PDR Technology: Repairing the Future

PDR technology, short for Paintless Dent Removal, has revolutionized the automotive repair industry. This innovative technique, utilizing specialized tools and techniques, allows technicians to remove dents and dings without the […]

PDR technology, short for Paintless Dent Removal, has revolutionized the automotive repair industry. This innovative technique, utilizing specialized tools and techniques, allows technicians to remove dents and dings without the need for traditional bodywork, paint, or sanding. The benefits of PDR are numerous, including faster repair times, reduced costs, and a more environmentally friendly approach to car repair.

The history of PDR dates back to the early 20th century, with advancements in tools and techniques occurring throughout the decades. Today, PDR is widely used by professionals across the globe, with its applications extending beyond automobiles to include aircraft, appliances, and other industries.

Introduction to PDR Technology

Paintless dent repair (PDR) is a specialized technique used to remove dents and dings from vehicles without the need for traditional bodywork, such as sanding, filling, and repainting. It involves using specialized tools to gently massage the metal back into its original shape, preserving the original paint finish.

PDR is a relatively new technology that has gained significant popularity in recent years due to its cost-effectiveness, efficiency, and minimal environmental impact.

History of PDR Technology

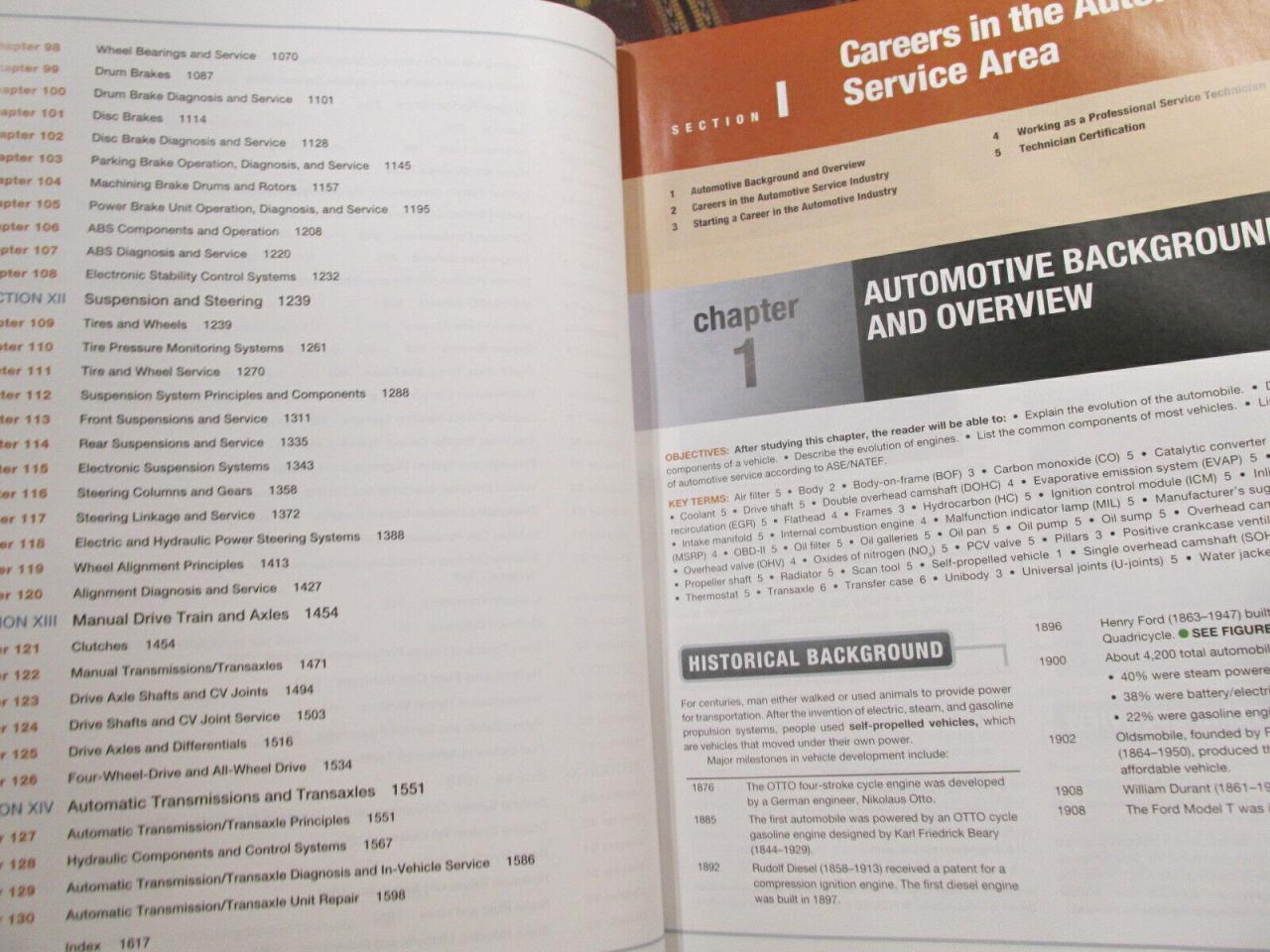

PDR technology emerged in the 1950s, initially developed by auto body repair technicians who sought more efficient ways to repair minor dents. Early PDR tools were rudimentary, often consisting of simple wooden or metal rods. The technique gained traction in the 1970s and 1980s as specialized tools and techniques were developed, allowing for more complex repairs. Today, PDR has become a widely accepted and practiced technique, with specialized training programs and certifications available for technicians.

