Refrigeration & Air Conditioning Technology: A Comprehensive Overview

Refrigeration & air conditioning technology has revolutionized our lives, shaping everything from food preservation to comfortable living spaces. From the early days of ice harvesting to modern-day smart systems, the […]

Refrigeration & air conditioning technology has revolutionized our lives, shaping everything from food preservation to comfortable living spaces. From the early days of ice harvesting to modern-day smart systems, the journey of this technology is a testament to human ingenuity and the constant pursuit of a cooler, more comfortable world.

This technology has transformed how we live, work, and even travel. It plays a vital role in industries like food storage, pharmaceutical manufacturing, and data centers, ensuring the safety and preservation of essential goods. But beyond its practical applications, refrigeration and air conditioning have profoundly impacted human comfort and well-being, making our lives more pleasant and productive.

History and Evolution of Refrigeration and Air Conditioning

The journey of refrigeration and air conditioning technology spans centuries, marked by groundbreaking innovations that transformed how we live, work, and preserve food. From rudimentary methods to sophisticated systems, this evolution has significantly impacted our world.

Early Methods of Refrigeration

Early civilizations developed various methods to keep food and beverages cool. The Egyptians used evaporative cooling techniques, placing porous jars filled with water in the sun. This process relied on the evaporation of water to absorb heat, creating a cooling effect. The Greeks and Romans used ice harvested from mountains during winter and stored in underground chambers for later use. These methods provided temporary relief from the heat but were limited in their scope and effectiveness.

The Birth of Mechanical Refrigeration

The 18th century witnessed significant advancements in the understanding of heat and thermodynamics. In 1748, William Cullen demonstrated the first artificial refrigeration process using an ether-based system. However, this invention was primarily a scientific curiosity and did not have practical applications.

- In 1834, Jacob Perkins, an American inventor, patented the first practical vapor-compression refrigeration system using ether as the refrigerant. This system used a closed loop to circulate the refrigerant, enabling continuous cooling.

- In the mid-19th century, Ferdinand Carré, a French engineer, developed the first commercially successful absorption refrigeration system. This system used ammonia as the refrigerant and water as the absorbent, offering a simpler and more efficient alternative to vapor-compression systems.

- The development of mechanical refrigeration revolutionized food preservation and storage. It enabled the transportation and distribution of perishable goods over long distances, significantly impacting the food industry and global trade.

Early Air Conditioning Systems

The concept of air conditioning emerged in the late 19th century, with the primary focus on improving indoor comfort and reducing humidity.

- In 1881, Willis Carrier, an American engineer, invented the first practical air conditioning system. Carrier’s invention, initially designed to control humidity in a printing press, marked the beginning of modern air conditioning technology.

- Carrier’s system used a combination of refrigeration, ventilation, and dehumidification to create a controlled environment. It revolutionized industrial processes and opened new possibilities for comfortable living in hot and humid climates.

Evolution of Refrigeration and Air Conditioning Systems

Throughout the 20th century, refrigeration and air conditioning technologies continued to evolve, driven by innovation and advancements in materials, engineering, and electronics.

- The development of synthetic refrigerants, such as Freon, in the 1930s significantly improved the efficiency and safety of refrigeration systems. Freon was non-flammable and had a low boiling point, making it ideal for use in household refrigerators and air conditioners.

- The advent of electronic controls in the 1950s and 1960s allowed for greater precision and automation in refrigeration and air conditioning systems. This led to the development of more efficient and user-friendly appliances.

- The 1970s and 1980s saw the introduction of energy-efficient technologies, such as variable-speed compressors and inverter technology, reducing energy consumption and environmental impact.

Modern Innovations in Refrigeration and Air Conditioning

Today, refrigeration and air conditioning technology is at the forefront of innovation, driven by the need for sustainable solutions and improved performance.

- The use of natural refrigerants, such as carbon dioxide and propane, is gaining traction as a more environmentally friendly alternative to synthetic refrigerants. These refrigerants have a lower global warming potential and contribute to reducing greenhouse gas emissions.

