Refrigeration & Air Conditioning Technology 9th Edition: Mastering Cooling Systems

Refrigeration & Air Conditioning Technology 9th Edition delves into the fascinating world of cooling systems, exploring the science behind keeping things cold and comfortable. This comprehensive guide covers the fundamental […]

Refrigeration & Air Conditioning Technology 9th Edition delves into the fascinating world of cooling systems, exploring the science behind keeping things cold and comfortable. This comprehensive guide covers the fundamental principles, thermodynamic cycles, and practical applications of refrigeration and air conditioning, from basic concepts to cutting-edge technologies. Whether you’re a student, a professional, or simply curious about the science of keeping things cool, this book provides a deep dive into the history, evolution, and future of this essential field.

The book starts by laying the groundwork with an introduction to the core principles of refrigeration and air conditioning. It then dives into the thermodynamics that govern these systems, explaining concepts like enthalpy, entropy, and specific heat capacity. The book then moves on to explore the different refrigeration cycles, including vapor-compression, absorption, and air cycles, and how they are used in various applications.

Introduction to Refrigeration and Air Conditioning

Refrigeration and air conditioning are essential technologies that play a vital role in modern society, contributing to our comfort, health, and economic well-being. They involve the process of removing heat from a space or object, creating a cooler environment.

Fundamental Principles

Refrigeration and air conditioning systems operate based on the principles of thermodynamics, particularly the transfer of heat between different substances. The core principle involves a refrigerant, a substance that readily absorbs and releases heat. The refrigerant undergoes a cycle of evaporation, compression, condensation, and expansion, facilitating the transfer of heat from the space to be cooled to the outside environment.

History and Evolution, Refrigeration & air conditioning technology 9th edition

Refrigeration and air conditioning technologies have a rich history, evolving from rudimentary methods to sophisticated systems.

- Early Refrigeration: The earliest forms of refrigeration involved using natural ice harvested in winter and stored for use during summer. Later, methods like evaporative cooling and ice-making machines using mechanical energy were developed.

- Mechanical Refrigeration: The invention of the vapor-compression refrigeration cycle in the late 19th century marked a significant breakthrough. This cycle, using a compressor, condenser, expansion valve, and evaporator, revolutionized refrigeration technology, enabling the production of artificial cold on a larger scale.

- Air Conditioning: Air conditioning evolved from early methods of ventilation and cooling using fans and evaporative systems. The development of the first modern air conditioner in the early 20th century, using refrigeration principles, enabled the control of both temperature and humidity in enclosed spaces.

Applications of Refrigeration and Air Conditioning

Refrigeration and air conditioning systems have numerous applications across various sectors, contributing to improved living standards, food preservation, and industrial processes.

- Residential: Home refrigerators, air conditioners, and freezers are essential appliances for food storage, comfort, and maintaining a comfortable living environment.

- Commercial: Supermarkets, restaurants, and retail stores rely heavily on refrigeration systems for food preservation and display. Commercial air conditioning systems maintain comfortable temperatures in buildings and public spaces.

- Industrial: Refrigeration and air conditioning are critical in industries such as food processing, pharmaceuticals, and manufacturing. They play a vital role in maintaining specific temperature and humidity conditions for production processes and product storage.

- Transportation: Refrigerated trucks and railway cars are essential for transporting perishable goods, while air conditioning systems in vehicles provide comfort for passengers and drivers.

- Healthcare: Hospitals and medical facilities utilize refrigeration systems for storing medications, vaccines, and blood products. Air conditioning systems maintain optimal temperature and humidity levels for patient comfort and safety.

Thermodynamic Principles

Refrigeration and air conditioning systems rely on fundamental thermodynamic principles to achieve their cooling and heating functions. Understanding these principles is crucial for comprehending the operation and design of these systems.

Thermodynamic Cycles

Thermodynamic cycles describe the sequence of processes that a refrigerant undergoes as it absorbs heat from a cold source, transfers it to a hot source, and completes the cycle. The most common cycles used in refrigeration and air conditioning are the vapor-compression cycle and the absorption cycle.

- Vapor-compression cycle: This cycle is the most widely used in refrigeration and air conditioning systems. It involves four key processes:

- Evaporation: The refrigerant absorbs heat from the cold source (e.g., the evaporator coil in a refrigerator) and changes from a liquid to a vapor. This process is endothermic, meaning it absorbs heat from the surroundings.

- Compression: The refrigerant vapor is compressed by a compressor, increasing its pressure and temperature. This process is exothermic, meaning it releases heat to the surroundings.

- Condensation: The high-pressure, high-temperature refrigerant vapor releases heat to the hot source (e.g., the condenser coil in a refrigerator) and changes back to a liquid. This process is exothermic.

- Expansion: The high-pressure liquid refrigerant passes through an expansion valve, reducing its pressure and temperature. This process is endothermic.

- Absorption cycle: This cycle is less common than the vapor-compression cycle but is used in applications where electricity is scarce or expensive. It involves using an absorbent to absorb the refrigerant vapor, increasing its concentration and allowing for easier condensation. The absorbent solution is then heated, releasing the refrigerant vapor, which can then be used in the cooling cycle.

