RPM Technology: Revolutionizing Business Operations

RPM technology, a powerful tool for optimizing business processes, has transformed industries by providing real-time insights and data-driven decision-making. This technology has evolved significantly over the years, from its humble […]

RPM technology, a powerful tool for optimizing business processes, has transformed industries by providing real-time insights and data-driven decision-making. This technology has evolved significantly over the years, from its humble beginnings to its current sophisticated state, impacting everything from manufacturing to healthcare.

The core principles of RPM technology revolve around collecting and analyzing data from various sources, including sensors, devices, and software applications. This data is then processed and interpreted to provide actionable insights, enabling businesses to identify trends, optimize performance, and make informed decisions.

RPM Technology Overview

RPM technology is a package management system widely used in Linux distributions for installing, updating, and removing software packages. It is a powerful tool that simplifies software management and ensures consistency across different systems.

Historical Evolution of RPM Technology

The RPM package management system has evolved significantly over the years, driven by the need to streamline software installation and maintenance. The first version of RPM, known as RPM 0.3, was released in 1997. This early version focused on providing basic package management capabilities, such as installing, removing, and querying packages.

Over time, RPM has undergone numerous improvements and enhancements, including:

- The introduction of dependencies, which allowed packages to specify other packages they required for proper functionality.

- The development of a standardized package format, ensuring compatibility across different Linux distributions.

- The integration of features such as package signing and verification, enhancing security and integrity.

- The creation of tools and utilities for managing RPM packages, including yum, dnf, and zypper.

Today, RPM is a mature and robust package management system that plays a crucial role in the Linux ecosystem. It is used by a wide range of distributions, including Red Hat Enterprise Linux (RHEL), Fedora, CentOS, and openSUSE.

Key Components of an RPM System

An RPM system consists of several key components that work together to manage software packages. These components include:

- RPM Database: The RPM database stores information about all installed packages, including their version, dependencies, and installation paths. This database is essential for tracking installed packages and resolving dependencies.

- RPM Package Manager (rpm): The rpm command-line utility is the primary tool for interacting with the RPM system. It provides a wide range of commands for installing, removing, querying, and verifying packages.

- Package Repositories: Package repositories are centralized locations where RPM packages are stored. These repositories can be local or remote, and they provide a convenient way to access and download packages.

- Package Managers: Package managers, such as yum, dnf, and zypper, provide a higher-level interface for managing RPM packages. They automate tasks such as dependency resolution, package updates, and package upgrades.

Benefits of RPM Technology

RPM technology offers several benefits for users and system administrators, including:

- Simplified Software Installation and Management: RPM streamlines the process of installing, updating, and removing software packages, reducing manual intervention and potential errors.

- Dependency Resolution: RPM automatically resolves dependencies between packages, ensuring that all necessary components are installed and that packages function correctly.

- Package Integrity and Security: RPM supports package signing and verification, providing a mechanism for ensuring that packages are authentic and have not been tampered with.

- Consistency Across Systems: RPM’s standardized package format and management tools ensure consistency in software installations across different Linux systems, facilitating easier deployment and maintenance.

