Refrigeration & Air Conditioning Technology 8th Edition: A Comprehensive Guide

Refrigeration & Air Conditioning Technology 8th Edition delves into the fascinating world of cooling and temperature control, exploring the fundamental principles, diverse systems, and cutting-edge advancements that shape this vital […]

Refrigeration & Air Conditioning Technology 8th Edition delves into the fascinating world of cooling and temperature control, exploring the fundamental principles, diverse systems, and cutting-edge advancements that shape this vital field. From understanding the history and evolution of refrigeration to navigating the complexities of modern air conditioning systems, this comprehensive guide equips readers with a deep understanding of the science, technology, and applications that drive this essential industry.

This 8th edition provides an updated and insightful exploration of refrigeration and air conditioning technology, covering everything from basic concepts to advanced applications. It examines the various types of refrigeration cycles, the components of refrigeration systems, and the principles of air conditioning. Additionally, it delves into the properties of refrigerants, the design and installation of systems, and the crucial aspects of energy efficiency and sustainability. The book also highlights emerging technologies and trends, showcasing the future direction of this dynamic field.

Introduction to Refrigeration and Air Conditioning

Refrigeration and air conditioning are essential technologies that play a vital role in modern society, impacting various aspects of our lives, from food preservation and comfort in homes to industrial processes and medical advancements. The fundamental principle underlying both refrigeration and air conditioning is the transfer of heat from one location to another, utilizing various thermodynamic cycles and working fluids.

Fundamental Principles

Refrigeration and air conditioning systems rely on the principle of heat transfer, specifically the movement of heat from a colder region to a warmer region. This process is achieved by utilizing a refrigerant, a substance that readily absorbs heat when it changes state from a liquid to a gas. The basic refrigeration cycle involves four key stages:

- Evaporation: The refrigerant absorbs heat from the cold region (e.g., inside a refrigerator) as it evaporates, becoming a cold gas.

- Compression: The refrigerant vapor is compressed, increasing its temperature and pressure.

- Condensation: The hot, compressed refrigerant releases heat to the surrounding environment (e.g., the condenser coils on the back of a refrigerator) as it condenses back into a liquid.

- Expansion: The liquid refrigerant expands, decreasing its temperature and pressure, preparing it to absorb heat again.

This continuous cycle allows for the continuous removal of heat from the desired space, maintaining a lower temperature. Air conditioning systems operate similarly, using a refrigerant to cool the air in a room or building. The key difference lies in the application, with refrigeration systems primarily focused on cooling specific objects or spaces, while air conditioning systems are designed to cool entire environments.

History and Evolution, Refrigeration & air conditioning technology 8th edition

The history of refrigeration and air conditioning technology dates back centuries, with early attempts at cooling utilizing natural methods like ice and evaporation. The development of modern refrigeration and air conditioning systems began in the 19th century, with significant advancements in the understanding of thermodynamics and the properties of refrigerants.

- 1834: Jacob Perkins patented the first vapor-compression refrigeration system, utilizing ether as a refrigerant.

- 1850s: Ferdinand Carré developed the first practical absorption refrigeration system, which used water and ammonia.

- 1914: Willis Carrier invented the first modern air conditioning system, using a centrifugal chiller to cool air for a printing press.

- 1920s-1930s: The development of new refrigerants, such as Freon, led to the widespread adoption of refrigeration and air conditioning in homes, businesses, and industries.

Over the years, advancements in technology have led to the development of more efficient and environmentally friendly refrigeration and air conditioning systems, including the use of alternative refrigerants and improved compressor designs.

Applications of Refrigeration and Air Conditioning

Refrigeration and air conditioning technology finds applications in various industries, playing a crucial role in numerous aspects of our daily lives.

- Food Preservation: Refrigeration is essential for storing and preserving perishable food products, ensuring their safety and quality.

- Residential and Commercial Buildings: Air conditioning provides comfort and improves productivity in homes, offices, and public spaces.

- Industrial Processes: Refrigeration and air conditioning are critical for various industrial processes, including food processing, chemical manufacturing, and pharmaceutical production.

- Medical Applications: Refrigeration and air conditioning are essential in healthcare facilities for storing medicines, vaccines, and biological samples.

- Transportation: Refrigeration is used to transport perishable goods, while air conditioning provides comfort for passengers in vehicles.

