Scaling Industrial Technologies: A Revolution in Progress

Scales industrial technologies – Scaling industrial technologies takes center stage as a driving force behind innovation and progress, transforming industries and shaping the future of work. From the dawn of […]

Scales industrial technologies – Scaling industrial technologies takes center stage as a driving force behind innovation and progress, transforming industries and shaping the future of work. From the dawn of the Industrial Revolution to the current era of digital transformation, the relentless pursuit of efficiency, productivity, and sustainability has fueled the development of groundbreaking technologies. This journey has been marked by pivotal milestones, each contributing to a profound shift in how we manufacture, produce, and consume goods and services.

The ability to scale industrial technologies effectively is crucial for unlocking their full potential and realizing their transformative impact. This involves addressing critical challenges such as standardization, modularity, and interoperability, ensuring seamless integration across different systems and processes. Successful scaling strategies often leverage data analytics, artificial intelligence, and other emerging technologies to optimize resource utilization, enhance decision-making, and drive innovation.

Evolution of Industrial Technologies

The history of industrial technologies is a captivating journey marked by groundbreaking innovations that have reshaped societies and economies. From the dawn of the Industrial Revolution to the digital age, technological advancements have continuously driven progress, transforming industrial processes, boosting productivity, and fostering economic growth. This evolution has been characterized by distinct eras, each defined by its unique set of technological breakthroughs and their profound impact on the world.

The First Industrial Revolution (Late 1700s – Early 1800s)

This era witnessed the birth of modern industrialization, driven by key innovations such as the steam engine, the power loom, and the cotton gin. These inventions revolutionized manufacturing, enabling mass production and ushering in a new era of mechanized labor. The steam engine, for example, provided a new source of power that transformed industries like mining and transportation. The power loom, another key innovation, significantly increased the speed and efficiency of textile production. The impact of these innovations was profound, leading to increased productivity, the growth of factories, and the rise of industrial cities.

The Second Industrial Revolution (Late 1800s – Early 1900s)

This period witnessed the emergence of new technologies such as electricity, the internal combustion engine, and the telephone. These innovations further transformed industries, enabling mass production on an unprecedented scale. Electricity revolutionized manufacturing by providing a reliable and efficient source of power. The internal combustion engine paved the way for the development of automobiles and airplanes, transforming transportation and communication. The telephone, meanwhile, revolutionized communication, enabling instant communication over long distances.

The Third Industrial Revolution (Mid-20th Century – Late 20th Century)

This era is often referred to as the “digital revolution” and was characterized by the development of computers, the internet, and automation technologies. These innovations revolutionized information processing, communication, and manufacturing, leading to significant increases in productivity and efficiency. Computers enabled businesses to automate complex tasks, while the internet revolutionized communication and information sharing. Automation technologies, such as robots and computer-aided manufacturing (CAM), further transformed manufacturing processes, enabling higher production volumes and greater precision.

The Fourth Industrial Revolution (Present Day)

This ongoing revolution is characterized by the convergence of digital, physical, and biological technologies, including artificial intelligence (AI), the Internet of Things (IoT), and advanced robotics. These technologies are driving a new wave of innovation, leading to the development of smart factories, autonomous vehicles, and personalized healthcare solutions. AI is enabling machines to learn and adapt, while the IoT is connecting devices and systems, creating a vast network of data that can be used to optimize processes and improve decision-making. Advanced robotics is automating tasks with greater precision and flexibility, further transforming manufacturing and other industries.

Key Aspects of Scaling Industrial Technologies: Scales Industrial Technologies

Scaling industrial technologies involves expanding production capacity, increasing efficiency, and optimizing operations to meet growing market demands. It presents both challenges and opportunities, requiring careful planning, strategic execution, and a deep understanding of the underlying technologies and their applications.

Challenges and Opportunities of Scaling Industrial Technologies

Scaling industrial technologies poses unique challenges and presents significant opportunities for businesses.

- Challenges:

- Cost Optimization: Scaling up production often involves substantial capital investment, making it crucial to optimize costs and ensure a return on investment.