Enthalpy, Entropy, and Specific Heat Capacity

These thermodynamic properties are essential for understanding the energy transfer and changes in state that occur during refrigeration and air conditioning cycles.

- Enthalpy (H): Represents the total energy of a system, including its internal energy and the energy associated with its pressure and volume. It is a measure of the heat content of a system.

H = U + PV

where:

- H = enthalpy

- U = internal energy

- P = pressure

- V = volume

- Entropy (S): Represents the degree of disorder or randomness in a system. It is a measure of the system’s ability to transfer energy as heat.

dS = dQ/T

where:

- dS = change in entropy

- dQ = heat transferred

- T = temperature

- Specific Heat Capacity (Cp): Represents the amount of heat required to raise the temperature of a unit mass of a substance by one degree Celsius. It is a measure of the substance’s ability to store heat energy.

Cp = dQ/(m*dT)

where:

- Cp = specific heat capacity

- dQ = heat transferred

- m = mass

- dT = change in temperature

Refrigerant Properties

Refrigerants are the working fluids in refrigeration and air conditioning systems. Their properties play a significant role in system performance and efficiency.

- Boiling Point: The temperature at which a refrigerant changes from a liquid to a vapor at a given pressure. A refrigerant with a low boiling point is desirable for low-temperature applications, such as refrigerators and freezers.

- Condensation Temperature: The temperature at which a refrigerant changes from a vapor to a liquid at a given pressure. A refrigerant with a high condensation temperature is desirable for high-temperature applications, such as air conditioners.

- Latent Heat of Vaporization: The amount of heat required to change a unit mass of a refrigerant from a liquid to a vapor at its boiling point. A refrigerant with a high latent heat of vaporization can absorb more heat from the cold source per unit mass.

- Specific Heat: The amount of heat required to raise the temperature of a unit mass of a refrigerant by one degree Celsius. A refrigerant with a low specific heat can be cooled and heated more quickly, improving system efficiency.

- Thermal Conductivity: The rate at which heat is transferred through a refrigerant. A refrigerant with a high thermal conductivity can transfer heat more efficiently, improving system performance.

- Toxicity: The potential for a refrigerant to cause harm to humans or the environment. Non-toxic refrigerants are preferred for safety and environmental reasons.

- Flammability: The potential for a refrigerant to ignite or explode. Non-flammable refrigerants are preferred for safety reasons.

Refrigeration Cycles

Refrigeration cycles are the heart of refrigeration and air conditioning systems, responsible for transferring heat from a cold space to a warmer one. They utilize a working fluid, typically a refrigerant, to absorb heat from the cold space and release it to the warmer space, creating a cooling effect.

Vapor-Compression Refrigeration Cycle

The vapor-compression refrigeration cycle is the most common type used in residential, commercial, and industrial applications. It consists of four main components:

- Compressor: The compressor increases the pressure and temperature of the refrigerant vapor.

- Condenser: The condenser releases heat from the refrigerant vapor, converting it into a liquid.

- Expansion Valve: The expansion valve reduces the pressure and temperature of the liquid refrigerant, causing it to partially vaporize.

- Evaporator: The evaporator absorbs heat from the cold space, causing the remaining liquid refrigerant to fully vaporize.

The refrigerant circulates through these components, absorbing heat in the evaporator and releasing it in the condenser, creating a continuous cooling cycle.

Advantages of Vapor-Compression Refrigeration Cycles

- High efficiency: Vapor-compression cycles are highly efficient in transferring heat, achieving high COP (Coefficient of Performance) values.

- Versatility: They can be used in a wide range of applications, from small refrigerators to large industrial chillers.

- Reliability: Vapor-compression cycles are generally reliable and have a long lifespan.

Disadvantages of Vapor-Compression Refrigeration Cycles

- High initial cost: The equipment required for vapor-compression cycles can be expensive.

- Potential for environmental impact: Refrigerants used in these cycles can have environmental impacts if not properly managed.

- Noise and vibration: Compressors can generate noise and vibration, which may be a concern in some applications.

Examples of Applications

- Domestic refrigerators and freezers

- Commercial refrigeration systems in supermarkets and restaurants

- Industrial chillers for process cooling

- Air conditioning systems for buildings and vehicles

Absorption Refrigeration Cycle

The absorption refrigeration cycle uses a solution of water and lithium bromide to absorb the refrigerant (ammonia or water) and transfer heat. The cycle consists of four main components:

- Absorber: The absorber absorbs the refrigerant vapor into the lithium bromide solution.

- Generator: The generator uses heat to separate the refrigerant from the lithium bromide solution.

- Condenser: The condenser releases heat from the refrigerant vapor, converting it into a liquid.

- Evaporator: The evaporator absorbs heat from the cold space, causing the liquid refrigerant to vaporize.

The process involves absorbing the refrigerant in the absorber, separating it in the generator, condensing it in the condenser, and evaporating it in the evaporator.

