Refrigeration and Air Conditioning Technology 9th Edition: A Comprehensive Guide

Refrigeration and Air Conditioning Technology 9th Edition takes center stage, offering a comprehensive exploration of the science and engineering behind keeping things cool. This book delves into the history, principles, […]

Refrigeration and Air Conditioning Technology 9th Edition takes center stage, offering a comprehensive exploration of the science and engineering behind keeping things cool. This book delves into the history, principles, and applications of refrigeration and air conditioning, providing readers with a deep understanding of these essential technologies.

From the fundamental thermodynamic cycles to the intricacies of system design and installation, this book covers a wide range of topics. Readers will gain insights into the different types of refrigeration and air conditioning systems, their components, and the properties of refrigerants. The book also explores the crucial aspects of energy efficiency, sustainability, and emerging advancements in the field.

Introduction to Refrigeration and Air Conditioning

Refrigeration and air conditioning have become integral parts of modern life, influencing our comfort, food preservation, and numerous industries. This technology has evolved significantly over the years, from rudimentary ice harvesting to sophisticated systems that regulate temperature and humidity with precision.

History and Evolution of Refrigeration and Air Conditioning, Refrigeration and air conditioning technology 9th edition

The concept of refrigeration dates back centuries, with early methods relying on natural ice and evaporation. In the 18th century, scientists began to understand the principles of heat transfer and thermodynamics, paving the way for mechanical refrigeration. The first practical vapor-compression refrigeration system was developed in the 1830s by Jacob Perkins, utilizing ether as a refrigerant.

In the late 19th century, the invention of the electric motor revolutionized refrigeration, making it more efficient and accessible. The development of new refrigerants, such as ammonia and Freon, further enhanced the technology.

Air conditioning emerged in the early 20th century, initially used for industrial purposes. Willis Carrier developed the first modern air conditioning system in 1902, using a spray of water to cool air. The widespread adoption of air conditioning in homes and businesses began in the mid-20th century, driven by advancements in technology and the increasing demand for comfort and climate control.

Fundamental Principles of Refrigeration and Air Conditioning

Refrigeration and air conditioning systems operate based on the principles of thermodynamics, particularly the transfer of heat energy. The core principle is the refrigeration cycle, which involves four main stages:

- Evaporation: The refrigerant absorbs heat from the surrounding environment as it evaporates, becoming a low-temperature, low-pressure vapor.

- Compression: The refrigerant vapor is compressed, increasing its temperature and pressure.

- Condensation: The compressed refrigerant vapor releases heat to the environment as it condenses into a liquid.

- Expansion: The condensed refrigerant is expanded, lowering its temperature and pressure, preparing it for the next evaporation cycle.

This continuous cycle allows for the transfer of heat from a cold space (such as a refrigerator) to a warmer space (such as the outside environment).

Importance of Refrigeration and Air Conditioning

Refrigeration and air conditioning play crucial roles in various industries and aspects of daily life:

- Food Preservation: Refrigeration is essential for extending the shelf life of perishable foods, preventing spoilage and ensuring food safety.

- Comfort and Health: Air conditioning provides a comfortable living and working environment, particularly in hot climates. It also helps to improve indoor air quality and reduce the spread of airborne diseases.

- Industrial Processes: Refrigeration and air conditioning are vital in numerous industrial processes, including manufacturing, pharmaceuticals, and data centers.

- Medical Applications: Refrigeration is crucial for storing vaccines, blood products, and other medical supplies, ensuring their effectiveness and safety.

As technology continues to advance, refrigeration and air conditioning systems are becoming more energy-efficient, environmentally friendly, and integrated with smart home and building automation systems.

Refrigeration Systems

Refrigeration systems are essential in various applications, from keeping food fresh in our homes to cooling large industrial processes. They work by transferring heat from a cold space to a warmer space, using a refrigerant as a working fluid. Different refrigeration systems employ varying principles and components, each with its own advantages and disadvantages.

Vapor-Compression Refrigeration Systems

Vapor-compression refrigeration systems are the most common type used in residential, commercial, and industrial applications. They operate on a thermodynamic cycle that involves four key stages: evaporation, compression, condensation, and expansion.

- Evaporation: The refrigerant absorbs heat from the cold space, evaporating from a liquid to a gas. This process cools the space.

- Compression: The refrigerant vapor is compressed by a compressor, increasing its pressure and temperature.

- Condensation: The hot, high-pressure refrigerant vapor is then cooled and condensed back into a liquid, releasing heat to the environment.

- Expansion: The liquid refrigerant is expanded through an expansion valve, lowering its pressure and temperature. This prepares it for the next evaporation cycle.

The vapor-compression cycle is governed by the laws of thermodynamics, where heat flows from a higher temperature to a lower temperature.

Components of a Vapor-Compression Refrigeration System

- Compressor: The compressor is the heart of the system, pumping the refrigerant through the cycle.

- Condenser: The condenser is responsible for releasing heat from the refrigerant to the environment.

- Expansion Valve: The expansion valve controls the flow of refrigerant and lowers its pressure and temperature.

- Evaporator: The evaporator absorbs heat from the cold space, causing the refrigerant to evaporate.

Advantages of Vapor-Compression Refrigeration Systems

- High efficiency: Vapor-compression systems are known for their high efficiency in converting energy into cooling.

- Wide range of applications: They can be used in various applications, from small refrigerators to large industrial chillers.

- Relatively low cost: Compared to other refrigeration systems, vapor-compression systems are relatively inexpensive to manufacture and operate.

Disadvantages of Vapor-Compression Refrigeration Systems

- Use of refrigerants: Many refrigerants used in vapor-compression systems have a high global warming potential (GWP) and can contribute to climate change.