These are just a few examples of the numerous applications of refrigeration and air conditioning, highlighting their impact on various industries and aspects of modern life.

Refrigeration Cycles and Systems

Refrigeration cycles are the heart of refrigeration and air conditioning systems, responsible for transferring heat from a cold space to a warmer environment. Understanding these cycles is crucial for comprehending the operation of refrigeration systems. This section delves into the various types of refrigeration cycles, their components, and their applications.

Vapor-Compression Refrigeration Cycle

The vapor-compression refrigeration cycle is the most prevalent type used in residential, commercial, and industrial applications. It involves a series of processes that transfer heat using a refrigerant.

The vapor-compression cycle consists of four main components:

- Compressor: The compressor draws in low-pressure, low-temperature refrigerant vapor and compresses it, increasing its pressure and temperature.

- Condenser: The compressed refrigerant vapor is then passed through the condenser, where it releases heat to the surroundings, typically air or water, and condenses into a liquid.

- Expansion Valve: The high-pressure liquid refrigerant then flows through the expansion valve, where it undergoes a sudden pressure drop, causing it to partially vaporize and cool down.

- Evaporator: The cold, partially vaporized refrigerant enters the evaporator, where it absorbs heat from the cold space, evaporating completely.

The cycle then repeats as the low-pressure vapor is drawn back into the compressor.

The vapor-compression cycle is based on the principle of heat transfer and the change of state of a refrigerant.

Absorption Refrigeration Cycle

The absorption refrigeration cycle differs from the vapor-compression cycle by using a solution, typically water and lithium bromide, to absorb the refrigerant vapor instead of a compressor. This cycle is commonly employed in applications where heat is readily available, such as industrial processes or solar energy systems.

The absorption cycle consists of four main components:

- Absorber: The absorber absorbs the refrigerant vapor from the evaporator using the absorbent solution.

- Generator: The absorbent solution is then pumped to the generator, where heat is applied to release the refrigerant vapor.

- Condenser: The released refrigerant vapor is condensed into a liquid, similar to the vapor-compression cycle.

- Evaporator: The liquid refrigerant then flows through the expansion valve and into the evaporator, where it absorbs heat from the cold space.

Air Refrigeration Cycle

The air refrigeration cycle utilizes air as the refrigerant, employing a process of compression, cooling, and expansion to achieve refrigeration. This cycle is primarily used in aircraft and other applications where a non-toxic refrigerant is required.

The air refrigeration cycle consists of four main components:

- Compressor: The compressor draws in low-pressure air and compresses it, increasing its pressure and temperature.

- Cooler: The compressed air is then passed through the cooler, where it releases heat to the surroundings and cools down.

- Expansion Turbine: The cooled air is then passed through the expansion turbine, where it expands and cools further.

- Evaporator: The cold air then enters the evaporator, where it absorbs heat from the cold space.

Comparison of Refrigeration Cycles

| Cycle | Advantages | Disadvantages |

|---|---|---|

| Vapor-Compression | Highly efficient, relatively inexpensive, widely available. | Uses refrigerants that can be harmful to the environment. |

| Absorption | Environmentally friendly, can use waste heat as energy source. | Less efficient than vapor-compression, requires a heat source. |

| Air | Uses air as refrigerant, non-toxic. | Less efficient than vapor-compression, bulky and heavy. |