Applications of RPM Technology

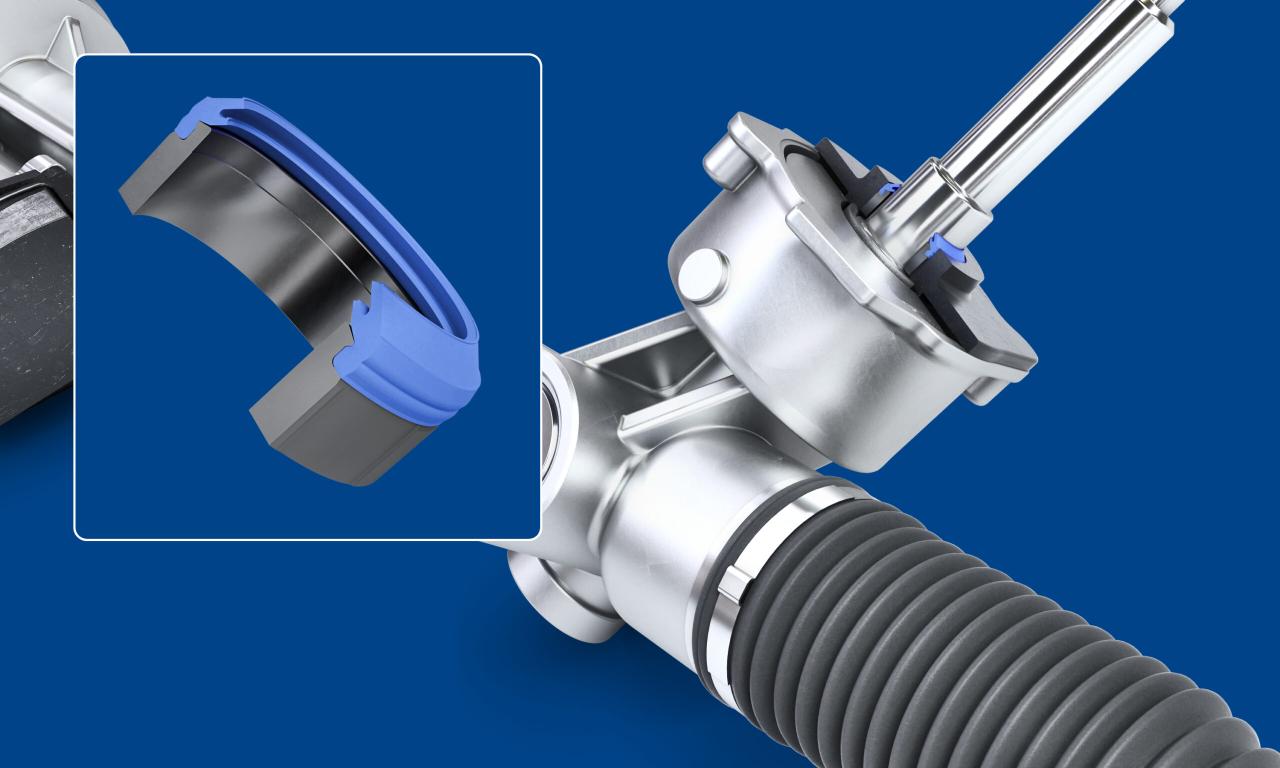

RPM technology, with its ability to continuously monitor and analyze rotating machinery, has found widespread application across various industries. From power generation to manufacturing, its implementation has significantly improved operational efficiency, reduced downtime, and enhanced safety.

Applications in Power Generation

RPM technology plays a crucial role in ensuring the reliable and efficient operation of power generation plants. The continuous monitoring of critical rotating equipment, such as turbines and generators, enables early detection of potential issues, preventing catastrophic failures.

- Predictive Maintenance: By analyzing vibration data, RPM technology can predict potential failures in rotating machinery, allowing for proactive maintenance before any significant damage occurs. This minimizes downtime and reduces the risk of unexpected outages.

- Performance Optimization: RPM technology helps optimize the performance of power generation equipment by providing insights into operational parameters like speed, torque, and vibration levels. This data can be used to adjust operating conditions and improve overall efficiency.

- Safety Enhancement: RPM technology contributes to safety by detecting anomalies that could lead to accidents. For instance, it can identify imbalances in rotating components, which can cause excessive vibration and potential damage.

Applications in Manufacturing

RPM technology is essential for optimizing manufacturing processes and ensuring the smooth operation of production lines. Its applications range from monitoring the performance of motors and pumps to analyzing the health of bearings and gears.

- Production Line Efficiency: RPM technology can monitor the speed and torque of motors and pumps used in manufacturing processes, ensuring optimal performance and minimizing downtime. This translates to increased production efficiency and reduced operational costs.

- Asset Management: By analyzing vibration data, RPM technology can provide insights into the health of bearings and gears, allowing for timely maintenance and replacement. This helps to prevent unexpected breakdowns and extends the lifespan of critical machinery.

- Quality Control: RPM technology can be used to monitor the speed and accuracy of rotating machinery involved in manufacturing processes. This ensures consistent product quality and reduces the risk of defects.

Applications in Aerospace

RPM technology is critical for ensuring the safety and reliability of aircraft engines, propellers, and other rotating components. It plays a vital role in detecting potential issues early on, preventing catastrophic failures and ensuring the smooth operation of aircraft.