- Potential for leaks: The system’s components can leak refrigerant, which can be harmful to the environment.

- Noise and vibration: Compressors can generate noise and vibration, which may be a concern in some applications.

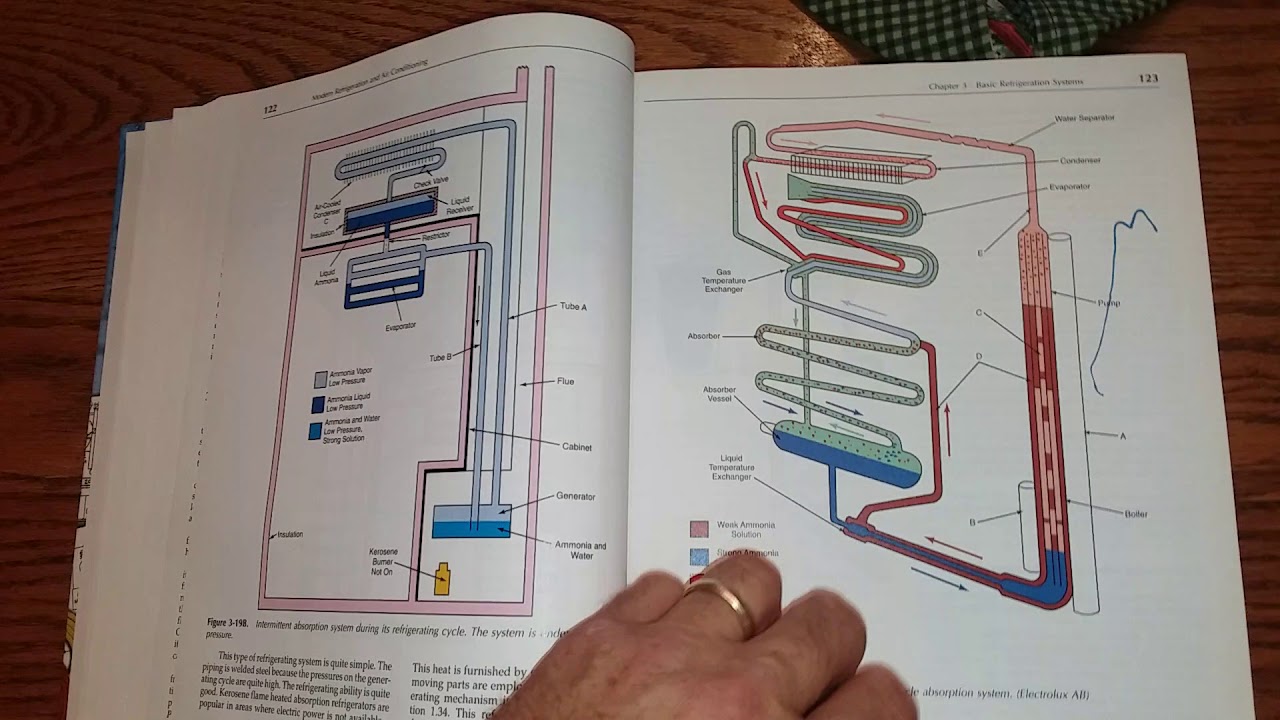

Absorption Refrigeration Systems

Absorption refrigeration systems utilize a different approach to achieve cooling, relying on a chemical reaction to absorb and release the refrigerant. These systems typically use water as the refrigerant and lithium bromide as the absorbent.

- Absorption: The absorbent (lithium bromide) absorbs the refrigerant (water) in a process that releases heat.

- Generation: Heat is applied to the absorbent solution, causing the refrigerant to be released as vapor.

- Condensation: The refrigerant vapor is condensed back into a liquid, releasing heat to the environment.

- Absorption: The condensed refrigerant is reabsorbed by the absorbent, completing the cycle.

Components of an Absorption Refrigeration System

- Absorber: The absorber is where the refrigerant is absorbed by the absorbent.

- Generator: The generator uses heat to release the refrigerant from the absorbent solution.

- Condenser: The condenser cools and condenses the refrigerant vapor.

- Evaporator: The evaporator absorbs heat from the cold space, causing the refrigerant to evaporate.

Advantages of Absorption Refrigeration Systems

- Environmentally friendly: Absorption systems use water as the refrigerant, which has a low GWP and is considered environmentally friendly.

- Suitable for waste heat recovery: They can be powered by waste heat from industrial processes, reducing energy consumption.

- Quiet operation: Absorption systems are generally quieter than vapor-compression systems.

Disadvantages of Absorption Refrigeration Systems

- Lower efficiency: Absorption systems are typically less efficient than vapor-compression systems.

- Higher initial cost: They are more expensive to manufacture and install than vapor-compression systems.

- Limited capacity: Absorption systems are generally limited in their cooling capacity.

Thermoelectric Refrigeration Systems

Thermoelectric refrigeration systems utilize the Peltier effect to create a temperature difference between two junctions. This effect occurs when an electric current is passed through a junction of two dissimilar materials, causing heat to be absorbed at one junction and released at the other.

- Peltier effect: The Peltier effect is a phenomenon where heat is absorbed or released at the junction of two dissimilar materials when an electric current is passed through them.

- Thermoelectric module: A thermoelectric module consists of multiple junctions of dissimilar materials, creating a temperature difference between the hot and cold sides.

- Cooling: When an electric current is passed through the module, heat is absorbed on the cold side and released on the hot side, creating a cooling effect.

Components of a Thermoelectric Refrigeration System

- Thermoelectric module: The heart of the system, containing multiple junctions of dissimilar materials.

- Heat sink: The heat sink absorbs heat released from the hot side of the module.

