Manufacturing and Mechanical Engineering Technology Jobs: A Career Guide

Manufacturing and mechanical engineering technology jobs set the stage for this enthralling narrative, offering readers a glimpse into a world of innovation, precision, and problem-solving. These industries are at the […]

Manufacturing and mechanical engineering technology jobs set the stage for this enthralling narrative, offering readers a glimpse into a world of innovation, precision, and problem-solving. These industries are at the heart of modern society, driving advancements in everything from automobiles to medical devices. The demand for skilled professionals in these fields is steadily increasing, making it a promising career path for those with a passion for engineering and a desire to make a tangible impact.

This guide will explore the diverse range of job roles, essential skills, career paths, and technological advancements shaping the future of manufacturing and mechanical engineering. We will delve into the challenges and opportunities facing these industries, providing valuable insights for aspiring professionals and seasoned veterans alike.

Industry Overview

The manufacturing and mechanical engineering technology sectors are dynamic and essential to the global economy. These industries are constantly evolving, driven by technological advancements, shifting consumer demands, and global economic trends. Understanding the current state of the job market, key trends, and challenges is crucial for individuals seeking careers in these fields.

Current State of the Job Market

The manufacturing and mechanical engineering technology job market is currently experiencing a mix of opportunities and challenges. While some areas face labor shortages, others are undergoing significant automation and technological disruption. The overall outlook is positive, with projected growth in certain segments, but the demand for skilled professionals is evolving rapidly.

Key Trends and Challenges

- Automation and Robotics: Automation is rapidly transforming manufacturing processes, increasing efficiency and productivity. This trend is creating new job opportunities in areas like robotics programming, system integration, and maintenance. However, it also leads to displacement of workers in some traditional roles.

- Digital Transformation: The adoption of digital technologies, such as the Internet of Things (IoT), cloud computing, and artificial intelligence (AI), is driving innovation and efficiency in manufacturing. These technologies are creating demand for professionals with skills in data analysis, software development, and cybersecurity.

- Sustainability and Environmental Concerns: Growing concerns about environmental sustainability are influencing manufacturing practices. Companies are seeking to reduce their carbon footprint and implement more sustainable production processes. This trend creates opportunities for professionals with expertise in green manufacturing, energy efficiency, and renewable energy technologies.

- Global Competition: The manufacturing landscape is increasingly globalized, with companies competing on a worldwide stage. This competition is driving innovation and pushing companies to adopt new technologies and strategies to remain competitive.

- Skills Gap: Despite the growth potential in these industries, a significant skills gap exists. Many companies struggle to find qualified professionals with the necessary technical skills, particularly in areas like advanced manufacturing, automation, and data analytics.

Projected Growth and Demand

The U.S. Bureau of Labor Statistics projects strong job growth in manufacturing and mechanical engineering technology occupations over the next decade. For example, the demand for mechanical engineers is expected to grow by 7% from 2020 to 2030, faster than the average for all occupations. This growth is driven by several factors, including:

- Increased Infrastructure Investments: Governments are investing in infrastructure projects, such as roads, bridges, and energy systems, which will create demand for engineers and technicians.

- Growth in Advanced Manufacturing: The adoption of advanced manufacturing technologies, such as 3D printing and robotics, is creating new job opportunities.

- Demand for Customized Products: Consumers are increasingly demanding personalized and customized products, leading to a shift towards more flexible and adaptable manufacturing processes.

Job Roles and Responsibilities

The manufacturing and mechanical engineering technology field encompasses a wide range of job roles, each with unique responsibilities and skill requirements. Understanding these roles is crucial for individuals interested in pursuing a career in this dynamic sector.

Common Job Roles in Manufacturing and Mechanical Engineering Technology

This section provides an overview of some common job roles in manufacturing and mechanical engineering technology, along with their respective responsibilities and skill requirements.

