Max Air Technology Actuators: Powerful Movement

Max air technology actuators are the muscle behind countless industrial processes, quietly driving machines and systems across diverse industries. These powerful devices, utilizing compressed air, hydraulics, or electricity, provide precise […]

Max air technology actuators are the muscle behind countless industrial processes, quietly driving machines and systems across diverse industries. These powerful devices, utilizing compressed air, hydraulics, or electricity, provide precise and reliable motion control, making them essential components in automation and machinery.

From the simple act of opening and closing valves to the complex movements of robots and manufacturing equipment, Max air technology actuators are the unsung heroes of modern engineering. Their ability to generate force and motion with accuracy and repeatability makes them indispensable in countless applications.

Max Air Technology Actuator

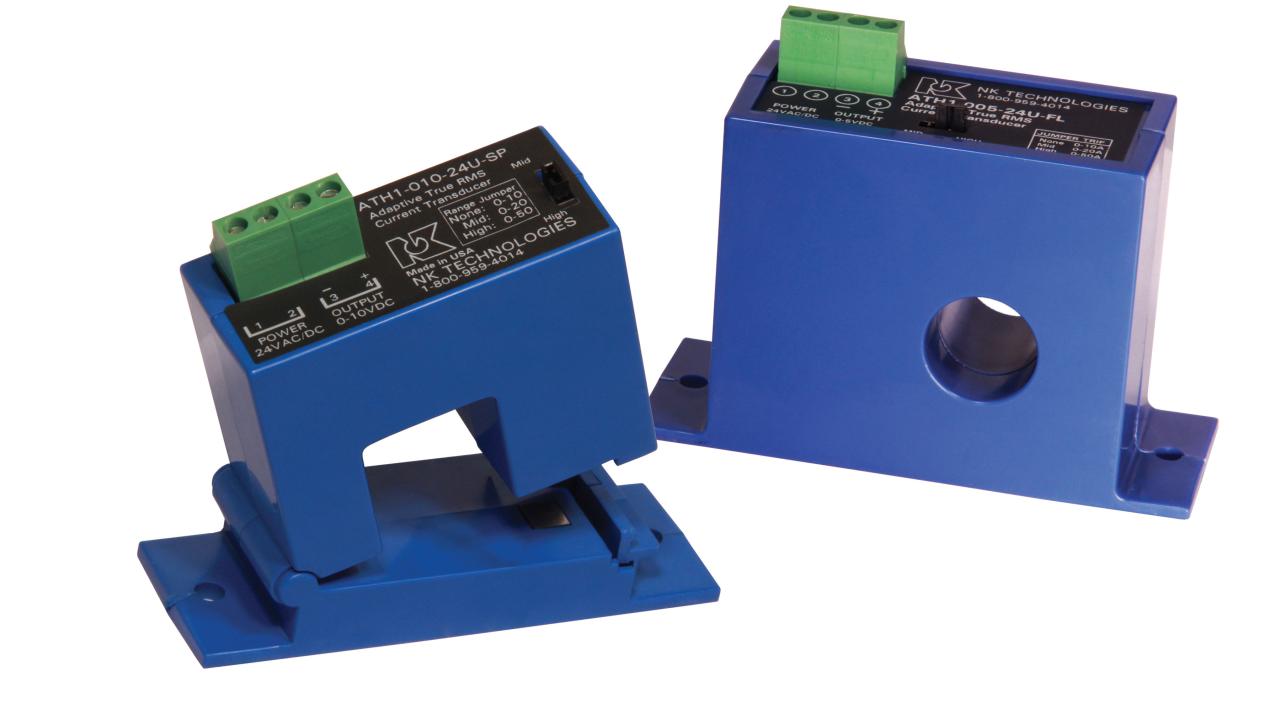

A Max Air Technology actuator is a type of electromechanical device that converts electrical energy into mechanical motion, specifically utilizing compressed air as the driving force. It consists of a motor, a pneumatic cylinder, and a control system that regulates the flow of compressed air to achieve precise and controlled linear or rotary movement.

Max Air Technology actuators operate based on the principles of pneumatics, where compressed air is used to generate force and motion. The compressed air is directed into the pneumatic cylinder, which contains a piston that moves in response to the pressure difference. This movement is then transmitted to the actuator’s output shaft, resulting in linear or rotary motion.

