Operational Technology Manager: Bridging IT and Industrial Processes

Operational technology managers are the crucial link between information technology (IT) and industrial processes, ensuring the smooth and secure operation of complex systems in various industries. They play a vital […]

Operational technology managers are the crucial link between information technology (IT) and industrial processes, ensuring the smooth and secure operation of complex systems in various industries. They play a vital role in optimizing performance, mitigating risks, and driving innovation in a rapidly evolving technological landscape.

Their responsibilities encompass a wide range of areas, from managing and securing critical infrastructure to integrating systems and automating processes. As industries increasingly rely on interconnected networks and advanced technologies, the demand for skilled operational technology managers continues to grow.

Role and Responsibilities of an Operational Technology Manager

An Operational Technology (OT) Manager is a crucial role in organizations that rely heavily on industrial control systems and automation. They are responsible for the smooth operation, maintenance, and security of these systems, ensuring production efficiency and safety.

Core Responsibilities of an Operational Technology Manager

The core responsibilities of an OT Manager encompass various aspects of operational technology, including:

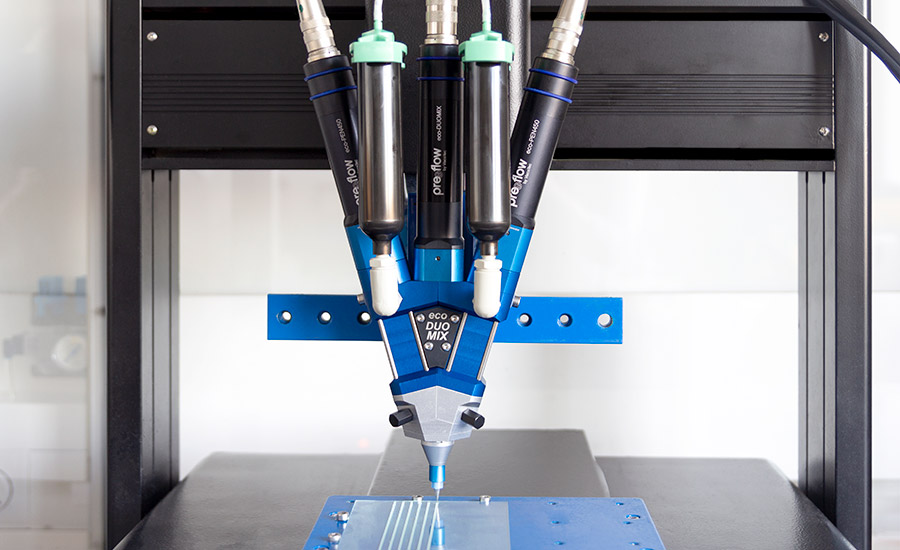

- System Design and Implementation: Planning, designing, and implementing new OT systems or upgrades to existing ones, ensuring they meet the organization’s operational requirements.

- System Maintenance and Support: Overseeing the day-to-day maintenance and support of OT systems, including troubleshooting issues, performing regular backups, and implementing security updates.

- Security Management: Developing and implementing robust security protocols for OT systems to protect against cyber threats and data breaches. This includes vulnerability assessments, penetration testing, and incident response planning.

- Performance Optimization: Monitoring and analyzing OT system performance, identifying areas for improvement, and implementing solutions to enhance efficiency and reliability.

- Compliance and Standards: Ensuring that OT systems adhere to relevant industry standards and regulations, including safety, environmental, and cybersecurity compliance.

