Metal Technologies at Auburn: Shaping the Future

Metal technologies auburn – Metal Technologies at Auburn University stands as a beacon of innovation, pushing the boundaries of materials science and engineering. This program, steeped in history and dedicated […]

Metal technologies auburn – Metal Technologies at Auburn University stands as a beacon of innovation, pushing the boundaries of materials science and engineering. This program, steeped in history and dedicated to research, offers a comprehensive curriculum that equips students with the knowledge and skills to tackle the challenges of the modern world.

From advanced manufacturing techniques to cutting-edge materials development, Auburn’s metal technologies program delves into the heart of these fields, fostering a culture of collaboration and discovery. Students engage with renowned faculty, state-of-the-art facilities, and industry partners, ensuring they graduate with a deep understanding of the metal technologies landscape and the ability to contribute meaningfully to its future.

Key Metal Technologies at Auburn University

Auburn University is a leading institution in the field of metal technologies, boasting a strong research focus and a wide range of advanced materials expertise. The university’s research efforts contribute significantly to the development and advancement of various metal technologies, leading to innovative applications across diverse industries.

Metal Additive Manufacturing

Metal additive manufacturing, also known as 3D printing, has emerged as a transformative technology in the manufacturing sector. This process involves building three-dimensional objects layer by layer from a computer-aided design (CAD) model using a metal powder or wire. Auburn University researchers are actively involved in exploring various aspects of metal additive manufacturing, including:

- Process optimization: Research focuses on optimizing the parameters of the additive manufacturing process, such as laser power, scan speed, and powder bed temperature, to enhance the quality, efficiency, and cost-effectiveness of the process.

- Material development: Auburn University researchers are investigating the development of new metal alloys and powder materials specifically tailored for additive manufacturing, leading to improved mechanical properties, corrosion resistance, and other desirable characteristics.

- Applications in various industries: The university’s research explores the application of metal additive manufacturing in diverse industries, including aerospace, automotive, medical devices, and energy, showcasing its potential for producing complex geometries, customized designs, and lightweight components.

