Refrigeration and Air Conditioning Technology 9th Edition: Mastering Cooling Systems

Refrigeration and Air Conditioning Technology 9th Edition delves into the intricate world of cooling systems, exploring the fundamental principles that govern their operation and the evolution of technologies that have […]

Refrigeration and Air Conditioning Technology 9th Edition delves into the intricate world of cooling systems, exploring the fundamental principles that govern their operation and the evolution of technologies that have shaped modern comfort and efficiency. This comprehensive guide unveils the science behind refrigeration and air conditioning, offering a detailed examination of thermodynamic cycles, system components, refrigerant management, and emerging trends.

From the history of ice houses to the advancements in energy-efficient systems, the book provides a captivating journey through the evolution of cooling technologies. It equips readers with a thorough understanding of refrigeration and air conditioning systems, encompassing design, analysis, troubleshooting, and maintenance. Whether you’re a student, professional, or simply curious about the science behind keeping things cool, this edition offers a valuable resource for gaining insights into this vital field.

Introduction to Refrigeration and Air Conditioning

Refrigeration and air conditioning are essential technologies that play a crucial role in modern life. They provide comfort, preserve food, and enable various industrial processes. This chapter will delve into the fundamental principles, history, and applications of these technologies.

Fundamental Principles of Refrigeration and Air Conditioning, Refrigeration and air conditioning technology 9th edition

Refrigeration and air conditioning are based on the principles of thermodynamics, specifically the transfer of heat between different systems. The primary objective of both processes is to remove heat from a specific area or object, thus lowering its temperature. This heat removal is achieved through a cycle involving a refrigerant, which undergoes a series of phase changes, absorbing heat during evaporation and releasing heat during condensation.

The refrigeration cycle typically involves four key components:

- Compressor: The compressor increases the pressure and temperature of the refrigerant vapor, forcing it to a higher energy state.

- Condenser: The high-pressure, high-temperature refrigerant vapor releases heat to the surrounding environment, transitioning into a liquid state.

- Expansion Valve: The expansion valve reduces the pressure of the liquid refrigerant, causing it to cool down and partially evaporate.

- Evaporator: The low-pressure, low-temperature refrigerant absorbs heat from the refrigerated space, evaporating and completing the cycle.

Air conditioning systems operate on a similar principle, but instead of focusing on cooling a specific object, they aim to reduce the temperature and humidity of an entire space. Air conditioners utilize a similar refrigeration cycle, but they incorporate additional components such as fans and air filters to circulate and purify the air.

The fundamental principle behind refrigeration and air conditioning is the transfer of heat from one system to another using a refrigerant that undergoes phase changes.

History and Evolution of Refrigeration and Air Conditioning Technologies

The history of refrigeration dates back to ancient times, with early methods involving the use of ice and natural cooling techniques. However, the development of modern refrigeration technology began in the 19th century with the invention of the vapor-compression refrigeration cycle.

- 1834: Jacob Perkins patented the first practical vapor-compression refrigeration system.

- 1850s: Ferdinand Carré developed an absorption refrigeration system, which utilized water and ammonia.

- 1920s: The development of chlorofluorocarbons (CFCs) as refrigerants revolutionized the industry, offering improved efficiency and safety.

- 1980s: Concerns about the environmental impact of CFCs led to the development of ozone-friendly alternatives, such as hydrofluorocarbons (HFCs).

- Present: Ongoing research and development focus on improving energy efficiency, reducing environmental impact, and exploring new technologies, such as magnetic refrigeration.

The evolution of air conditioning technology has paralleled that of refrigeration. Early air conditioning systems relied on simple methods like fans and evaporative cooling. The development of the vapor-compression cycle in the early 20th century enabled the creation of more efficient and effective air conditioning systems.

- 1902: Willis Carrier developed the first modern air conditioning system, which was used to control humidity in a printing plant.

- 1930s: Air conditioning became increasingly popular in homes, businesses, and public spaces, leading to significant growth in the industry.