- Power supply: Provides electrical energy to the thermoelectric module.

Advantages of Thermoelectric Refrigeration Systems

- Environmentally friendly: Thermoelectric systems do not use refrigerants, making them environmentally friendly.

- Quiet operation: They are very quiet and vibration-free.

- Compact size: Thermoelectric systems are small and compact, making them suitable for portable applications.

Disadvantages of Thermoelectric Refrigeration Systems

- Low efficiency: Thermoelectric systems are relatively inefficient compared to other refrigeration systems.

- High cost: They are more expensive than vapor-compression and absorption systems.

- Limited cooling capacity: Thermoelectric systems have a limited cooling capacity.

Air Conditioning Systems

Air conditioning systems are designed to regulate the temperature, humidity, and air quality within a space. These systems play a crucial role in maintaining comfortable and productive environments for both residential and commercial applications.

Air conditioning systems are classified based on their design, application, and cooling capacity. Different types of air conditioning systems are employed for various purposes, from cooling individual rooms to entire buildings.

Refrigeration and air conditioning technology is a constantly evolving field, with new innovations emerging all the time. One exciting development is the integration of z technology , which promises to revolutionize how we cool our homes and businesses. This technology has the potential to significantly improve energy efficiency and reduce environmental impact, making it a valuable tool for the future of refrigeration and air conditioning.

Types of Air Conditioning Systems

Air conditioning systems are broadly classified into three main categories: central air conditioning, window units, and split systems. Each system offers unique features and advantages, making it suitable for specific applications and environments.

- Central air conditioning: Central air conditioning systems are designed to cool an entire house or building using a single, centralized unit. These systems typically consist of an outdoor unit, an indoor unit, and a network of ductwork that distributes cooled air throughout the space. Central air conditioning systems offer efficient cooling for larger areas and provide consistent temperature control.

- Window units: Window units are compact and self-contained air conditioners designed to cool a single room. These units are typically installed in windows and have a built-in fan, evaporator, condenser, and compressor. Window units are an affordable and simple option for cooling individual rooms.

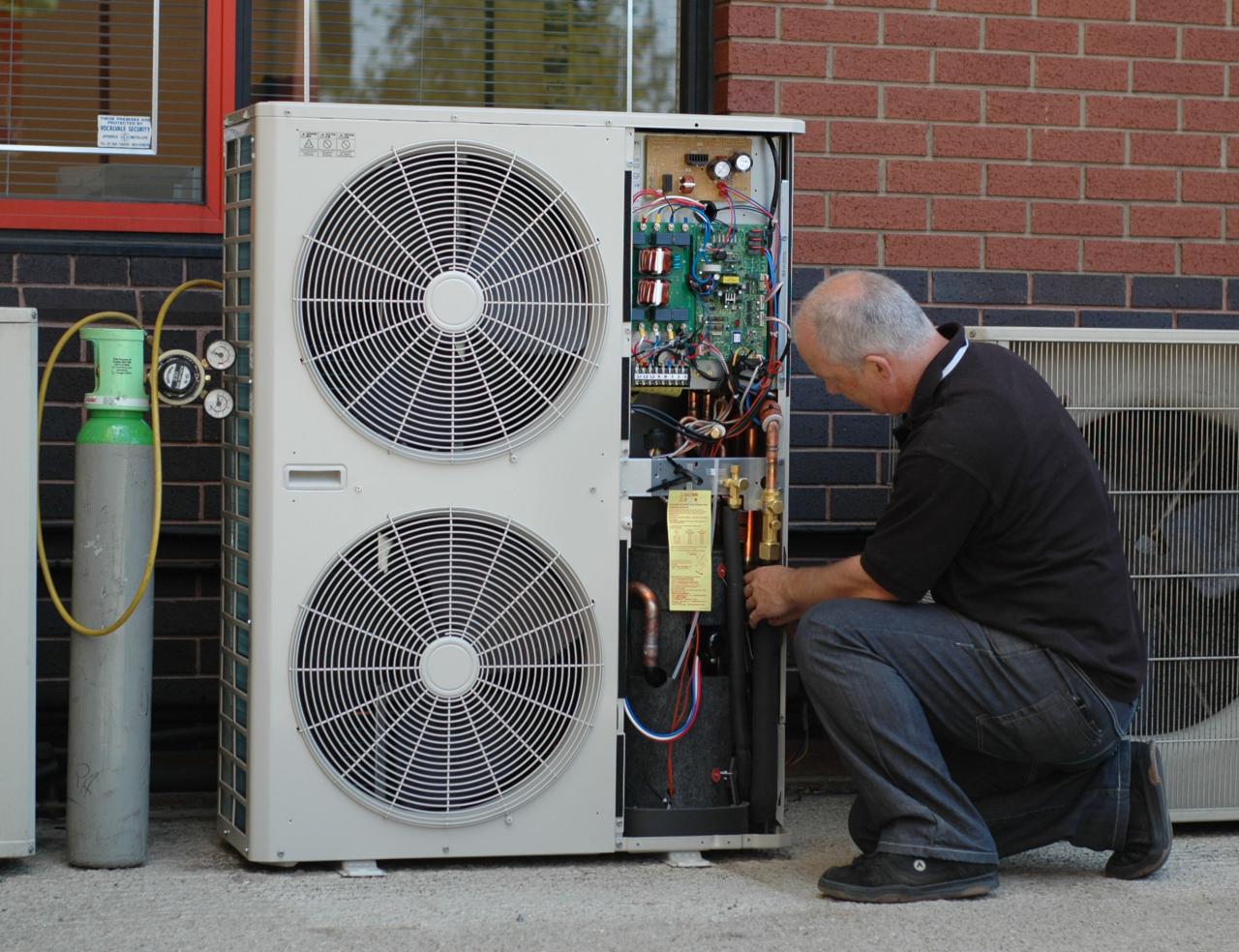

- Split systems: Split systems are a popular choice for both residential and commercial applications. These systems consist of two separate units: an outdoor unit that houses the compressor and condenser, and an indoor unit that contains the evaporator and fan. The indoor unit can be installed in various ways, including wall-mounted, ceiling-mounted, or floor-mounted, depending on the space and design requirements. Split systems offer greater flexibility in installation and provide efficient cooling for individual rooms or larger areas.