- Complexity Management: As production scales, managing the increased complexity of operations, supply chains, and technological systems becomes paramount.

- Process Consistency: Maintaining consistent quality and performance across scaled-up production processes is essential to meet customer expectations and maintain brand reputation.

- Talent Acquisition and Development: Scaling requires skilled workforce, necessitating effective talent acquisition and development strategies to support the growing operations.

- Technological Adaptability: Rapid technological advancements demand constant adaptation and integration of new technologies to remain competitive and efficient.

- Opportunities:

- Market Expansion: Scaling allows businesses to reach wider markets and capture larger market share.

- Cost Reduction: Economies of scale can lead to significant cost reductions through optimized resource utilization and bulk purchasing.

- Innovation Acceleration: Scaling provides resources and infrastructure for research and development, accelerating innovation and product development.

- Competitive Advantage: Successful scaling can create a competitive advantage by establishing a strong market presence and building brand loyalty.

- Sustainable Growth: Scaling can be achieved sustainably by integrating environmentally friendly practices and technologies, minimizing environmental impact.

Importance of Standardization, Modularity, and Interoperability

Standardization, modularity, and interoperability play a crucial role in scaling industrial technologies.

- Standardization: Standardization ensures uniformity and consistency across different components, processes, and systems, facilitating seamless integration and reducing compatibility issues. This simplifies operations, reduces costs, and improves efficiency.

- Modularity: Modular design allows for the construction of systems from interchangeable, standardized components. This enables flexibility, scalability, and ease of maintenance, as individual modules can be replaced or upgraded without affecting the entire system.

- Interoperability: Interoperability ensures that different systems and components can communicate and exchange data effectively. This allows for seamless data flow, real-time monitoring, and enhanced collaboration across various departments and stakeholders.

Examples of Successful Scaling Strategies

Several leading industrial companies have successfully implemented scaling strategies.

- Tesla: Tesla’s Gigafactories exemplify a modular approach to scaling electric vehicle production. By creating massive, self-contained production facilities with standardized modules, Tesla can quickly expand capacity and meet growing demand.

- Amazon: Amazon’s cloud computing platform, AWS, is a prime example of successful scaling through standardization and interoperability. By offering a wide range of standardized services and APIs, AWS allows businesses to easily integrate and scale their operations.

- Siemens: Siemens leverages its expertise in automation and digitalization to help industrial companies scale their operations. Siemens’ solutions focus on integrating standardized systems and processes, enabling real-time data analysis and optimized performance.

Emerging Technologies and their Impact

The rapid evolution of technology has ushered in a new era of industrial transformation, with emerging technologies like artificial intelligence (AI), robotics, and blockchain poised to reshape industrial processes and drive unprecedented levels of efficiency, innovation, and resource optimization.