Advantages of Absorption Refrigeration Cycles

- Use of waste heat: Absorption cycles can utilize waste heat from industrial processes or solar energy to operate.

- Environmentally friendly: They typically use ammonia as the refrigerant, which has a low global warming potential.

- Quiet operation: Absorption cycles are generally quieter than vapor-compression cycles.

Disadvantages of Absorption Refrigeration Cycles

- Lower efficiency: Absorption cycles are generally less efficient than vapor-compression cycles, resulting in lower COP values.

- Higher initial cost: The equipment required for absorption cycles can be more expensive than for vapor-compression cycles.

- Limited applications: Absorption cycles are typically used in specific applications, such as industrial process cooling and large buildings with access to waste heat.

Examples of Applications

- Industrial process cooling

- Large commercial buildings with waste heat sources

- Solar-powered cooling systems

Air Refrigeration Cycle

The air refrigeration cycle utilizes air as the refrigerant. It operates on a similar principle to the vapor-compression cycle, but instead of using a refrigerant, it uses air as the working fluid. The cycle consists of four main components:

- Compressor: The compressor increases the pressure and temperature of the air.

- Condenser: The condenser releases heat from the air, cooling it down.

- Expansion Valve: The expansion valve reduces the pressure and temperature of the air, causing it to cool further.

- Evaporator: The evaporator absorbs heat from the cold space, causing the air to cool down even more.

The air circulates through these components, absorbing heat in the evaporator and releasing it in the condenser, creating a cooling cycle.

Advantages of Air Refrigeration Cycles

- Environmentally friendly: Air refrigeration cycles use air as the refrigerant, which has no environmental impact.

- Simple design: They are relatively simple to design and operate.

- Low maintenance: Air refrigeration cycles require minimal maintenance.

Disadvantages of Air Refrigeration Cycles

- Low efficiency: Air refrigeration cycles are less efficient than vapor-compression cycles, resulting in lower COP values.

- Limited cooling capacity: They have a limited cooling capacity compared to vapor-compression cycles.

- Not suitable for all applications: Air refrigeration cycles are not suitable for all applications, particularly those requiring low temperatures.

Examples of Applications

- Small portable air conditioners

- Aircraft cabin cooling systems

- Some industrial applications where low temperatures are not required.

Components of Refrigeration Systems: Refrigeration & Air Conditioning Technology 9th Edition

Refrigeration systems are comprised of various components, each playing a crucial role in the overall refrigeration process. Understanding the function and operation of these components is essential for the effective design, operation, and maintenance of refrigeration systems.

Compressor

The compressor is the heart of a refrigeration system, responsible for compressing the refrigerant vapor, increasing its pressure and temperature. The compressor pumps the refrigerant through the system, ensuring continuous circulation.

The selection of a compressor is determined by factors such as the desired cooling capacity, operating conditions, refrigerant type, and system design.

There are various types of compressors used in refrigeration systems, including:

- Reciprocating compressors: These are commonly used in residential and commercial refrigeration systems, employing a piston-cylinder arrangement to compress the refrigerant.

- Rotary compressors: These are smaller and more compact than reciprocating compressors, suitable for smaller applications.

- Scroll compressors: These compressors use two intermeshing spirals to compress the refrigerant, offering high efficiency and quiet operation.

- Centrifugal compressors: These are typically used in large-scale refrigeration systems, capable of handling high refrigerant flow rates.

Condenser

The condenser is responsible for rejecting heat from the refrigerant, converting it from a high-pressure, high-temperature vapor to a high-pressure, high-temperature liquid. This heat rejection process is achieved by transferring heat from the refrigerant to a cooling medium, typically air or water.

The selection of a condenser depends on factors such as the cooling capacity, operating conditions, refrigerant type, and available space.

Types of condensers include:

- Air-cooled condensers: These use air as the cooling medium, employing fans to draw air across the condenser coils.

- Water-cooled condensers: These use water as the cooling medium, circulating water through the condenser coils.

- Evaporative condensers: These utilize a combination of air and water to cool the refrigerant, providing efficient heat rejection.

Evaporator

The evaporator is where the refrigerant absorbs heat from the refrigerated space, changing from a low-pressure, low-temperature liquid to a low-pressure, low-temperature vapor. This heat absorption process cools the refrigerated space.

The selection of an evaporator is influenced by factors such as the cooling capacity, operating conditions, refrigerant type, and the type of refrigerated space.

Types of evaporators include:

- Direct-expansion (DX) evaporators: These are commonly used in residential and commercial refrigeration systems, where the refrigerant directly evaporates within the evaporator coils.

- Flooded evaporators: These are typically used in large-scale refrigeration systems, where the evaporator is partially filled with liquid refrigerant.