Components of Air Conditioning Systems

All air conditioning systems share common components that work together to regulate the temperature and humidity of the air. These components include:

- Compressor: The compressor is the heart of the air conditioning system. It compresses refrigerant gas, increasing its temperature and pressure. The high-pressure refrigerant then flows to the condenser.

- Condenser: The condenser is responsible for releasing heat from the refrigerant. The hot refrigerant gas passes through the condenser coils, where it releases heat to the surrounding air. The cooled refrigerant then changes from a gas to a liquid.

- Expansion valve: The expansion valve controls the flow of refrigerant from the condenser to the evaporator. It reduces the pressure of the refrigerant, causing it to change from a liquid to a gas.

- Evaporator: The evaporator absorbs heat from the air. The low-pressure refrigerant gas flows through the evaporator coils, where it absorbs heat from the surrounding air. The heat absorbed by the refrigerant causes it to evaporate and change back into a gas.

- Fan: The fan circulates air through the system. The fan draws air across the evaporator coils, where it absorbs heat from the refrigerant. The cooled air is then blown out into the space, providing a refreshing breeze.

- Thermostat: The thermostat is a control device that regulates the temperature of the air conditioning system. It senses the room temperature and turns the system on or off to maintain the desired temperature setting.

- Air filter: The air filter traps dust, pollen, and other airborne particles, improving the air quality within the space. Regular air filter replacement is essential for maintaining optimal system performance and ensuring clean air.

Working Principles of Air Conditioning Systems

Air conditioning systems work based on the principles of thermodynamics, specifically the transfer of heat between a refrigerant and the surrounding air. The refrigerant, a special type of fluid, absorbs heat from the air inside the space and releases it outside. The process involves four key steps:

- Evaporation: The refrigerant absorbs heat from the air inside the space as it evaporates, cooling the air. The heat absorbed by the refrigerant causes it to change from a liquid to a gas.

- Compression: The compressor compresses the refrigerant gas, increasing its temperature and pressure.

- Condensation: The hot refrigerant gas passes through the condenser coils, where it releases heat to the surrounding air. The cooled refrigerant then changes from a gas to a liquid.

- Expansion: The expansion valve reduces the pressure of the refrigerant, causing it to change from a liquid to a gas again. This low-pressure refrigerant is then ready to absorb heat from the air inside the space, completing the cycle.

Commercial and Industrial Air Conditioning Systems

Commercial and industrial settings require specialized air conditioning systems to meet the unique cooling needs of large spaces and diverse environments. These systems are designed to handle higher cooling capacities and provide efficient and reliable operation.

- Package units: Package units are self-contained air conditioning systems that combine all the essential components into a single unit. These units are typically installed on rooftops or ground level and provide cooling for large areas such as offices, retail stores, and warehouses.

- Chillers: Chillers are large-scale air conditioning systems that produce chilled water, which is then circulated through a network of pipes to cool air handlers. Chillers are commonly used in commercial buildings, hospitals, and industrial facilities. They offer high cooling capacities and efficient operation.

- Variable refrigerant flow (VRF) systems: VRF systems are modular air conditioning systems that allow for customized cooling solutions. They use variable-speed compressors and variable-capacity indoor units to provide precise temperature control for individual zones within a building. VRF systems offer energy efficiency and flexibility in installation.

- Air handling units (AHUs): AHUs are large, centralized systems that handle the distribution of conditioned air throughout a building. They typically include a fan, filter, coil, and other components that regulate the temperature, humidity, and air quality of the air. AHUs are commonly used in large commercial buildings, hospitals, and industrial facilities.

Refrigeration and Air Conditioning Components

Refrigeration and air conditioning systems rely on several key components working together to achieve their desired cooling effect. These components are responsible for transferring heat from one location to another, using a refrigerant as the medium. Understanding the function and operation of each component is crucial for effective system design, maintenance, and troubleshooting.

Compressors

Compressors are the heart of any refrigeration or air conditioning system. Their primary function is to increase the pressure and temperature of the refrigerant vapor. This process is essential for driving the heat transfer process. Compressors work by compressing the refrigerant vapor, which reduces its volume and increases its pressure and temperature.

- Reciprocating Compressors: These compressors utilize a piston and cylinder mechanism to compress the refrigerant vapor. They are commonly used in residential and small commercial applications due to their simplicity and relatively low cost.

- Rotary Compressors: Rotary compressors use a rotating vane or screw mechanism to compress the refrigerant vapor. They offer higher efficiency and quieter operation compared to reciprocating compressors, making them suitable for larger systems.

- Scroll Compressors: Scroll compressors employ two spiral-shaped scrolls that mesh together to compress the refrigerant vapor. They are known for their high efficiency, quiet operation, and compact size, making them ideal for applications with limited space.

- Centrifugal Compressors: Centrifugal compressors use a rotating impeller to accelerate the refrigerant vapor, increasing its pressure and temperature. They are typically used in large-scale industrial and commercial applications due to their high capacity and ability to handle large volumes of refrigerant.

The selection of a compressor depends on factors such as the system’s capacity, operating conditions, space constraints, and cost considerations.