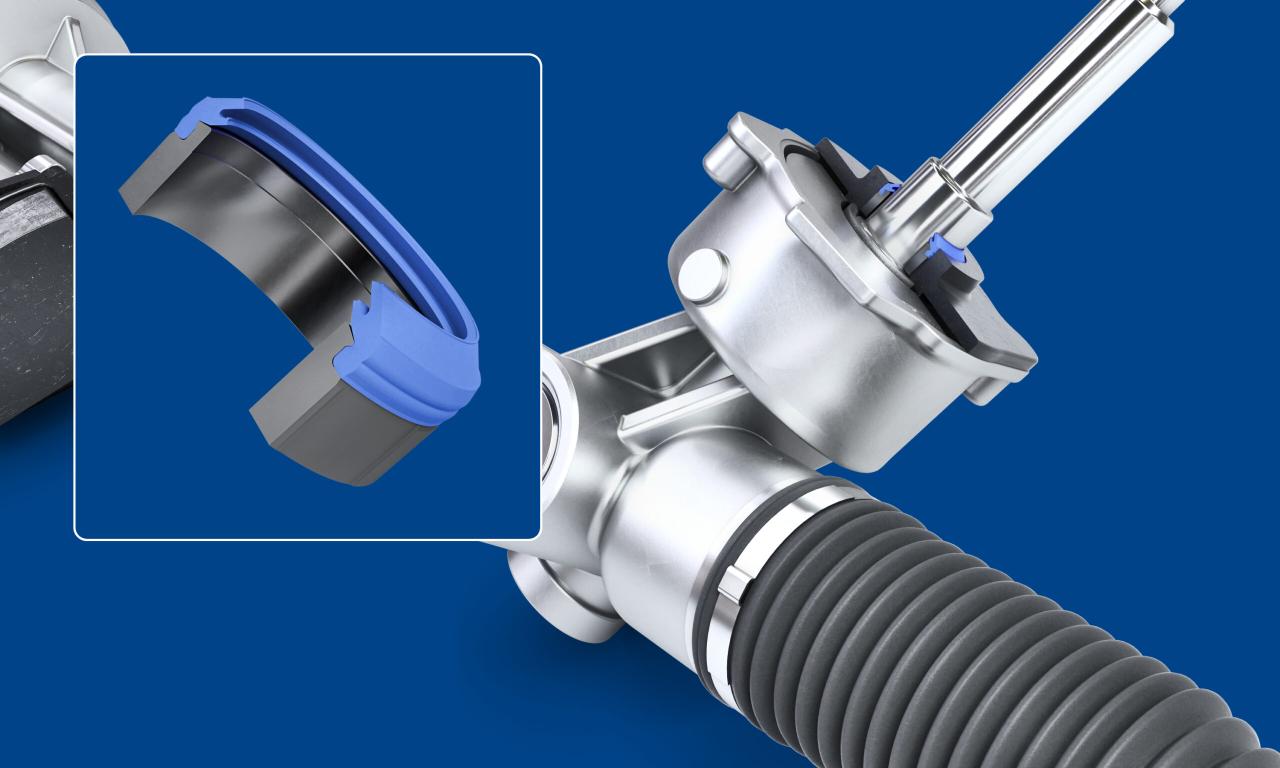

Refrigeration System Components

A typical refrigeration system comprises several essential components that work together to achieve refrigeration. These components include:

- Compressor: The compressor is the heart of the refrigeration system, responsible for compressing the refrigerant vapor and increasing its pressure and temperature.

- Condenser: The condenser is responsible for releasing heat from the compressed refrigerant vapor to the surroundings, causing it to condense into a liquid.

- Expansion Valve: The expansion valve controls the flow of refrigerant from the high-pressure side to the low-pressure side of the system, causing it to partially vaporize and cool down.

- Evaporator: The evaporator is where the cold refrigerant absorbs heat from the cold space, causing it to evaporate completely.

Refrigeration System Diagram

[Diagram of a simple refrigeration system with labels for each component]

Air Conditioning Systems

Air conditioning systems are essential for maintaining comfortable indoor environments, particularly in hot and humid climates. They provide cooling, dehumidification, and air circulation, enhancing both comfort and health. Air conditioning systems have evolved significantly, offering various options to suit diverse needs and applications.

Types of Air Conditioning Systems

Different types of air conditioning systems cater to various cooling requirements, space sizes, and budget constraints. Each system operates on the principle of heat transfer and refrigeration, but their design and installation vary.

- Central Air Conditioning: This system uses a single, centralized unit to cool an entire building or home. It comprises a condenser unit located outdoors and an evaporator unit placed indoors. Refrigerant circulates between these units, absorbing heat from the indoor air and releasing it outdoors. Central air conditioning offers efficient cooling for large spaces and is typically installed during construction.

- Window Units: Window units are compact and self-contained systems designed for individual rooms. They are relatively inexpensive and easy to install, making them suitable for smaller spaces. Window units typically have a single unit that combines the condenser and evaporator, with air intake and exhaust through the window opening.

- Split Systems: Split systems consist of two separate units: an outdoor condenser unit and an indoor evaporator unit. They offer greater flexibility in placement, allowing for discreet installation in various locations. Split systems are popular for their quiet operation and efficient cooling.