Metal Joining and Welding

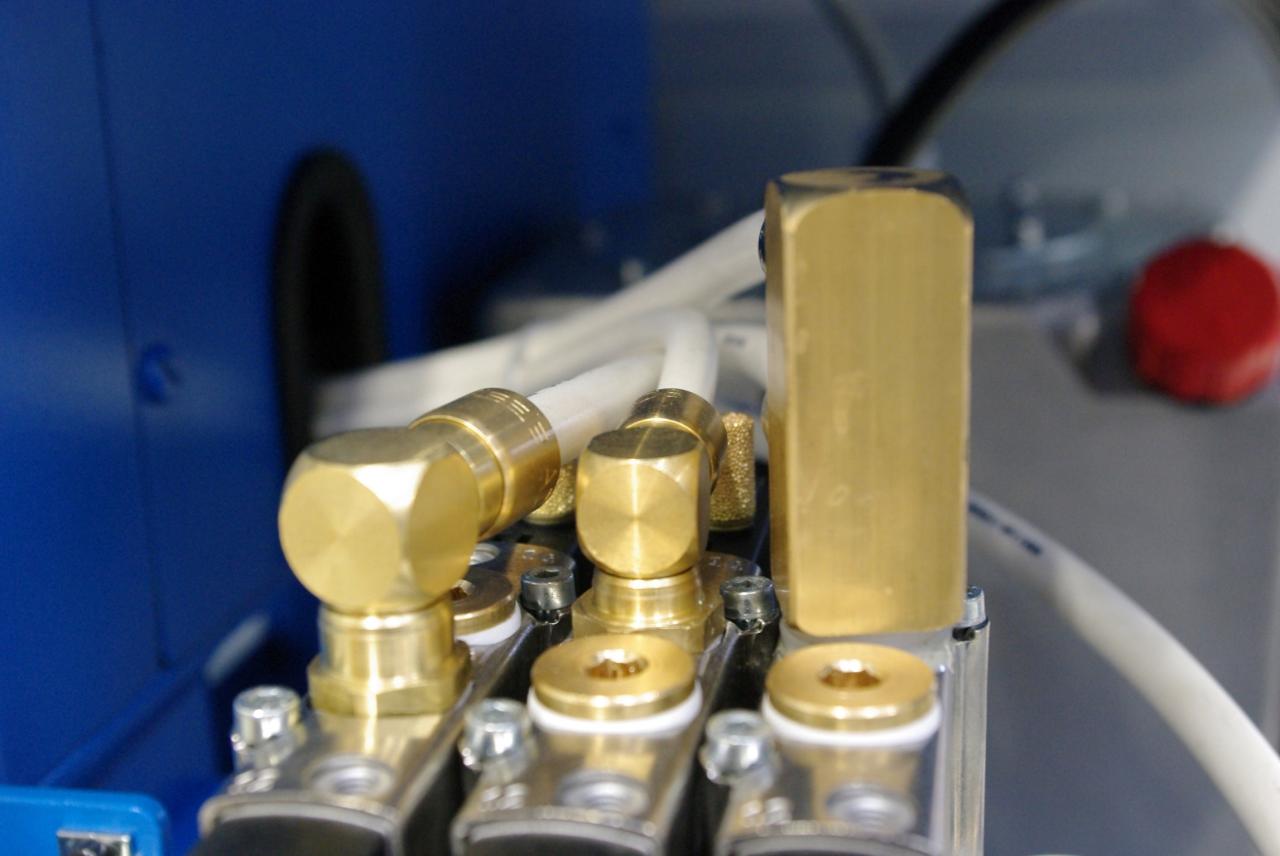

Metal joining and welding are essential processes in various manufacturing sectors, enabling the permanent bonding of metal components. Auburn University researchers are actively involved in exploring advanced welding techniques and investigating the metallurgical aspects of welding processes. Their research focuses on:

- Advanced welding techniques: Auburn University researchers are investigating advanced welding techniques, such as laser welding, electron beam welding, and friction stir welding, to achieve high-quality joints with improved mechanical properties and reduced heat input.

- Welding metallurgy: The research delves into the metallurgical aspects of welding processes, focusing on understanding the microstructure, phase transformations, and residual stresses in welded joints. This research aims to optimize welding parameters to achieve desired properties and minimize defects.

- Applications in critical industries: Auburn University researchers are exploring the applications of advanced welding techniques in critical industries, such as aerospace, nuclear power, and pipeline construction, where reliability and safety are paramount.

Metal Forming and Processing

Metal forming and processing involve shaping and modifying metals into desired forms using various techniques. Auburn University researchers are actively engaged in exploring innovative metal forming and processing techniques, including:

- High-pressure forming: This technique involves applying high pressure to metals to achieve desired shapes and improve mechanical properties. Auburn University researchers are investigating the use of high-pressure forming in various applications, such as automotive components, aerospace parts, and medical devices.

- Roll forming: This process involves bending metal sheets into specific shapes using rollers. Auburn University researchers are investigating the use of roll forming for producing complex geometries and lightweight components, particularly in the automotive and aerospace industries.

- Metal powder processing: Auburn University researchers are exploring the use of metal powders in various processing techniques, including powder metallurgy, metal injection molding, and powder-based additive manufacturing. This research focuses on developing new materials and processes for producing high-performance metal components.

Corrosion and Degradation of Metals

Corrosion is a significant concern in various industries, leading to material degradation and structural failures. Auburn University researchers are actively involved in understanding the mechanisms of corrosion and developing strategies for preventing and mitigating corrosion damage. Their research focuses on:

- Corrosion mechanisms: Auburn University researchers are investigating the various mechanisms of corrosion, including uniform corrosion, pitting corrosion, and stress corrosion cracking, to understand the factors influencing corrosion behavior.

- Corrosion protection: The research focuses on developing effective corrosion protection strategies, including coatings, inhibitors, and cathodic protection, to enhance the durability and lifespan of metal components.

- Corrosion monitoring and diagnostics: Auburn University researchers are developing innovative techniques for monitoring and diagnosing corrosion damage in various environments, enabling early detection and timely intervention to prevent catastrophic failures.

