Spray Master Technologies: Precision Application & Innovation

Spray Master Technologies revolutionize how we apply materials, transforming industries with precise, efficient, and sustainable solutions. From automotive painting to agricultural spraying, these technologies deliver consistent results, minimizing waste and […]

Spray Master Technologies revolutionize how we apply materials, transforming industries with precise, efficient, and sustainable solutions. From automotive painting to agricultural spraying, these technologies deliver consistent results, minimizing waste and maximizing productivity.

This exploration delves into the diverse world of Spray Master Technologies, examining their types, applications, benefits, and future potential. We’ll uncover how these advanced systems are shaping various industries and driving innovation across the globe.

Spray Master Technologies

Spray Master Technologies encompass a range of techniques and equipment used to apply coatings, adhesives, sealants, and other materials in a controlled and precise manner. These technologies are essential in various industries for enhancing product quality, improving efficiency, and achieving desired surface finishes.

Applications of Spray Master Technologies

Spray Master Technologies find extensive applications across diverse industries, including:

- Automotive: Spray painting vehicles, applying protective coatings, and sealing components.

- Aerospace: Coating aircraft components with specialized materials for corrosion resistance, heat protection, and aerodynamic efficiency.

- Electronics: Applying conformal coatings to protect electronic circuits and components from environmental factors.

- Construction: Spraying insulation, fireproofing materials, and applying decorative coatings to buildings.

- Food and Beverage: Applying protective coatings to food packaging materials and spraying edible coatings on fruits and vegetables.

- Pharmaceuticals: Coating medical devices and applying protective layers to pharmaceutical products.

Advantages of Spray Master Technologies

Spray Master Technologies offer several advantages, including:

- Uniform and Consistent Coating Application: Spraying techniques enable the application of coatings with a uniform thickness and consistency, minimizing defects and inconsistencies.

- Increased Efficiency and Speed: Spraying processes are typically faster than manual application methods, significantly improving productivity and reducing labor costs.

- Improved Material Utilization: Spraying minimizes material waste, reducing overall costs and environmental impact.

- Versatility: Spray Master Technologies can be adapted to handle a wide range of materials, including liquids, powders, and pastes.

- Enhanced Surface Finish: Spraying techniques can create smooth, even, and aesthetically pleasing surface finishes.

Limitations of Spray Master Technologies

While Spray Master Technologies offer significant benefits, they also have certain limitations:

- Initial Investment Costs: Acquiring specialized spraying equipment can involve substantial upfront costs.

- Operator Skill and Training: Skilled operators are required to operate and maintain spraying equipment effectively.

- Environmental Considerations: Spraying processes can generate overspray and volatile organic compounds (VOCs), requiring proper ventilation and waste management.

- Safety Concerns: Handling and applying certain materials may require specific safety precautions and protective equipment.

Applications of Spray Master Technologies

Spray Master Technologies have a wide range of applications across various sectors, impacting productivity, efficiency, and product quality in numerous industries. The advanced capabilities of these technologies enable precise and controlled application of materials, leading to enhanced performance and improved outcomes.

Industrial Applications

Spray Master Technologies are widely used in industrial settings for various purposes. These technologies play a crucial role in manufacturing, automotive, aerospace, and other industries, where precise application of materials is essential.

- Painting and Coating: Spray Master Technologies are used for applying paint, coatings, and protective layers to various surfaces. This includes automotive painting, industrial equipment coating, and architectural finishes. The precise control offered by these technologies ensures even and consistent application, reducing defects and improving the overall finish.

- Surface Preparation: Spray Master Technologies are also used for surface preparation, such as sandblasting, cleaning, and priming. These processes are essential for achieving optimal adhesion and durability of coatings. Spray Master Technologies enable efficient and controlled surface preparation, minimizing waste and maximizing efficiency.

- Material Deposition: In manufacturing processes, Spray Master Technologies are used for depositing various materials, including metals, ceramics, and plastics. These technologies enable precise and controlled deposition of materials, leading to improved product quality and performance. This is particularly important in industries like electronics, aerospace, and medical devices, where precision and accuracy are critical.

Agricultural Applications

Spray Master Technologies have revolutionized agricultural practices, enabling precise and efficient application of fertilizers, pesticides, and other agricultural chemicals. These technologies help farmers optimize resource utilization, minimize environmental impact, and improve crop yields.

- Precision Farming: Spray Master Technologies are integrated into precision farming systems, allowing farmers to apply fertilizers and pesticides only where needed. This targeted application reduces chemical usage, minimizing environmental impact and reducing costs.