Condensers

Condensers are responsible for rejecting heat from the refrigerant, converting it from a high-pressure, high-temperature vapor to a high-pressure, high-temperature liquid. This process occurs by transferring heat from the refrigerant to the surrounding environment.

- Air-Cooled Condensers: These condensers use air as the cooling medium. Air is blown over the condenser coils, transferring heat from the refrigerant to the air. Air-cooled condensers are commonly used in residential and commercial applications due to their simplicity and low cost.

- Water-Cooled Condensers: Water-cooled condensers use water as the cooling medium. Water flows through the condenser coils, absorbing heat from the refrigerant. Water-cooled condensers are typically used in larger commercial and industrial applications where ample water supply is available.

- Evaporative Condensers: Evaporative condensers use a combination of air and water for cooling. Water is sprayed over the condenser coils, and air is blown over the wet coils, facilitating heat transfer through evaporation. Evaporative condensers offer a more efficient cooling solution compared to air-cooled condensers, particularly in hot and humid climates.

The choice of condenser type depends on factors such as the cooling capacity, available cooling medium, environmental conditions, and cost considerations.

Evaporators

Evaporators are responsible for absorbing heat from the surrounding environment, converting the refrigerant from a low-pressure, low-temperature liquid to a low-pressure, low-temperature vapor. This process occurs by transferring heat from the environment to the refrigerant.

- Direct Expansion (DX) Evaporators: DX evaporators directly contact the air or fluid being cooled. The refrigerant vaporizes within the evaporator coils, absorbing heat from the surrounding environment. DX evaporators are commonly used in residential and commercial applications due to their simplicity and efficiency.

- Flooded Evaporators: Flooded evaporators are submerged in the fluid being cooled. The refrigerant vaporizes within the evaporator coils, absorbing heat from the fluid. Flooded evaporators are typically used in industrial applications where large volumes of fluid need to be cooled.

The selection of an evaporator type depends on factors such as the cooling capacity, the type of environment being cooled, and cost considerations.

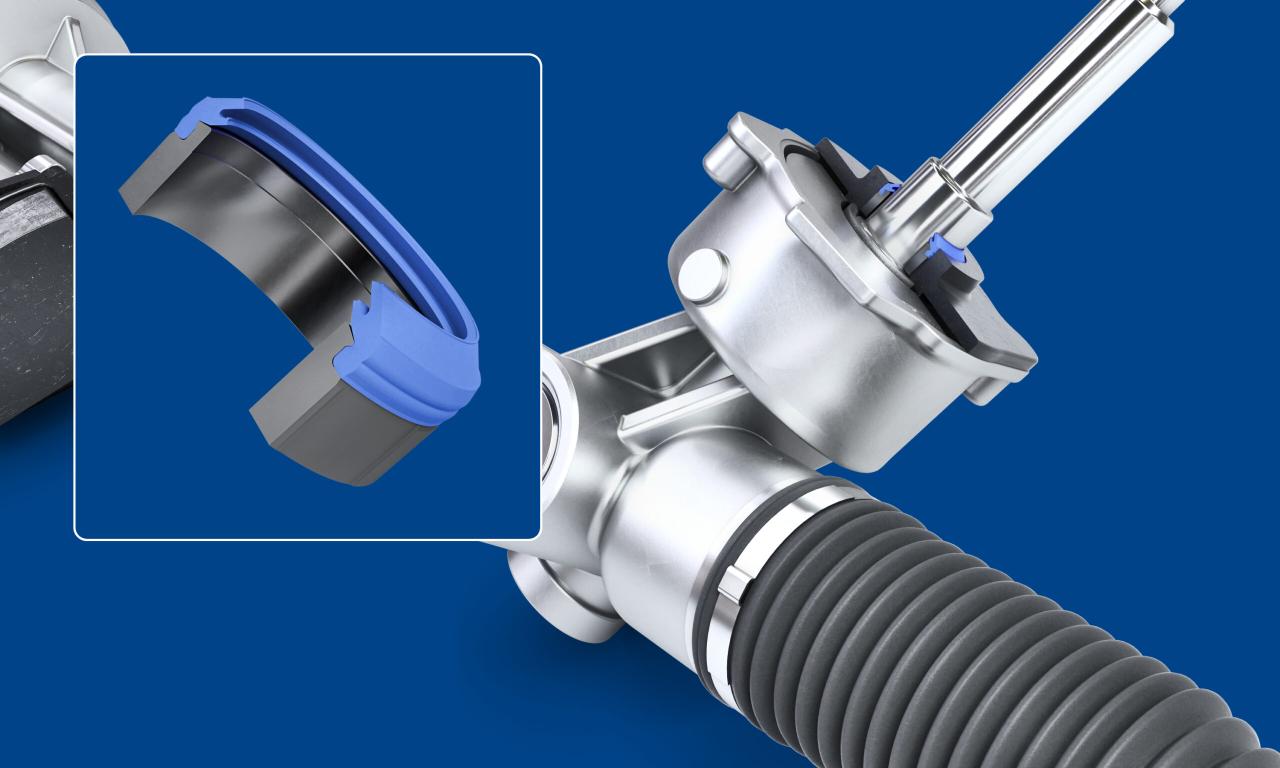

Expansion Valves

Expansion valves control the flow of refrigerant into the evaporator. They are responsible for reducing the refrigerant’s pressure and temperature, allowing it to absorb heat from the environment.

- Thermostatic Expansion Valves (TXVs): TXVs use a sensor to measure the temperature of the refrigerant entering the evaporator. They adjust the flow of refrigerant to maintain a constant evaporator temperature. TXVs are commonly used in residential and commercial applications due to their simplicity and efficiency.