Impact of Emerging Technologies on Industrial Processes

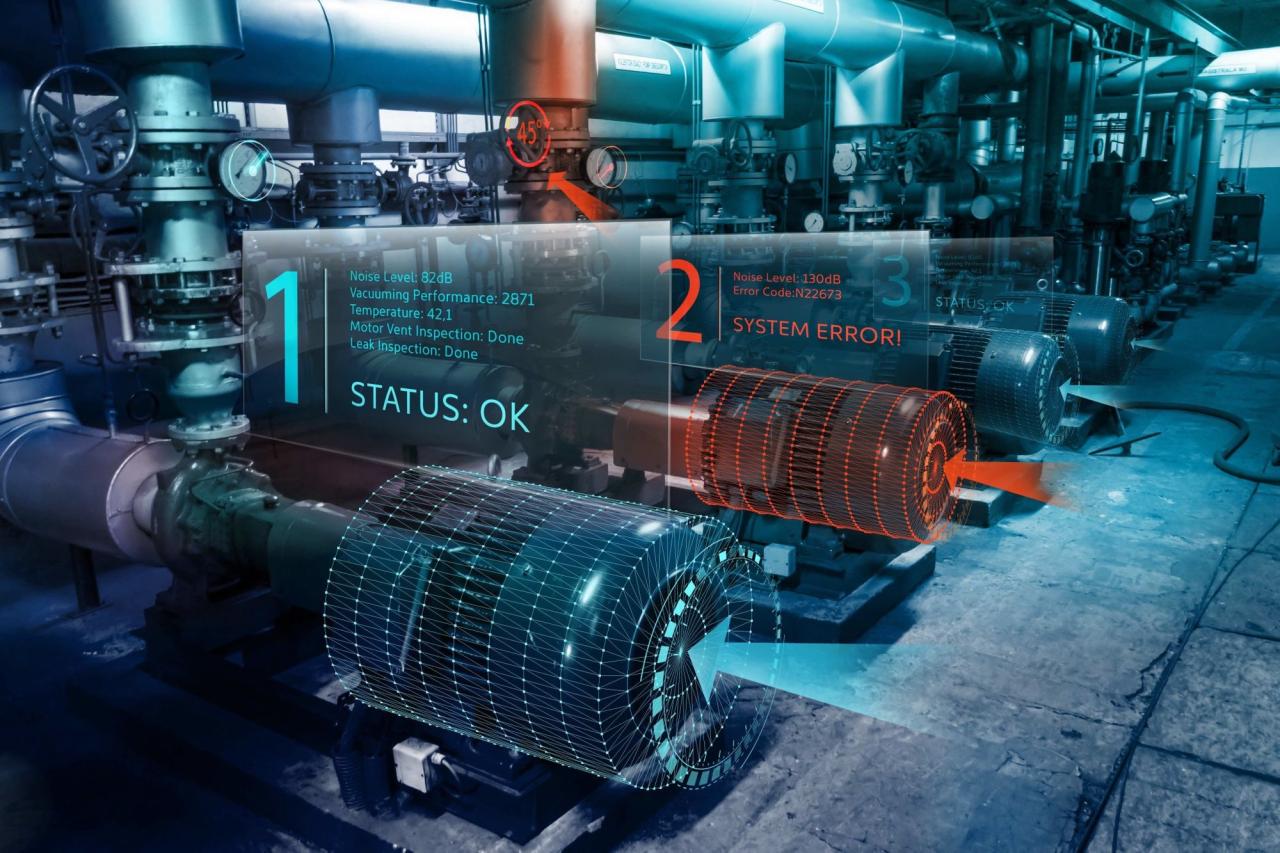

The integration of emerging technologies into industrial environments presents a unique opportunity to enhance operational efficiency, optimize resource utilization, and foster innovation. AI, with its ability to analyze vast datasets and identify patterns, can revolutionize predictive maintenance, optimize production scheduling, and improve quality control. Robotics, with their precision and tireless work ethic, can automate repetitive and hazardous tasks, freeing up human workers for more complex and strategic roles. Blockchain technology, with its decentralized and immutable nature, can streamline supply chain management, enhance transparency, and ensure secure data sharing.

Enhancing Efficiency and Optimizing Resource Utilization

Emerging technologies are instrumental in driving efficiency and optimizing resource utilization across various industrial sectors. AI-powered predictive maintenance systems can analyze sensor data to identify potential equipment failures before they occur, minimizing downtime and reducing maintenance costs. Robotics can automate tasks like welding, painting, and assembly, increasing production speed and reducing labor costs. Blockchain technology can improve supply chain visibility and transparency, reducing waste and optimizing logistics.

Driving Innovation and New Business Models

Emerging technologies are not only enhancing existing industrial processes but also driving innovation and the emergence of new business models. AI can be used to develop new products and services, analyze customer data to personalize offerings, and create innovative solutions to complex problems. Robotics can be integrated into collaborative environments, working alongside humans to perform tasks that require both precision and human intelligence. Blockchain technology can enable secure and transparent transactions, fostering trust and collaboration within supply chains and facilitating the development of new decentralized business models.

Challenges and Ethical Considerations

While the potential benefits of integrating emerging technologies into industrial environments are significant, there are also challenges and ethical considerations that need to be addressed. One of the major challenges is the need for skilled workers to manage and maintain these technologies. The rapid adoption of AI and robotics could lead to job displacement, raising concerns about the future of the workforce. Ethical considerations include ensuring the responsible use of AI, preventing bias in algorithms, and safeguarding data privacy.