- Crop Protection: Spray Master Technologies are used to apply pesticides and herbicides, ensuring efficient and uniform coverage of crops. This helps protect crops from pests and diseases, improving yields and reducing losses.

- Seed Treatment: Spray Master Technologies are used for seed treatment, applying protective coatings and fungicides to enhance seed germination and seedling growth. This improves crop establishment and reduces the risk of disease outbreaks.

Other Applications

Spray Master Technologies find applications in various other sectors, including:

- Construction: Spray Master Technologies are used for applying concrete, insulation, and fireproofing materials. These technologies enable efficient and controlled application, improving the quality and durability of construction projects.

- Medical: Spray Master Technologies are used in medical applications, such as drug delivery, wound healing, and tissue engineering. These technologies enable precise and controlled application of materials, improving treatment outcomes and minimizing side effects.

- Food Processing: Spray Master Technologies are used in food processing for applying coatings, glazes, and seasonings. These technologies ensure uniform and controlled application, improving product quality and shelf life.

Benefits of Using Spray Master Technologies

Spray Master Technologies offer a wide range of benefits, contributing to improved efficiency, cost savings, and environmental sustainability across various industries. By leveraging advanced spray application techniques, these technologies deliver precise and controlled material deposition, minimizing waste and maximizing productivity.

Economic Benefits

Spray Master Technologies offer significant economic advantages by optimizing material usage, reducing labor costs, and increasing production efficiency. These technologies enable precise material application, minimizing overspray and waste, leading to substantial cost savings on materials. Furthermore, the automation and efficiency provided by Spray Master Technologies reduce labor requirements, leading to lower labor costs and improved productivity.

- Reduced Material Costs: Precise application techniques minimize overspray and waste, leading to significant savings on material costs. For example, in automotive painting, Spray Master Technologies can reduce paint usage by up to 20%, leading to substantial cost savings.

- Increased Production Efficiency: Automated spray systems increase production speed and throughput, enabling faster completion of tasks and higher output. This translates to increased productivity and higher overall profitability. For instance, in manufacturing, Spray Master Technologies can increase production rates by 15-20%, leading to significant economic gains.

- Reduced Labor Costs: Automation and efficiency provided by Spray Master Technologies reduce the need for manual labor, leading to lower labor costs and increased profitability. In industries like agriculture, Spray Master Technologies can reduce the labor required for pesticide application by up to 50%, leading to significant cost savings.

Environmental Benefits, Spray master technologies

Spray Master Technologies play a crucial role in promoting environmental sustainability by minimizing waste, reducing emissions, and conserving resources. Precise material application reduces overspray and waste, minimizing the environmental impact of manufacturing and other industrial processes. Additionally, these technologies can reduce emissions of volatile organic compounds (VOCs), contributing to cleaner air quality.

- Reduced Waste and Overspray: Precise application techniques minimize overspray and waste, reducing the amount of material that ends up in landfills or pollutes the environment. In the construction industry, Spray Master Technologies can reduce paint waste by up to 50%, significantly minimizing the environmental impact of construction projects.

- Reduced Emissions: Spray Master Technologies can reduce emissions of volatile organic compounds (VOCs), contributing to cleaner air quality. In automotive painting, Spray Master Technologies can reduce VOC emissions by up to 80%, leading to significant improvements in air quality.

- Conservation of Resources: By optimizing material usage and minimizing waste, Spray Master Technologies contribute to the conservation of valuable resources. In agriculture, Spray Master Technologies can reduce the amount of pesticides and fertilizers used by up to 30%, minimizing the environmental impact of agricultural practices.

Social Benefits

Spray Master Technologies contribute to social benefits by creating safer working environments, improving product quality, and enhancing worker satisfaction. These technologies can reduce exposure to hazardous materials, improving worker safety and health. Furthermore, the precise application techniques employed by Spray Master Technologies lead to higher product quality and consistency, improving customer satisfaction.

- Improved Worker Safety: Spray Master Technologies can reduce exposure to hazardous materials, improving worker safety and health. In industries like painting and coating, Spray Master Technologies can reduce worker exposure to harmful chemicals and fumes, leading to a safer working environment.

- Enhanced Product Quality: Precise application techniques employed by Spray Master Technologies lead to higher product quality and consistency, improving customer satisfaction. In manufacturing, Spray Master Technologies can improve the quality and consistency of coatings and finishes, leading to higher customer satisfaction and loyalty.