Principles of Air Conditioning

Air conditioning systems operate based on fundamental principles of heat transfer, humidity control, and air circulation.

- Heat Transfer: Air conditioning systems use refrigerants to transfer heat from the indoor environment to the outdoors. Refrigerant absorbs heat from the indoor air as it evaporates in the evaporator unit. This cooled air is then circulated throughout the space. The refrigerant then travels to the condenser unit outdoors, where it releases the absorbed heat into the atmosphere. This process continues in a closed loop, effectively removing heat from the indoor environment.

- Humidity Control: Air conditioning systems also control humidity levels by removing moisture from the air. The evaporator unit cools the air, causing water vapor to condense. This condensate is collected and drained away, reducing humidity levels and creating a more comfortable environment.

- Air Circulation: Air conditioning systems rely on fans to circulate cool air throughout the space. This ensures that the entire area is cooled evenly and that the temperature remains consistent. The air circulation system also helps to remove stale air and replace it with fresh air from outside.

Factors Influencing Air Conditioning System Selection and Design

Several factors influence the selection and design of air conditioning systems. These factors include:

- Space Size: The size of the space to be cooled is a primary factor in determining the capacity of the air conditioning system required. Larger spaces require more powerful systems to effectively cool the entire area.

- Climate: The prevailing climate and temperature extremes significantly influence the selection of an air conditioning system. Regions with hot and humid climates require more powerful systems to maintain comfortable temperatures.

- Budget: The cost of the air conditioning system is a major consideration for homeowners and businesses. Various systems are available at different price points, ranging from budget-friendly window units to more expensive central air conditioning systems.

- Energy Efficiency: Energy efficiency is becoming increasingly important in air conditioning system selection. Systems with higher SEER (Seasonal Energy Efficiency Ratio) ratings consume less energy and can result in significant cost savings over time.

- Aesthetics: The aesthetics of the air conditioning system are also a factor, particularly in residential applications. Indoor units should blend seamlessly with the interior design, while outdoor units should be discreet and visually appealing.

Comparison of Air Conditioning Systems

| Feature | Central Air Conditioning | Window Unit | Split System |

|---|---|---|---|

| Cooling Capacity | High | Low to Medium | Medium to High |

| Installation | Complex, often during construction | Simple, DIY possible | Moderate, professional installation recommended |

| Cost | High | Low | Medium |

| Energy Efficiency | High | Moderate | High |

| Noise Level | Low | Moderate to High | Low |

| Space Coverage | Entire building or home | Single room | Multiple rooms or zones |

| Flexibility | Limited | High | High |

| Aesthetics | Can be integrated with interior design | Can be visually intrusive | Indoor units can be discreet |

Refrigerants and Their Properties

Refrigerants are essential components of refrigeration and air conditioning systems. They absorb heat from the refrigerated space and release it to the surroundings, facilitating the cooling process. The choice of refrigerant depends on various factors, including its thermodynamic properties, environmental impact, and safety considerations.

Types of Refrigerants

Refrigerants can be classified based on their chemical composition and properties. The most common types include:

- Halogenated Refrigerants: These refrigerants contain halogens like chlorine, fluorine, and bromine. They are known for their good thermodynamic properties and were widely used in the past. However, due to their environmental impact, their use is now restricted in many countries. Examples include R-12 (dichlorodifluoromethane), R-22 (chlorodifluoromethane), and R-134a (tetrafluoroethane).

- Hydrocarbon Refrigerants: These refrigerants are composed of hydrogen and carbon. They are environmentally friendly and have good thermodynamic properties. However, they are flammable and require careful handling. Examples include propane (R-290), butane (R-600a), and isobutane (R-600).

- Hydrofluorocarbons (HFCs): These refrigerants contain hydrogen, fluorine, and carbon. They have low ozone depletion potential (ODP) but contribute to global warming. Examples include R-134a, R-404A, and R-410A.

- Natural Refrigerants: These refrigerants are naturally occurring substances and have zero ODP and low global warming potential (GWP). They include ammonia (R-717), carbon dioxide (R-744), and water (R-718).

Properties of Refrigerants

The properties of refrigerants play a crucial role in their performance and efficiency. Some important properties include:

- Boiling Point: The boiling point of a refrigerant determines the temperature at which it changes from a liquid to a gas. Refrigerants with lower boiling points are suitable for lower temperature applications.