- Smart technology is being integrated into refrigeration and air conditioning systems, enabling remote monitoring, control, and optimization. This allows for greater energy efficiency and personalized comfort.

- Advances in materials science and engineering are leading to the development of more efficient and durable components, such as high-performance insulation and compact heat exchangers.

Fundamental Principles and Concepts

Refrigeration and air conditioning are based on fundamental principles of thermodynamics and heat transfer. Understanding these concepts is crucial for comprehending the operation and design of refrigeration and air conditioning systems.

Thermodynamics and Heat Transfer, Refrigeration & air conditioning technology

Thermodynamics deals with the relationships between heat, work, and energy. Heat transfer involves the movement of thermal energy from one object or system to another. In refrigeration and air conditioning, these principles are applied to extract heat from a cold space and transfer it to a warmer environment.

The first law of thermodynamics states that energy cannot be created or destroyed, only transferred or transformed.

The second law of thermodynamics states that heat always flows from a hotter body to a colder body.

Heat transfer can occur through three primary modes: conduction, convection, and radiation.

- Conduction: Heat transfer through direct contact between objects or substances at different temperatures.

- Convection: Heat transfer through the movement of fluids, such as air or water.

- Radiation: Heat transfer through electromagnetic waves, such as infrared radiation.

Refrigerants

Refrigerants are fluids used in refrigeration and air conditioning systems to absorb heat from the cold space and release it to the warmer environment. They undergo a phase change, transitioning from a liquid to a gas and back again, to facilitate this heat transfer process.

- Refrigerant Properties: Refrigerants are chosen based on their specific properties, such as boiling point, critical temperature, pressure, and heat capacity. These properties determine their effectiveness in absorbing and releasing heat.

- Types of Refrigerants: There are various types of refrigerants, including:

- HFCs (Hydrofluorocarbons): These are commonly used refrigerants, but they have a high global warming potential (GWP).

- HCFCs (Hydrochlorofluorocarbons): These refrigerants are being phased out due to their ozone-depleting potential.

- Natural Refrigerants: These include ammonia (NH3), carbon dioxide (CO2), and hydrocarbons (such as propane and butane), which have a lower GWP and are more environmentally friendly.

Refrigeration Cycles

Refrigeration cycles are the processes used to extract heat from a cold space and transfer it to a warmer environment. The most common refrigeration cycle is the vapor compression cycle.

Vapor Compression Cycle

The vapor compression cycle is a closed loop system that uses a refrigerant to transfer heat. The cycle consists of four main components:

- Compressor: Compresses the refrigerant vapor, increasing its pressure and temperature.

- Condenser: Cools and condenses the high-pressure, high-temperature refrigerant vapor into a liquid.

- Expansion Valve: Reduces the pressure of the refrigerant liquid, causing it to partially vaporize and become very cold.

- Evaporator: Absorbs heat from the cold space, causing the refrigerant to evaporate and become a vapor.

Absorption Cycle

The absorption cycle is similar to the vapor compression cycle but uses a different method to compress the refrigerant. It uses an absorbent solution, typically water, to absorb the refrigerant vapor and concentrate it.

Air Cycles

Air cycles use air as the refrigerant. They are less efficient than vapor compression cycles but are often used in applications where safety is a concern, such as in aircraft.

Refrigeration Systems and Components

Refrigeration systems are the backbone of modern cooling technologies, responsible for maintaining low temperatures in various applications, from household refrigerators to industrial processes. Understanding the components and their interactions is crucial for comprehending the principles of refrigeration.