- Engine Health Monitoring: RPM technology continuously monitors the vibration and performance of aircraft engines, detecting anomalies that could indicate potential problems. This enables early intervention and reduces the risk of in-flight failures.

- Predictive Maintenance: By analyzing vibration data, RPM technology can predict potential failures in aircraft engines and other rotating components, allowing for scheduled maintenance before any significant damage occurs. This minimizes downtime and ensures the safety of passengers and crew.

- Performance Optimization: RPM technology can be used to optimize the performance of aircraft engines and other rotating components, improving fuel efficiency and reducing emissions.

Applications in Automotive, Rpm technology

RPM technology plays a crucial role in the automotive industry, contributing to the development of efficient and reliable vehicles. It is used to monitor the performance of engines, transmissions, and other rotating components, ensuring optimal performance and safety.

- Engine Performance Monitoring: RPM technology continuously monitors the speed and torque of automotive engines, detecting potential issues that could affect performance and fuel efficiency. This allows for timely intervention and ensures optimal engine operation.

- Transmission Health Monitoring: RPM technology can monitor the performance of transmissions, detecting anomalies that could indicate potential failures. This enables early maintenance and reduces the risk of unexpected breakdowns.

- Safety Enhancement: RPM technology can be used to monitor the speed and stability of vehicles, detecting potential issues that could lead to accidents. This contributes to overall vehicle safety and driver confidence.

Applications in Oil and Gas

RPM technology is widely employed in the oil and gas industry to monitor and analyze the performance of rotating equipment, such as pumps, compressors, and turbines. This ensures efficient and reliable operation, reduces downtime, and enhances safety.

- Pump Performance Monitoring: RPM technology can monitor the speed and torque of pumps used in oil and gas operations, ensuring optimal performance and detecting potential issues that could affect production. This helps to maximize production efficiency and minimize downtime.

- Compressor Health Monitoring: RPM technology can analyze the vibration and performance of compressors, detecting anomalies that could indicate potential failures. This allows for timely maintenance and prevents unexpected shutdowns, ensuring the smooth operation of oil and gas facilities.

- Turbine Performance Optimization: RPM technology can be used to optimize the performance of turbines used in oil and gas operations, improving efficiency and reducing fuel consumption. This contributes to overall cost savings and environmental sustainability.

Benefits and Challenges of RPM Technology

RPM technology, with its ability to remotely monitor and manage assets, offers a plethora of benefits across various industries. However, its implementation also comes with its share of challenges that require careful consideration.

Advantages of RPM Technology

The benefits of RPM technology are far-reaching, impacting efficiency, cost-effectiveness, and safety in diverse settings.

- Enhanced Asset Monitoring and Management: RPM technology provides real-time data on asset performance, enabling proactive maintenance and early detection of potential issues. This leads to reduced downtime, increased operational efficiency, and minimized maintenance costs.

- Improved Safety and Security: By monitoring asset performance remotely, RPM technology can identify potential safety hazards, allowing for timely intervention and reducing the risk of accidents. It also enhances security by providing remote access control and monitoring, deterring unauthorized access and tampering.

- Increased Productivity and Efficiency: RPM technology enables remote optimization of asset performance, maximizing output and minimizing resource consumption. This leads to increased productivity, reduced operational costs, and improved overall efficiency.

- Reduced Costs and Improved Profitability: By minimizing downtime, optimizing asset performance, and reducing maintenance costs, RPM technology contributes to significant cost savings and improved profitability.

Challenges of RPM Technology

While RPM technology offers numerous advantages, its implementation also presents certain challenges.

- Initial Investment Costs: Implementing RPM technology requires significant upfront investment in hardware, software, and infrastructure. This can be a barrier for organizations with limited budgets.

- Security Risks: Remote access to critical assets raises security concerns. Data breaches, unauthorized access, and cyberattacks pose a significant risk to the integrity and safety of operations.

- Data Management and Analysis: RPM technology generates vast amounts of data, requiring robust data management systems and advanced analytical tools to extract meaningful insights.

- Technical Expertise and Training: Implementing and managing RPM technology requires specialized technical expertise and training. This can be a challenge for organizations with limited IT resources or expertise.

