RBT Technology: Transforming Industries

RBT technology, a convergence of robotics, automation, and artificial intelligence, is revolutionizing industries across the globe. From manufacturing and healthcare to agriculture and logistics, RBT systems are transforming processes, enhancing […]

RBT technology, a convergence of robotics, automation, and artificial intelligence, is revolutionizing industries across the globe. From manufacturing and healthcare to agriculture and logistics, RBT systems are transforming processes, enhancing efficiency, and pushing the boundaries of innovation. This technology is poised to play an even more significant role in shaping the future, promising a world where machines and humans collaborate to achieve unprecedented levels of productivity and progress.

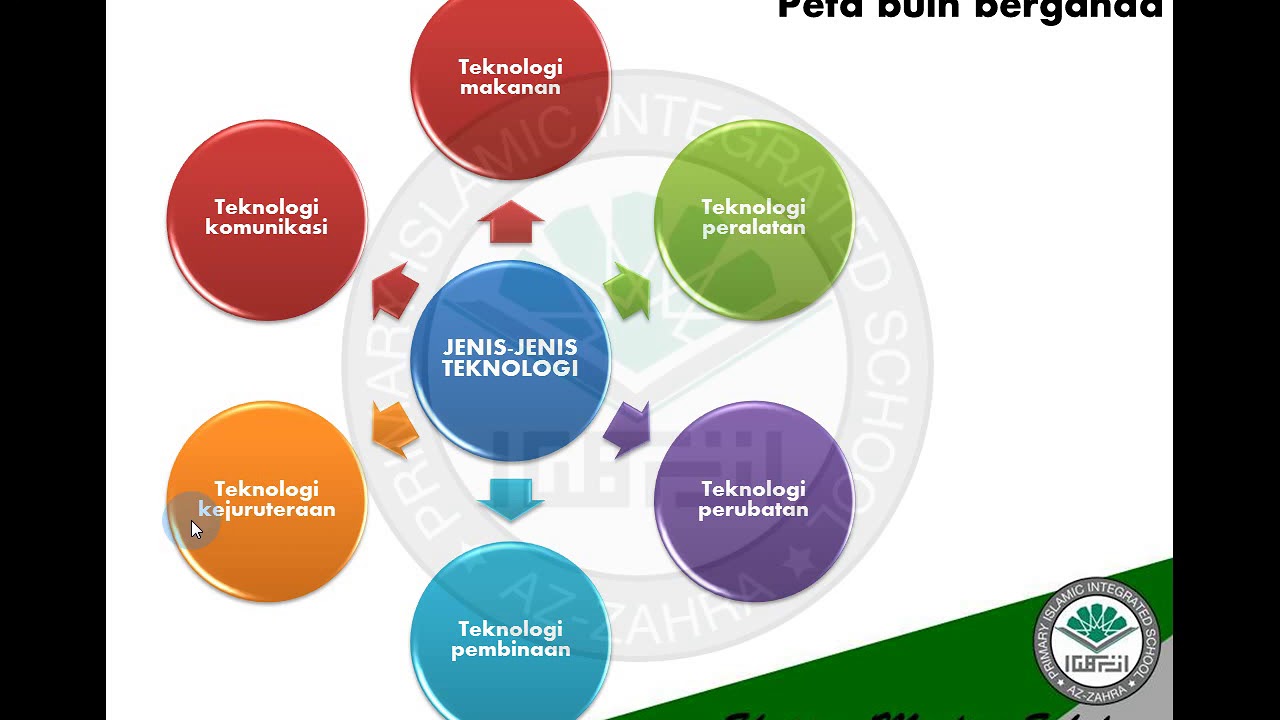

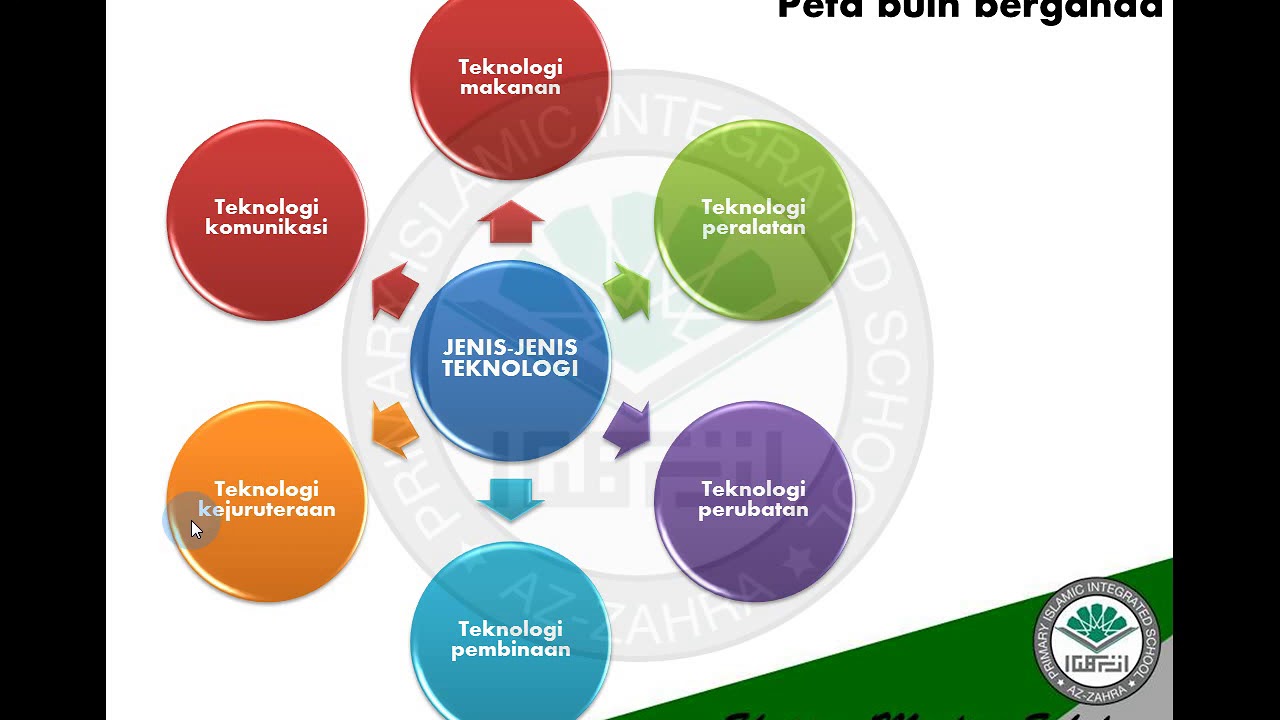

RBT technology encompasses a wide range of applications, each tailored to address specific industry needs. In manufacturing, robots perform intricate tasks with precision and speed, boosting production rates and minimizing errors. Healthcare benefits from RBT-assisted surgeries, rehabilitation programs, and patient care, leading to improved outcomes and enhanced patient safety. Agriculture utilizes RBT technology for precision farming, automated harvesting, and livestock management, increasing yield and optimizing resource allocation. Logistics and transportation rely on RBT systems for warehouse automation, delivery optimization, and autonomous vehicles, streamlining operations and enhancing efficiency.

RBT Technology in Manufacturing

RBT technology, also known as robotic process automation, has become increasingly prevalent in the manufacturing industry. It involves using robots to automate repetitive tasks, improving efficiency and productivity.

Applications of RBT Technology in Manufacturing Processes

RBT technology finds diverse applications in manufacturing processes, such as:

- Assembly: Robots can precisely assemble components, reducing errors and improving speed. For instance, in the automotive industry, robots are employed for assembling car parts, ensuring consistency and accuracy.

- Welding: Robots can perform welding tasks with high precision and repeatability. This ensures consistent weld quality and minimizes defects. In the aerospace industry, robots are used for welding complex metal structures, achieving high standards of accuracy and strength.

- Painting: Robots can apply paint evenly and efficiently, reducing material waste and improving paint quality. In the automotive industry, robots are used for painting car bodies, ensuring a smooth and uniform finish.

Benefits of Using RBT Technology in Manufacturing

The implementation of RBT technology in manufacturing offers several benefits, including:

- Increased Efficiency: Robots can work continuously without breaks, leading to higher production output and reduced lead times. For example, in a manufacturing plant, robots can work around the clock, increasing production efficiency by 20% or more.

- Enhanced Productivity: By automating repetitive tasks, robots free up human workers to focus on more complex and value-adding activities. This leads to a significant increase in overall productivity. In a study conducted by the National Institute of Standards and Technology, it was found that the use of robots in manufacturing can increase productivity by up to 30%.

- Improved Quality: Robots can perform tasks with greater precision and consistency than humans, resulting in improved product quality and reduced defects. For instance, in the pharmaceutical industry, robots are used for packaging and labeling medications, ensuring accuracy and preventing contamination.

- Reduced Costs: By automating tasks, RBT technology can reduce labor costs and minimize errors, resulting in overall cost savings. In a report by Deloitte, it was estimated that the use of robots in manufacturing can reduce operational costs by up to 15%.