Key Components of a Refrigeration System

The following table summarizes the essential components of a typical refrigeration system, highlighting their functions and characteristics:

| Component | Function | Characteristics |

|—|—|—|

| Compressor | Compresses the refrigerant vapor, increasing its pressure and temperature | – Can be reciprocating, rotary, screw, or scroll types. – Power consumption is significant. – Plays a crucial role in the system’s efficiency. |

| Condenser | Releases heat from the refrigerant, transitioning it from a high-pressure vapor to a high-pressure liquid. | – Can be air-cooled, water-cooled, or evaporative. – Size and design depend on the system’s cooling capacity. – Heat dissipation is a key aspect. |

| Expansion Device | Reduces the pressure of the refrigerant, causing it to partially vaporize and absorb heat from the surroundings. | – Can be a capillary tube, thermostatic expansion valve (TXV), or electronic expansion valve (EEV). – Precise control of refrigerant flow is essential. – Affects system efficiency and performance. |

| Evaporator | Absorbs heat from the refrigerated space, causing the refrigerant to evaporate. | – Can be a direct-expansion (DX) or flooded type. – Size and design depend on the cooling load. – Efficient heat transfer is critical. |

Compressors

Compressors are the heart of a refrigeration system, responsible for driving the refrigerant through the system. They increase the pressure and temperature of the refrigerant vapor, enabling heat rejection in the condenser.

Types of Compressors

- Reciprocating Compressors: These compressors utilize a piston-cylinder arrangement to compress the refrigerant. They are simple, reliable, and commonly used in small-scale applications.

- Rotary Compressors: Rotary compressors use rotating vanes or screws to compress the refrigerant. They are known for their high efficiency and compact size, making them suitable for medium-to-large systems.

- Screw Compressors: Screw compressors employ two intermeshing screws to compress the refrigerant. They are designed for high-capacity applications and are characterized by their smooth operation and high efficiency.

- Scroll Compressors: Scroll compressors utilize two spiral-shaped scrolls to compress the refrigerant. They are known for their quiet operation, compact size, and high efficiency, making them suitable for a wide range of applications.

Condensers

Condensers are responsible for releasing heat from the high-pressure refrigerant vapor, transforming it into a high-pressure liquid. The heat is transferred to the surrounding environment, typically air or water.

Types of Condensers

- Air-Cooled Condensers: These condensers utilize air as the cooling medium, typically using fans to draw air across finned coils containing the refrigerant. They are commonly used in residential and commercial applications due to their simplicity and low cost.

- Water-Cooled Condensers: Water-cooled condensers use water as the cooling medium, circulating it through the condenser coils. They offer higher efficiency and lower noise levels compared to air-cooled condensers, but require a water source and may be more expensive.

- Evaporative Condensers: Evaporative condensers use water evaporation to cool the refrigerant. They are more efficient than air-cooled condensers and require less water than water-cooled condensers. However, they require a water source and may be more complex to maintain.

Evaporators

Evaporators are the components responsible for absorbing heat from the refrigerated space, causing the refrigerant to evaporate. This process cools the refrigerated space, maintaining the desired temperature.

Types of Evaporators

- Direct-Expansion (DX) Evaporators: DX evaporators are directly connected to the refrigeration system, allowing the refrigerant to flow through them and absorb heat from the surrounding air. They are commonly used in residential and commercial applications due to their simplicity and efficiency.

- Flooded Evaporators: Flooded evaporators are partially filled with liquid refrigerant, which absorbs heat from the surrounding air and evaporates. They are typically used in large-scale industrial applications where high cooling capacity is required.