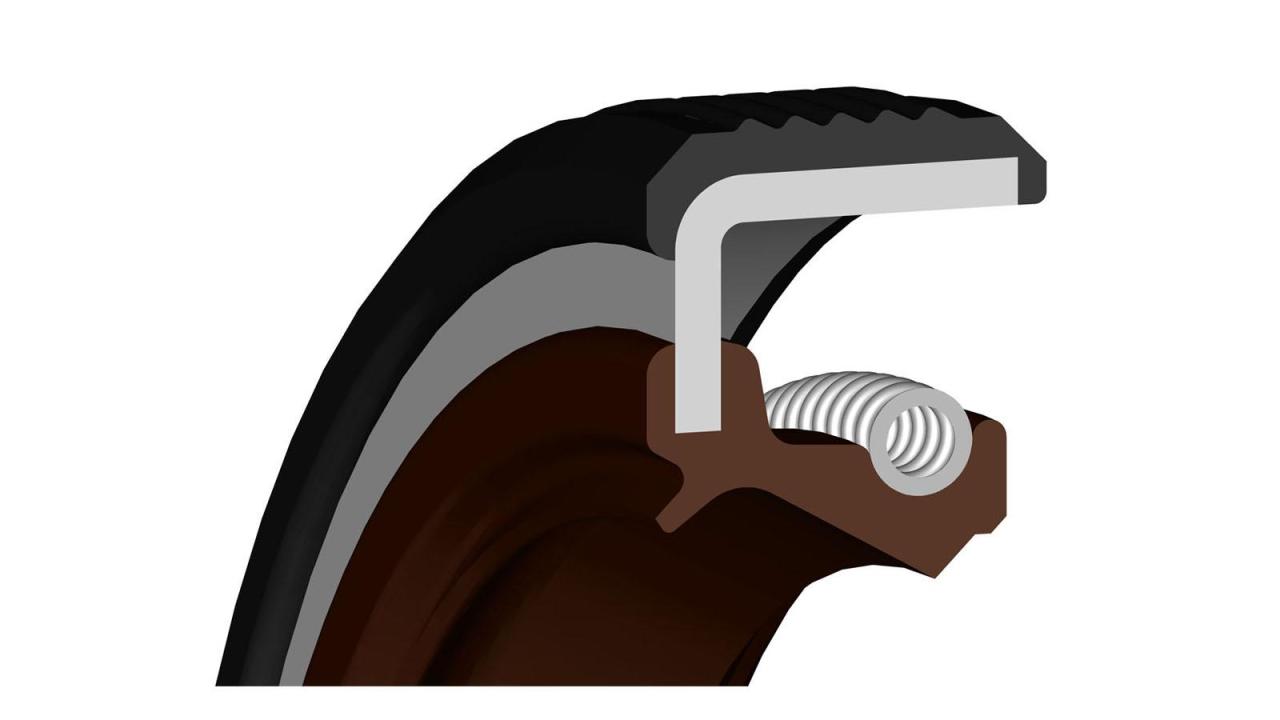

Expansion Device

The expansion device controls the flow of refrigerant into the evaporator, reducing its pressure and temperature. This process ensures that the refrigerant can effectively absorb heat in the evaporator.

The selection of an expansion device depends on factors such as the cooling capacity, operating conditions, refrigerant type, and system design.

Types of expansion devices include:

- Thermostatic expansion valves (TXV): These are commonly used in refrigeration systems, adjusting the refrigerant flow based on the evaporator temperature and pressure.

- Capillary tubes: These are simple and inexpensive expansion devices, suitable for smaller refrigeration systems.

- Electronic expansion valves (EEV): These are more sophisticated expansion devices, offering precise control of refrigerant flow.

Components of Refrigeration Systems Table

| Component | Function | Selection Criteria |

|---|---|---|

| Compressor | Compresses the refrigerant vapor, increasing its pressure and temperature. | Cooling capacity, operating conditions, refrigerant type, system design. |

| Condenser | Rejects heat from the refrigerant, converting it from a vapor to a liquid. | Cooling capacity, operating conditions, refrigerant type, available space. |

| Evaporator | Absorbs heat from the refrigerated space, changing the refrigerant from a liquid to a vapor. | Cooling capacity, operating conditions, refrigerant type, type of refrigerated space. |

| Expansion Device | Controls the flow of refrigerant into the evaporator, reducing its pressure and temperature. | Cooling capacity, operating conditions, refrigerant type, system design. |

Air Conditioning Systems

Air conditioning is a technology that controls the temperature, humidity, and air quality of an indoor environment. It uses refrigeration cycles to remove heat from the air, making it cooler and more comfortable. Air conditioning plays a vital role in maintaining comfortable indoor environments, especially in hot and humid climates.

Types of Air Conditioning Systems

Different types of air conditioning systems are available, each with its own characteristics and applications. These systems are designed to meet various needs and budgets.

- Central air conditioning systems are the most common type of air conditioning system. They use a single unit to cool the entire house. The system includes a condenser unit, located outside the house, and an evaporator unit, located inside the house. The condenser unit removes heat from the refrigerant, while the evaporator unit cools the air.

- Split systems consist of two units: an outdoor unit and an indoor unit. The outdoor unit houses the compressor and condenser, while the indoor unit contains the evaporator and fan. These systems are popular in homes and apartments because they are relatively easy to install and offer flexibility in placement.