- Enthalpy: Enthalpy is a measure of the total energy of a system. In refrigeration, the enthalpy of the refrigerant changes as it absorbs and releases heat. A high enthalpy change indicates a higher capacity to transfer heat.

- Ozone Depletion Potential (ODP): ODP is a measure of a refrigerant’s ability to deplete the ozone layer. Refrigerants with high ODP have been phased out due to their environmental impact.

- Global Warming Potential (GWP): GWP is a measure of a refrigerant’s contribution to global warming. Refrigerants with high GWP have a greater impact on climate change.

- Toxicity: Refrigerants should be non-toxic or have low toxicity to ensure safety in case of leaks.

- Flammability: Flammable refrigerants require special precautions to prevent fire hazards.

Environmental Impact of Refrigerants

Refrigerants can have a significant environmental impact. Halogenated refrigerants, especially those containing chlorine, contribute to ozone layer depletion. All refrigerants, including HFCs, contribute to global warming due to their greenhouse gas effect. The use of environmentally friendly refrigerants is crucial to mitigate these impacts.

Importance of Using Environmentally Friendly Alternatives

Using environmentally friendly refrigerants is essential for reducing the environmental impact of refrigeration and air conditioning systems. These refrigerants have low ODP and GWP, minimizing their contribution to ozone depletion and global warming. They also offer improved energy efficiency, reducing overall energy consumption.

Summary of Refrigerant Properties

The following table summarizes the key properties of various refrigerants:

| Refrigerant | Chemical Formula | Boiling Point (°C) | ODP | GWP | Toxicity | Flammability |

|---|---|---|---|---|---|---|

| R-12 | CCl2F2 | -29.8 | 1.0 | 1090 | Low | Non-flammable |

| R-22 | CHClF2 | -40.8 | 0.05 | 1810 | Low | Non-flammable |

| R-134a | CH2FCF3 | -26.1 | 0 | 1430 | Low | Non-flammable |

| R-410A | Blend of HFCs | -51.4 | 0 | 2088 | Low | Non-flammable |

| R-290 | C3H8 | -42.1 | 0 | 3 | Low | Flammable |

| R-717 | NH3 | -33.3 | 0 | 0 | Toxic | Non-flammable |

| R-744 | CO2 | -78.5 | 0 | 1 | Non-toxic | Non-flammable |

System Components and Accessories

Refrigeration and air conditioning systems consist of various components that work together to achieve the desired cooling effect. These components play crucial roles in the refrigeration cycle, transferring heat and facilitating the change of state of the refrigerant. Understanding the function and operation of each component is essential for effective system design, installation, and maintenance.

Compressors

Compressors are the heart of refrigeration and air conditioning systems, responsible for increasing the pressure and temperature of the refrigerant vapor. They are essential for driving the refrigeration cycle and achieving the desired cooling effect.

The selection of a compressor depends on several factors, including the system’s capacity, operating conditions, and refrigerant type. Compressors are classified based on their operating principle and design.

- Reciprocating compressors are the most common type, using a piston and cylinder arrangement to compress the refrigerant. They are relatively simple and cost-effective, suitable for small to medium-capacity systems.

- Rotary compressors use a rotating vane or screw to compress the refrigerant. They are known for their smooth operation and high efficiency, often used in residential and commercial air conditioning systems.

- Scroll compressors utilize two intermeshing scrolls to compress the refrigerant. They are compact, quiet, and efficient, commonly found in residential and commercial applications.

- Centrifugal compressors use a rotating impeller to increase the refrigerant’s velocity and pressure. They are suitable for large-capacity systems, such as industrial refrigeration and air conditioning applications.

| Type | Characteristics |

|---|---|

| Reciprocating | Simple, cost-effective, suitable for small to medium-capacity systems. |

| Rotary | Smooth operation, high efficiency, often used in residential and commercial air conditioning systems. |

| Scroll | Compact, quiet, and efficient, commonly found in residential and commercial applications. |

| Centrifugal | Suitable for large-capacity systems, such as industrial refrigeration and air conditioning applications. |

System Design and Installation

Designing and installing refrigeration and air conditioning systems involve a meticulous process that ensures optimal performance, efficiency, and safety. The design phase focuses on selecting the right components and sizing the system to meet specific needs, while the installation phase involves adhering to proper techniques and safety procedures.