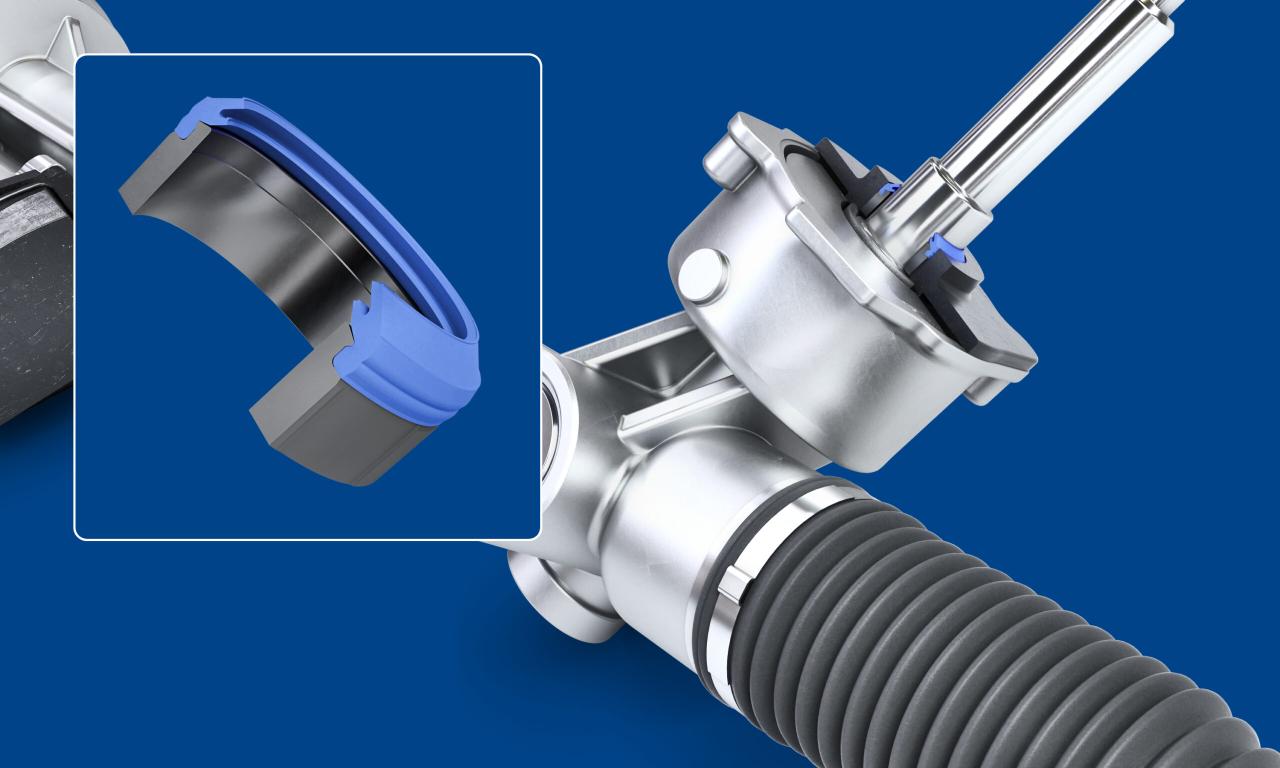

Expansion Devices

Expansion devices are responsible for reducing the pressure of the refrigerant, causing it to partially vaporize and absorb heat from the surrounding air. This process is essential for maintaining the desired temperature in the refrigerated space.

Types of Expansion Devices

- Capillary Tubes: Capillary tubes are small, precisely sized tubes that restrict the flow of refrigerant, causing a pressure drop. They are simple, inexpensive, and commonly used in small-scale refrigeration systems.

- Thermostatic Expansion Valves (TXVs): TXVs are automatic valves that regulate the flow of refrigerant based on the temperature of the evaporator. They are more complex than capillary tubes but offer better control over the refrigerant flow, leading to improved system efficiency.

- Electronic Expansion Valves (EEVs): EEVs are electronically controlled valves that use sensors to regulate the refrigerant flow. They offer the highest level of control and flexibility, allowing for precise temperature regulation and optimization of system performance.

Air Conditioning Systems and Components

Air conditioning systems are designed to cool, dehumidify, and circulate air in indoor spaces, providing a comfortable and healthy environment. These systems are essential for maintaining a comfortable temperature in homes, offices, and other buildings, particularly during hot weather.

Types of Air Conditioning Systems

There are various types of air conditioning systems available, each with its own advantages and disadvantages. The choice of system depends on factors such as the size of the space to be cooled, budget, and energy efficiency requirements.