Metal Characterization and Analysis

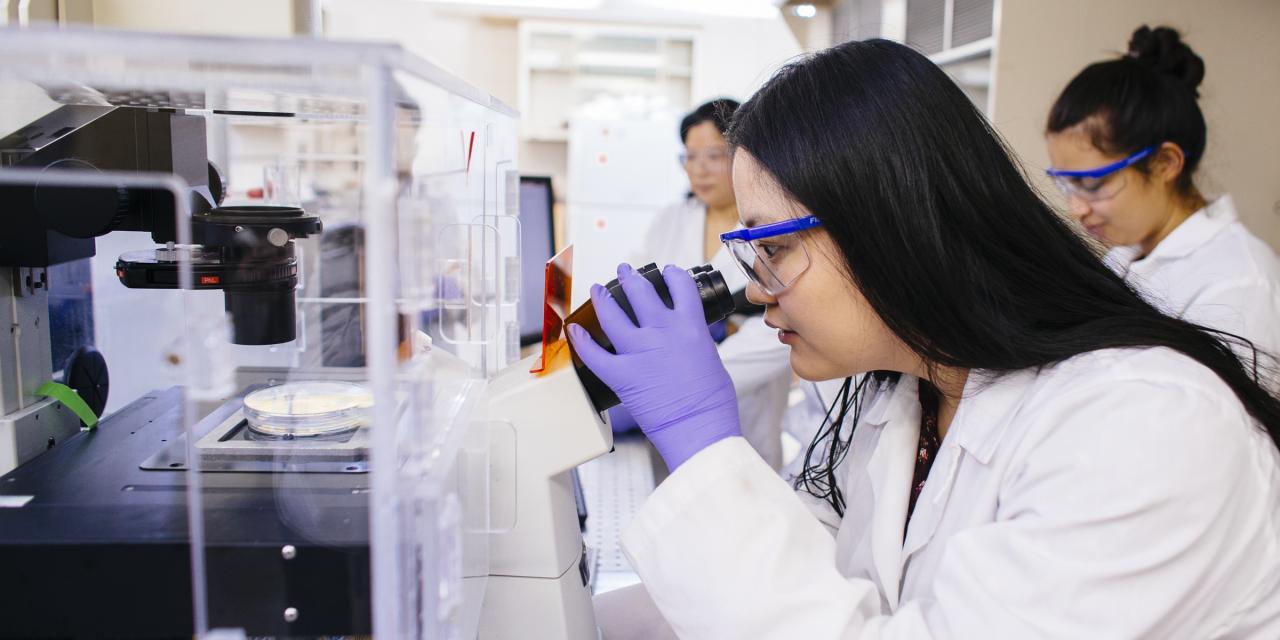

Understanding the microstructure, properties, and behavior of metals is crucial for designing and manufacturing reliable and durable metal components. Auburn University researchers are actively involved in developing and utilizing advanced characterization and analysis techniques to investigate the properties of metals. Their research focuses on:

- Microstructural analysis: Auburn University researchers utilize advanced microscopy techniques, such as scanning electron microscopy (SEM) and transmission electron microscopy (TEM), to investigate the microstructure of metals and understand the relationship between microstructure and properties.

- Mechanical testing: The research involves conducting various mechanical tests, including tensile testing, hardness testing, and fatigue testing, to evaluate the mechanical properties of metals and assess their performance under different loading conditions.

- Chemical analysis: Auburn University researchers utilize various analytical techniques, such as X-ray diffraction (XRD) and X-ray photoelectron spectroscopy (XPS), to determine the chemical composition and phases present in metals.

Table of Key Metal Technologies at Auburn University

| Metal Technology | Applications | Research Projects |

|---|---|---|

| Metal Additive Manufacturing | Aerospace, Automotive, Medical Devices, Energy | Process optimization, Material development, Applications in various industries |

| Metal Joining and Welding | Aerospace, Nuclear Power, Pipeline Construction | Advanced welding techniques, Welding metallurgy, Applications in critical industries |

| Metal Forming and Processing | Automotive, Aerospace, Medical Devices | High-pressure forming, Roll forming, Metal powder processing |

| Corrosion and Degradation of Metals | Various industries | Corrosion mechanisms, Corrosion protection, Corrosion monitoring and diagnostics |

| Metal Characterization and Analysis | Research and development, Quality control | Microstructural analysis, Mechanical testing, Chemical analysis |