- 1950s: The invention of the window air conditioner made air conditioning accessible to a wider audience.

- Present: Advancements in technology have led to the development of smart air conditioning systems, variable-speed compressors, and energy-efficient designs.

Importance and Applications of Refrigeration and Air Conditioning

Refrigeration and air conditioning technologies play a vital role in various industries and sectors, impacting our daily lives in numerous ways.

- Food Preservation: Refrigeration is essential for preserving food, extending its shelf life, and preventing spoilage. It enables the storage and transportation of perishable goods, ensuring food security and reducing food waste.

- Medical Applications: Refrigeration is crucial in the healthcare industry for storing vaccines, medications, and blood products. Air conditioning provides a comfortable and controlled environment for hospitals, clinics, and pharmaceutical facilities.

- Industrial Processes: Refrigeration and air conditioning are used in various industrial processes, such as manufacturing, chemical processing, and data centers. They provide temperature control, maintain product quality, and ensure optimal operating conditions.

- Commercial Applications: Refrigeration and air conditioning are essential for retail stores, restaurants, hotels, and other commercial establishments. They create comfortable environments for customers and employees, improve product display, and enhance customer experience.

- Residential Comfort: Air conditioning provides comfort and improves indoor air quality in homes. It helps regulate temperature, reduce humidity, and create a more pleasant living environment.

Refrigeration Systems

Refrigeration systems are essential in various applications, from keeping food fresh in our homes to providing cooling in large industrial processes. These systems work by transferring heat from a cold space to a warmer space, using a refrigerant as a working fluid. The process involves a series of steps that include evaporation, compression, condensation, and expansion.

Types of Refrigeration Systems

Refrigeration systems can be categorized based on their working principles and applications. Understanding the different types allows for choosing the most suitable system for a particular need.

- Vapor-Compression Refrigeration Systems: These are the most common type of refrigeration systems, widely used in residential, commercial, and industrial applications. They operate on a closed cycle, using a refrigerant to absorb heat from the cold space and release it to the warmer environment. The system consists of a compressor, condenser, expansion valve, and evaporator, each playing a crucial role in the refrigeration process.