- Connectivity Issues: Reliable and consistent connectivity is crucial for effective RPM operation. Interruptions in network connectivity can lead to data loss, delayed responses, and compromised asset performance.

Comparison with Other Solutions

RPM technology is not the only solution for remote asset management. Other options include:

- Telematics: This technology focuses on vehicle tracking and fleet management, offering data on vehicle location, speed, fuel consumption, and driver behavior. While telematics is valuable for transportation and logistics, it has limited capabilities for monitoring and managing assets beyond vehicles.

- Internet of Things (IoT): IoT encompasses a wide range of connected devices and sensors that collect and transmit data. While IoT can be used for asset monitoring, it lacks the specific functionalities and data analytics capabilities that RPM technology offers.

- Cloud Computing: Cloud computing provides scalable and cost-effective infrastructure for data storage, processing, and analysis. While cloud platforms can support RPM applications, they are not a direct replacement for the specialized features and functionalities of RPM technology.

Future Trends in RPM Technology

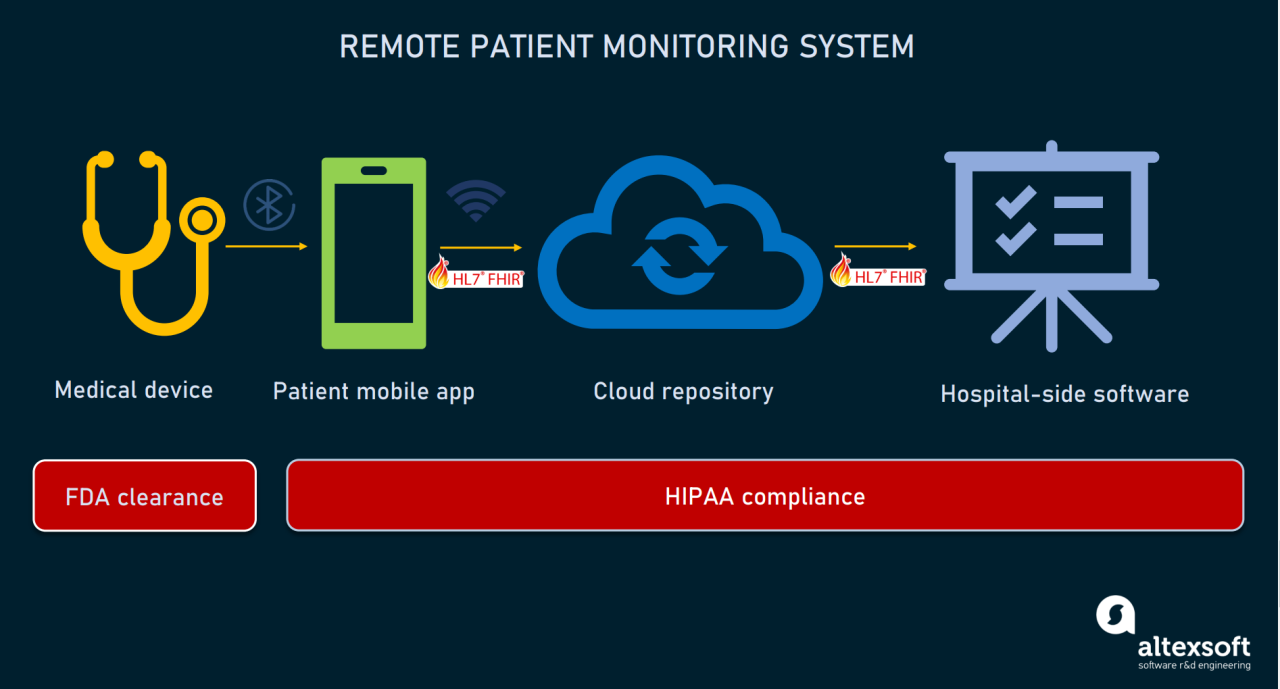

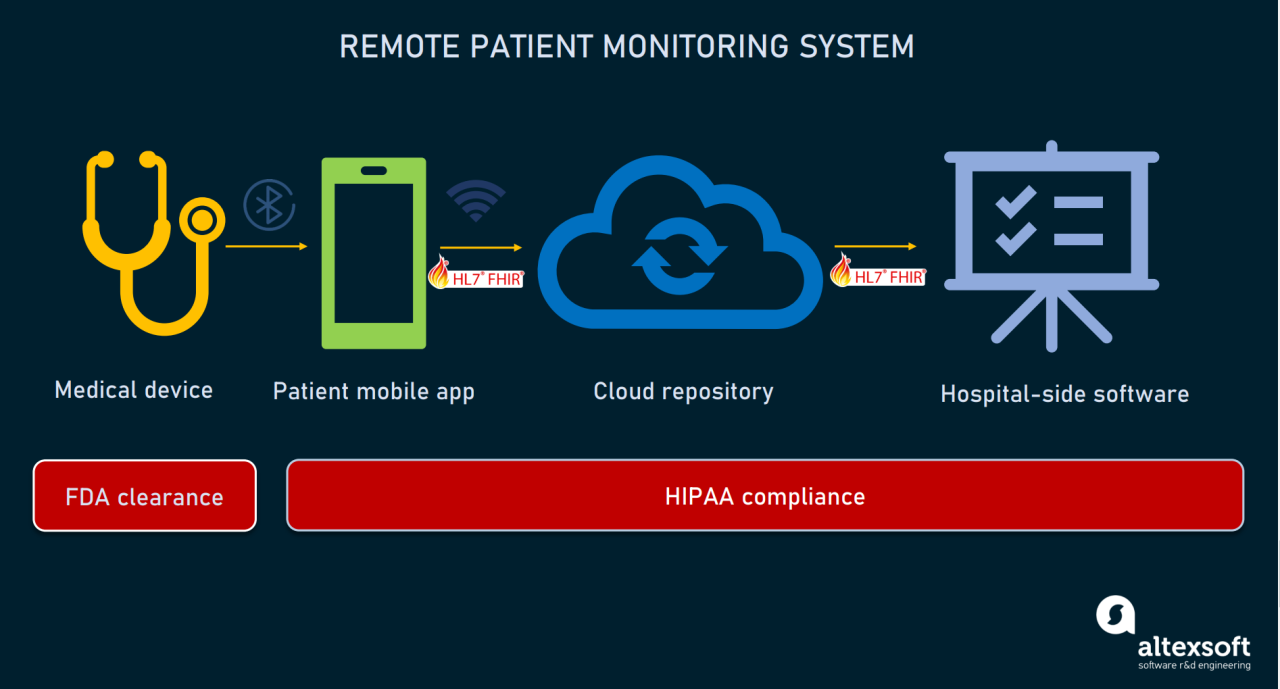

The field of RPM technology is rapidly evolving, with advancements in data analytics, artificial intelligence, and wearable technologies driving the development of innovative solutions. These trends are shaping the future of RPM, expanding its applications and improving patient outcomes.

Integration with Artificial Intelligence (AI)