Industry Partnerships and Collaboration: Metal Technologies Auburn

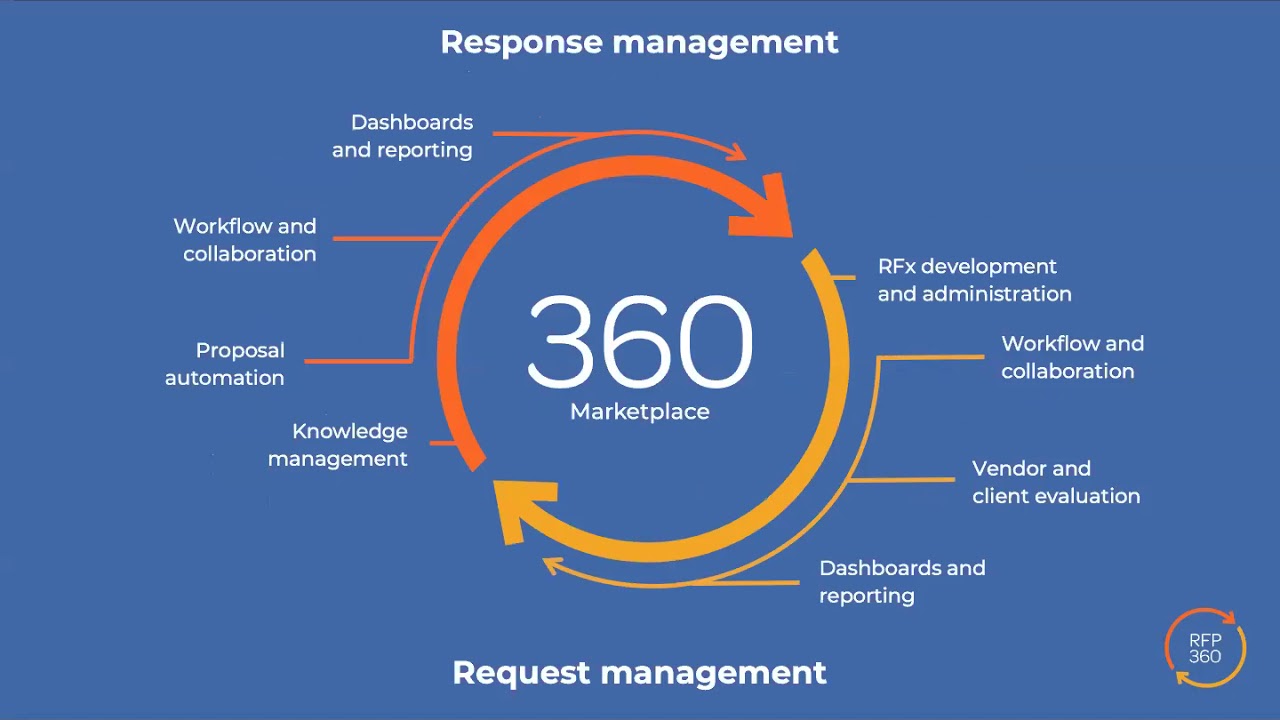

Auburn University’s metal technologies program thrives on robust collaborations with industry leaders, fostering innovation and shaping the future of metal processing. These partnerships go beyond theoretical research, translating academic knowledge into practical applications that benefit both academia and industry.

Industry Partnerships and Their Impact

The collaborations between Auburn University and industry leaders are multifaceted, encompassing joint research projects, internships, and industry-sponsored initiatives. These partnerships contribute significantly to the development and advancement of metal technologies by:

- Bridging the Gap Between Academia and Industry: Partnerships provide a platform for researchers to gain insights into real-world challenges faced by industry, while industry leaders benefit from access to cutting-edge research and technological advancements.

- Developing Innovative Solutions: Joint research projects address industry-specific problems, leading to the development of new materials, processes, and technologies that enhance efficiency, reduce costs, and improve sustainability in metal production and manufacturing.

- Providing Practical Training Opportunities: Internships offer students valuable hands-on experience in industry settings, allowing them to apply their theoretical knowledge and develop practical skills. These opportunities enhance their employability and prepare them for successful careers in the metal technologies sector.

- Facilitating Knowledge Transfer: Industry-sponsored initiatives enable the transfer of research findings and technological advancements from the university to industry, accelerating the adoption of innovative solutions and driving progress in the field.