- Window units are compact and self-contained air conditioning systems that are installed in windows. They are suitable for smaller spaces, such as single rooms or apartments. Window units are typically less expensive than other types of air conditioning systems.

- Ductless mini-split systems are becoming increasingly popular. They consist of multiple indoor units connected to a single outdoor unit. This allows for individual temperature control in different rooms. Ductless mini-splits are energy-efficient and can be installed in existing homes without the need for ductwork.

Comparison of Air Conditioning Systems

The choice of air conditioning system depends on factors such as the size of the space to be cooled, the budget, and the desired level of comfort. Here is a comparison of the characteristics and applications of different air conditioning systems:

| System Type | Characteristics | Applications |

|---|---|---|

| Central air conditioning | – Cools the entire house – Requires ductwork – Typically more expensive than other systems |

– Large homes – Multi-story homes – Homes with existing ductwork |

| Split system | – Two units: outdoor and indoor – No ductwork required – Relatively easy to install |

– Homes – Apartments – Smaller spaces |

| Window unit | – Compact and self-contained – Installed in windows – Less expensive than other systems |

– Single rooms – Apartments – Small spaces |

| Ductless mini-split | – Multiple indoor units connected to a single outdoor unit – Individual temperature control in different rooms – Energy-efficient – No ductwork required |

– Homes – Apartments – Rooms with unique cooling needs |

Refrigeration and Air Conditioning Applications

Refrigeration and air conditioning technology plays a vital role in numerous industries, significantly impacting our daily lives. These technologies are indispensable for preserving food, ensuring comfortable living environments, and facilitating various industrial processes. This section delves into the diverse applications of refrigeration and air conditioning, exploring their unique requirements and challenges across different sectors.

Food Preservation

The preservation of food is a critical application of refrigeration technology. Refrigeration systems are designed to maintain low temperatures, slowing down the growth of bacteria and other microorganisms that cause spoilage. This extends the shelf life of perishable foods, reducing waste and ensuring food safety.

- Supermarkets and Grocery Stores: Refrigeration systems are essential for maintaining the freshness of fruits, vegetables, meats, dairy products, and other perishable items. These systems typically use large walk-in coolers and display cases to keep food at optimal temperatures.

- Food Processing Plants: Food processing plants utilize refrigeration for various stages, including cooling ingredients, chilling products, and storing finished goods. Refrigeration systems in these facilities are often customized to meet specific requirements, such as maintaining precise temperature control for different products.

- Cold Storage Warehouses: Cold storage warehouses provide large-scale refrigeration for long-term storage of perishable goods. These facilities are designed to maintain consistent temperatures and humidity levels, ensuring the quality and safety of food products over extended periods.

Pharmaceutical Storage

The pharmaceutical industry relies heavily on refrigeration and air conditioning for maintaining the stability and efficacy of sensitive medications. Precise temperature control is crucial for preventing degradation and ensuring the safety and effectiveness of drugs.

- Pharmaceutical Manufacturing Facilities: Pharmaceutical manufacturers use refrigeration systems to control the temperature of sensitive ingredients, intermediates, and finished products. This ensures that the drugs maintain their desired properties and meet regulatory standards.

- Hospitals and Pharmacies: Hospitals and pharmacies rely on refrigeration systems to store vaccines, blood products, and other temperature-sensitive medications. These systems must be reliable and maintain strict temperature ranges to prevent spoilage and ensure patient safety.

- Research Laboratories: Research laboratories use refrigeration systems for various purposes, including storing biological samples, culturing cells, and conducting experiments that require specific temperature conditions.

Industrial Processes

Refrigeration and air conditioning technologies play crucial roles in various industrial processes, contributing to efficiency, productivity, and safety.

- Manufacturing: Refrigeration is used in manufacturing processes for cooling machinery, lubricating tools, and controlling the temperature of materials. Air conditioning systems provide comfortable working environments for employees, enhancing productivity and safety.

- Chemical Processing: Refrigeration is used in chemical processing for controlling reaction temperatures, condensing vapors, and separating components. Air conditioning systems are used to maintain optimal conditions for sensitive chemical reactions.

- Data Centers: Data centers require robust air conditioning systems to maintain optimal operating temperatures for servers and other IT equipment. Refrigeration systems are used to remove heat generated by these devices, ensuring their reliability and performance.

Commercial Buildings

Refrigeration and air conditioning are essential for creating comfortable and productive environments in commercial buildings.

- Office Buildings: Air conditioning systems are widely used in office buildings to maintain comfortable temperatures and improve air quality. These systems enhance employee productivity and create a pleasant working environment.

- Retail Stores: Air conditioning systems are crucial for maintaining comfortable temperatures in retail stores, attracting customers and enhancing their shopping experience. Refrigeration systems are used to keep food and beverages fresh and appealing.

- Hotels and Restaurants: Air conditioning systems provide comfortable accommodations for guests in hotels and restaurants. Refrigeration systems are used for food storage, beverage cooling, and ice production.