Applications of PDR Technology

PDR is primarily used in the automotive industry to repair dents and dings on vehicles. However, its applications extend to other industries as well, including:

- Aerospace: PDR techniques are used to repair dents and dings on aircraft panels, preserving the structural integrity and aerodynamic properties of the aircraft.

- Manufacturing: PDR is used to repair dents and dings on metal components and parts during the manufacturing process, reducing waste and improving efficiency.

- Construction: PDR techniques can be used to repair dents and dings on metal structures, such as roofing panels and siding.

Benefits of PDR Technology

PDR offers numerous benefits over traditional bodywork methods:

- Cost-Effectiveness: PDR is generally less expensive than traditional bodywork, as it eliminates the need for paint and labor associated with sanding, filling, and repainting.

- Efficiency: PDR repairs can be completed much faster than traditional bodywork, reducing downtime for vehicle owners and increasing productivity for repair shops.

- Preservation of Original Paint: PDR avoids the need for repainting, preserving the original paint finish and maintaining the vehicle’s value.

- Environmental Friendliness: PDR eliminates the use of paint, fillers, and other chemicals associated with traditional bodywork, reducing environmental impact.

Types of PDR Tools

PDR technicians utilize a variety of specialized tools to achieve the desired results:

- Glue Pullers: These tools involve attaching a special glue tab to the dent and then pulling it out using a specialized pulling tool. Glue pullers are effective for removing dents that are relatively shallow and accessible.

- Slide Hammers: Slide hammers consist of a hammer head that slides along a rod, allowing the technician to apply controlled force to the dent. Slide hammers are used for deeper dents and can be used in conjunction with other tools.

- Rods and Hooks: These tools are used to access dents that are located in hard-to-reach areas. They are often used in conjunction with other tools to manipulate the metal from the inside.

Types of PDR Technology

Paintless dent repair (PDR) technology encompasses various methods for removing dents and dings from vehicles without resorting to traditional bodywork techniques. These methods can be broadly categorized into traditional and advanced approaches, each with its unique tools, techniques, and benefits.

Traditional PDR Methods

Traditional PDR methods rely on manual techniques and tools to manipulate the metal back to its original shape. These methods are often used for smaller dents and require a skilled technician to achieve optimal results.

- Slide Hammer Technique: This technique involves using a slide hammer, a specialized tool with a weighted head that is attached to a hook or suction cup. The technician pulls the slide hammer, generating force that pulls the dent outward. This method is effective for shallow dents, but it may not be suitable for deep or complex dents.

- Glue Pull Technique: This method involves attaching a specialized glue tab to the dent and then pulling it with a specialized tool. The glue tab adheres strongly to the metal and allows the technician to apply controlled force to the dent. This technique is effective for dents of various sizes and depths, but it may leave a small glue residue that needs to be cleaned.

- Manual Pushing and Pulling: This technique involves using specialized tools to push and pull the metal back into its original shape. The technician uses a combination of leverage, pressure, and finesse to manipulate the dent. This method is effective for dents in various locations, but it requires a high level of skill and experience.

Advanced PDR Methods

Advanced PDR methods utilize specialized tools and techniques to enhance the effectiveness and efficiency of dent removal. These methods often employ technology to assist the technician in achieving optimal results.

- Heat-Assisted PDR: This method involves applying heat to the dented area to make the metal more malleable. The heat softens the metal, allowing the technician to manipulate it more easily. This technique is effective for dents in thicker metal panels and can help to reduce the risk of damage to the surrounding paint.

- Light-Assisted PDR: This method uses specialized lighting to illuminate the dent and reveal its contours. The light helps the technician to visualize the dent’s shape and depth, making it easier to manipulate the metal back to its original shape. This technique is particularly useful for dents in complex areas or those that are difficult to access.

- Robotic PDR: This emerging technology utilizes robots equipped with specialized tools to perform PDR. The robots are programmed to follow specific paths and apply precise forces to the dent. This method is still in its early stages of development, but it has the potential to automate the PDR process and improve efficiency.

Applications of PDR Technology

PDR technology finds widespread application across various industries, offering a comprehensive approach to solving real-world problems. This technology is employed in diverse fields, from automotive repair to aerospace engineering, leveraging its unique capabilities to address challenges related to damage repair, material restoration, and surface restoration.

Automotive Industry

The automotive industry is a prominent user of PDR technology. PDR techniques are widely employed in auto body shops to repair dents and dings on vehicles without resorting to traditional bodywork methods like sanding, priming, and painting. This process is often faster and more cost-effective than traditional methods, minimizing the need for extensive repairs and reducing the overall repair time.