- Central Air Conditioning: This type of system is typically used for cooling entire homes or large buildings. It consists of a central unit located outside the building, which houses the condenser and compressor. The cooled air is distributed throughout the house via a network of ducts connected to an indoor unit that contains the evaporator and blower. Central air conditioning systems are known for their efficiency and ability to provide consistent cooling throughout the entire space.

- Split Systems: Split systems are a popular choice for homes and apartments. They consist of two units: an outdoor unit that houses the condenser and compressor, and an indoor unit that contains the evaporator and blower. The two units are connected by refrigerant lines. Split systems offer flexibility in placement and are often more energy-efficient than window units.

- Window Units: Window units are portable air conditioners that are installed in windows. They are typically used for cooling individual rooms. Window units are relatively inexpensive, but they are less efficient than central or split systems and can be noisy.

Key Components of an Air Conditioning System

Air conditioning systems consist of several essential components that work together to cool the air. These components include:

- Blower: The blower is responsible for circulating the air throughout the system. It draws in warm air from the room, passes it over the evaporator coil, and then blows the cooled air back into the room.

- Evaporator: The evaporator is a coil that absorbs heat from the air as it passes over it. The refrigerant in the evaporator absorbs the heat, causing it to evaporate. The refrigerant then flows to the condenser.

- Condenser: The condenser is a coil that releases the heat absorbed by the refrigerant into the outside air. The refrigerant condenses back into a liquid state as it releases the heat. The condensed refrigerant then flows back to the evaporator, completing the cycle.

- Compressor: The compressor is a pump that increases the pressure of the refrigerant. This increases the temperature of the refrigerant, allowing it to release heat to the condenser. The compressor is a crucial component of the air conditioning system, as it drives the entire refrigeration cycle.

- Thermostat: The thermostat is a device that controls the operation of the air conditioning system. It senses the temperature of the room and turns the system on or off to maintain the desired temperature.

Role of Air Filters, Humidifiers, and Dehumidifiers

- Air Filters: Air filters are essential for removing dust, pollen, and other airborne particles from the air. They are typically located in the air handler or blower unit. Regular replacement of air filters is crucial for maintaining air quality and system efficiency.

- Humidifiers: Humidifiers are devices that add moisture to the air. They are often used in dry climates to improve air quality and comfort. Some air conditioning systems have built-in humidifiers.

- Dehumidifiers: Dehumidifiers are devices that remove moisture from the air. They are often used in humid climates to reduce condensation and improve indoor air quality. Some air conditioning systems have built-in dehumidifiers.

Applications and Industries

Refrigeration and air conditioning technology play a crucial role in various industries, contributing significantly to human comfort, food preservation, and technological advancements. These systems are essential for maintaining optimal conditions in diverse environments, ranging from residential buildings to sophisticated industrial facilities.

Impact on Human Comfort and Well-being

The impact of refrigeration and air conditioning on human comfort and well-being is undeniable. These technologies provide a comfortable living environment, allowing individuals to thrive in diverse climates and weather conditions. They contribute to:

- Improved Indoor Air Quality: Air conditioning systems remove pollutants, allergens, and moisture from the air, improving indoor air quality and reducing the risk of respiratory problems. This is particularly important in urban areas with high levels of air pollution.

- Enhanced Sleep Quality: A comfortable temperature promotes restful sleep, leading to improved cognitive function, reduced stress levels, and overall better health. Studies have shown that individuals sleep better in cooler environments.

- Increased Productivity: A comfortable indoor temperature enhances productivity and focus, especially in workplaces and educational institutions. Studies have shown that productivity can decline in excessively hot or cold environments.

Food Storage and Preservation

Refrigeration is fundamental to food storage and preservation, ensuring food safety and reducing food waste. Refrigeration technology plays a vital role in:

- Extending Food Shelf Life: Refrigeration slows down the growth of bacteria and microorganisms, extending the shelf life of perishable foods, such as fruits, vegetables, and meat. This reduces food spoilage and waste, contributing to food security.