- Manufacturing Engineer: Manufacturing engineers are responsible for designing, planning, and overseeing the production process. They work to optimize efficiency, reduce costs, and ensure product quality. Their responsibilities include:

- Developing and implementing manufacturing processes

- Selecting and designing manufacturing equipment

- Analyzing production data and identifying areas for improvement

- Ensuring compliance with safety and quality standards

Essential skills for manufacturing engineers include:

- Strong analytical and problem-solving skills

- Knowledge of manufacturing processes and technologies

- Proficiency in computer-aided design (CAD) and manufacturing (CAM) software

- Excellent communication and teamwork skills

- Mechanical Engineer: Mechanical engineers design, analyze, and manufacture mechanical systems. They apply principles of physics and materials science to create innovative solutions for a wide range of applications. Their responsibilities include:

- Designing and developing mechanical components and systems

- Analyzing and testing prototypes and products

- Preparing technical drawings and specifications

- Collaborating with other engineers and technicians

Essential skills for mechanical engineers include:

- Strong understanding of mechanics, thermodynamics, and fluid mechanics

- Proficiency in CAD software and simulation tools

- Excellent problem-solving and analytical skills

- Strong communication and teamwork skills

- Industrial Engineer: Industrial engineers focus on optimizing processes and systems within organizations. They use data analysis and statistical methods to improve efficiency, reduce waste, and enhance productivity. Their responsibilities include:

- Analyzing and improving workflows and processes

- Designing and implementing lean manufacturing systems

- Developing and implementing quality control procedures

- Optimizing resource allocation and utilization

Essential skills for industrial engineers include:

- Strong analytical and problem-solving skills

- Knowledge of statistical analysis and data interpretation

- Proficiency in process mapping and simulation software

- Excellent communication and teamwork skills

- Quality Engineer: Quality engineers are responsible for ensuring that products and processes meet established quality standards. They develop and implement quality control procedures, monitor production processes, and identify and resolve quality issues. Their responsibilities include:

- Developing and implementing quality control plans

- Monitoring production processes and identifying quality issues

- Analyzing data and identifying root causes of defects

- Implementing corrective actions and preventive measures

Essential skills for quality engineers include:

- Strong analytical and problem-solving skills

- Knowledge of statistical process control (SPC)

- Proficiency in quality management systems (QMS)