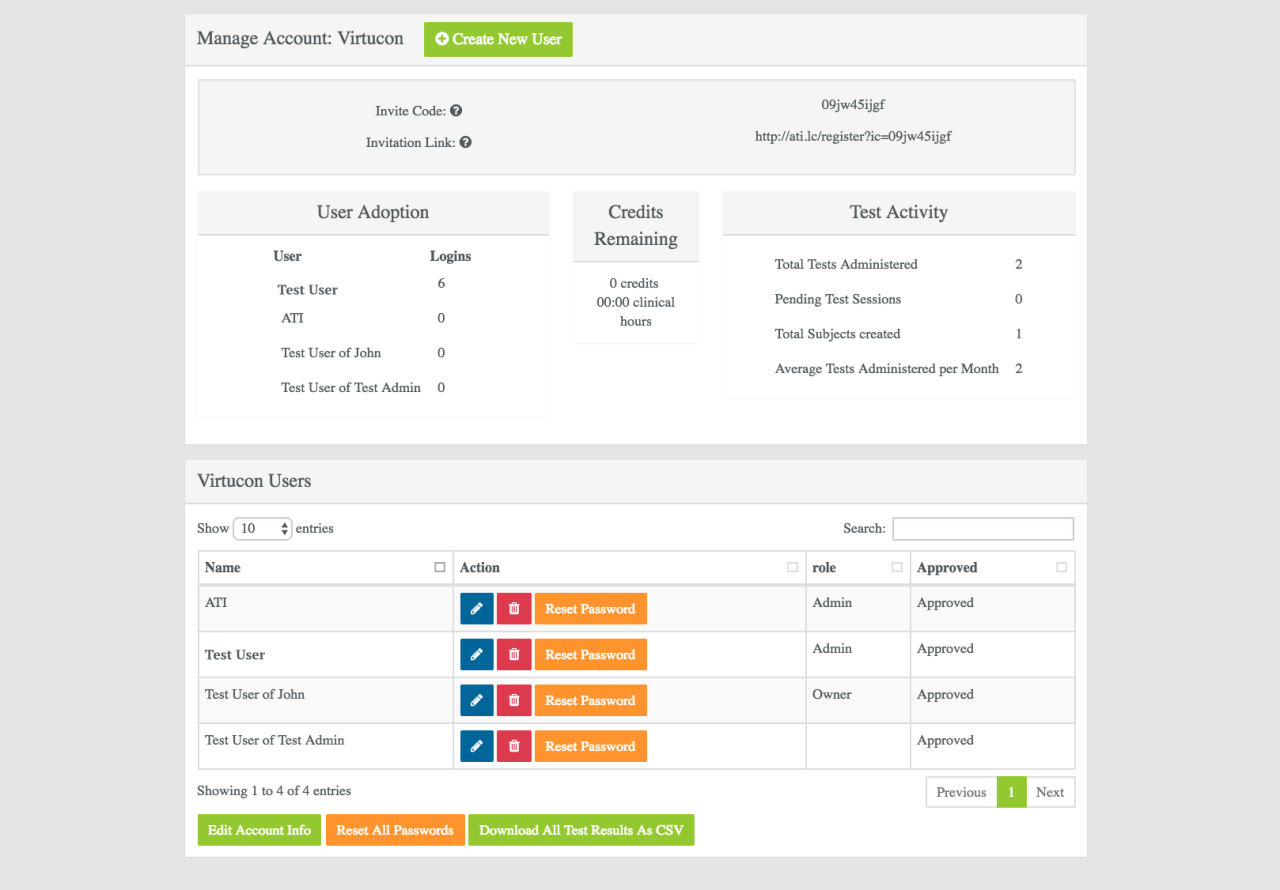

- Team Management: Leading and managing a team of OT engineers and technicians, providing guidance, training, and support.

- Budget Management: Developing and managing the OT budget, ensuring efficient resource allocation and cost control.

Key Skills and Qualifications

To succeed in this role, an OT Manager needs a combination of technical expertise and leadership skills:

- Strong Technical Background: A deep understanding of OT systems, including hardware, software, and communication protocols. This might include knowledge of industrial automation systems (PLC, DCS, SCADA), networking, cybersecurity, and data analytics.

- Problem-Solving Skills: The ability to diagnose and resolve complex technical issues in a timely and efficient manner, often under pressure.

- Communication and Collaboration Skills: Excellent communication skills to effectively interact with colleagues from various departments, including IT, engineering, and operations, as well as external stakeholders.

- Leadership and Management Skills: The ability to lead and motivate a team, delegate tasks, and provide constructive feedback.

- Project Management Skills: Experience in managing complex projects, including planning, execution, and monitoring.

- Continuous Learning: The willingness and ability to stay updated with the latest advancements in OT technologies and best practices.

Typical Day-to-Day Tasks and Challenges

The day-to-day tasks of an OT Manager can vary depending on the specific industry and organization. However, some common tasks and challenges include:

- Troubleshooting and resolving technical issues: Responding to alarms, diagnosing system failures, and implementing corrective actions. This might involve working with engineers and technicians to identify the root cause of the problem and implement a solution.

- Monitoring system performance: Analyzing system logs, dashboards, and other data to identify potential issues and areas for improvement. This might involve developing and implementing performance metrics to track key indicators.

- Implementing security updates and patches: Staying informed about security vulnerabilities and applying necessary updates to OT systems to mitigate risks. This requires a strong understanding of cybersecurity best practices and the ability to manage security risks effectively.

- Collaborating with other departments: Working closely with IT, engineering, and operations teams to ensure smooth integration and coordination of OT systems with other business processes. This might involve attending meetings, providing technical expertise, and resolving interdepartmental issues.

- Managing projects and budgets: Planning and overseeing OT projects, ensuring they are completed on time and within budget. This involves coordinating resources, managing timelines, and monitoring progress.

- Staying informed about industry trends: Keeping up-to-date with the latest developments in OT technologies, security best practices, and industry regulations. This might involve attending conferences, reading industry publications, and participating in professional development activities.

Importance of Collaboration with Other Departments

Effective collaboration with other departments is essential for an OT Manager to succeed. This is because OT systems are often integrated with other business processes, such as IT infrastructure, production processes, and supply chain management.

- IT Department: Collaboration with the IT department is crucial for ensuring the security and compatibility of OT systems with the overall IT infrastructure. This might involve coordinating security updates, managing network connectivity, and implementing data sharing protocols.

- Engineering Department: Working closely with the engineering department is essential for understanding the technical requirements of OT systems and ensuring they meet the needs of production processes. This might involve collaborating on system design, troubleshooting issues, and implementing process improvements.

- Operations Department: Strong communication with the operations department is vital for understanding operational needs and ensuring OT systems are effectively supporting production processes. This might involve providing training, resolving operational issues, and collaborating on process optimization.

Final Summary: Operational Technology Manager

In conclusion, the role of an operational technology manager is both challenging and rewarding. By combining technical expertise with strong leadership and communication skills, these professionals are instrumental in shaping the future of industrial operations. As the world becomes increasingly reliant on technology, the importance of skilled OT managers will only continue to rise.

An operational technology manager is responsible for overseeing the technology that keeps a company’s operations running smoothly. This can include everything from industrial control systems to data analytics platforms. To stay ahead of the curve, operational technology managers should be familiar with the latest advancements in the field.

A great resource for this is the directory of technology , which provides a comprehensive overview of emerging technologies and their applications. By staying informed about these advancements, operational technology managers can ensure that their organizations are using the most efficient and effective technology possible.