Micro Etch Technologies: Shaping the Future

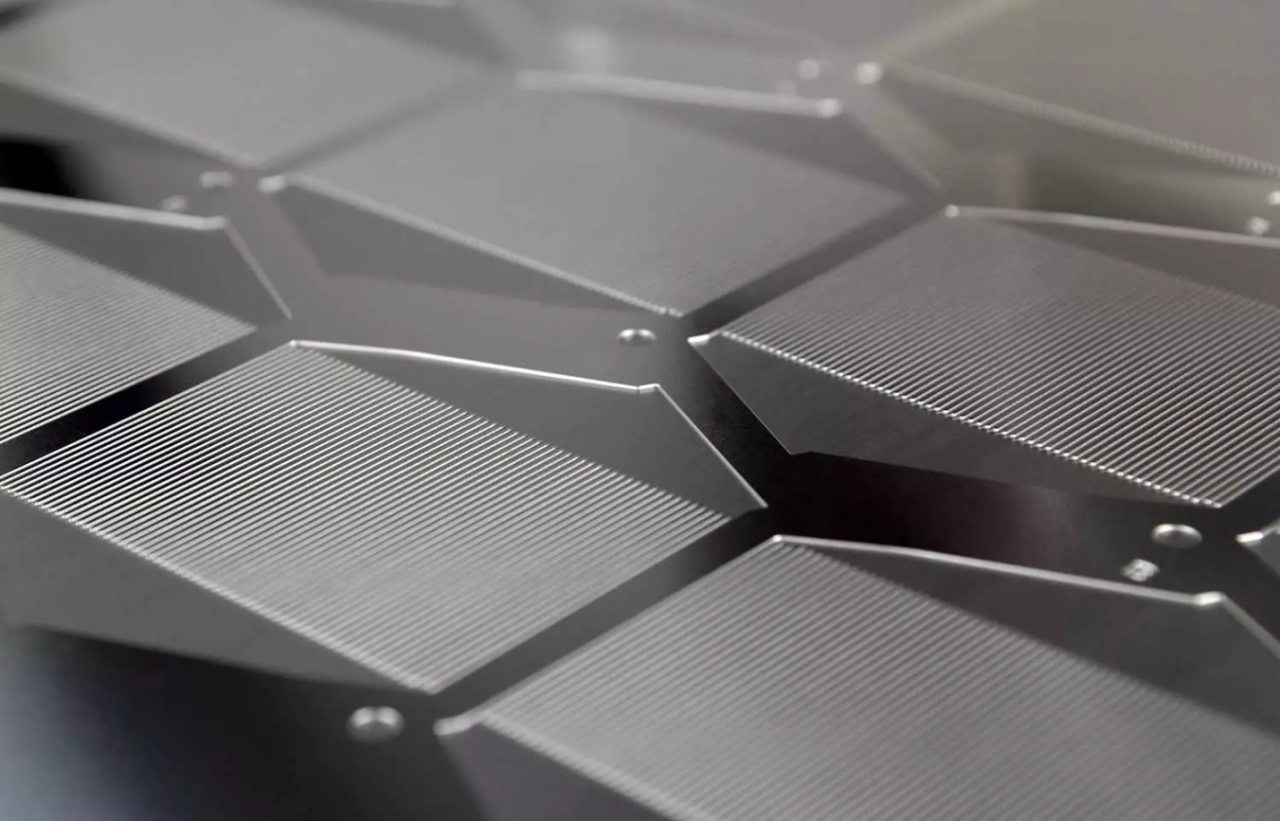

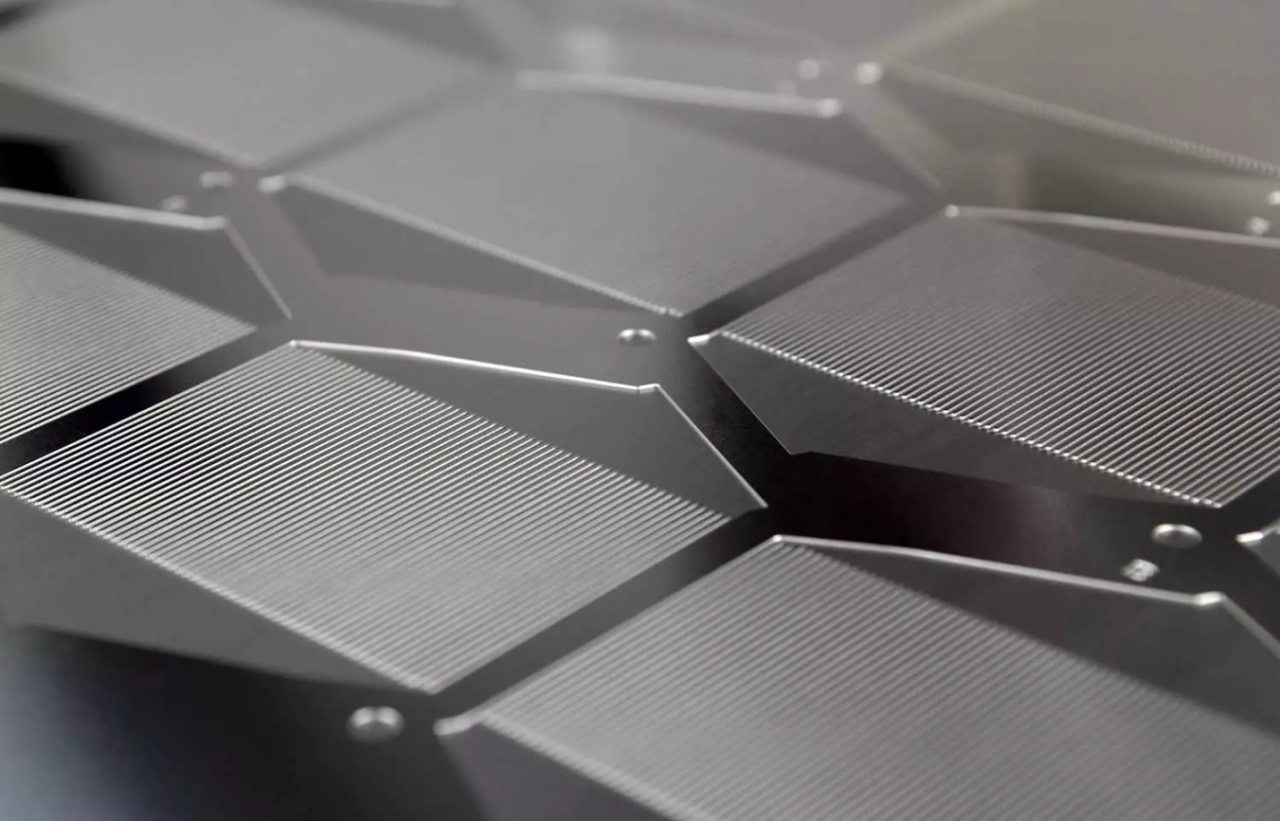

Micro etch technologies are revolutionizing industries by enabling the creation of intricate and highly precise structures at the microscopic level. These techniques, often referred to as microfabrication, involve the selective […]

Micro etch technologies are revolutionizing industries by enabling the creation of intricate and highly precise structures at the microscopic level. These techniques, often referred to as microfabrication, involve the selective removal of material from a substrate using a variety of methods, including wet etching, dry etching, and plasma etching. The history of micro-etching dates back to the early days of semiconductor manufacturing, and its impact on our world continues to grow with each advancement.

Micro-etching plays a crucial role in the development of microfluidic devices, which are used in a wide range of applications, from drug delivery and diagnostics to lab-on-a-chip systems. Additionally, micro-etching techniques are essential for the fabrication of micro-sensors and micro-actuators, which are critical components in various fields, including aerospace, automotive, and robotics.

Applications of Micro-Etch Technologies

Micro-etch technologies have revolutionized various fields by enabling the creation of intricate microstructures and devices with exceptional precision. These techniques have paved the way for groundbreaking advancements in electronics, optics, biomedicine, and beyond.