System Design Considerations

The design phase is crucial for ensuring the system meets the intended cooling or heating requirements. The following considerations are essential:

- Load Calculation: Accurately determining the cooling or heating load is paramount. This involves considering factors like the size of the space, the number of occupants, the types of equipment, and the desired temperature. Load calculations are typically performed using specialized software or manual calculations based on established formulas.

- System Type Selection: Choosing the appropriate system type depends on various factors, including the application, budget, space constraints, and energy efficiency requirements. Common system types include split systems, packaged units, and central air conditioning systems.

- Component Selection: Selecting the right components, such as compressors, condensers, evaporators, and refrigerant lines, is critical for system performance and reliability. Considerations include efficiency, capacity, compatibility, and durability.

- System Sizing: Proper system sizing ensures that the system can handle the calculated load efficiently. An undersized system will struggle to maintain the desired temperature, while an oversized system will operate inefficiently and may experience short cycling.

Installation Techniques and Safety Procedures

Proper installation is crucial for optimal system performance, longevity, and safety. The following techniques and procedures are essential:

- Installation Location: Selecting an appropriate location for the system components is essential for efficient operation and ease of maintenance. Considerations include ventilation, accessibility, and proximity to power sources.

- Piping and Wiring: Proper installation of refrigerant lines, electrical wiring, and control systems is crucial for system functionality and safety. Adhering to industry standards and codes is paramount.

- Refrigerant Charging: Charging the system with the correct amount of refrigerant is critical for optimal performance and efficiency. Overcharging or undercharging can lead to system malfunctions and safety hazards.

- Leak Detection and Repair: Identifying and repairing leaks in the refrigerant system is crucial for environmental protection and system performance. Leak detection techniques include electronic leak detectors, soap bubbles, and dye tracing.

- Safety Procedures: Adhering to safety procedures during installation and maintenance is essential for preventing accidents and injuries. This includes wearing appropriate personal protective equipment (PPE), using proper tools and equipment, and following established safety protocols.

Troubleshooting and Diagnosis

Troubleshooting and diagnosing problems in refrigeration and air conditioning systems involve a systematic approach to identify the root cause of the malfunction. Common problems include:

- Refrigerant Leaks: Leaks can occur in the refrigerant lines, fittings, or components. Symptoms include reduced cooling capacity, abnormal system noises, and refrigerant pressure fluctuations.

- Compressor Malfunctions: Compressor failure can result in complete system shutdown. Symptoms include lack of cooling, abnormal noises, and high pressure readings.

- Condenser Problems: Condenser issues can affect heat rejection and reduce system efficiency. Symptoms include reduced cooling capacity, high condenser pressure, and excessive fan noise.

- Evaporator Problems: Evaporator issues can affect heat absorption and reduce cooling capacity. Symptoms include ice buildup on the evaporator coil, reduced airflow, and low evaporator pressure.

- Control System Malfunctions: Control system problems can affect system operation and performance. Symptoms include inconsistent temperature control, incorrect fan operation, and system shutdowns.

Energy Efficiency and Sustainability

The refrigeration and air conditioning industry plays a vital role in modern life, providing comfort, food preservation, and enabling various industrial processes. However, these systems consume significant amounts of energy, contributing to greenhouse gas emissions and environmental impact. Therefore, enhancing energy efficiency and adopting sustainable practices in refrigeration and air conditioning is crucial for mitigating environmental damage and promoting a more sustainable future.

Energy Consumption Analysis

Refrigeration and air conditioning systems consume a substantial portion of global energy consumption. The energy consumption of these systems depends on various factors, including system size, operating conditions, refrigerant type, and efficiency of components.

- System Size: Larger systems naturally consume more energy than smaller systems, as they have to cool or heat a larger space.

- Operating Conditions: Ambient temperature, humidity, and the desired temperature setpoint significantly impact energy consumption. Higher ambient temperatures and larger temperature differences between the inside and outside require more energy to maintain the desired temperature.

- Refrigerant Type: Refrigerants have different thermodynamic properties, influencing energy consumption. Refrigerants with higher energy efficiency ratings (EERs) generally require less energy to achieve the desired cooling effect.