- Maintaining Food Quality: Refrigeration helps maintain the freshness, flavor, and nutritional value of food. This is crucial for maintaining the quality of produce, dairy products, and other perishable goods.

- Facilitating Food Distribution: Refrigeration systems enable the safe and efficient transportation and distribution of food products, ensuring that fresh and nutritious food is available to consumers worldwide.

Pharmaceutical Manufacturing

Refrigeration and air conditioning are essential in pharmaceutical manufacturing to maintain the stability and efficacy of sensitive medications. These systems are critical for:

- Maintaining Drug Stability: Many pharmaceuticals require specific temperature ranges for storage and transportation to prevent degradation and maintain their potency. Refrigeration systems ensure that drugs remain stable and effective throughout their shelf life.

- Controlling Humidity Levels: Humidity control is crucial for pharmaceutical manufacturing to prevent moisture damage to sensitive medications and equipment. Air conditioning systems regulate humidity levels, ensuring optimal conditions for production and storage.

- Maintaining Cleanroom Environments: Pharmaceutical manufacturing relies on cleanroom environments to minimize contamination risks. Air conditioning systems provide filtered and controlled airflow, maintaining a sterile environment for drug production and packaging.

Data Centers

Refrigeration and air conditioning are crucial for maintaining the optimal operating conditions of data centers, which house critical computing infrastructure. These systems are essential for:

- Heat Dissipation: Servers and other data center equipment generate significant heat. Refrigeration systems remove this heat, preventing overheating and ensuring the reliable operation of critical IT infrastructure.

- Temperature and Humidity Control: Data centers require precise temperature and humidity control to prevent damage to sensitive electronic equipment. Air conditioning systems maintain optimal conditions, ensuring data integrity and system stability.

- Power Efficiency: Efficient cooling systems are crucial for optimizing energy consumption in data centers. Modern refrigeration and air conditioning technologies are designed to minimize energy use, reducing operational costs and environmental impact.

Advancements and Innovations

The field of refrigeration and air conditioning is constantly evolving, driven by the need for greater energy efficiency, environmental responsibility, and innovative solutions. Advancements in technology, materials, and design are leading to more efficient, sustainable, and intelligent systems.

Energy Efficiency

Energy efficiency is a critical concern in refrigeration and air conditioning, as these systems consume a significant amount of energy. Recent advancements have focused on improving system efficiency through various approaches:

- Variable Speed Compressors: These compressors adjust their speed based on the cooling demand, reducing energy consumption during periods of low demand. For example, in a residential air conditioner, a variable speed compressor can operate at a lower speed during cooler nights, resulting in significant energy savings.

- Smart Controls and Automation: Advanced control systems optimize system operation by adjusting settings based on real-time conditions and user preferences. Smart thermostats, for instance, can learn user habits and adjust temperature settings accordingly, minimizing energy waste.

- Improved Insulation and Sealing: Advanced insulation materials and improved sealing techniques minimize heat transfer, reducing the energy required for cooling. This is particularly important in commercial refrigeration systems, where large cold storage areas require efficient insulation to maintain desired temperatures.

- Heat Recovery Systems: These systems capture waste heat from refrigeration systems and use it for other purposes, such as heating water or space heating. This approach significantly improves energy efficiency by reducing energy consumption and promoting sustainability.

Smart Systems

The integration of smart technologies is transforming the refrigeration and air conditioning industry. Smart systems offer enhanced control, monitoring, and optimization capabilities, leading to improved efficiency and user experience.

- Internet of Things (IoT) Integration: Refrigeration and air conditioning systems are increasingly being connected to the internet, enabling remote monitoring, control, and data analysis. This allows for proactive maintenance, early detection of faults, and optimization of system performance.

- Predictive Maintenance: Smart systems use data analysis to predict potential failures and schedule maintenance proactively. This reduces downtime, minimizes repair costs, and ensures optimal system performance.