Residential Applications

Refrigeration and air conditioning are integral parts of modern residential living.

- Home Appliances: Refrigerators, freezers, and air conditioners are essential home appliances that enhance comfort, preserve food, and provide a comfortable living environment. These systems have become increasingly energy-efficient and feature advanced technologies for optimal performance.

- Residential Buildings: Air conditioning systems are widely used in residential buildings to maintain comfortable temperatures and improve air quality. These systems provide a comfortable living environment for residents, especially during hot weather conditions.

Energy Efficiency and Sustainability

In the realm of refrigeration and air conditioning, energy efficiency and sustainability are paramount concerns. As these systems consume significant amounts of energy, minimizing their environmental impact is crucial.

Impact of Refrigerant Selection and System Design on Energy Consumption

The selection of refrigerants and the design of refrigeration and air conditioning systems have a direct impact on energy consumption.

- Refrigerant Selection: The choice of refrigerant influences energy efficiency due to its thermodynamic properties. Refrigerants with higher energy efficiency ratios (EERs) and lower global warming potentials (GWPs) are preferred. For example, R-410A, a widely used refrigerant in residential and commercial air conditioning, has a higher EER than older refrigerants like R-22. However, R-410A has a higher GWP, leading to increased environmental impact. Therefore, the selection of refrigerants requires careful consideration of both energy efficiency and environmental impact.

- System Design: The design of refrigeration and air conditioning systems plays a crucial role in energy efficiency. Factors such as insulation, ductwork, and component selection can significantly impact energy consumption. Well-insulated systems reduce heat loss and gain, leading to lower energy requirements. Efficient ductwork minimizes air leakage and ensures proper airflow, enhancing system performance. The selection of high-efficiency compressors, fans, and other components also contributes to energy savings.

Sustainable Practices and Technologies

The refrigeration and air conditioning industry is actively pursuing sustainable practices and technologies to reduce its environmental impact.

- Energy-Efficient Technologies: Advances in technology have led to the development of energy-efficient components and systems. Variable-speed compressors, for instance, adjust their speed based on demand, reducing energy consumption during periods of low cooling requirements. Other technologies include smart thermostats, which optimize system operation based on occupancy and weather conditions.

- Natural Refrigerants: Natural refrigerants, such as ammonia, carbon dioxide, and hydrocarbons, have lower GWPs than synthetic refrigerants. They are becoming increasingly popular as alternatives to traditional refrigerants, particularly in commercial and industrial applications. While natural refrigerants have their own challenges, such as flammability and toxicity, their environmental benefits are significant.

- Renewable Energy Integration: Integrating renewable energy sources, such as solar and wind power, into refrigeration and air conditioning systems can reduce reliance on fossil fuels. Solar-powered refrigeration systems, for example, can provide a sustainable and cost-effective solution in areas with abundant sunlight.

- System Optimization and Maintenance: Regular maintenance and optimization of refrigeration and air conditioning systems are crucial for ensuring energy efficiency and extending their lifespan. Properly maintained systems operate at peak performance, reducing energy consumption and minimizing refrigerant leaks. Routine checks and cleaning of filters, coils, and other components can significantly improve system efficiency.

System Design and Installation

Designing and installing refrigeration and air conditioning systems is a complex process that requires a thorough understanding of the principles of thermodynamics, heat transfer, and fluid mechanics. The goal of system design is to create a system that meets the specific needs of the application while operating efficiently and reliably. Installation involves the careful assembly and connection of all components, ensuring proper operation and safety.

Factors Influencing System Design

System design is influenced by several factors, including the specific requirements of the application, the environmental conditions, and the budget.

- Load Calculations: Accurate load calculations are crucial for determining the size and capacity of the refrigeration or air conditioning system. Load calculations take into account factors such as the space to be cooled or heated, the desired temperature, the heat gains from various sources, and the infiltration and ventilation rates.

- Refrigerant Selection: The choice of refrigerant is critical for system performance and environmental impact. Factors to consider include the refrigerant’s thermodynamic properties, safety considerations, environmental impact, and availability.

- Component Sizing: The size and capacity of components such as compressors, condensers, evaporators, and expansion devices must be carefully selected to ensure optimal system performance. Oversizing or undersizing components can lead to reduced efficiency, increased energy consumption, and premature failure.

- System Layout: The layout of the system is important for efficient operation and ease of maintenance. Factors to consider include the location of the components, the piping and ductwork routing, and the accessibility of the system for servicing.

- Control Systems: Modern refrigeration and air conditioning systems often incorporate sophisticated control systems to optimize performance and energy efficiency. Control systems can adjust the system’s operation based on factors such as temperature, humidity, and occupancy.

Installation and Commissioning

Once the system is designed, it must be carefully installed and commissioned. The following steps Artikel the typical process for installing and commissioning a refrigeration or air conditioning system:

- Site Preparation: The installation site must be prepared to accommodate the system. This may involve installing a concrete pad, providing electrical and plumbing connections, and ensuring adequate ventilation.