History of Max Air Technology

Max Air Technology has been a prominent player in the actuator industry for over three decades. The company was founded in 1985 with a vision to provide innovative and reliable actuator solutions for various applications. Max Air Technology has played a significant role in advancing actuator technology by introducing several groundbreaking innovations, such as:

- Development of high-performance, energy-efficient actuators that minimize energy consumption while maximizing output.

- Introduction of advanced control systems that enable precise and responsive actuator operation.

- Pioneering the use of robust materials and manufacturing processes to ensure long-lasting durability and reliability.

Advantages and Disadvantages of Max Air Technology Actuators

Max Air Technology actuators, also known as pneumatic actuators, are devices that convert compressed air energy into mechanical motion. They are widely used in various industries, including manufacturing, automation, and aerospace. Max Air Technology actuators offer several advantages over other actuator technologies, such as electric actuators or hydraulic actuators, but also have some limitations.

Advantages of Max Air Technology Actuators

The advantages of Max Air Technology actuators stem from their simple design, reliable operation, and inherent safety features.

- High Force and Torque: Max Air Technology actuators can generate significant force and torque, making them suitable for applications requiring heavy lifting or high-pressure operations. For example, they are used in industrial presses, robotic arms, and aircraft control surfaces.

- Reliability and Durability: Pneumatic actuators are known for their robust construction and resistance to harsh environments. They are less susceptible to wear and tear compared to electric actuators, making them suitable for applications with high duty cycles or demanding operating conditions.

- Safety Features: Max Air Technology actuators are inherently safe due to their use of compressed air as the power source. Compressed air is less hazardous than electricity or hydraulic fluids, reducing the risk of electrical shocks or fluid leaks.

- Cost-Effectiveness: Max Air Technology actuators are generally more affordable than electric or hydraulic actuators, especially for simple applications. Their low maintenance requirements also contribute to their cost-effectiveness over time.

- Environmental Compatibility: Max Air Technology actuators are environmentally friendly as they do not use hazardous fluids or generate significant heat. They are also suitable for use in potentially explosive environments, as compressed air is non-flammable.

Disadvantages of Max Air Technology Actuators

While Max Air Technology actuators offer many advantages, they also have some limitations that need to be considered.

- Speed Limitations: Pneumatic actuators are generally slower than electric actuators due to the compressibility of air. This can be a limitation in applications requiring fast response times.

- Air Consumption: Max Air Technology actuators require a constant supply of compressed air, which can be an energy-intensive process. The cost of air compressors and air distribution systems can add to the overall operating expenses.

- Temperature Sensitivity: The performance of Max Air Technology actuators can be affected by temperature variations. Extreme temperatures can affect the viscosity of air, impacting the actuator’s speed and force output.

- Noise Generation: Pneumatic actuators can generate significant noise during operation, which can be a concern in noise-sensitive environments.

- Limited Control Accuracy: Achieving precise control with Max Air Technology actuators can be challenging due to the compressibility of air. This can be a limitation in applications requiring high-precision positioning.

Comparison with Other Actuator Technologies, Max air technology actuator

- Electric Actuators: Electric actuators are generally faster and more precise than Max Air Technology actuators. They are also more energy-efficient and generate less noise. However, they are more expensive and can be less reliable in harsh environments.

- Hydraulic Actuators: Hydraulic actuators can generate high force and torque, similar to Max Air Technology actuators. They are also suitable for applications requiring high speed and precision. However, they are more complex to operate and maintain, and they use hazardous fluids that require special handling.

Final Review

As technology advances, Max air technology actuators continue to evolve, incorporating new materials, designs, and control systems. Their future looks bright, with potential applications in areas like robotics, aerospace, and even medical devices. The journey of these powerful actuators is far from over, and their impact on our world is sure to continue expanding.

The Max Air Technology Actuator is a key component in many modern vehicles, ensuring optimal airflow for performance and efficiency. For example, the mdx with technology package relies on this technology to deliver a comfortable and responsive driving experience.

By adjusting the airflow dynamically, the Max Air Technology Actuator contributes to a smooth and efficient ride, enhancing the overall driving experience.