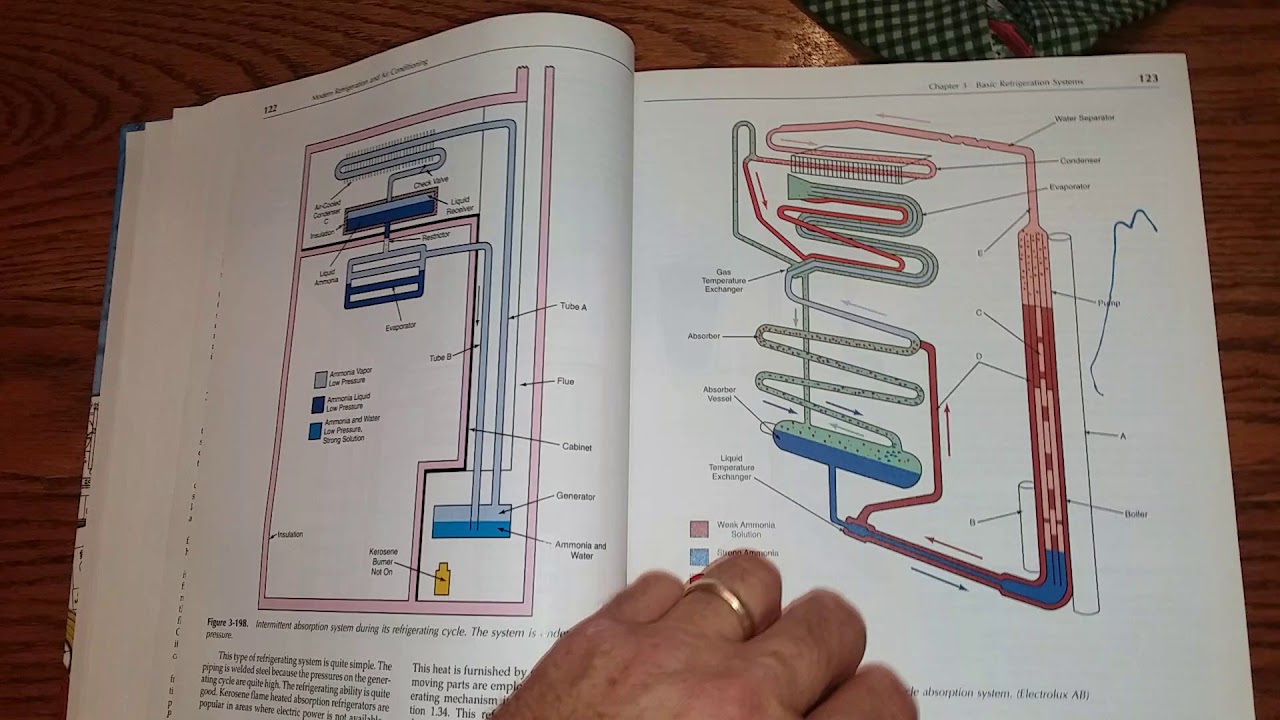

- Vapor-Absorption Refrigeration Systems: These systems use a solution of water and lithium bromide to absorb and release heat. They are typically used in applications where heat is readily available, such as industrial processes or cogeneration plants. They are less efficient than vapor-compression systems but offer advantages in specific situations.

- Air-Cycle Refrigeration Systems: These systems use air as the working fluid, relying on the principles of compression and expansion to achieve cooling. They are often used in applications requiring low temperatures, such as aircraft cabin cooling or cryogenic applications. Air-cycle systems are generally less efficient than vapor-compression systems but offer advantages in certain applications.

- Thermoelectric Refrigeration Systems: These systems use the Peltier effect to transfer heat. They are compact and have no moving parts, making them suitable for small-scale applications like portable coolers or medical devices. However, they are less efficient than traditional refrigeration systems.