- Excellent communication and teamwork skills

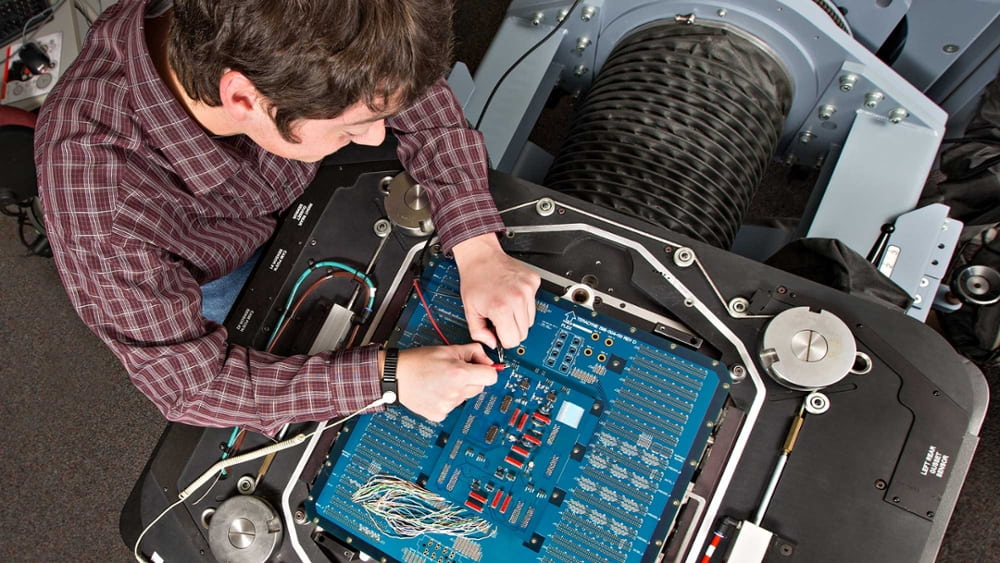

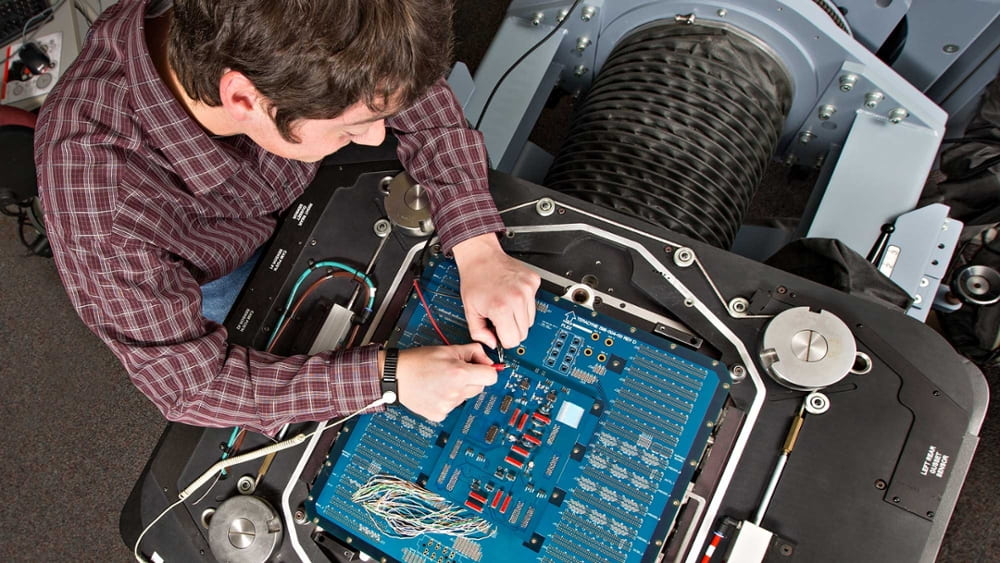

- Robotics Engineer: Robotics engineers design, build, and program robots for various applications. They work in industries such as manufacturing, healthcare, and logistics. Their responsibilities include:

- Designing and developing robotic systems

- Programming robots to perform specific tasks

- Integrating robots into existing systems

- Testing and troubleshooting robotic systems

Essential skills for robotics engineers include:

- Strong understanding of robotics, mechatronics, and computer science

- Proficiency in programming languages such as C++, Python, and ROS

- Experience with robotic hardware and software

- Excellent problem-solving and analytical skills

Career Paths and Advancement

Career paths and advancement opportunities in manufacturing and mechanical engineering technology vary depending on the specific role and individual’s experience and skills. However, there are some common progression paths:

- Entry-level positions: Graduates with a degree in manufacturing or mechanical engineering technology typically start their careers in entry-level roles such as:

- Manufacturing Technician

- Mechanical Designer

- Quality Inspector

- Mid-level positions: With experience and further education, individuals can progress to mid-level roles such as:

- Manufacturing Engineer

- Mechanical Engineer

- Industrial Engineer

- Quality Engineer

- Senior-level positions: Experienced professionals can advance to senior-level roles such as:

- Manufacturing Manager

- Engineering Manager

- Quality Manager

- Director of Operations

- Leadership roles: With exceptional skills and experience, individuals can progress to leadership roles such as:

- Chief Technology Officer (CTO)

- Chief Operating Officer (COO)

- Chief Executive Officer (CEO)

Essential Skills and Qualifications

A successful career in manufacturing and mechanical engineering technology requires a blend of technical expertise and soft skills. This section delves into the essential skills and qualifications necessary for success in these roles, highlighting the importance of certifications, licenses, and degrees for both entry-level and advanced positions.

Technical Skills

Technical skills form the foundation of manufacturing and mechanical engineering technology. These skills are acquired through formal education, training programs, and practical experience.

- Computer-Aided Design (CAD): Proficiency in CAD software, such as AutoCAD, SolidWorks, or Creo, is essential for creating detailed drawings, models, and simulations. This skill is crucial for designing and developing products, machines, and systems.

- Computer-Aided Manufacturing (CAM): Understanding CAM software, such as Mastercam or NX CAM, is essential for translating CAD designs into manufacturing instructions. This involves programming CNC machines and optimizing production processes.

- Manufacturing Processes: A strong understanding of manufacturing processes, including machining, welding, casting, and molding, is vital. This knowledge enables engineers to select the most appropriate processes for specific applications and ensure quality control.

- Materials Science: Knowledge of different materials, their properties, and applications is crucial for selecting the right materials for specific designs and applications. This includes understanding material strengths, weaknesses, and how they behave under different conditions.

- Robotics and Automation: Familiarity with robotics and automation technologies is becoming increasingly important in modern manufacturing. This includes understanding programming, operation, and maintenance of robotic systems.

- Quality Control: Proficiency in quality control techniques, including statistical process control (SPC) and Six Sigma, is essential for ensuring product quality and meeting industry standards.