- Increased Worker Satisfaction: The automation and efficiency provided by Spray Master Technologies can reduce the physical strain on workers and improve their working conditions, leading to increased worker satisfaction and productivity. In industries like agriculture, Spray Master Technologies can reduce the physical demands of pesticide application, improving worker satisfaction and reducing workplace injuries.

Summary of Benefits

| Benefit | Impact | Example |

|---|---|---|

| Reduced Material Costs | Economic | Automotive painting: Reduced paint usage by 20% |

| Increased Production Efficiency | Economic | Manufacturing: Increased production rates by 15-20% |

| Reduced Labor Costs | Economic | Agriculture: Reduced labor required for pesticide application by 50% |

| Reduced Waste and Overspray | Environmental | Construction: Reduced paint waste by 50% |

| Reduced Emissions | Environmental | Automotive painting: Reduced VOC emissions by 80% |

| Conservation of Resources | Environmental | Agriculture: Reduced pesticide and fertilizer usage by 30% |

| Improved Worker Safety | Social | Painting and coating: Reduced worker exposure to hazardous materials |

| Enhanced Product Quality | Social | Manufacturing: Improved quality and consistency of coatings and finishes |

| Increased Worker Satisfaction | Social | Agriculture: Reduced physical demands of pesticide application |

Future Trends in Spray Master Technologies

Spray Master Technologies are constantly evolving, driven by advancements in materials science, automation, and digitalization. This dynamic landscape presents exciting opportunities for innovation and the development of new applications across various industries.

Advancements in Materials Science

The development of novel materials and coatings is a key driver of progress in Spray Master Technologies. For instance, researchers are exploring the use of nanomaterials to create coatings with enhanced properties such as durability, corrosion resistance, and thermal conductivity. These advancements are leading to the creation of more efficient and effective spray systems for diverse applications.