Vapor-Compression Refrigeration System

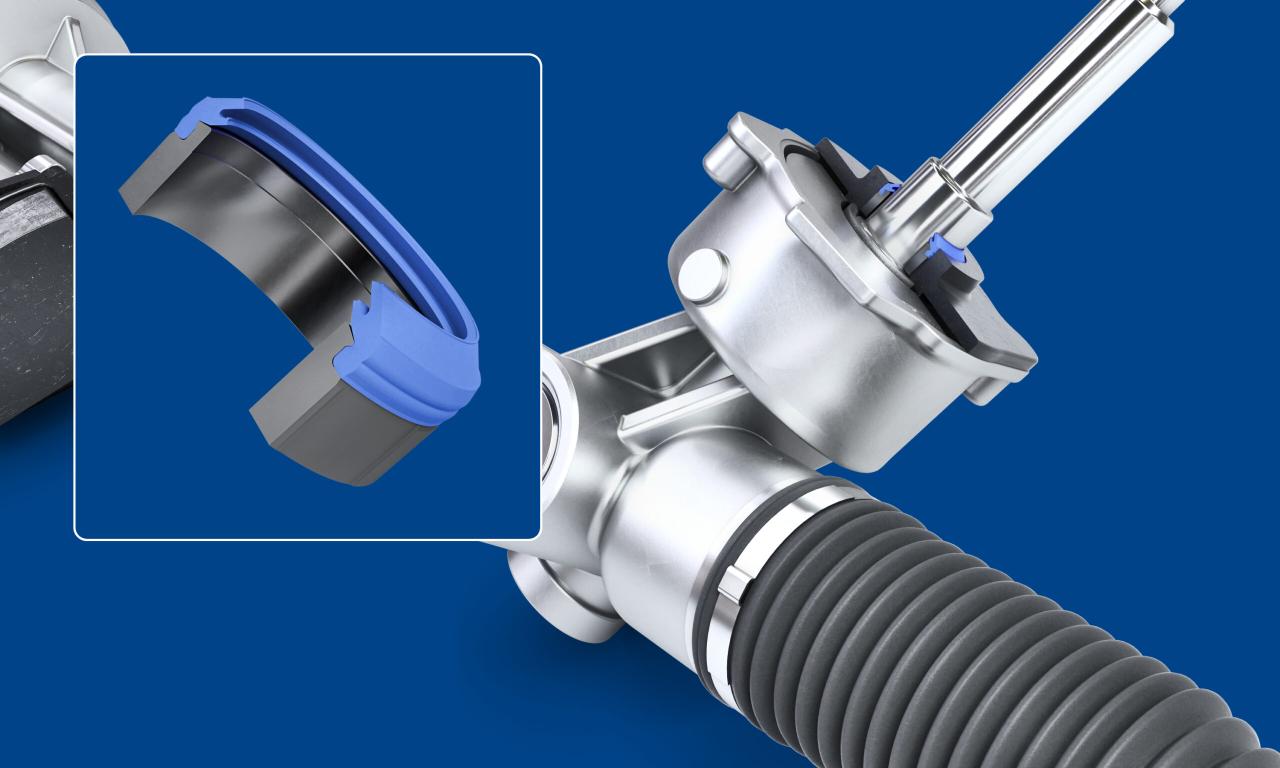

Vapor-compression refrigeration systems are the most common type of refrigeration systems. They operate on a closed cycle, using a refrigerant to absorb heat from the cold space and release it to the warmer environment. The system consists of four main components:

- Compressor: The compressor is the heart of the system, responsible for compressing the refrigerant vapor. This increases the pressure and temperature of the refrigerant, preparing it for condensation.

- Condenser: The condenser is where the high-pressure, high-temperature refrigerant vapor releases heat to the surrounding environment. This process causes the refrigerant to condense into a liquid state.

- Expansion Valve: The expansion valve controls the flow of refrigerant into the evaporator. As the refrigerant passes through the expansion valve, its pressure and temperature decrease, causing it to partially evaporate.

- Evaporator: The evaporator is where the refrigerant absorbs heat from the cold space. The refrigerant absorbs heat as it evaporates, cooling the space. The low-pressure, low-temperature refrigerant vapor then returns to the compressor, completing the cycle.

Comparison of Refrigeration Systems

| System Type | Working Principle | Advantages | Disadvantages | Applications |

|---|---|---|---|---|

| Vapor-Compression | Closed cycle, refrigerant absorption and release | High efficiency, wide range of applications | Requires refrigerant, potential environmental impact | Residential, commercial, industrial |

| Vapor-Absorption | Solution of water and lithium bromide absorbs and releases heat | Uses readily available heat sources, environmentally friendly | Lower efficiency, bulky and complex | Industrial processes, cogeneration plants |

| Air-Cycle | Compression and expansion of air | Suitable for low temperatures, no refrigerant required | Lower efficiency, high energy consumption | Aircraft cabin cooling, cryogenic applications |

| Thermoelectric | Peltier effect | Compact, no moving parts, silent operation | Low efficiency, limited cooling capacity | Portable coolers, medical devices |

Refrigerants and Refrigerant Management

Refrigerants are the working fluids in refrigeration and air conditioning systems, responsible for absorbing heat from the refrigerated space and releasing it to the environment. The choice of refrigerant is crucial, as it impacts the system’s efficiency, safety, and environmental impact.

Refrigerant management involves practices and procedures for handling, storing, and disposing of refrigerants in a responsible and environmentally friendly manner. This is essential to minimize the environmental impact of these chemicals and comply with regulations.

Refrigerant Properties and Characteristics

The selection of a refrigerant depends on various properties and characteristics, including:

- Thermodynamic properties: These properties determine the refrigerant’s ability to absorb and release heat efficiently. Key properties include:

- Boiling point: The temperature at which the refrigerant changes from a liquid to a gas at a given pressure.

- Specific heat: The amount of heat required to raise the temperature of a unit mass of the refrigerant by one degree.

- Latent heat of vaporization: The amount of heat absorbed or released during the phase change from liquid to gas or vice versa.

