Plastics Plus Technology: Shaping the Future

Plastics plus technology takes center stage, ushering in an era where innovation and sustainability intertwine. From the humble beginnings of synthetic polymers to the cutting-edge advancements in bioplastics and smart […]

Plastics plus technology takes center stage, ushering in an era where innovation and sustainability intertwine. From the humble beginnings of synthetic polymers to the cutting-edge advancements in bioplastics and smart materials, plastics have become integral to our lives. This exploration delves into the fascinating evolution of plastics, highlighting the technological advancements that have propelled them into the forefront of modern society.

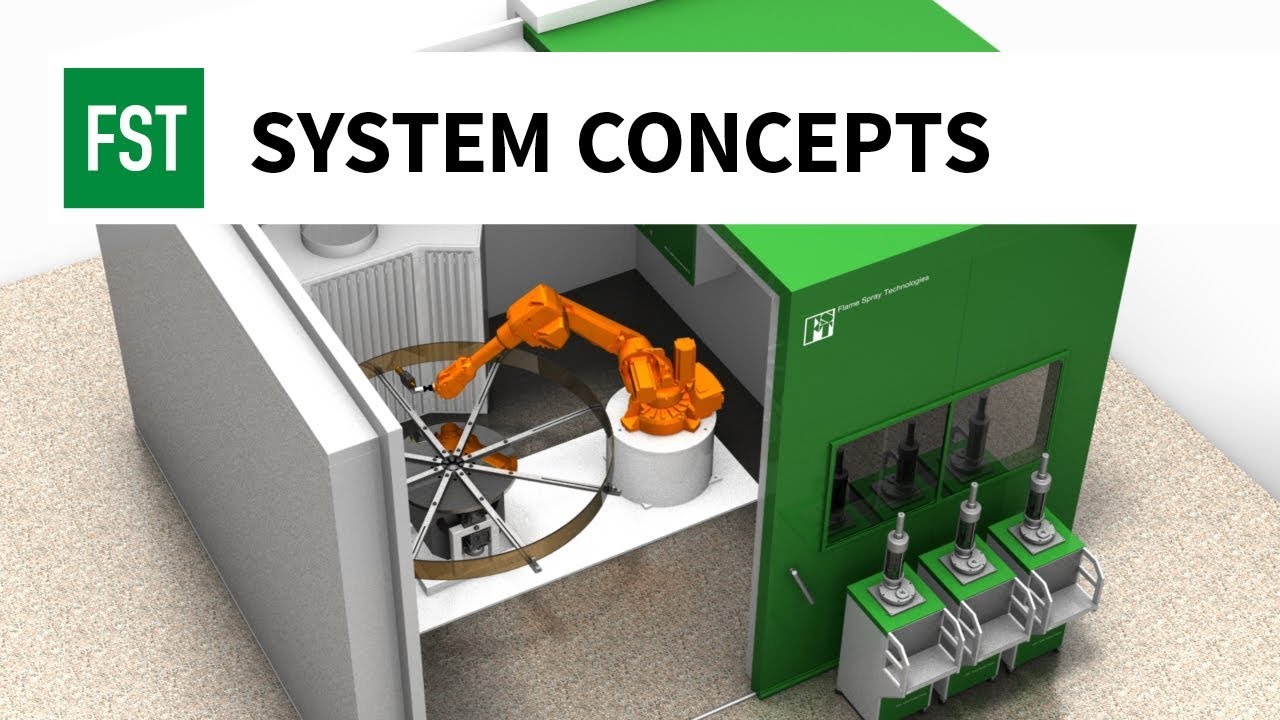

We will examine the impact of nanotechnology, the rise of bioplastics, and the development of biodegradable and compostable alternatives. We’ll also explore the diverse manufacturing processes used to create plastic products, from traditional injection molding to the revolutionary world of 3D printing. The versatility of plastics is evident in their widespread applications across various industries, including packaging, construction, automotive, and healthcare.

The Evolution of Plastics: Plastics Plus Technology

Plastics have revolutionized countless industries, from packaging and construction to healthcare and electronics. Their journey from humble beginnings to sophisticated materials is a testament to human ingenuity and the constant pursuit of innovation.

The Birth of Plastics, Plastics plus technology

The first synthetic plastic, Bakelite, was invented in 1907 by Leo Baekeland. This groundbreaking material, derived from formaldehyde and phenol, ushered in the era of synthetic polymers. Bakelite’s unique properties, including its heat resistance and electrical insulation, made it ideal for various applications, such as electrical components and phone receivers.

The Rise of Thermoplastics

The discovery of thermoplastics in the early 20th century marked a significant milestone in the evolution of plastics. Unlike thermosets, thermoplastics can be repeatedly softened by heating and reshaped, making them highly versatile.

Types of Thermoplastics and Their Applications

- Polyethylene (PE): One of the most widely used plastics, polyethylene is known for its flexibility, durability, and low cost. It finds applications in packaging, films, and bottles.

- Polypropylene (PP): This strong and lightweight thermoplastic is used in a wide range of applications, including containers, fibers, and automotive parts.

- Polyvinyl Chloride (PVC): PVC is a versatile plastic with excellent durability and weather resistance. It is commonly used in pipes, flooring, and window frames.

- Polystyrene (PS): Known for its insulation properties, polystyrene is used in packaging, insulation, and disposable cups.

The Advent of Advanced Polymers

The development of advanced polymers in the latter half of the 20th century opened up new frontiers in materials science. These high-performance polymers possess exceptional properties, such as high strength, heat resistance, and chemical resistance.

Examples of Advanced Polymers

- Polycarbonate (PC): This strong and transparent thermoplastic is used in bulletproof glass, optical lenses, and compact discs.

- Polyethylene Terephthalate (PET): PET is a durable and recyclable plastic commonly used in beverage bottles, clothing fibers, and food packaging.

- Polytetrafluoroethylene (PTFE): PTFE, also known as Teflon, is a non-stick material with excellent chemical resistance and low friction. It is used in cookware, bearings, and electrical insulation.

Conclusive Thoughts

As we look toward the future, the fusion of plastics and technology promises even more groundbreaking possibilities. The emergence of smart plastics with integrated sensors and electronics holds immense potential for transforming industries and enhancing our daily lives. The integration of artificial intelligence and machine learning will optimize plastic production and recycling, paving the way for a more sustainable future. Through ongoing research and development, we can expect to witness the creation of new plastics with extraordinary properties and functionalities, pushing the boundaries of what’s possible.

The combination of plastics and technology has led to some incredible innovations, from lightweight and durable smartphones to advanced medical devices. This same combination is also driving advancements in law enforcement technology, with companies like Halo Technologies creating robust and reliable body cameras.

The Halo Technologies body camera is a prime example, utilizing durable plastic casings to withstand the rigors of everyday use while offering cutting-edge video recording capabilities. This fusion of plastics and technology is shaping the future of law enforcement, ensuring officers have the tools they need to protect and serve their communities.