Examples of Emerging Technologies in Industrial Environments

- AI-powered predictive maintenance: Companies like GE and Siemens are using AI to analyze sensor data from industrial equipment to predict potential failures and schedule maintenance proactively, reducing downtime and maintenance costs.

- Robotic automation in manufacturing: Companies like Tesla and Toyota are using robots to automate tasks like welding, painting, and assembly, increasing production speed and efficiency.

- Blockchain-enabled supply chain management: Companies like Walmart and Nestle are using blockchain to track products from origin to destination, ensuring transparency, traceability, and food safety.

The Future of Industrial Technologies

As emerging technologies continue to evolve and mature, their impact on industrial processes will only grow. The future of industrial technologies is likely to be characterized by increased automation, greater data-driven decision-making, and the emergence of new business models. The integration of emerging technologies into industrial environments presents both opportunities and challenges, and it is crucial for businesses to embrace these technologies responsibly and ethically to reap their full potential.

The Role of Data and Analytics

The digital revolution has brought a tidal wave of data into the industrial landscape, and with it, a profound shift in how businesses operate. Data analytics, the process of examining raw data to extract meaningful insights, has emerged as a critical enabler for optimizing industrial processes, improving decision-making, and identifying areas for improvement.

The Power of Data-Driven Insights

Data analytics plays a pivotal role in transforming industrial operations. It allows companies to gain a deeper understanding of their processes, identify patterns, and predict future outcomes. This knowledge empowers them to make informed decisions, streamline operations, and drive efficiency.

- Predictive Maintenance: Data analytics enables the prediction of equipment failures before they occur. By analyzing sensor data, historical maintenance records, and operational parameters, companies can identify potential issues and schedule preventative maintenance, reducing downtime and minimizing costly repairs.

- Enhanced Production Efficiency: Data analytics can optimize production processes by identifying bottlenecks, inefficiencies, and areas for improvement. Real-time data analysis helps manufacturers monitor production lines, adjust parameters, and optimize resource allocation, leading to increased output and reduced waste.

- Quality Control and Assurance: Data analytics plays a crucial role in ensuring product quality. By analyzing data from sensors, inspection systems, and customer feedback, manufacturers can identify defects, track quality trends, and implement corrective actions to prevent future issues.

Sustainable Industrial Technologies

The industrial sector plays a crucial role in economic growth, but it also contributes significantly to environmental challenges. Sustainable practices are essential for minimizing the environmental impact of industrial processes while ensuring resource conservation and long-term viability. Sustainable industrial technologies are key to achieving this balance, driving innovation and creating a more sustainable future.

Environmental Impact and Resource Conservation

Sustainable industrial practices are vital for minimizing the environmental impact of industrial activities. By reducing pollution, conserving resources, and promoting circular economy principles, industries can operate more responsibly and contribute to a healthier planet.

- Reducing Pollution: Sustainable technologies can significantly reduce pollution from industrial processes. For example, advanced filtration systems can capture harmful emissions from manufacturing plants, while cleaner production methods can minimize waste generation.

- Conserving Resources: Sustainable industrial practices focus on efficient resource utilization. This includes using renewable energy sources, reducing water consumption, and optimizing material usage.

- Promoting Circular Economy: The circular economy model emphasizes resource reuse and recycling, reducing reliance on virgin materials. Sustainable technologies can facilitate this by enabling efficient waste management, product design for recyclability, and material recovery processes.

Role of Industrial Technologies in Reducing Carbon Emissions, Scales industrial technologies

Industrial technologies play a critical role in reducing carbon emissions, a key factor in mitigating climate change.

- Energy Efficiency: Technologies such as smart sensors, data analytics, and advanced automation can optimize energy consumption in industrial processes, reducing energy waste and carbon emissions.

- Renewable Energy Integration: Integrating renewable energy sources like solar, wind, and geothermal into industrial operations can significantly reduce reliance on fossil fuels and decrease carbon emissions.

- Carbon Capture and Storage: Carbon capture and storage (CCS) technologies can capture CO2 emissions from industrial sources and store them underground, preventing them from entering the atmosphere.