- Safety properties: These properties relate to the refrigerant’s toxicity, flammability, and potential for explosion.

- Toxicity: The degree to which the refrigerant can cause harm to humans or animals upon inhalation or contact.

- Flammability: The ease with which the refrigerant can ignite and burn in the presence of a source of ignition.

- Flammability Class: This classification system, defined by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), categorizes refrigerants based on their flammability. Class A refrigerants are highly flammable, Class B are slightly flammable, and Class C are non-flammable.

- Environmental properties: These properties concern the refrigerant’s impact on the environment, particularly its global warming potential (GWP) and ozone depletion potential (ODP).

- Global Warming Potential (GWP): This metric compares the heat-trapping effect of a refrigerant to that of carbon dioxide (CO2) over a specified period. A higher GWP indicates a greater contribution to global warming.

- Ozone Depletion Potential (ODP): This metric measures the refrigerant’s ability to deplete the ozone layer in the stratosphere. Refrigerants with a higher ODP contribute to ozone depletion, which can lead to increased ultraviolet radiation reaching the Earth’s surface.

- Other properties: These include:

- Chemical stability: The refrigerant’s resistance to decomposition or chemical reactions under operating conditions.

- Miscibility: The ability of the refrigerant to mix with other substances, such as oil, which is essential for proper lubrication in refrigeration systems.

Environmental Impact of Refrigerants

Refrigerants can have significant environmental impacts, primarily due to their contribution to global warming and ozone depletion.

- Global Warming Potential (GWP): Refrigerants with high GWPs, when released into the atmosphere, can trap heat and contribute to climate change. For example, HFC-134a, a widely used refrigerant in the past, has a GWP of 1,430, meaning it is 1,430 times more potent than CO2 in trapping heat over a 100-year period. The release of these refrigerants during leaks, servicing, or disposal can significantly contribute to greenhouse gas emissions.

- Ozone Depletion Potential (ODP): Refrigerants containing chlorine, such as CFCs and HCFCs, can deplete the ozone layer, which protects life on Earth from harmful ultraviolet radiation. These refrigerants have been phased out under the Montreal Protocol, an international agreement to protect the ozone layer. However, some HCFCs are still in use, and their gradual phase-out continues.

Refrigerant Management

Refrigerant management is essential to minimize the environmental impact of refrigerants and ensure their safe and responsible use. Key aspects of refrigerant management include:

- Leak prevention and detection: Regular inspections and maintenance of refrigeration systems are crucial to identify and repair leaks promptly. This helps to prevent refrigerant emissions into the atmosphere.

- Leak detection methods: Electronic leak detectors, soap bubbles, and halide torch are commonly used methods for detecting refrigerant leaks.

- Proper handling and storage: Refrigerants should be handled and stored according to safety guidelines and regulations to prevent leaks and spills.

- Storage requirements: Refrigerants should be stored in well-ventilated areas, away from heat sources and incompatible materials.

- Recovery, recycling, and reclamation: Refrigerants should be recovered from refrigeration systems during servicing or disposal and recycled or reclaimed for reuse.

- Recovery: The process of removing refrigerant from a system and storing it in a container for later use or disposal.

- Recycling: The process of cleaning and purifying recovered refrigerant to meet purity standards for reuse.

- Reclamation: The process of chemically processing recovered refrigerant to meet original specifications for reuse.

- Disposal: Refrigerants that cannot be recycled or reclaimed should be disposed of properly in accordance with environmental regulations.

- Disposal regulations: Regulations vary depending on the type of refrigerant and the location. It is essential to consult local authorities or a licensed refrigerant disposal company for guidance on proper disposal methods.

Regulations and Standards

Refrigerant use and handling are subject to various regulations and standards to ensure environmental protection and safety.

- Montreal Protocol: An international agreement to phase out ozone-depleting substances, including CFCs and HCFCs, in refrigeration and other applications.

- Kyoto Protocol: An international agreement to reduce greenhouse gas emissions, including those from refrigerants with high GWPs.