- Troubleshooting and Problem Solving: Manufacturing and mechanical engineers must be able to identify, analyze, and solve technical problems efficiently. This involves applying technical knowledge, critical thinking, and problem-solving skills.

Soft Skills

While technical skills are essential, soft skills play a crucial role in fostering collaboration, communication, and leadership within the manufacturing and mechanical engineering technology field.

- Communication: Effective communication skills are essential for collaborating with colleagues, clients, and suppliers. This includes clear and concise written and verbal communication, as well as active listening skills.

- Teamwork: Manufacturing and mechanical engineering projects often involve working in teams. Strong teamwork skills, including collaboration, conflict resolution, and consensus building, are essential for project success.

- Problem-Solving: The ability to identify, analyze, and solve problems is crucial in manufacturing and mechanical engineering. This involves critical thinking, analytical skills, and creative problem-solving approaches.

- Time Management: Manufacturing and mechanical engineers often work under tight deadlines. Effective time management skills are crucial for prioritizing tasks, meeting deadlines, and delivering projects on time.

- Adaptability: The manufacturing and mechanical engineering field is constantly evolving. The ability to adapt to new technologies, processes, and challenges is essential for long-term success.

Certifications, Licenses, and Degrees

Formal qualifications, including certifications, licenses, and degrees, are important for demonstrating competence and advancing in manufacturing and mechanical engineering technology careers.

Entry-Level Positions

- Associate’s Degree in Manufacturing Technology or Mechanical Engineering Technology: This degree provides a foundation in technical skills and prepares graduates for entry-level roles in manufacturing and engineering environments.

- Industry-Specific Certifications: Certifications, such as Certified Manufacturing Technologist (CMfgT) or Certified Manufacturing Engineer (CMfgE), demonstrate specialized knowledge and skills in specific areas of manufacturing.

Advanced Positions

- Bachelor’s Degree in Mechanical Engineering or Manufacturing Engineering: A bachelor’s degree provides a more in-depth understanding of engineering principles, design, and analysis. This qualification is often required for supervisory and management roles.

- Professional Engineer (PE) License: A PE license is a legal requirement for engineers who provide engineering services to the public. Obtaining a PE license requires a bachelor’s degree, passing the Fundamentals of Engineering (FE) exam, gaining practical experience, and passing the Professional Engineering (PE) exam.

- Master’s Degree in Mechanical Engineering or Manufacturing Engineering: A master’s degree offers advanced knowledge and skills in specialized areas, such as robotics, automation, or materials science. This qualification is often required for research and development roles.

Developing and Enhancing Skills

Continuous learning and development are crucial for staying competitive in the rapidly evolving manufacturing and mechanical engineering technology field. Here are some ways to develop and enhance relevant skills:

- Formal Education: Pursuing associate’s, bachelor’s, or master’s degrees in manufacturing technology or mechanical engineering provides a structured and comprehensive foundation in technical knowledge and skills.

- Training Programs: Industry-specific training programs, offered by manufacturers, professional organizations, and educational institutions, provide hands-on experience and specialized knowledge in specific areas, such as CAD software, CNC machining, or robotics.

- Professional Development: Attending conferences, workshops, and seminars provides opportunities to learn about emerging technologies, best practices, and industry trends. Networking with peers and industry experts can also lead to valuable insights and career advancement opportunities.

- On-the-Job Training: Practical experience gained through internships, apprenticeships, or entry-level positions provides valuable hands-on experience and allows individuals to apply their knowledge in real-world settings.

- Self-Study: Utilizing online resources, books, and tutorials to learn new skills or enhance existing ones is a valuable method for continuous learning and development.

Career Paths and Advancement Opportunities

A career in manufacturing and mechanical engineering technology offers diverse pathways for growth and advancement. Professionals in this field can choose to specialize in various areas, pursue higher education, or take on leadership roles, all contributing to increased earning potential and job satisfaction.

Career Paths

A career in manufacturing and mechanical engineering technology offers a range of specializations and career paths.

- Manufacturing Engineer: These professionals are responsible for designing, planning, and overseeing the production process. They work to optimize efficiency, reduce costs, and ensure product quality.

- Mechanical Design Engineer: Mechanical design engineers are involved in the creation and development of mechanical systems, components, and products. They use computer-aided design (CAD) software to create detailed drawings and specifications.