- Electronic Expansion Valves (EEVs): EEVs use an electronic sensor to measure the temperature of the refrigerant entering the evaporator. They use an electronic controller to adjust the flow of refrigerant to maintain a constant evaporator temperature. EEVs offer more precise temperature control compared to TXVs and are commonly used in commercial and industrial applications.

- Capillary Tubes: Capillary tubes are small, thin tubes that restrict the flow of refrigerant. They are commonly used in residential applications due to their simplicity and low cost.

The selection of an expansion valve depends on factors such as the system’s capacity, the type of evaporator, and the desired temperature control.

Refrigerant

Refrigerant is the working fluid in a refrigeration or air conditioning system. It absorbs heat from the environment and releases it to the surrounding air or water. Refrigerants are chosen based on their thermodynamic properties, environmental impact, and safety considerations.

- R-22 (Chlorodifluoromethane): R-22 is a hydrochlorofluorocarbon (HCFC) refrigerant that has been widely used in the past. However, due to its ozone-depleting potential, its production and use have been phased out in many countries.

- R-410A (HFC-32/HFC-125): R-410A is a hydrofluorocarbon (HFC) refrigerant that is a popular alternative to R-22. It has a lower ozone-depleting potential but still contributes to global warming.

- R-32 (Difluoromethane): R-32 is a single-component HFC refrigerant with a lower global warming potential than R-410A. It is becoming increasingly popular as a replacement for R-410A.

- R-134a (1,1,1,2-Tetrafluoroethane): R-134a is an HFC refrigerant that has been widely used in automotive air conditioning systems. However, it has a high global warming potential.

The selection of a refrigerant depends on factors such as the system’s capacity, operating conditions, environmental regulations, and cost considerations.

Refrigerants and Their Properties

Refrigerants are essential components of refrigeration and air conditioning systems. They are responsible for absorbing heat from the space being cooled and transferring it to a different location, thus achieving the desired temperature reduction. Understanding the properties of refrigerants is crucial for selecting the appropriate refrigerant for a specific application and ensuring safe and efficient system operation.

Refrigerant Classification

Refrigerants are classified based on their chemical composition and properties. The most common classifications include:

- Halocarbons: These refrigerants are composed of halogenated hydrocarbons, such as chlorine, fluorine, and bromine. They are generally effective in heat transfer and have a long lifespan. However, many halocarbons have been found to have significant environmental impacts, leading to their phasing out in many applications.

- Hydrocarbons: These refrigerants are composed of hydrogen and carbon. They are natural, readily available, and have low global warming potential (GWP). However, they are flammable and can be explosive under certain conditions.

- HFCs (Hydrofluorocarbons): These refrigerants are composed of hydrogen, fluorine, and carbon. They have a lower ozone depletion potential (ODP) than halocarbons but still contribute to global warming.

- HFOs (Hydrofluoro-olefins): These refrigerants are similar to HFCs but contain a double bond between carbon atoms. They have a very low GWP and are considered to be environmentally friendly.

- Ammonia (NH3): Ammonia is a natural refrigerant with excellent thermodynamic properties. It is widely used in industrial refrigeration systems but is toxic and requires specialized handling.

- Carbon Dioxide (CO2): Carbon dioxide is a natural refrigerant with a low GWP. It is becoming increasingly popular in commercial refrigeration systems due to its environmental benefits.

Refrigerant Properties

The properties of refrigerants are crucial for determining their suitability for a specific application. Some important properties include:

- Boiling Point: The boiling point of a refrigerant determines its operating pressure and temperature range. A refrigerant with a low boiling point will operate at lower pressures and temperatures, while a refrigerant with a high boiling point will operate at higher pressures and temperatures.

- Specific Heat: The specific heat of a refrigerant is the amount of heat required to raise the temperature of one unit mass of the refrigerant by one degree Celsius. A refrigerant with a high specific heat can absorb more heat from the space being cooled.

- Latent Heat of Vaporization: The latent heat of vaporization is the amount of heat required to change the refrigerant from a liquid to a gas at a constant temperature. A refrigerant with a high latent heat of vaporization can absorb more heat during the vaporization process.

- Thermal Conductivity: The thermal conductivity of a refrigerant determines its ability to transfer heat. A refrigerant with a high thermal conductivity can transfer heat more efficiently.

- Toxicity: The toxicity of a refrigerant is a crucial factor to consider, especially in occupied spaces. Some refrigerants are toxic and can cause health problems if they leak.

- Flammability: The flammability of a refrigerant is another important safety consideration. Some refrigerants are flammable and can pose a fire hazard if they leak.

- Ozone Depletion Potential (ODP): The ODP of a refrigerant measures its ability to deplete the ozone layer in the stratosphere. Halocarbons have high ODPs, while other refrigerants have low or zero ODPs.

- Global Warming Potential (GWP): The GWP of a refrigerant measures its ability to contribute to global warming. Refrigerants with high GWP values contribute significantly to climate change.

Environmental Impact of Refrigerants

Refrigerants have a significant impact on the environment. Halocarbons, such as CFCs (chlorofluorocarbons) and HCFCs (hydrochlorofluorocarbons), were widely used in the past but were found to have a high ODP. They contributed significantly to the depletion of the ozone layer, which protects the Earth from harmful ultraviolet radiation.

The Montreal Protocol, an international treaty signed in 1987, aimed to phase out the production and consumption of ozone-depleting substances, including halocarbons. This led to the development of alternative refrigerants with lower ODPs, such as HFCs. However, HFCs still have a high GWP, contributing to global warming.

The Kigali Amendment to the Montreal Protocol, adopted in 2016, aims to phase down the production and consumption of HFCs. This agreement will accelerate the transition to low-GWP refrigerants, such as HFOs and natural refrigerants like ammonia and CO2.