- Dent Removal: PDR is used to remove dents and dings from vehicle panels without damaging the original paint. This process involves using specialized tools to push the dent from the inside out, restoring the panel to its original shape.

- Hail Damage Repair: Hail damage can cause significant dents on vehicles. PDR is a preferred method for repairing hail damage as it preserves the original paint and avoids the need for extensive bodywork.

- Door Dings: Minor dents caused by door dings are easily repaired using PDR techniques. This process involves using specialized tools to access the dent from behind the panel and carefully push it back into place.

Aerospace Industry

PDR technology is increasingly used in the aerospace industry to repair damage to aircraft structures. This technology is particularly valuable for repairing composite materials, which are commonly used in modern aircraft.

- Composite Material Repair: PDR techniques are effective in repairing dents and dings on composite panels, which are susceptible to damage during handling and operation. This process involves using specialized tools to carefully push the damaged area back into its original shape, restoring the structural integrity of the panel.

- Aircraft Skin Repair: PDR can be used to repair minor damage to aircraft skin, such as dents, scratches, and impact marks. This method avoids the need for extensive repairs and reduces the time required to return the aircraft to service.

Other Industries

PDR technology finds applications in various other industries, including:

- Manufacturing: PDR is used in manufacturing to repair dents and dings on metal parts and components, minimizing waste and reducing production downtime.

- Construction: PDR techniques are employed in construction to repair damaged metal panels, roofing, and other structural components. This process minimizes the need for replacement and reduces repair costs.

- Marine Industry: PDR is used to repair dents and scratches on boats and other marine vessels, restoring the structural integrity and aesthetic appeal of the vessel.

- Aerospace: PDR could be used to repair composite materials used in aircraft, reducing downtime and repair costs.

- Construction: PDR could be used to repair concrete structures, minimizing damage and improving safety.

- Medical Devices: PDR could be used to repair delicate medical devices, ensuring their functionality and safety.

- Short Term (2-5 years): Increased use of AI-powered PDR systems, robotic arms, and advanced imaging techniques for precise damage assessment.

- Mid Term (5-10 years): Development of self-repairing materials that can automatically heal minor dents and scratches.

- Long Term (10+ years): Integration of PDR technology into autonomous vehicles, enabling self-repair capabilities.

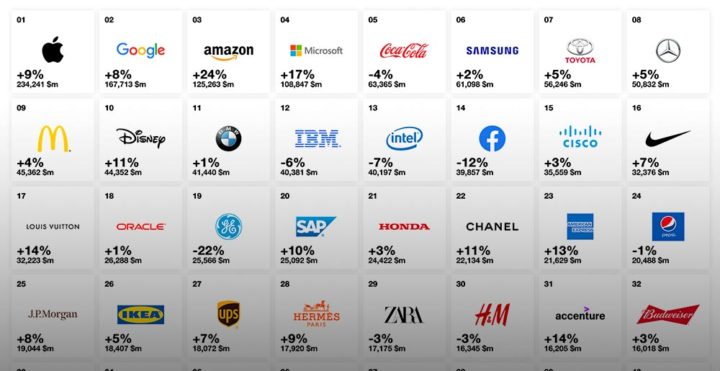

Table of Applications

| Industry | Applications |

|---|---|

| Automotive | Dent removal, hail damage repair, door dings |

| Aerospace | Composite material repair, aircraft skin repair |

| Manufacturing | Repair of metal parts and components |

| Construction | Repair of metal panels, roofing, and other structural components |

| Marine | Repair of dents and scratches on boats and other marine vessels |

Future Trends in PDR Technology

PDR technology is a rapidly evolving field, driven by advancements in artificial intelligence, robotics, and materials science. The future of PDR holds exciting possibilities for transforming various industries and creating new opportunities.

Emerging Technologies and Advancements

The integration of emerging technologies like artificial intelligence (AI) and robotics is expected to significantly enhance PDR capabilities. AI algorithms can analyze damage patterns and recommend optimal repair strategies, while robotic arms can execute repairs with precision and speed. This combination will lead to more efficient and effective PDR processes.

Potential Future Applications of PDR

The application of PDR technology is expected to expand beyond traditional automotive repair. Here are some potential future applications:

Timeline of PDR Technology Evolution

The evolution of PDR technology is expected to follow a trajectory marked by advancements in automation, precision, and material science.

Last Word

PDR technology represents a significant leap forward in the field of automotive repair, offering a sustainable and efficient solution for dent removal. As technology continues to advance, we can expect even more innovative PDR techniques and applications to emerge, further enhancing the efficiency and cost-effectiveness of this remarkable process.

PDR technology, or Predictive Dialer Routing, is a powerful tool for optimizing call center operations. It leverages data analytics to connect callers with the most relevant agents, improving customer satisfaction and agent efficiency. Companies like sichuan ai-link technology co.

ltd , a leading provider of AI-powered solutions, are at the forefront of developing innovative PDR solutions that enhance customer engagement and drive business growth. By implementing advanced algorithms and machine learning techniques, these solutions can significantly enhance the effectiveness of call centers, leading to improved customer experiences and increased productivity.