Examples of Industry Collaborations

Auburn University’s metal technologies program has forged strong partnerships with several industry leaders, resulting in impactful collaborations. Here are some notable examples:

| Industry Partner | Area of Collaboration | Benefits |

|---|---|---|

| [Industry Partner 1 Name] | [Area of Collaboration 1] | [Benefit 1] |

| [Industry Partner 2 Name] | [Area of Collaboration 2] | [Benefit 2] |

| [Industry Partner 3 Name] | [Area of Collaboration 3] | [Benefit 3] |

Impact and Future of Metal Technologies at Auburn University

Auburn University’s Metal Technologies program has a significant impact on both the local and global communities, contributing to advancements in various industries and fostering innovation in the field of metal science and engineering. This program plays a crucial role in addressing current and future challenges related to metal technologies, while also shaping the future of this field through cutting-edge research and development.

Impact of Auburn University’s Metal Technologies Program

Auburn University’s Metal Technologies program has a profound impact on the local and global communities through its research, education, and industry partnerships. The program’s research efforts have resulted in the development of innovative metal alloys, advanced manufacturing processes, and cutting-edge technologies that benefit various industries, including aerospace, automotive, and energy.

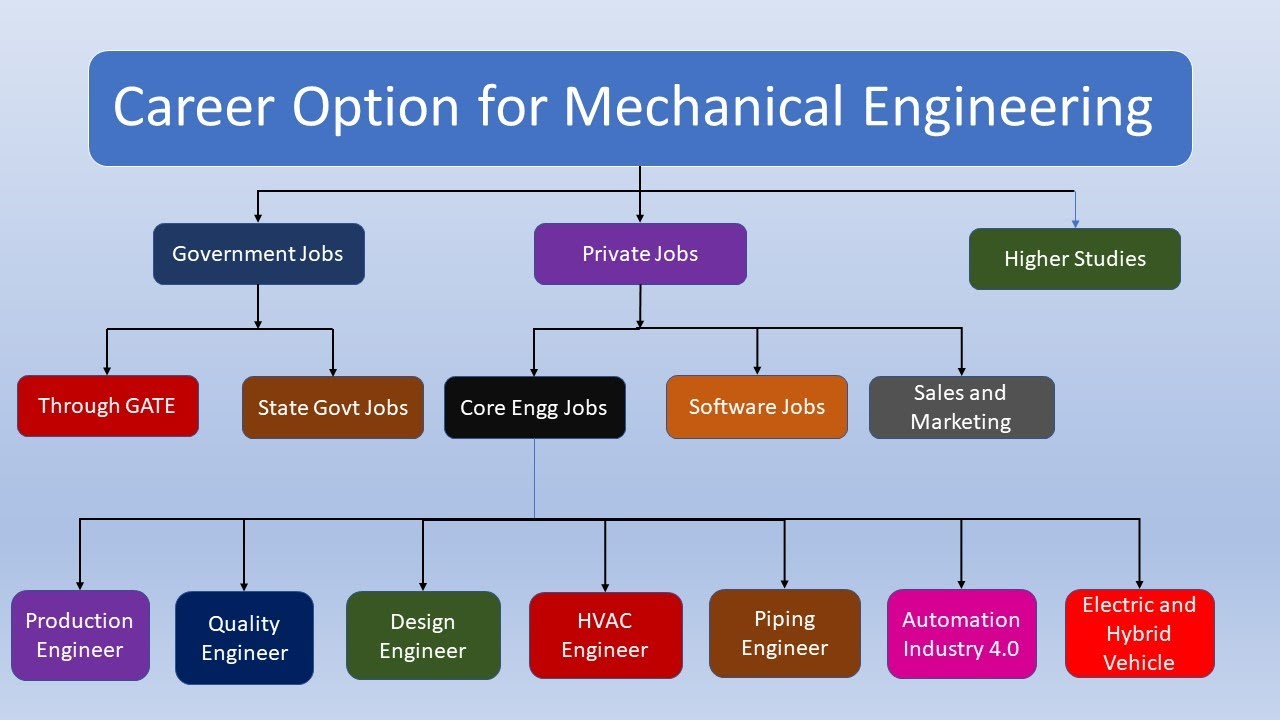

The program also plays a significant role in educating the next generation of metal scientists and engineers. Through its undergraduate and graduate programs, Auburn University prepares students with the skills and knowledge necessary to contribute to the advancement of metal technologies. These graduates go on to work in various industries, applying their expertise to solve real-world problems and contribute to technological advancements.