- Energy Management Systems: These systems integrate with smart grids and energy storage solutions to optimize energy consumption and reduce costs. They can adjust system operation based on real-time energy prices and grid conditions, minimizing energy bills and promoting grid stability.

Sustainable Refrigerants

The use of traditional refrigerants with high global warming potentials (GWPs) has raised environmental concerns. The industry is transitioning towards sustainable refrigerants with lower GWPs and minimal impact on the environment.

- Hydrofluoroolefins (HFOs): These refrigerants have low GWPs and are considered a viable alternative to traditional refrigerants. They are used in various applications, including residential and commercial air conditioning, and refrigeration.

- Natural Refrigerants: Natural refrigerants, such as carbon dioxide (CO2), ammonia (NH3), and hydrocarbons (HCs), have zero or low GWPs and are considered environmentally friendly. They are increasingly being used in commercial refrigeration systems, particularly in large-scale applications.

- Refrigerant Blends: Blends of different refrigerants are often used to achieve specific performance characteristics and reduce environmental impact. These blends typically combine traditional refrigerants with lower-GWP alternatives to minimize the overall GWP of the system.

Magnetic Refrigeration

Magnetic refrigeration is a novel cooling technology that utilizes the magnetocaloric effect. This effect refers to the temperature change of a material when subjected to a magnetic field.

- Working Principle: In magnetic refrigeration, a magnetic material is exposed to a magnetic field, causing its temperature to rise. When the magnetic field is removed, the material cools down. This temperature change is used to create a cooling effect.

- Advantages: Magnetic refrigeration offers several advantages over traditional vapor-compression refrigeration, including higher energy efficiency, reduced environmental impact, and the potential for miniaturization.

- Challenges: Despite its potential, magnetic refrigeration technology is still in its early stages of development and faces challenges such as high cost, limited availability of suitable materials, and the need for further research and development.

Thermoacoustic Cooling

Thermoacoustic cooling is a technology that uses sound waves to create a cooling effect. It relies on the interaction of sound waves with a gas, resulting in heat transfer and temperature differences.

- Working Principle: In thermoacoustic cooling, sound waves are generated in a resonant chamber filled with a gas. The sound waves cause the gas molecules to vibrate, creating temperature differences within the chamber. These temperature differences are then used to cool a heat sink or a refrigerated space.

- Advantages: Thermoacoustic cooling offers several advantages, including high energy efficiency, low operating noise, and the potential for use in various applications, such as refrigeration, air conditioning, and heat pump systems.

- Challenges: Despite its potential, thermoacoustic cooling technology is still under development and faces challenges such as the need for efficient sound wave generators, optimization of system design, and the development of suitable materials.

Key Advancements and Innovations

| Advancement/Innovation | Benefits | Challenges |

|---|---|---|

| Variable Speed Compressors | Increased energy efficiency, reduced operating costs, improved comfort | Higher initial cost, complex control systems |

| Smart Controls and Automation | Optimized system performance, enhanced user experience, proactive maintenance | Data security concerns, potential for system complexity |

| Improved Insulation and Sealing | Reduced heat transfer, minimized energy consumption, improved thermal efficiency | Cost of materials, potential for installation challenges |

| Heat Recovery Systems | Increased energy efficiency, reduced environmental impact, potential for cost savings | Complexity of system design, potential for space constraints |

| Internet of Things (IoT) Integration | Remote monitoring and control, proactive maintenance, data-driven optimization | Data security concerns, potential for network connectivity issues |

| Predictive Maintenance | Reduced downtime, minimized repair costs, optimized system performance | Data analysis complexity, potential for inaccurate predictions |

| Energy Management Systems | Optimized energy consumption, reduced costs, improved grid stability | System integration complexity, potential for high initial costs |

| Hydrofluoroolefins (HFOs) | Low global warming potential, reduced environmental impact, good performance characteristics | Potential for flammability, higher cost compared to traditional refrigerants |

| Natural Refrigerants | Zero or low global warming potential, environmentally friendly, readily available | Potential for toxicity or flammability, limited availability in certain applications |

| Refrigerant Blends | Optimized performance characteristics, reduced environmental impact, improved efficiency | Potential for complex system design, compatibility issues with existing systems |

| Magnetic Refrigeration | High energy efficiency, reduced environmental impact, potential for miniaturization | High cost, limited availability of suitable materials, ongoing research and development |

| Thermoacoustic Cooling | High energy efficiency, low operating noise, potential for various applications | Complexity of system design, ongoing research and development |