- Process Engineer: Process engineers focus on improving the efficiency and effectiveness of manufacturing processes. They analyze production data, identify bottlenecks, and implement solutions to enhance productivity.

- Quality Engineer: Quality engineers are responsible for ensuring that products meet established standards. They develop and implement quality control procedures, monitor production processes, and investigate and resolve quality issues.

- Project Engineer: Project engineers manage the execution of manufacturing projects from conception to completion. They coordinate with different teams, track progress, and ensure projects are completed on time and within budget.

- Production Supervisor: Production supervisors oversee the day-to-day operations of manufacturing facilities. They ensure that production targets are met, manage production teams, and resolve operational issues.

- Research and Development Engineer: Research and development engineers are involved in the development of new technologies and products. They conduct research, design prototypes, and test new concepts.

- Sales Engineer: Sales engineers combine technical knowledge with sales skills to promote and sell manufacturing products and services. They provide technical support to customers and understand their specific needs.

Specialization and Professional Development

Specialization within manufacturing and mechanical engineering technology can lead to increased earning potential and career opportunities. Professionals can focus on specific areas such as:

- Automation and Robotics: With the increasing adoption of automation in manufacturing, professionals specializing in robotics and automation systems are highly sought after.

- Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM): Expertise in CAD/CAM software is essential for designing and manufacturing products efficiently.

- Lean Manufacturing: Professionals with knowledge of lean manufacturing principles can optimize production processes and reduce waste.

- Six Sigma: Six Sigma certification demonstrates proficiency in quality improvement methodologies, making professionals highly valuable in manufacturing environments.

- Additive Manufacturing (3D Printing): The growing popularity of 3D printing is creating opportunities for professionals specializing in this emerging technology.

Professional development is crucial for staying competitive in this rapidly evolving field.

Manufacturing and mechanical engineering technology jobs often require a deep understanding of how things work, and this can extend beyond the factory floor. For instance, understanding the intricacies of land technology can be crucial in designing and building infrastructure that supports manufacturing operations.

This knowledge can be applied to optimizing logistics, creating efficient layouts, and even developing sustainable practices for the manufacturing process.

- Continuing Education: Pursuing certifications, taking online courses, or attending workshops can enhance skills and knowledge in specialized areas.

- Professional Organizations: Joining professional organizations like the American Society of Mechanical Engineers (ASME) or the Society of Manufacturing Engineers (SME) provides access to networking opportunities, industry updates, and professional development resources.

- Mentorship: Seeking guidance from experienced professionals can provide valuable insights and accelerate career growth.

Factors Contributing to Advancement and Salary Potential

Several factors influence career advancement and salary potential in manufacturing and mechanical engineering technology.

- Education and Certifications: A bachelor’s degree in mechanical engineering technology or a related field is generally required for entry-level positions. Advanced degrees, such as a master’s degree or a professional engineering license, can open doors to higher-level roles and increased earning potential.

- Experience: Gaining practical experience through internships, entry-level positions, or relevant projects is crucial for career progression.

- Skills and Abilities: Proficiency in technical skills, such as CAD software, manufacturing processes, and problem-solving, is essential for success.

- Leadership and Communication Skills: Effective communication, teamwork, and leadership abilities are valuable assets in manufacturing and engineering environments.

- Industry Knowledge: Staying up-to-date with industry trends, technological advancements, and best practices is essential for career growth.

Industry-Specific Technologies and Innovations: Manufacturing And Mechanical Engineering Technology Jobs

The manufacturing and mechanical engineering industry is constantly evolving, driven by rapid technological advancements. These innovations are transforming how products are designed, manufactured, and delivered, creating exciting opportunities and challenges for professionals in the field.

Automation and Robotics

Automation and robotics are playing a pivotal role in modern manufacturing, enhancing efficiency, productivity, and product quality. The use of robots in various tasks, from assembly and welding to material handling and inspection, has significantly impacted the industry.

- Increased Efficiency and Productivity: Robots can perform repetitive tasks with speed and accuracy, reducing human error and increasing output. This allows manufacturers to produce goods faster and more efficiently, leading to higher productivity and lower costs.

- Improved Product Quality: Robots can maintain consistent precision and quality throughout the production process, resulting in fewer defects and higher product quality. This is particularly important for industries that require high levels of precision and consistency, such as automotive and aerospace.

- Enhanced Safety: Robots can handle dangerous or hazardous tasks, protecting human workers from potential injuries. This is especially beneficial in industries where workers are exposed to harmful substances, heavy machinery, or extreme temperatures.