AI is revolutionizing RPM by enabling more sophisticated data analysis and personalized patient care. AI algorithms can analyze vast amounts of patient data, identify patterns, and predict potential health issues. This allows for early intervention, reducing the risk of complications and improving overall health outcomes.

For example, AI-powered RPM systems can analyze data from wearable devices, such as smartwatches and fitness trackers, to detect changes in heart rate, sleep patterns, and activity levels that may indicate an impending health crisis. This information can then be used to alert healthcare providers and enable timely intervention.

Advancements in Wearable Technology

Wearable devices are becoming increasingly sophisticated, providing more comprehensive and accurate data about patient health. These advancements are driving the adoption of RPM technology, enabling continuous monitoring and remote management of chronic conditions.

Wearable devices are becoming smaller, more comfortable, and more integrated with everyday life, allowing for seamless data collection and patient engagement.

For instance, wearable sensors can now measure blood glucose levels, blood pressure, and even detect falls, providing valuable insights into patient health and well-being. These advancements are transforming RPM from a reactive approach to a proactive one, allowing for early detection and intervention before serious health problems arise.

Increased Focus on Patient Engagement

RPM technology is increasingly focusing on patient engagement, empowering individuals to take an active role in managing their health. User-friendly interfaces, personalized feedback, and interactive platforms are being developed to improve patient adherence to treatment plans and enhance their overall health outcomes.