Transition to Environmentally Friendly Refrigerants

The transition to environmentally friendly refrigerants is a major challenge for the refrigeration and air conditioning industry. It requires significant investment in research and development, as well as changes in manufacturing processes, system design, and technician training.

However, the benefits of using environmentally friendly refrigerants outweigh the challenges. By reducing the use of high-GWP refrigerants, the industry can contribute to mitigating climate change and protecting the environment.

“The transition to environmentally friendly refrigerants is crucial for ensuring a sustainable future for the refrigeration and air conditioning industry.”

Factors Affecting Refrigerant Selection

The selection of a refrigerant for a specific application is influenced by several factors, including:

- Application Requirements: The type of refrigeration or air conditioning system, the desired temperature range, and the size of the space to be cooled are important considerations.

- Environmental Regulations: Regulations regarding the use of refrigerants, such as the Montreal Protocol and its amendments, are crucial factors in selecting a refrigerant.

- Safety Considerations: The toxicity, flammability, and other safety hazards of a refrigerant must be considered, especially in occupied spaces.

- Cost: The cost of the refrigerant, as well as the cost of installation and maintenance, are important economic considerations.

- Energy Efficiency: The energy efficiency of a refrigerant can impact operating costs and environmental impact.

System Design and Installation

Designing and installing a refrigeration or air conditioning system is a crucial process that ensures optimal performance, efficiency, and longevity. It involves careful consideration of various factors, including the specific needs of the space, environmental conditions, and the selection of appropriate components.

Load Calculations

Load calculations are essential for determining the cooling or heating capacity required for a particular space. They involve analyzing factors such as:

- Heat gain: This refers to the amount of heat entering the space from various sources, such as solar radiation, people, equipment, and lighting.

- Heat loss: This refers to the amount of heat escaping from the space, typically through walls, windows, and doors.

- Occupancy: The number of people occupying the space and their activity levels directly influence the heat load.

- Ventilation: The amount of fresh air required for the space impacts the heat load.

- Climate: The ambient temperature and humidity significantly affect the heat load.

Accurate load calculations are crucial for selecting the appropriate refrigeration or air conditioning system that can effectively meet the cooling or heating demands.

Component Selection

Once the load calculations are complete, the next step involves selecting the appropriate components for the system. These components include:

- Compressor: The heart of the system, the compressor is responsible for compressing the refrigerant, increasing its pressure and temperature.

- Condenser: The condenser rejects heat from the refrigerant, cooling it down and converting it from a gas to a liquid.

- Expansion valve: The expansion valve controls the flow of refrigerant, reducing its pressure and temperature before it enters the evaporator.

- Evaporator: The evaporator absorbs heat from the air or liquid being cooled, causing the refrigerant to evaporate.

- Air handler: The air handler circulates air through the system, delivering cooled or heated air to the space.

- Control system: The control system monitors and regulates the operation of the system, ensuring optimal performance and energy efficiency.

The selection of each component is crucial for the overall performance and efficiency of the system.

Installation and Commissioning

Proper installation and commissioning are critical for ensuring optimal performance and efficiency of the system. This includes:

- Installation according to manufacturer specifications: Following the manufacturer’s instructions for installation ensures that the system is properly installed and connected.

- Leak testing: Leak testing the system is essential to prevent refrigerant leaks, which can impact performance and damage the environment.

- Vacuuming: Vacuuming the system removes air and moisture, which can contaminate the refrigerant and reduce efficiency.

- Charging: Charging the system with the correct amount of refrigerant ensures optimal performance.

- Commissioning: Commissioning involves testing the system to ensure it operates correctly and meets the design specifications.

Troubleshooting and Maintenance

Regular maintenance and troubleshooting are essential for keeping the system operating efficiently and preventing breakdowns.

- Regular inspections: Regularly inspecting the system for signs of wear and tear can help identify potential problems early on.

- Cleaning: Cleaning the condenser and evaporator coils regularly can improve airflow and efficiency.

- Filter replacement: Replacing air filters regularly ensures proper airflow and prevents dust and debris from accumulating in the system.

- Refrigerant level checks: Regularly checking the refrigerant level can help identify leaks or other issues that may affect performance.

- Troubleshooting: Troubleshooting involves identifying and addressing any issues that may arise with the system. This may involve checking for electrical problems, refrigerant leaks, or mechanical failures.

“Proper maintenance is crucial for the longevity and efficiency of any refrigeration or air conditioning system.”

Energy Efficiency and Sustainability

The refrigeration and air conditioning (RAC) industry plays a crucial role in modern life, but it also has a significant impact on energy consumption and environmental sustainability. Understanding the energy consumption patterns of RAC systems and implementing strategies to improve efficiency is essential for reducing our carbon footprint and promoting a more sustainable future.

Energy Consumption Analysis

Energy consumption in RAC systems is influenced by several factors, including the size and type of system, operating conditions, and the efficiency of components. Understanding these factors is crucial for optimizing energy use and minimizing environmental impact.

- System Size and Type: Larger systems naturally consume more energy than smaller ones. The type of system, such as a split system or a central air conditioner, also affects energy consumption.

- Operating Conditions: Ambient temperature, humidity, and the desired indoor temperature all impact energy consumption. Higher temperatures and humidity levels require more energy to maintain a comfortable indoor environment.

- Component Efficiency: The efficiency of components like compressors, fans, and heat exchangers directly influences the overall energy consumption of the system. Newer technologies and design improvements can significantly reduce energy use.

Improving Energy Efficiency

Several technologies and strategies can be employed to improve the energy efficiency of RAC systems, leading to reduced energy consumption and lower operating costs.