- Enhanced Safety: Robots can perform dangerous or hazardous tasks, reducing the risk of accidents and injuries to human workers. For instance, in the construction industry, robots are used for demolition and other hazardous tasks, minimizing the risk of worker injury.

Successful RBT Implementations in Manufacturing Settings

Several companies have successfully implemented RBT technology in their manufacturing processes, achieving significant improvements:

- Toyota: Toyota has been a pioneer in the use of robots in manufacturing, employing them extensively in its assembly lines. This has resulted in increased production efficiency, reduced costs, and improved product quality. Toyota’s success with RBT technology has been a major driver for the widespread adoption of robotics in the automotive industry.

- Boeing: Boeing uses robots extensively in its aircraft manufacturing process, particularly for tasks like welding and drilling. The use of robots has enabled Boeing to achieve greater accuracy and consistency in its aircraft production, leading to improved safety and reliability. Boeing’s success with RBT technology has demonstrated the potential of robotics for complex and critical manufacturing processes.

- Amazon: Amazon has heavily invested in RBT technology for its fulfillment centers, employing robots for tasks like picking, packing, and sorting. The use of robots has significantly improved Amazon’s efficiency and productivity, allowing it to handle a massive volume of orders. Amazon’s success with RBT technology has highlighted the potential of robotics for e-commerce and logistics.

RBT Technology in Agriculture

RBT technology is revolutionizing the agricultural industry, enabling farmers to optimize their operations and achieve greater efficiency, sustainability, and profitability. From precision farming to crop harvesting and livestock management, RBTs are transforming traditional agricultural practices.

Precision Farming, Rbt technology

Precision farming refers to the use of technology to optimize agricultural practices by analyzing data and making informed decisions. RBTs play a crucial role in precision farming by collecting data on soil conditions, crop health, and weather patterns. This data can be used to optimize irrigation, fertilization, and pesticide application, leading to improved crop yields and reduced environmental impact.

- Data Collection and Analysis: RBTs equipped with sensors can collect real-time data on soil moisture, nutrient levels, and plant growth. This data is analyzed to identify areas that require specific interventions, such as irrigation or fertilization.

- Variable-Rate Application: RBTs can be used to apply fertilizers, pesticides, and other inputs at varying rates based on the specific needs of different areas within a field. This ensures that inputs are used efficiently and reduces waste.

- Precision Planting: RBTs can be used to plant seeds at precise depths and spacings, optimizing plant growth and maximizing yields. This also reduces the need for manual labor.

Crop Harvesting

RBTs are increasingly being used for crop harvesting, automating tasks that were traditionally performed by human workers. This not only increases efficiency but also reduces labor costs and improves safety.

- Autonomous Harvesting: RBTs can be programmed to harvest crops autonomously, following pre-defined paths and identifying ripe fruits or vegetables. This allows for continuous harvesting, even during night hours.

- Selective Harvesting: RBTs can be equipped with sensors to identify and harvest only ripe or mature crops, minimizing damage to the remaining plants. This improves crop quality and reduces waste.

- Increased Efficiency: RBTs can harvest crops at a much faster rate than humans, increasing overall efficiency and reducing labor costs.

Livestock Management

RBTs are transforming livestock management by providing real-time data on animal health, behavior, and productivity. This data can be used to improve animal welfare, optimize feed and water consumption, and enhance disease prevention.

- Animal Monitoring: RBTs can be used to monitor animal health, such as body temperature, heart rate, and movement patterns. This allows for early detection of illness and prompt treatment.

- Automated Feeding and Watering: RBTs can be used to automate the delivery of feed and water to livestock, ensuring consistent access to resources and reducing labor requirements.

- Precision Breeding: RBTs can be used to collect data on animal genetics and performance, facilitating more efficient breeding programs. This can lead to improved animal health and productivity.

RBT Technology in Logistics and Transportation

RBT technology is revolutionizing the logistics and transportation industry, automating processes, optimizing efficiency, and enhancing safety. From warehouse automation to delivery systems and autonomous vehicles, RBTs are transforming how goods are moved and delivered.

Warehouse Automation

RBTs are playing a crucial role in automating warehouse operations, enhancing efficiency, and reducing operational costs.

- Picking and Packing: Robots equipped with advanced vision systems and grippers can identify, pick, and pack items with precision and speed, significantly improving order fulfillment rates.

- Inventory Management: RBTs can scan and track inventory levels in real-time, providing accurate data for inventory management and reducing stockouts.