- ASHRAE Standard 34: Specifies requirements for the safe handling of refrigerants, including leak detection, recovery, recycling, and disposal.

- EPA’s Significant New Alternatives Policy (SNAP): A program that evaluates and approves alternative refrigerants with lower environmental impact.

- Refrigerant Management Programs: Many countries and regions have implemented refrigerant management programs to promote responsible refrigerant use and reduce emissions.

System Design and Analysis

Designing and analyzing refrigeration and air conditioning systems involves a systematic approach to ensure efficient and effective operation. This process involves several steps, from understanding the specific requirements to selecting appropriate components and evaluating system performance.

Psychrometric Charts and Tools

Psychrometric charts are essential tools for designing and analyzing refrigeration and air conditioning systems. They provide a graphical representation of the thermodynamic properties of moist air, allowing engineers to determine key parameters such as:

- Dry-bulb temperature

- Wet-bulb temperature

- Relative humidity

- Enthalpy

- Specific volume

By plotting these properties on the chart, engineers can track changes in air conditions during various processes, such as cooling, dehumidification, and heating. Other tools used in system design and analysis include:

- Computer-aided design (CAD) software

- Simulation software

- Refrigerant property tables

These tools facilitate the analysis of complex systems, optimize component selection, and predict system performance.

Calculating System Capacity

System capacity refers to the amount of heat that a refrigeration or air conditioning system can remove from a space. This is typically measured in tons of refrigeration (TR), where one TR equals 12,000 BTU/hour.

System capacity can be calculated using the following formula:

System Capacity (TR) = (Heat Load (BTU/hour)) / 12,000

For example, if a room requires 36,000 BTU/hour of cooling, the system capacity would be 3 TR.

Calculating Energy Consumption

Energy consumption is a critical factor in system design and analysis. It determines the operating cost of the system and its environmental impact.

Energy consumption can be calculated using the following formula:

Energy Consumption (kWh) = (System Capacity (kW) * Operating Hours) / 1,000

For example, a 5-ton (17.5 kW) air conditioning system operating for 10 hours per day would consume approximately 175 kWh of energy daily.

Other Performance Parameters

Besides capacity and energy consumption, other performance parameters are considered during system design and analysis, including:

- Coefficient of performance (COP): The ratio of cooling output to energy input

- Seasonal energy efficiency ratio (SEER): A measure of the system’s energy efficiency over a typical cooling season

- Sound level: The noise generated by the system

- Refrigerant charge: The amount of refrigerant required for optimal system operation

Analyzing these parameters ensures that the system meets the desired performance standards and operates efficiently.

Applications and Case Studies

Refrigeration and air conditioning technology has a wide range of applications across various industries, impacting our daily lives in numerous ways. These systems are essential for maintaining optimal temperatures, preserving food, and creating comfortable environments. This section explores the diverse applications of refrigeration and air conditioning, examines case studies of successful implementations, and discusses the challenges and opportunities associated with this technology.

Food Storage

Refrigeration plays a crucial role in the food industry, ensuring the preservation and safety of perishable goods. Refrigeration systems maintain optimal temperatures to slow down spoilage and extend the shelf life of food products.

- Supermarkets and Grocery Stores: Refrigeration systems are essential for storing a wide variety of fresh produce, meat, dairy products, and frozen foods. These systems maintain consistent temperatures to prevent spoilage and maintain food quality.

- Food Processing Plants: Refrigeration systems are used in various stages of food processing, such as chilling, freezing, and storage. These systems help maintain product quality, prevent microbial growth, and ensure food safety.

- Cold Storage Warehouses: Large-scale cold storage warehouses utilize sophisticated refrigeration systems to store vast quantities of food products, ensuring long-term preservation and distribution.

Pharmaceutical Manufacturing

Maintaining precise temperature control is critical in pharmaceutical manufacturing, as temperature fluctuations can affect the stability and efficacy of medications. Refrigeration and air conditioning systems play a vital role in ensuring optimal storage conditions for sensitive pharmaceuticals.