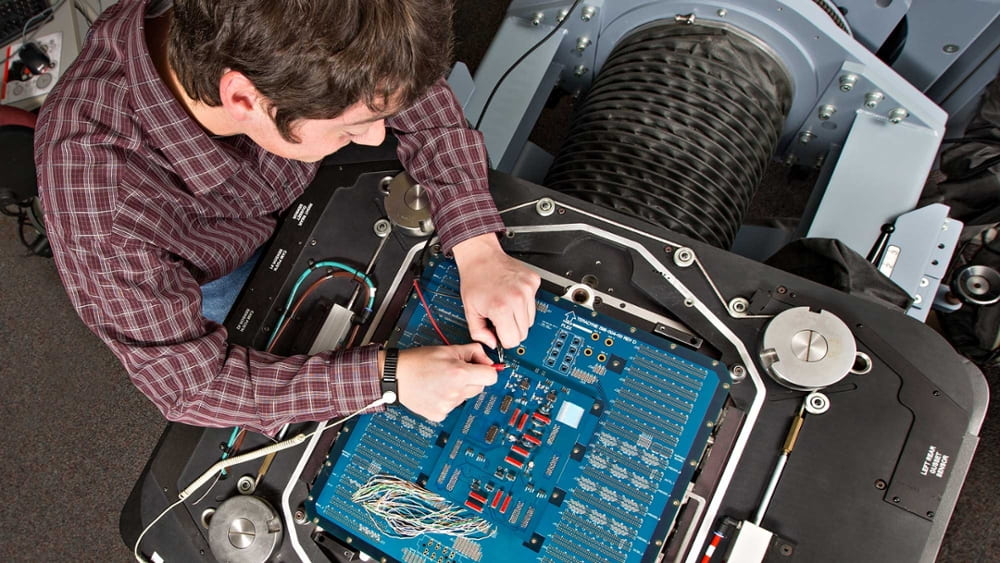

- Component Installation: The components of the system are installed according to the design specifications. This includes mounting the compressor, condenser, evaporator, and other components, connecting the piping and ductwork, and installing the control system.

- Refrigerant Charging: After the system is assembled, it must be charged with refrigerant. This involves evacuating the system to remove any air and moisture, then filling it with the appropriate amount of refrigerant.

- Leak Testing: After charging, the system must be leak-tested to ensure that there are no leaks in the refrigerant circuit. This is important for safety and to prevent refrigerant loss.

- Commissioning: Once the system is leak-tested and charged, it must be commissioned to ensure that it is operating properly. Commissioning involves testing the system under various operating conditions, adjusting the control system settings, and verifying that the system meets the design specifications.

Troubleshooting and Maintenance

Troubleshooting and maintenance are essential aspects of ensuring the efficient and reliable operation of refrigeration and air conditioning systems. By understanding common issues and implementing preventative measures, technicians can minimize downtime, extend system lifespan, and optimize energy consumption.

Troubleshooting Techniques

Troubleshooting involves identifying the root cause of a system malfunction and implementing appropriate corrective actions. Effective troubleshooting requires a systematic approach that combines technical knowledge, diagnostic tools, and a keen eye for detail.

- Visual Inspection: A thorough visual inspection of the system can often reveal obvious signs of trouble, such as leaks, loose connections, or damaged components.

- Temperature and Pressure Readings: Measuring temperatures and pressures at various points in the system can provide valuable insights into system performance and identify potential problems. For example, a low refrigerant charge can be indicated by low pressure readings in the suction line.

- Refrigerant Leak Detection: Refrigerant leaks can lead to decreased system efficiency and environmental damage. Technicians use various methods to detect leaks, including electronic leak detectors, soap bubbles, and ultraviolet dye.

- Electrical Testing: Testing electrical components, such as motors, compressors, and controls, can help diagnose problems related to power supply, wiring, or faulty components.

- Performance Analysis: Monitoring system performance metrics, such as energy consumption, cooling capacity, and operating temperatures, can provide valuable data for identifying potential issues and evaluating the effectiveness of repairs.

Importance of Regular Maintenance

Regular maintenance is crucial for maintaining optimal system performance, extending system lifespan, and preventing costly breakdowns. Preventive maintenance involves a series of routine inspections, cleaning, and adjustments that help to identify and address potential issues before they escalate into major problems.

- Increased Efficiency and Energy Savings: Regular maintenance helps to ensure that the system is operating at peak efficiency, reducing energy consumption and lowering operating costs.

- Extended System Lifespan: By addressing potential issues early, maintenance helps to prevent premature wear and tear, extending the lifespan of the system.

- Improved Reliability: A well-maintained system is less likely to experience unexpected breakdowns, ensuring consistent and reliable operation.

- Enhanced Safety: Regular maintenance helps to identify and address safety hazards, such as refrigerant leaks or electrical faults, reducing the risk of accidents.

Maintenance Checklist and Schedules

A comprehensive maintenance checklist should include a variety of tasks that are tailored to the specific system and its operating environment. Here is a general checklist for routine maintenance:

- Visual Inspection: Inspect all components for signs of damage, leaks, or corrosion.