- Flexibility and Adaptability: Modern robots are becoming increasingly flexible and adaptable, capable of performing a variety of tasks and easily reprogrammed for new applications. This allows manufacturers to quickly adjust their production lines to meet changing market demands.

Challenges and Opportunities

The manufacturing and mechanical engineering technology sectors face a dynamic landscape, marked by both significant challenges and exciting opportunities for growth and innovation. These industries are constantly evolving, adapting to technological advancements, global competition, and changing consumer demands.

Challenges in Manufacturing and Mechanical Engineering

The manufacturing and mechanical engineering technology sectors face several key challenges that require innovative solutions and strategic planning.

- Skilled Labor Shortage: The aging workforce and a decline in interest in STEM fields have created a shortage of skilled workers, making it difficult for companies to find qualified employees for critical roles.

- Technological Advancements: Rapid advancements in automation, artificial intelligence, and digital manufacturing technologies require significant investments and adaptation, putting pressure on companies to keep up with the pace of change.

- Global Competition: Increased competition from emerging economies with lower labor costs and government support presents a challenge for manufacturers in developed countries.

- Supply Chain Disruptions: Global events, such as pandemics and geopolitical tensions, can disrupt supply chains, leading to production delays and increased costs.

- Sustainability and Environmental Concerns: Growing concerns about environmental impact and sustainability require manufacturers to adopt eco-friendly practices and technologies, adding to the cost of production and requiring new skillsets.

Opportunities for Innovation and Growth

Despite the challenges, the manufacturing and mechanical engineering technology sectors present numerous opportunities for innovation and growth, driven by emerging technologies and evolving market demands.

- Automation and Robotics: Automation and robotics offer opportunities to improve efficiency, reduce labor costs, and enhance safety in manufacturing processes. This trend is particularly relevant in industries like automotive manufacturing, where robots are increasingly used for tasks such as welding, painting, and assembly.

- Additive Manufacturing (3D Printing): Additive manufacturing allows for the creation of complex designs and prototypes quickly and efficiently, reducing lead times and opening up new possibilities for product customization. This technology has gained traction in industries such as aerospace, medical devices, and automotive, where it allows for the production of lightweight and durable components with intricate geometries.

- Internet of Things (IoT) and Industry 4.0: The integration of IoT and Industry 4.0 technologies, such as sensors, data analytics, and cloud computing, allows for real-time monitoring, predictive maintenance, and improved decision-making in manufacturing processes. This enables companies to optimize operations, reduce downtime, and enhance product quality.

- Advanced Materials and Nanotechnology: Advancements in materials science and nanotechnology are leading to the development of new materials with enhanced properties, such as strength, durability, and conductivity. These materials are finding applications in various industries, including aerospace, automotive, and construction.

- Sustainable Manufacturing: Growing demand for sustainable products and processes is driving innovation in eco-friendly manufacturing practices. Companies are adopting circular economy principles, reducing waste, and minimizing their environmental footprint, creating opportunities for new technologies and solutions.

Impact of Global Competition and Economic Trends

The manufacturing and mechanical engineering technology sectors are heavily influenced by global competition and economic trends.

- Reshoring and Regionalization: In response to supply chain disruptions and geopolitical tensions, companies are increasingly considering reshoring or regionalizing their manufacturing operations, leading to growth opportunities in domestic markets. This trend is driven by factors such as reduced transportation costs, improved control over production, and a desire to support local economies.

- Emerging Markets: Rapid economic growth in emerging markets, such as China and India, is creating new demand for manufactured goods, presenting opportunities for companies to expand their reach and tap into these markets. This growth is particularly evident in industries such as consumer electronics, automotive, and infrastructure development.

- Technological Disruption: Disruptive technologies, such as artificial intelligence, automation, and 3D printing, are transforming the manufacturing landscape, creating both opportunities and challenges for companies. Companies need to adapt quickly to these changes and invest in new technologies to remain competitive.

Resources and Support

The manufacturing and mechanical engineering technology fields offer a wealth of resources and support for professionals at all stages of their careers. From professional organizations and educational institutions to job search platforms and mentorship programs, there are numerous avenues for individuals to enhance their skills, expand their networks, and stay abreast of industry trends.