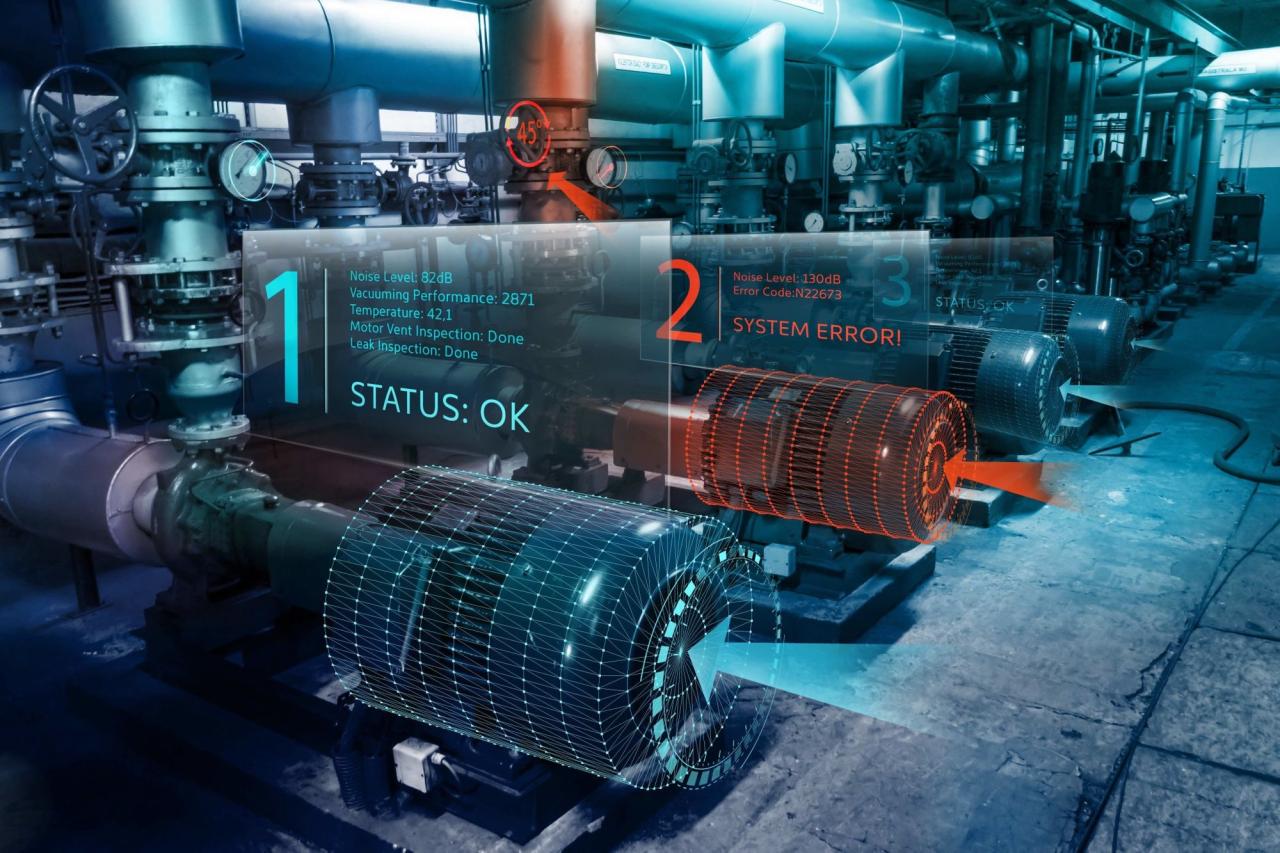

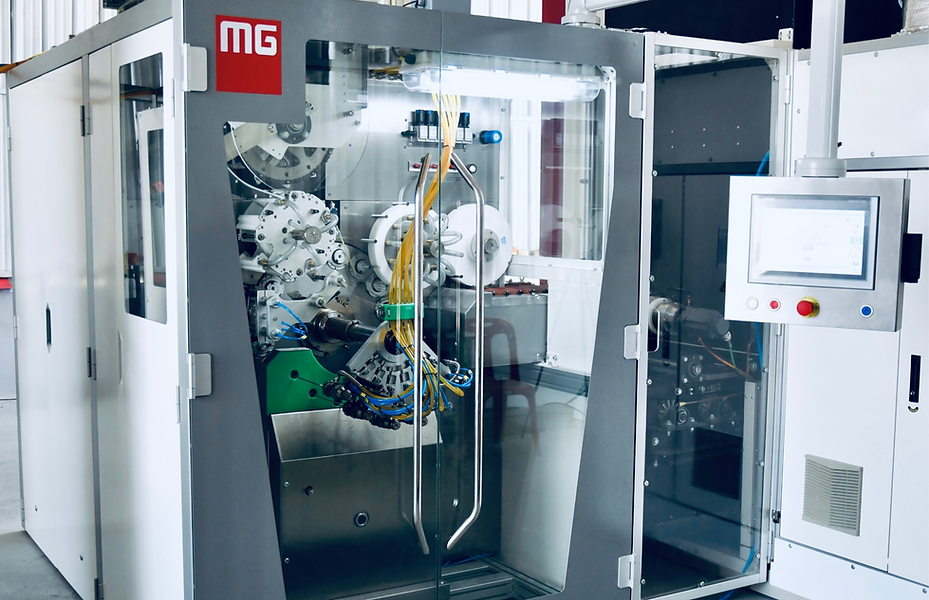

Automation and Robotics

Automation and robotics are transforming the field of Spray Master Technologies, enhancing precision, efficiency, and safety. The integration of robots into spray systems allows for greater control over the spray process, reducing human error and improving the consistency of the final product. This trend is particularly evident in industries such as automotive manufacturing, where robots are used to apply paint and coatings with high accuracy.

Digitalization and Data Analytics

Digitalization is playing a crucial role in optimizing spray processes and enhancing the overall efficiency of Spray Master Technologies. Real-time data collection and analysis provide valuable insights into spray performance, allowing for adjustments to optimize spray parameters and minimize waste. Cloud-based platforms enable remote monitoring and control of spray systems, enhancing operational efficiency and reducing downtime.

Sustainable Spray Technologies

The increasing focus on sustainability is driving the development of eco-friendly spray technologies. Researchers are exploring the use of water-based coatings and biodegradable materials to minimize environmental impact. This trend is also encouraging the development of energy-efficient spray systems, reducing the carbon footprint of spray operations.

Final Review

The evolution of Spray Master Technologies continues to push boundaries, offering unprecedented control and efficiency. As we move forward, we can expect even more innovative solutions to emerge, further optimizing processes, reducing environmental impact, and enhancing product quality. The future of spray technology promises a world where precision, sustainability, and efficiency are paramount.

Spray master technologies are often used in industries like automotive and manufacturing for their precision and efficiency. A key component of these systems is the ability to accurately control the spray pattern, which can be achieved through various methods, including the use of SE technology.

This technology allows for highly precise and repeatable spray patterns, ensuring consistent product quality and reducing waste. Ultimately, advancements in spray master technologies, like the integration of SE technology, are contributing to more efficient and sustainable production processes across a wide range of industries.