- Variable Speed Drives (VSDs): VSDs allow compressors and fans to operate at variable speeds, adjusting to the cooling load and reducing energy consumption. This technology is particularly effective in situations where the cooling load fluctuates throughout the day, such as in commercial buildings.

- Smart Controls: Smart controls utilize sensors and algorithms to optimize system performance based on real-time conditions. They can adjust operating parameters, such as fan speed and refrigerant flow, to ensure efficient operation while maintaining comfort levels.

- High-Efficiency Components: Utilizing high-efficiency compressors, fans, and heat exchangers can significantly reduce energy consumption. These components are often rated based on their Seasonal Energy Efficiency Ratio (SEER) or Energy Efficiency Ratio (EER), providing a measure of their efficiency.

Sustainable Practices in the RAC Industry

Sustainable practices in the RAC industry focus on minimizing environmental impact through responsible refrigerant management, system optimization, and the use of environmentally friendly technologies.

- Refrigerant Management: Refrigerants are a critical component of RAC systems, but they can also contribute to climate change if not properly managed. Sustainable practices include using refrigerants with lower global warming potential (GWP), minimizing leaks and spills, and ensuring proper recovery and recycling of refrigerants.

- System Optimization: Regular maintenance, cleaning, and system optimization can significantly improve energy efficiency and reduce environmental impact. This includes checking refrigerant levels, cleaning filters and coils, and ensuring proper airflow.

- Environmentally Friendly Technologies: The RAC industry is constantly innovating to develop more sustainable technologies. These include natural refrigerants, such as carbon dioxide (CO2) and hydrocarbons, which have lower GWP than traditional synthetic refrigerants.

Applications and Advancements: Refrigeration And Air Conditioning Technology 9th Edition

Refrigeration and air conditioning technology plays a crucial role in various sectors, ensuring the preservation of food, the safety of pharmaceuticals, and the comfort of individuals in diverse environments. Furthermore, the field is continuously evolving with the development of innovative technologies and advancements that aim to improve efficiency, reduce environmental impact, and address emerging challenges.

Applications in Various Sectors

Refrigeration and air conditioning technology finds applications in a wide range of sectors, including:

- Food Processing: Refrigeration is essential for preserving food quality and extending its shelf life. It involves maintaining low temperatures to slow down microbial growth and enzymatic activity, thus preventing spoilage and extending the time for transportation and distribution.

- Pharmaceuticals: The pharmaceutical industry relies heavily on refrigeration and air conditioning to maintain the stability and efficacy of sensitive drugs and vaccines. Controlled temperatures are crucial for preventing degradation and ensuring the effectiveness of these products.

- Transportation: Refrigerated trucks and containers are vital for transporting perishable goods, such as food, pharmaceuticals, and other temperature-sensitive products. These systems ensure that the goods maintain the required temperature throughout the journey, preventing spoilage and maintaining quality.

- Commercial Buildings: Air conditioning systems provide comfort and productivity in commercial buildings by maintaining optimal indoor temperatures and humidity levels. These systems are essential for creating comfortable working environments, especially in hot and humid climates.

- Residential Buildings: Residential air conditioning systems provide comfort and improve indoor air quality. They help regulate temperature and humidity, creating a comfortable living environment for occupants.

Emerging Technologies and Trends

The field of refrigeration and air conditioning is witnessing the emergence of innovative technologies and trends that are transforming the industry. These advancements aim to improve efficiency, reduce environmental impact, and enhance performance:

- Magnetic Refrigeration: This technology utilizes magnetic fields to cool substances, offering potential advantages over traditional vapor-compression refrigeration. Magnetic refrigeration systems are more energy-efficient and environmentally friendly, as they do not use harmful refrigerants.

- Advanced Control Systems: The integration of advanced control systems, such as building management systems (BMS) and intelligent thermostats, allows for precise temperature control and optimization of energy consumption. These systems can adjust cooling and heating based on real-time conditions, minimizing energy waste and maximizing efficiency.

- Natural Refrigerants: The industry is shifting towards the use of natural refrigerants, such as carbon dioxide (CO2), ammonia (NH3), and hydrocarbons, which have lower global warming potentials (GWP) compared to traditional synthetic refrigerants. These natural refrigerants contribute to reducing the environmental impact of refrigeration and air conditioning systems.

- Variable-Speed Compressors: Variable-speed compressors adjust their speed based on the cooling load, enabling more efficient operation. They can operate at lower speeds during periods of low demand, reducing energy consumption and noise levels.

Future Directions and Research Areas

The field of refrigeration and air conditioning is continuously evolving, with ongoing research and development focused on addressing emerging challenges and exploring new frontiers:

- Energy Efficiency and Sustainability: Research is ongoing to develop more energy-efficient and sustainable refrigeration and air conditioning technologies. This includes exploring new refrigerants with low GWP, optimizing system designs, and integrating renewable energy sources.

- Smart and Connected Systems: The integration of smart and connected technologies, such as the Internet of Things (IoT), is enabling the development of intelligent refrigeration and air conditioning systems. These systems can monitor performance, optimize energy consumption, and provide remote control capabilities.

- Advanced Materials and Components: Research is being conducted to develop advanced materials and components that improve the performance and efficiency of refrigeration and air conditioning systems. This includes exploring new insulation materials, heat exchangers, and compressors.

Final Summary

As we conclude our journey through Refrigeration and Air Conditioning Technology 9th Edition, we are left with a profound appreciation for the complexity and importance of these systems. This book serves as an invaluable resource for students, professionals, and anyone seeking a comprehensive understanding of this critical field. From the historical evolution to the latest technological advancements, this comprehensive guide equips readers with the knowledge and skills necessary to navigate the ever-evolving world of refrigeration and air conditioning.