Scales Industrial Technologies: From Past to Future

Scales Industrial Technologies: From Past to Future, explores the dynamic evolution of industrial processes, showcasing how technological advancements have driven efficiency, productivity, and societal progress. This journey takes us from […]

Scales Industrial Technologies: From Past to Future, explores the dynamic evolution of industrial processes, showcasing how technological advancements have driven efficiency, productivity, and societal progress. This journey takes us from the rudimentary beginnings of industrialization to the cutting-edge technologies shaping the future of manufacturing.

We delve into the core concepts of industrial scaling, analyzing the factors that influence the successful expansion of production, resource utilization, and technological integration. We examine the role of automation, robotics, and artificial intelligence in optimizing industrial operations, reducing costs, and enhancing accuracy.

Technologies Driving Industrial Scaling

Industrial scaling involves expanding production capacity, optimizing processes, and achieving greater efficiency. To accomplish this, industries are increasingly relying on cutting-edge technologies that enable them to overcome traditional limitations and unlock new levels of productivity.

Automation and Robotics

Automation and robotics are revolutionizing industrial processes by automating repetitive and labor-intensive tasks. These technologies not only enhance efficiency and accuracy but also reduce costs and improve safety.

- Increased Efficiency: Robots can work tirelessly without breaks, reducing downtime and accelerating production cycles. They perform tasks with precision and speed, minimizing errors and boosting output.

- Improved Accuracy: Robots are programmed to execute tasks with high accuracy, leading to consistent product quality and reduced waste. This minimizes rework and enhances customer satisfaction.

- Cost Reduction: Automation can significantly reduce labor costs by replacing human workers with machines. Additionally, it optimizes resource utilization, minimizes waste, and improves overall cost-effectiveness.

Artificial Intelligence (AI) and Machine Learning (ML), Scales industrial technologies

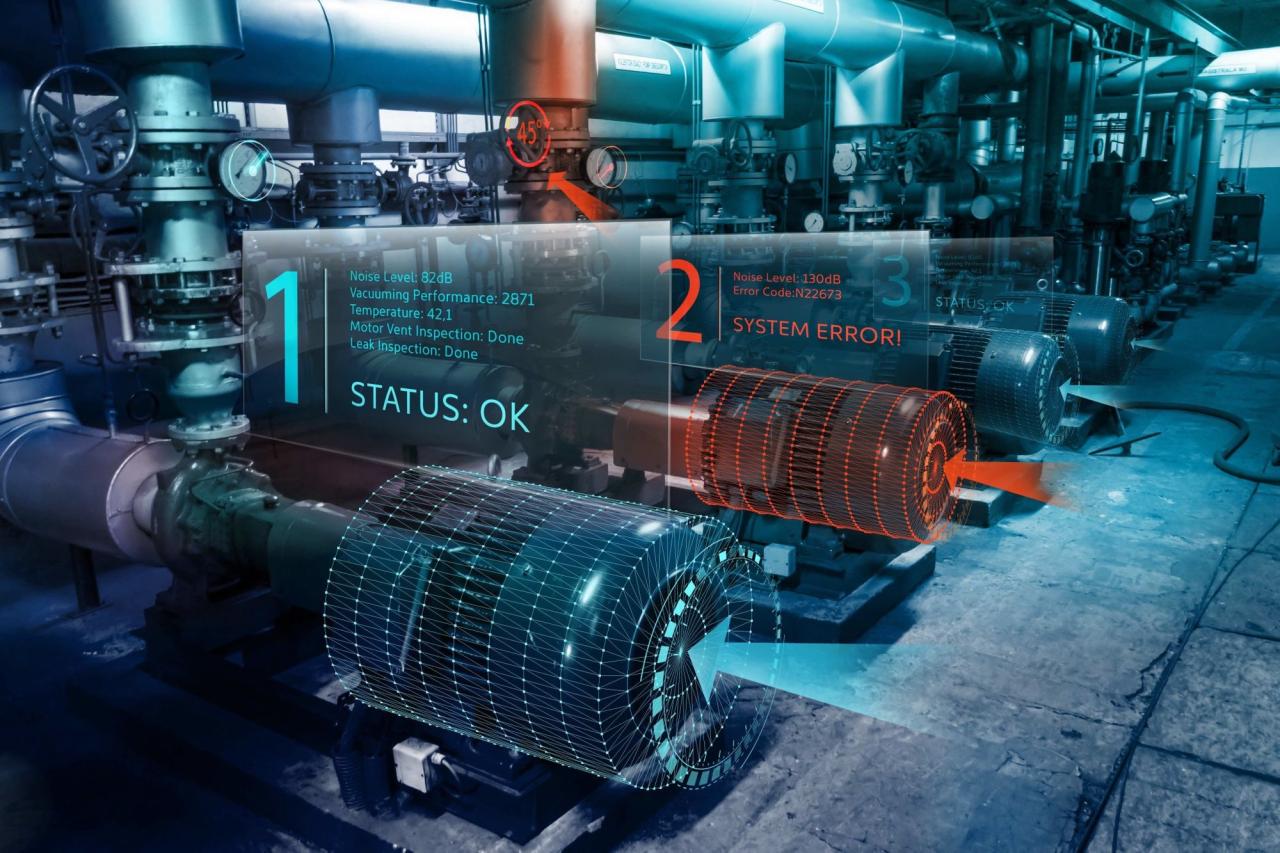

AI and ML are transforming industrial operations by providing intelligent insights and automating decision-making processes. These technologies are instrumental in optimizing resource allocation, enhancing predictive maintenance, and improving process control.

- Predictive Maintenance: AI algorithms analyze sensor data from machinery to predict potential failures before they occur. This allows for proactive maintenance, minimizing downtime and extending equipment lifespan.

- Process Control: AI-powered systems can monitor and adjust process parameters in real-time, ensuring optimal efficiency and product quality. They adapt to changing conditions and optimize performance based on real-time data analysis.

- Resource Allocation: AI algorithms can analyze production data and optimize resource allocation based on demand forecasts and real-time conditions. This minimizes waste, reduces inventory costs, and improves overall resource utilization.

Emerging Technologies

Emerging technologies like blockchain, the Internet of Things (IoT), and cloud computing are further driving industrial scaling by enabling seamless data management, improved connectivity, and enhanced collaboration.

- Blockchain: Blockchain technology facilitates secure and transparent data sharing across the supply chain. This improves traceability, reduces fraud, and enhances collaboration among stakeholders.

- Internet of Things (IoT): IoT devices collect real-time data from industrial equipment, enabling better monitoring, control, and optimization of processes. This allows for remote management, predictive maintenance, and data-driven decision-making.

- Cloud Computing: Cloud platforms provide scalable and flexible computing resources, enabling industries to access powerful data analytics and AI capabilities without significant upfront investments. This facilitates data storage, processing, and collaboration across distributed teams.

Closing Notes: Scales Industrial Technologies

As we navigate the challenges and opportunities presented by scaling industrial technologies, we recognize the importance of responsible innovation. Balancing the pursuit of progress with ethical considerations, environmental sustainability, and societal well-being is paramount. By embracing a forward-thinking approach, we can harness the transformative power of industrial scaling to create a future where innovation and sustainability go hand in hand.

Scales industrial technologies are evolving rapidly, with new innovations constantly emerging. One interesting development is the rise of the technology hat , which integrates sensors and communication capabilities to provide real-time data and insights. This technology has the potential to revolutionize various industries, from manufacturing to healthcare, by enhancing efficiency, safety, and productivity.