Microfluidic Devices

Microfluidic devices are miniature systems that manipulate and control fluids at the microscale. Micro-etching plays a crucial role in the fabrication of these devices, enabling the creation of complex microchannels, chambers, and valves. The precise control over fluid flow within these devices has led to numerous applications in areas such as:

- Lab-on-a-chip systems: Microfluidic devices have revolutionized diagnostic testing by miniaturizing complex laboratory procedures onto a single chip. These systems offer rapid, portable, and cost-effective analysis, enabling point-of-care diagnostics for various diseases.

- Drug delivery: Microfluidic devices can precisely control the release of drugs, enabling targeted delivery and minimizing side effects. Micro-etching allows the creation of microchannels and reservoirs for controlled drug release, enhancing the efficacy of treatments.

- Cell culture and analysis: Microfluidic devices provide a controlled environment for cell culture and analysis, mimicking the conditions of the human body. Micro-etching enables the creation of micro-environments for cell growth and manipulation, facilitating research in tissue engineering and drug discovery.

Micro-Sensors

Micro-sensors are tiny devices that detect and measure physical or chemical parameters, such as temperature, pressure, light, or chemical concentrations. Micro-etching enables the fabrication of these sensors with high sensitivity and accuracy, enabling the development of advanced sensing systems for various applications.

- Environmental monitoring: Micro-sensors can be deployed in the environment to monitor pollutants, toxins, and other parameters, providing real-time data for environmental protection and management.

- Medical diagnostics: Micro-sensors can be used to monitor vital signs, such as heart rate, blood pressure, and glucose levels, enabling continuous health monitoring and early disease detection.

- Industrial process control: Micro-sensors can be integrated into industrial processes to monitor parameters such as temperature, pressure, and flow rate, optimizing production efficiency and safety.

Micro-Actuators, Micro etch technologies

Micro-actuators are miniature devices that convert electrical or chemical energy into mechanical motion. Micro-etching enables the fabrication of these actuators with precise control over their size, shape, and functionality, leading to applications in areas such as:

- Robotics: Micro-actuators are used in the development of miniature robots, allowing for precise manipulation and control in confined spaces. These robots have applications in areas such as medical surgery, micro-assembly, and exploration.

- Microfluidic pumps: Micro-actuators can be used to pump fluids within microfluidic devices, enabling precise control over fluid flow for applications in drug delivery, diagnostics, and lab-on-a-chip systems.

- MEMS devices: Micro-actuators are essential components of Micro-Electro-Mechanical Systems (MEMS), which integrate sensors, actuators, and electronics on a single chip. MEMS devices have applications in various fields, including automotive, aerospace, and consumer electronics.

Advanced Materials and Nanomaterials

Micro-etching plays a vital role in the development of advanced materials and nanomaterials with unique properties. By creating intricate microstructures and nanoscale features, micro-etching enables the modification of material properties such as surface area, conductivity, and optical properties.

- Surface modification: Micro-etching can be used to create patterned surfaces with specific functionalities, such as anti-reflective coatings, superhydrophobic surfaces, and biocompatible surfaces. These modified surfaces have applications in areas such as optics, electronics, and biomedicine.

- Nanomaterial synthesis: Micro-etching can be used to create templates for the synthesis of nanomaterials, such as nanowires, nanoparticles, and nanofilms. These nanomaterials have unique properties and applications in areas such as electronics, energy storage, and catalysis.

- Micro- and nano-fabrication: Micro-etching is a key enabling technology for the fabrication of micro- and nano-scale devices and structures. These devices have applications in various fields, including electronics, optics, and biomedicine.

Conclusion: Micro Etch Technologies

Micro-etch technologies are constantly evolving, with new techniques and applications emerging at an astonishing pace. The future of micro-etching holds immense potential, particularly in areas like quantum computing and artificial intelligence. As we delve deeper into the nanoscale, micro-etching will continue to play a vital role in shaping the world around us, enabling the development of groundbreaking technologies that address some of humanity’s most pressing challenges.

Micro etch technologies are a fascinating field, involving the manipulation of materials at the microscopic level. These techniques have applications in various industries, including medicine. For those interested in learning more about the intersection of technology and healthcare, a great starting point is introduction to surgical technology.

This field explores the use of cutting-edge tools and procedures in the operating room, including those utilizing micro etch technologies.