Future Directions

The field of refrigeration and air conditioning is poised for significant evolution, driven by a confluence of technological advancements, environmental concerns, and evolving societal needs. The future of this industry will be shaped by the need to balance energy efficiency, sustainability, and innovation to address the challenges of a changing world.

Climate Change Impact

Climate change presents both challenges and opportunities for the refrigeration and air conditioning industry. As global temperatures rise, the demand for cooling solutions is expected to increase significantly, putting pressure on energy consumption and greenhouse gas emissions.

The International Energy Agency (IEA) projects that global energy demand for cooling will triple by 2050, making it a critical factor in mitigating climate change.

The industry is actively exploring ways to reduce the environmental footprint of refrigeration and air conditioning systems. This includes developing more efficient refrigerants, improving system designs, and integrating renewable energy sources.

Sustainable and Energy-Efficient Solutions

Sustainability and energy efficiency are paramount considerations in the future of refrigeration and air conditioning. The industry is focusing on developing solutions that minimize environmental impact and reduce energy consumption.

- Energy-Efficient Refrigerants: The transition to low global warming potential (GWP) refrigerants is crucial to reduce greenhouse gas emissions. Advancements in natural refrigerants, such as ammonia, CO2, and hydrocarbons, are gaining traction. These refrigerants have a lower environmental impact compared to traditional synthetic refrigerants.

- Smart Controls and Automation: Implementing smart controls and automation can optimize system performance and reduce energy consumption. These systems can adjust cooling capacity based on real-time conditions, minimizing energy waste.

- Renewable Energy Integration: Integrating renewable energy sources, such as solar and wind power, into refrigeration and air conditioning systems can significantly reduce reliance on fossil fuels. This can be achieved through hybrid systems that combine conventional and renewable energy sources.

Future Applications

Refrigeration and air conditioning technology is finding new applications in diverse sectors, driven by the need for controlled environments and thermal management.

- Transportation: Refrigeration systems are crucial for maintaining the temperature of perishable goods during transportation. Advancements in refrigeration technology are enabling the development of more efficient and sustainable solutions for refrigerated trucks and containers.

- Healthcare: Precise temperature control is critical in healthcare settings for storing medications, vaccines, and biological samples. Refrigeration and air conditioning systems play a vital role in maintaining the integrity of these materials and ensuring patient safety.

- Space Exploration: Refrigeration and air conditioning technology are essential for maintaining habitable environments in spacecraft and space stations. Advancements in miniaturization and energy efficiency are crucial for developing sustainable cooling solutions for long-duration space missions.

Summary: Refrigeration & Air Conditioning Technology

As we move forward, the future of refrigeration and air conditioning technology holds immense potential. The focus is shifting towards sustainable solutions, energy efficiency, and innovative designs. With advancements in areas like magnetic refrigeration and thermoacoustic cooling, we can anticipate a future where comfort and sustainability go hand in hand.

Refrigeration and air conditioning technology is constantly evolving, bringing us innovative solutions for comfort and efficiency. From smart thermostats to advanced cooling systems, the industry is pushing boundaries. Just like these advancements, home automation has also taken a leap forward, with devices like the automatic technology australia garage door opener offering convenience and security.

The integration of such technologies into our daily lives highlights the importance of embracing innovation, especially in areas like refrigeration and air conditioning, where energy efficiency and sustainability are paramount.