- Material Handling: Automated guided vehicles (AGVs) and robotic arms are used for transporting materials within warehouses, minimizing manual labor and optimizing workflow.

Delivery Systems

RBTs are transforming delivery systems, making them faster, more efficient, and more reliable.

- Drone Delivery: Drones are increasingly used for delivering packages, especially in remote areas or congested urban environments, reducing delivery times and improving accessibility.

- Autonomous Delivery Vehicles: Self-driving delivery vehicles are being tested and deployed in various locations, promising to revolutionize last-mile delivery, reduce traffic congestion, and improve delivery efficiency.

- Automated Sorting Systems: RBTs are used in sorting centers to efficiently sort and route packages, optimizing delivery routes and reducing delivery times.

Autonomous Vehicles

Autonomous vehicles are poised to transform the transportation industry, offering significant benefits in terms of safety, efficiency, and sustainability.

- Freight Transportation: Autonomous trucks are being developed to transport goods over long distances, reducing driver fatigue, improving fuel efficiency, and enhancing safety.

- Public Transportation: Autonomous buses and trains are being tested and deployed in various cities, offering potential to improve public transportation services, reduce congestion, and enhance accessibility.

RBT Technology Challenges and Future Directions

RBT technology holds immense promise for revolutionizing various industries, but its widespread adoption faces several challenges. This section explores the key obstacles hindering RBT implementation, discusses the ethical implications of its use, and delves into the exciting future directions of this transformative technology.

Challenges in RBT Development and Implementation

Developing and implementing RBT technology involves overcoming significant challenges. These challenges stem from various factors, including technical limitations, cost considerations, and the need for robust safety protocols.

- Technical limitations: RBTs are complex systems that require sophisticated software and hardware, making them susceptible to technical glitches and errors. Ensuring the reliability and accuracy of these systems is crucial for their successful operation.

- High development and implementation costs: The development and deployment of RBT technology often involve substantial financial investments. The cost of hardware, software, and integration can be a barrier for smaller businesses and organizations.

- Safety and security concerns: As RBTs interact with their environment and potentially work alongside humans, safety and security are paramount. Ensuring that these systems operate safely and securely without posing risks to humans or the environment is a critical challenge.

- Lack of standardized protocols: The absence of standardized protocols for interoperability between different RBT systems can hinder their integration and adoption. Developing standardized protocols can promote compatibility and facilitate wider adoption.

Ethical Considerations of RBT Technology

The use of RBT technology raises important ethical considerations, particularly concerning the potential for job displacement and privacy concerns.

- Job displacement: One of the most significant ethical concerns associated with RBT technology is the potential for job displacement. As RBTs become more sophisticated and capable of performing tasks previously done by humans, there is a risk of job losses in certain sectors. This raises questions about the social and economic impact of automation and the need for retraining and upskilling programs.

- Privacy concerns: RBTs often collect and process vast amounts of data, which can raise concerns about privacy. Ensuring that data collected by RBTs is used responsibly and ethically is crucial.

Future Directions of RBT Technology

RBT technology is rapidly evolving, driven by advancements in artificial intelligence (AI), robotics, and sensor technology. These advancements are paving the way for even more sophisticated and versatile RBT systems.

- Advancements in AI: AI is playing a crucial role in enhancing the capabilities of RBTs. Advancements in machine learning, deep learning, and computer vision are enabling RBTs to perform more complex tasks, learn from experience, and adapt to changing environments.

- Robotics advancements: Robotics technology is continuously evolving, leading to the development of more agile, precise, and adaptable robots. Advancements in areas like robotic manipulation, locomotion, and sensor technology are contributing to the development of more sophisticated RBT systems.

- Sensor technology: Sensor technology is playing a critical role in enabling RBTs to perceive and interact with their environment. Advancements in sensor technology, including lidar, radar, and vision systems, are allowing RBTs to gather more data, improve their perception, and navigate complex environments.

Outcome Summary: Rbt Technology

RBT technology represents a paradigm shift in the way we work, interact, and live. Its transformative power extends far beyond individual industries, ushering in a new era of automation, efficiency, and collaboration. As RBT technology continues to evolve, we can expect to see even more groundbreaking applications, pushing the boundaries of human ingenuity and redefining the landscape of our future.

RBT technology, or Robotic Process Automation, is revolutionizing industries by automating repetitive tasks. This can free up human employees to focus on more strategic work. One interesting application of RBT technology is in the realm of aroma technologies , where robots can be used to precisely blend and dispense essential oils for aromatherapy products.

This kind of automation ensures consistent quality and efficiency in the production of these products, while also minimizing human error.