy storage.

- Quantum Computing: Quantum computers utilize the principles of quantum mechanics to perform calculations at speeds far exceeding those of traditional computers. Cryogenic temperatures are essential for maintaining the delicate quantum states of qubits, the fundamental units of information in quantum computers. The development of efficient and reliable cryogenic cooling systems is crucial for the advancement of quantum computing.

- Energy Storage: Sub-zero technology can be applied to develop advanced energy storage solutions. Cryogenic energy storage involves storing energy in the form of cryogenic fluids, such as liquid nitrogen or liquid hydrogen. These fluids can be stored at extremely low temperatures, enabling efficient energy storage and release on demand.

Impact of Sub-Zero Technology on Industries and Society

The applications of sub-zero technology extend beyond scientific research and development, impacting various industries and aspects of society.

- Healthcare: Sub-zero technology plays a vital role in healthcare, enabling the preservation of organs, tissues, and blood for transplantation and medical research. Cryogenic preservation techniques are essential for extending the shelf life of vaccines and other medical supplies.

- Food Industry: Cryogenic freezing is widely used in the food industry to preserve food quality and extend shelf life. This technology is also used for food processing, such as flash freezing and cryogenic grinding, which can enhance the texture and quality of food products.

- Manufacturing: Sub-zero technology finds applications in various manufacturing processes, such as cryogenic machining, which enhances tool life and surface finish. Cryogenic treatment can also improve the strength and durability of materials, leading to the development of advanced materials for various industries.

Closing Notes

As we delve deeper into the mysteries of the universe, sub-zero technology will undoubtedly play a pivotal role in shaping our future. From unlocking the secrets of quantum computing to developing innovative energy storage solutions, the potential of this field is vast and ever-expanding. By harnessing the power of cold, we can push the boundaries of human ingenuity and pave the way for a world of transformative possibilities.

Sub-zero technology, while often associated with refrigeration, can also play a crucial role in other industries. For instance, in the realm of vertical transportation, companies like elevator technology inc utilize sub-zero temperatures to test the durability and performance of their elevator components, ensuring the safe and reliable operation of these vital systems.

This rigorous testing process ultimately benefits the end user, guaranteeing a smooth and secure ride.