- Efficiency of Components: The efficiency of components such as compressors, condensers, evaporators, and fans directly affects energy consumption. Higher-efficiency components consume less energy to perform the same function.

Emerging Technologies and Trends: Refrigeration & Air Conditioning Technology 8th Edition

The refrigeration and air conditioning industry is constantly evolving, driven by advancements in technology and the need for greater energy efficiency and sustainability. Emerging technologies are transforming how we cool our homes, businesses, and even food, opening new possibilities for innovation and environmental responsibility.

Variable-Speed Compressors and Inverter Technology

Variable-speed compressors are revolutionizing refrigeration and air conditioning systems by adjusting their speed based on the cooling demand. This dynamic approach allows for more precise temperature control, reduced energy consumption, and quieter operation. Inverter technology, a key component of variable-speed compressors, uses electronic circuitry to seamlessly adjust the compressor’s speed, ensuring optimal performance.

Variable-speed compressors offer a significant advantage over traditional fixed-speed compressors by reducing energy consumption by up to 30% in some applications.

Smart Home Integration

The integration of refrigeration and air conditioning systems with smart home technology is enhancing user experience and energy efficiency. Smart thermostats, connected appliances, and voice control systems allow users to monitor and control their cooling systems remotely, optimizing comfort and minimizing energy waste.

Smart home integration allows users to adjust temperature settings, schedule cooling cycles, and receive alerts about system performance, all from their smartphones or voice assistants.

New Refrigerants and Energy-Efficient Designs

The industry is actively researching and developing new refrigerants with lower global warming potential (GWP) to reduce their environmental impact. These refrigerants, such as R32 and R454B, are designed to be more environmentally friendly while maintaining efficient cooling performance.

The transition to low-GWP refrigerants is a crucial step in mitigating climate change and ensuring a sustainable future for the refrigeration and air conditioning industry.

Alongside new refrigerants, innovative design approaches are being implemented to improve energy efficiency. These include advanced insulation materials, optimized airflow patterns, and smart control systems that dynamically adjust cooling based on real-time conditions.

Sustainable Cooling Solutions

Emerging technologies are paving the way for sustainable cooling solutions, addressing the growing demand for climate-friendly refrigeration and air conditioning. These solutions include:

- District cooling systems: These centralized systems provide chilled water to multiple buildings, reducing energy consumption and minimizing environmental impact compared to individual cooling systems.

- Passive cooling techniques: These methods leverage natural ventilation, shading, and other design strategies to reduce the need for mechanical cooling, minimizing energy consumption and carbon footprint.

- Solar-powered cooling systems: These systems utilize solar energy to power refrigeration and air conditioning systems, reducing reliance on fossil fuels and promoting clean energy adoption.

Innovative Cooling Solutions and Case Studies

Several innovative solutions are emerging, showcasing the transformative potential of emerging technologies in refrigeration and air conditioning.

For example, the use of magnetic refrigeration technology, which utilizes magnetic fields to create cooling effects, offers a highly efficient and environmentally friendly alternative to traditional vapor-compression systems.

Case studies highlight the impact of these technologies:

- Supermarkets: Variable-speed compressors have been implemented in supermarket refrigeration systems, leading to significant energy savings and reduced operating costs.

- Commercial buildings: Smart home integration has enabled building managers to optimize cooling systems based on occupancy levels and real-time weather data, resulting in improved energy efficiency and reduced greenhouse gas emissions.

- Developing countries: Sustainable cooling solutions, such as solar-powered refrigeration systems, are providing access to essential cooling services in remote areas, improving food preservation and healthcare outcomes.

Conclusive Thoughts

As technology continues to evolve, the field of refrigeration and air conditioning is poised for further innovation. This 8th edition provides a valuable resource for students, professionals, and anyone seeking to understand the principles and practices that shape this essential industry. From the fundamental concepts to the latest advancements, this guide offers a comprehensive overview of the science, technology, and applications that drive the world of cooling and temperature control.

Refrigeration and air conditioning technology is a constantly evolving field, with advancements in energy efficiency and sustainability being key areas of focus. The 8th edition of this textbook provides a comprehensive overview of the latest developments, including the role of companies like mccown technology corporation in shaping the industry.

Mccown’s expertise in refrigeration and HVAC systems is essential for ensuring that buildings and facilities remain comfortable and energy-efficient, reflecting the principles outlined in the textbook.