Professional Organizations and Associations

Professional organizations and associations play a vital role in fostering professional growth and providing a platform for networking and knowledge sharing. Membership in these organizations offers access to industry events, publications, and resources, as well as opportunities to connect with peers and mentors.

- American Society of Mechanical Engineers (ASME): ASME is a global professional organization that promotes the art, science, and practice of mechanical engineering. It offers a range of resources for members, including technical publications, professional development courses, and networking events.

- Society of Manufacturing Engineers (SME): SME is a global professional organization dedicated to advancing manufacturing technology and education. It offers a wide array of resources, including technical conferences, workshops, and certification programs.

- National Institute of Standards and Technology (NIST): NIST is a non-regulatory federal agency that promotes U.S. innovation and industrial competitiveness. It offers a variety of resources for manufacturers, including research and development services, standards development, and technical assistance.

- American Welding Society (AWS): AWS is a professional organization that promotes the safe and efficient use of welding technology. It offers a range of resources, including certification programs, educational materials, and industry standards.

Educational Institutions

Educational institutions play a crucial role in preparing individuals for careers in manufacturing and mechanical engineering technology. They offer a wide range of programs, from associate degrees to doctoral degrees, providing students with the knowledge and skills they need to succeed in these fields.

- Community Colleges: Community colleges offer associate degrees in manufacturing and mechanical engineering technology, providing a solid foundation for entry-level positions.

- Technical Schools: Technical schools offer specialized training in specific areas of manufacturing and mechanical engineering technology, such as welding, machining, and robotics.

- Universities: Universities offer bachelor’s, master’s, and doctoral degrees in manufacturing and mechanical engineering technology, providing students with advanced knowledge and research opportunities.

Job Search Resources, Manufacturing and mechanical engineering technology jobs

Numerous online platforms and resources can assist professionals in finding manufacturing and mechanical engineering technology jobs. These platforms connect job seekers with employers and provide tools for managing job applications and career development.

- Indeed: Indeed is a popular job search engine that aggregates job listings from a variety of sources.

- LinkedIn: LinkedIn is a professional networking platform that allows users to connect with other professionals, search for jobs, and build their professional profiles.

- Monster: Monster is a job search website that offers a variety of resources for job seekers, including career advice, resume writing tips, and interview preparation tools.

- CareerBuilder: CareerBuilder is a job search website that provides a wide range of job listings, as well as career advice and resume writing services.

Career Development Resources

Career development is an ongoing process that involves continuous learning, skill enhancement, and professional growth. Numerous resources can support individuals in their career development journeys.

- Professional Development Courses: Professional development courses offered by professional organizations, educational institutions, and online platforms can help individuals enhance their skills and knowledge in specific areas of manufacturing and mechanical engineering technology.

- Certifications: Certifications can demonstrate proficiency in specific skills and knowledge, making individuals more competitive in the job market.

- Mentorship Programs: Mentorship programs connect individuals with experienced professionals who can provide guidance, support, and career advice.

Professional Networking

Professional networking is essential for building relationships, expanding career opportunities, and staying abreast of industry trends. Numerous opportunities exist for professionals to network with peers and mentors.

- Industry Events: Attending industry events, such as conferences, trade shows, and workshops, provides opportunities to connect with other professionals and learn about new technologies and trends.

- Professional Organizations: Membership in professional organizations offers opportunities to attend networking events and connect with other members.

- Online Platforms: Online platforms, such as LinkedIn, provide opportunities to connect with professionals in the manufacturing and mechanical engineering technology fields.

Mentorship and Professional Guidance

Mentorship and professional guidance are invaluable in navigating the complexities of manufacturing and mechanical engineering technology careers. Mentors can provide valuable insights, support, and guidance, helping individuals overcome challenges, develop their skills, and advance their careers.

- Formal Mentorship Programs: Formal mentorship programs are often offered by professional organizations, educational institutions, and companies, connecting individuals with experienced professionals who can provide guidance and support.

- Informal Mentorship: Informal mentorship can develop through professional relationships, networking events, and industry connections.

Final Summary

As we conclude our exploration of manufacturing and mechanical engineering technology jobs, it is clear that these fields offer a dynamic and rewarding career landscape. The future holds exciting possibilities for those who are passionate about innovation, problem-solving, and contributing to the advancement of society. With the right skills, dedication, and a willingness to embrace change, professionals in these industries can build fulfilling and impactful careers, leaving their mark on the world.