For example, mobile applications can provide patients with personalized health recommendations, track their progress, and facilitate communication with healthcare providers. This empowers patients to take ownership of their health, improving adherence to treatment plans and leading to better outcomes.

Expansion of Applications

RPM technology is expanding beyond traditional applications in chronic disease management. It is now being used in areas such as mental health, rehabilitation, and even preventative care. This expansion is driven by the growing recognition of the benefits of remote monitoring and personalized healthcare.

For example, RPM technology is being used to support patients with mental health conditions, such as depression and anxiety, through remote therapy sessions, medication management, and mood tracking. This allows for more accessible and convenient care, reducing the stigma associated with mental health and improving patient outcomes.

Case Studies and Examples

Real-world applications of RPM technology demonstrate its transformative potential across various industries. These case studies showcase successful implementations, highlighting the benefits and challenges encountered, providing valuable insights for organizations considering adopting RPM.

Case Studies of Successful RPM Implementations

Here are some notable case studies demonstrating the successful implementation of RPM technology:

- Industry: Healthcare

- Application: Remote patient monitoring for chronic conditions like heart failure and diabetes

- Benefits: Improved patient outcomes, reduced hospital readmissions, enhanced patient engagement, and lower healthcare costs

- Challenges: Data privacy and security concerns, patient acceptance and adherence to monitoring, and integration with existing healthcare systems

- Industry: Manufacturing

- Application: Predictive maintenance for industrial equipment, optimizing asset performance and minimizing downtime

- Benefits: Reduced maintenance costs, increased equipment uptime, improved operational efficiency, and enhanced safety

- Challenges: Implementing robust data analytics capabilities, integrating with existing manufacturing systems, and managing complex data streams

- Industry: Transportation

- Application: Fleet management for optimizing vehicle performance, fuel efficiency, and driver safety

- Benefits: Reduced fuel consumption, improved driver safety, increased vehicle uptime, and enhanced operational efficiency

- Challenges: Integrating with existing telematics systems, ensuring data accuracy and reliability, and managing data security

Table of Key Aspects of Case Studies

| Case Study | Industry | Application | Benefits | Challenges |

|—|—|—|—|—|

| Remote Patient Monitoring for Chronic Conditions | Healthcare | Monitoring vital signs, medication adherence, and patient activity | Improved patient outcomes, reduced hospital readmissions, enhanced patient engagement, and lower healthcare costs | Data privacy and security concerns, patient acceptance and adherence to monitoring, and integration with existing healthcare systems |

| Predictive Maintenance for Industrial Equipment | Manufacturing | Monitoring equipment performance, identifying potential failures, and scheduling maintenance | Reduced maintenance costs, increased equipment uptime, improved operational efficiency, and enhanced safety | Implementing robust data analytics capabilities, integrating with existing manufacturing systems, and managing complex data streams |

| Fleet Management for Optimizing Vehicle Performance | Transportation | Monitoring vehicle performance, fuel consumption, and driver behavior | Reduced fuel consumption, improved driver safety, increased vehicle uptime, and enhanced operational efficiency | Integrating with existing telematics systems, ensuring data accuracy and reliability, and managing data security |

Impact of RPM Technology on Business Outcomes

An infographic could visually represent the impact of RPM technology on business outcomes. It could showcase how RPM technology helps improve patient outcomes, reduce costs, increase equipment uptime, and enhance operational efficiency. The infographic could use data points and visuals to illustrate the tangible benefits of implementing RPM technology.

Wrap-Up

As RPM technology continues to evolve, we can expect to see even more innovative applications emerge. From predictive maintenance to personalized customer experiences, the possibilities are vast. By embracing this technology, businesses can gain a competitive edge, enhance efficiency, and unlock new opportunities for growth.

RPM technology, short for “Revolutions Per Minute,” is a key aspect of many mechanical systems. It measures the rotational speed of a component, crucial for optimizing performance and ensuring smooth operation. For businesses seeking to implement RPM technology, lvl technologies offers comprehensive solutions, including hardware and software integration, to help streamline processes and improve overall efficiency.

By leveraging RPM technology, businesses can gain valuable insights into their operations, leading to better decision-making and ultimately, improved results.