Examples of Innovative Industrial Technologies for Sustainability

Numerous innovative technologies are driving the transition towards a more sustainable industrial future.

- 3D Printing: Additive manufacturing, or 3D printing, can reduce waste by creating products on demand, eliminating the need for large-scale production and excess inventory.

- Bio-based Materials: Using bio-based materials derived from renewable sources like plants and algae can reduce dependence on fossil fuels and create more sustainable products.

- Internet of Things (IoT): The IoT enables real-time monitoring and data analysis, allowing industries to optimize processes, reduce waste, and improve resource efficiency.

- Artificial Intelligence (AI): AI can be used to optimize industrial processes, predict maintenance needs, and identify opportunities for energy savings, contributing to a more sustainable and efficient operation.

The Future of Industrial Technologies

The future of industrial technologies is poised for transformative advancements, driven by the convergence of automation, artificial intelligence (AI), and other emerging fields. These trends will reshape the industrial landscape, impacting the future of work, economic development, and the very fabric of our societies.

Impact on the Future of Work

The integration of automation and AI into industrial processes will undoubtedly lead to significant changes in the workforce. While some jobs will be automated, new opportunities will emerge in areas like AI development, data analysis, and advanced robotics maintenance. This transition will require reskilling and upskilling initiatives to ensure workers possess the necessary competencies for the future job market.

Impact on Industrial Landscapes

Industrial landscapes will witness a profound transformation as smart factories and connected ecosystems become the norm. Advancements in robotics, 3D printing, and advanced materials will enable distributed manufacturing, customized production, and on-demand delivery. This shift will redefine traditional manufacturing models, fostering greater agility, efficiency, and responsiveness to evolving market demands.

Impact on Economic Development

The widespread adoption of industrial technologies will have a profound impact on economic development. Increased automation and productivity will lead to higher output and improved efficiency, driving economic growth. However, it’s crucial to address the potential challenges of job displacement and ensure equitable access to the benefits of technological advancements.

Future Industrial Technologies

The following table highlights potential future industrial technologies, their applications, and their expected impact:

| Technology | Applications | Impact |

|---|---|---|

| Artificial Intelligence (AI) | Predictive maintenance, quality control, process optimization, supply chain management, customer service | Improved efficiency, reduced downtime, enhanced decision-making, personalized customer experiences |

| Robotics | Automated assembly, welding, painting, material handling, logistics | Increased productivity, reduced labor costs, improved safety, enhanced precision |

| 3D Printing | Prototyping, customized manufacturing, on-demand production, medical implants | Faster product development cycles, reduced material waste, customized products, innovative solutions |

| Internet of Things (IoT) | Real-time data collection, remote monitoring, predictive analytics, smart factories | Enhanced visibility and control, improved decision-making, optimized processes, predictive maintenance |

| Cloud Computing | Data storage, processing, and analysis, software applications, collaboration tools | Scalability, flexibility, reduced IT infrastructure costs, improved data management |

| Blockchain Technology | Supply chain transparency, traceability, secure data management, financial transactions | Increased trust, reduced fraud, improved efficiency, enhanced accountability |

| Augmented and Virtual Reality (AR/VR) | Training simulations, remote collaboration, product visualization, maintenance support | Enhanced training effectiveness, improved collaboration, immersive experiences, enhanced productivity |

Closing Summary

As we navigate the evolving landscape of industrial technologies, the future holds immense promise for advancements in automation, artificial intelligence, and sustainable practices. These trends are poised to reshape the industrial landscape, creating new opportunities and challenges. By embracing innovation, fostering collaboration, and prioritizing sustainability, we can harness the power of scaling industrial technologies to create a more prosperous and sustainable future for all.

Scales industrial technologies are rapidly evolving, and one exciting area of development is the application of automation in retail. Autonomous store technology, such as that found in autonomous stores , promises to revolutionize the shopping experience by eliminating the need for cashiers and streamlining the checkout process.

As these technologies continue to mature, they will likely play a significant role in shaping the future of retail and the broader landscape of industrial automation.