- Refrigerant Charge: Check the refrigerant charge and top off as needed.

- Air Filters: Clean or replace air filters to ensure proper airflow.

- Condenser and Evaporator Coils: Clean condenser and evaporator coils to remove dirt and debris that can impede airflow and reduce efficiency.

- Motor Bearings: Lubricate motor bearings to prevent premature wear and tear.

- Electrical Connections: Inspect and tighten electrical connections to ensure proper grounding and prevent electrical faults.

- Control Systems: Check the operation of control systems, such as thermostats, pressure switches, and safety devices.

| Maintenance Task | Recommended Frequency |

|---|---|

| Visual Inspection | Monthly |

| Air Filter Replacement | Every 3-6 months |

| Condenser and Evaporator Coil Cleaning | Twice a year |

| Refrigerant Charge Check | Annually |

| Full System Inspection and Service | Every 2-3 years |

Emerging Technologies and Trends

The refrigeration and air conditioning industry is constantly evolving, driven by the need for greater energy efficiency, environmental sustainability, and improved comfort. Emerging technologies are transforming the way we design, operate, and maintain these systems, paving the way for a more sustainable and efficient future.

Advanced Refrigerants

The use of traditional refrigerants, such as chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs), has been phased out due to their impact on the ozone layer. The industry is transitioning to new refrigerants with lower global warming potential (GWP), such as hydrofluoroolefins (HFOs) and natural refrigerants like ammonia and carbon dioxide.

- HFOs offer a significant reduction in GWP compared to traditional refrigerants. Examples include R-1234yf and R-1234ze, which are used in automotive air conditioning systems. These refrigerants are also non-flammable and have a low toxicity, making them safer to handle.

- Natural refrigerants, such as ammonia and carbon dioxide, have a GWP of 0, making them environmentally friendly. However, these refrigerants require specialized equipment and handling procedures due to their inherent properties. For example, ammonia is toxic and flammable, requiring careful system design and maintenance.

Smart Controls

Smart controls are revolutionizing the way we manage refrigeration and air conditioning systems. These systems utilize sensors, data analytics, and artificial intelligence (AI) to optimize system performance and energy efficiency.

- Smart thermostats can learn user preferences and adjust temperatures accordingly, reducing energy consumption and improving comfort. These thermostats can also be controlled remotely through mobile applications, allowing users to adjust settings from anywhere.

- Predictive maintenance uses data analytics to identify potential problems before they occur, reducing downtime and maintenance costs. Sensors can monitor system performance and alert technicians to potential issues, allowing for proactive maintenance and repairs.

- Cloud-based platforms enable remote monitoring and control of refrigeration and air conditioning systems. This allows technicians to diagnose problems and make adjustments from any location, reducing response times and improving system availability.

Energy-Efficient Technologies

The demand for energy-efficient refrigeration and air conditioning systems is growing due to rising energy costs and environmental concerns. Emerging technologies are enabling significant improvements in system efficiency.

- Variable-speed compressors adjust their speed based on the cooling load, reducing energy consumption compared to traditional fixed-speed compressors. This technology is particularly effective in applications with fluctuating cooling demands, such as commercial buildings.

- Heat recovery systems utilize waste heat from refrigeration systems to provide heating or hot water. This can significantly reduce energy consumption and improve overall system efficiency.

- High-efficiency air filters remove dust, pollen, and other pollutants from the air, improving indoor air quality and reducing the strain on the HVAC system. This can lead to increased system efficiency and lower energy consumption.

Emerging Technologies and their Anticipated Benefits and Challenges

| Technology | Anticipated Benefits | Anticipated Challenges |

|---|---|---|

| Advanced Refrigerants | Reduced environmental impact, improved safety | Higher cost, potential compatibility issues with existing systems |

| Smart Controls | Improved energy efficiency, reduced maintenance costs, enhanced comfort | High initial investment, potential security risks, dependence on technology |

| Energy-Efficient Technologies | Reduced energy consumption, lower operating costs, environmental sustainability | Higher initial investment, potential for complex installation and maintenance |

Closing Summary

From the intricate workings of refrigeration systems to the design and installation of air conditioning units, Refrigeration & Air Conditioning Technology 9th Edition equips you with the knowledge and skills to understand, troubleshoot, and maintain these essential technologies. The book also emphasizes the importance of energy efficiency and sustainability in the field, highlighting advancements and trends that are shaping the future of cooling systems. Whether you’re looking to enhance your knowledge, pursue a career in this dynamic industry, or simply understand the science behind keeping things cool, this book is a valuable resource.

Refrigeration and air conditioning technology is a constantly evolving field, and the 9th edition of the textbook provides a comprehensive overview of the latest advancements. One key area of development is in the realm of demand technology , which focuses on optimizing energy consumption and reducing environmental impact.

By understanding these principles, HVAC professionals can design and implement systems that are both efficient and sustainable, contributing to a more comfortable and eco-friendly future.