- Drug Manufacturing Facilities: Refrigeration systems are used to maintain controlled temperatures for various processes, including drug synthesis, formulation, and packaging.

- Pharmaceutical Warehouses: Refrigeration systems are essential for storing temperature-sensitive medications, ensuring their stability and effectiveness.

- Hospitals and Pharmacies: Refrigeration systems are used to store vaccines, blood products, and other temperature-sensitive medications, ensuring their quality and safety.

Commercial Buildings

Refrigeration and air conditioning systems are essential for creating comfortable and productive environments in commercial buildings. These systems regulate temperature, humidity, and air quality, enhancing occupant comfort and productivity.

- Office Buildings: Air conditioning systems provide temperature control and air filtration, creating a comfortable working environment for employees.

- Retail Stores: Refrigeration systems are used to maintain optimal temperatures for food storage and display, while air conditioning systems ensure comfortable shopping experiences.

- Hotels and Restaurants: Refrigeration systems are used for food storage and beverage cooling, while air conditioning systems provide comfort for guests and patrons.

Transportation

Refrigeration and air conditioning systems are crucial for maintaining the temperature of goods during transportation, ensuring their quality and safety.

- Trucking and Shipping: Refrigerated trucks and containers are used to transport perishable goods, such as food, pharmaceuticals, and other temperature-sensitive products.

- Air Travel: Airplanes are equipped with air conditioning systems to maintain comfortable cabin temperatures for passengers.

- Rail Transportation: Refrigerated rail cars are used to transport perishable goods over long distances, ensuring their quality and safety.

Case Studies

The successful implementation of refrigeration and air conditioning systems can significantly impact the efficiency and sustainability of various industries.

- Supermarket Energy Efficiency: A supermarket chain implemented energy-efficient refrigeration systems, resulting in significant energy savings and reduced carbon emissions. The new systems utilized advanced technology to optimize cooling capacity and minimize energy consumption.

- Pharmaceutical Cold Chain Management: A pharmaceutical company implemented a robust cold chain management system, ensuring the safe and effective transportation of temperature-sensitive medications. The system utilized GPS tracking, temperature monitoring, and data analysis to maintain optimal storage conditions throughout the supply chain.

- Building Automation and Control: A commercial building implemented a building automation system that integrated refrigeration and air conditioning systems. The system optimized energy consumption, reduced operating costs, and enhanced occupant comfort.

Challenges and Opportunities

The refrigeration and air conditioning industry faces challenges and opportunities related to sustainability, efficiency, and technological advancements.

- Environmental Impact: Refrigeration and air conditioning systems contribute to greenhouse gas emissions. The industry is actively developing and implementing sustainable solutions to minimize environmental impact.

- Energy Efficiency: Improving energy efficiency in refrigeration and air conditioning systems is crucial for reducing operating costs and environmental impact.

- Technological Advancements: Advancements in technology, such as smart controls, variable-speed compressors, and natural refrigerants, are creating opportunities for more efficient and sustainable systems.

Concluding Remarks: Refrigeration And Air Conditioning Technology 9th Edition

Refrigeration and Air Conditioning Technology 9th Edition serves as an invaluable resource for anyone seeking to delve into the fascinating world of cooling systems. From the fundamental principles to the latest advancements, this comprehensive guide provides a thorough understanding of the science, design, and applications of refrigeration and air conditioning. With its detailed explanations, practical examples, and insightful discussions, this book empowers readers to navigate the complexities of cooling technology and contribute to the ongoing evolution of this essential field.

Refrigeration and air conditioning technology is a fascinating field, constantly evolving to meet the demands of a changing world. From the basic principles outlined in the 9th edition textbook to the advanced systems found in modern vehicles, understanding the core concepts is essential.

For example, the Acura TLX 2021 Technology Package boasts innovative climate control features that integrate seamlessly with the vehicle’s overall design. These technological advancements highlight the interconnectedness of different fields, demonstrating how refrigeration and air conditioning principles are applied in various applications, from homes to automobiles.