Future Trends and Challenges in Metal Technologies

The field of metal technologies is constantly evolving, driven by advancements in materials science, manufacturing processes, and technological innovations. Some key trends and challenges that are shaping the future of metal technologies include:

- Sustainable Metal Production and Recycling: The increasing demand for metals coupled with environmental concerns has led to a growing emphasis on sustainable metal production and recycling practices. This involves developing efficient and environmentally friendly methods for extracting, processing, and recycling metals.

- Additive Manufacturing and 3D Printing: Additive manufacturing, also known as 3D printing, is revolutionizing the way metals are produced. This technology allows for the creation of complex metal parts with intricate designs, enabling the production of lightweight, high-performance components for various applications.

- Advanced Materials Development: Researchers are constantly developing new and improved metal alloys with enhanced properties such as strength, corrosion resistance, and high-temperature performance. These advancements are crucial for addressing the demands of emerging technologies and industries.

- Digitalization and Automation: The increasing adoption of digital technologies and automation in the metal industry is transforming manufacturing processes, leading to increased efficiency, productivity, and precision.

Potential Research Directions and Innovations

Auburn University’s Metal Technologies program is at the forefront of research and innovation in the field. The program focuses on addressing key challenges and exploring emerging opportunities in metal technologies. Some potential research directions and innovations include:

- Development of High-Entropy Alloys: High-entropy alloys (HEAs) are a new class of metallic materials that exhibit exceptional properties, such as high strength, excellent corrosion resistance, and enhanced wear resistance. HEAs have the potential to revolutionize various industries, including aerospace, automotive, and energy.

- Advanced Metal Matrix Composites: Metal matrix composites (MMCs) are materials that combine the strength and stiffness of metals with the lightweight properties of ceramics or polymers. MMCs offer significant advantages in terms of weight reduction, improved strength-to-weight ratio, and enhanced thermal properties.

- Biocompatible Metals for Medical Implants: The development of biocompatible metals is crucial for the success of medical implants. Researchers are exploring new metal alloys and surface treatments that enhance biocompatibility, minimize inflammation, and promote tissue integration.

- Closed-Loop Metal Recycling: Closed-loop metal recycling aims to minimize waste and maximize resource utilization by recovering and reusing metals from end-of-life products. Research in this area focuses on developing efficient and environmentally friendly recycling processes.

Timeline of Key Milestones and Future Directions, Metal technologies auburn

Auburn University’s Metal Technologies program has a rich history of innovation and achievement. The program’s timeline highlights key milestones and future directions:

| Year | Milestone |

|---|---|

| 1950s | Establishment of the Department of Metallurgy and Materials Science at Auburn University. |

| 1970s | Development of advanced metal processing techniques, including powder metallurgy and casting. |

| 1980s | Focus on research in high-temperature alloys, corrosion science, and metal fatigue. |

| 1990s | Expansion of the program to include research in composites, biomaterials, and nanomaterials. |

| 2000s | Establishment of the Auburn University Metal Technology Center, providing state-of-the-art facilities for research and education. |

| 2010s | Increased emphasis on sustainable metal production, additive manufacturing, and digitalization. |

| 2020s and Beyond | Continued focus on research and innovation in high-entropy alloys, advanced metal matrix composites, biocompatible metals, and closed-loop metal recycling. |

Summary

Auburn University’s metal technologies program is a testament to the transformative power of research and innovation. By fostering a collaborative environment that embraces both academic excellence and industry partnerships, the program is poised to continue shaping the future of metal technologies, creating solutions that benefit society and advance the field for generations to come.

Metal Technologies Auburn is a leading provider of innovative metal fabrication solutions. Their expertise extends beyond traditional manufacturing, encompassing cutting-edge technologies like the Pace Technology golf cart GPS , which enhances efficiency and precision in various applications. By integrating such advanced systems, Metal Technologies Auburn continues to deliver exceptional results in the metalworking industry.