Linen Tracking Technology: Optimizing Laundry Operations

Linen tracking technology has revolutionized the laundry and textile industries, transforming how businesses manage their linen inventory and operations. By implementing sophisticated tracking systems, organizations gain real-time visibility into linen […]

Linen tracking technology has revolutionized the laundry and textile industries, transforming how businesses manage their linen inventory and operations. By implementing sophisticated tracking systems, organizations gain real-time visibility into linen usage, location, and status, enabling them to optimize processes, reduce costs, and improve customer satisfaction.

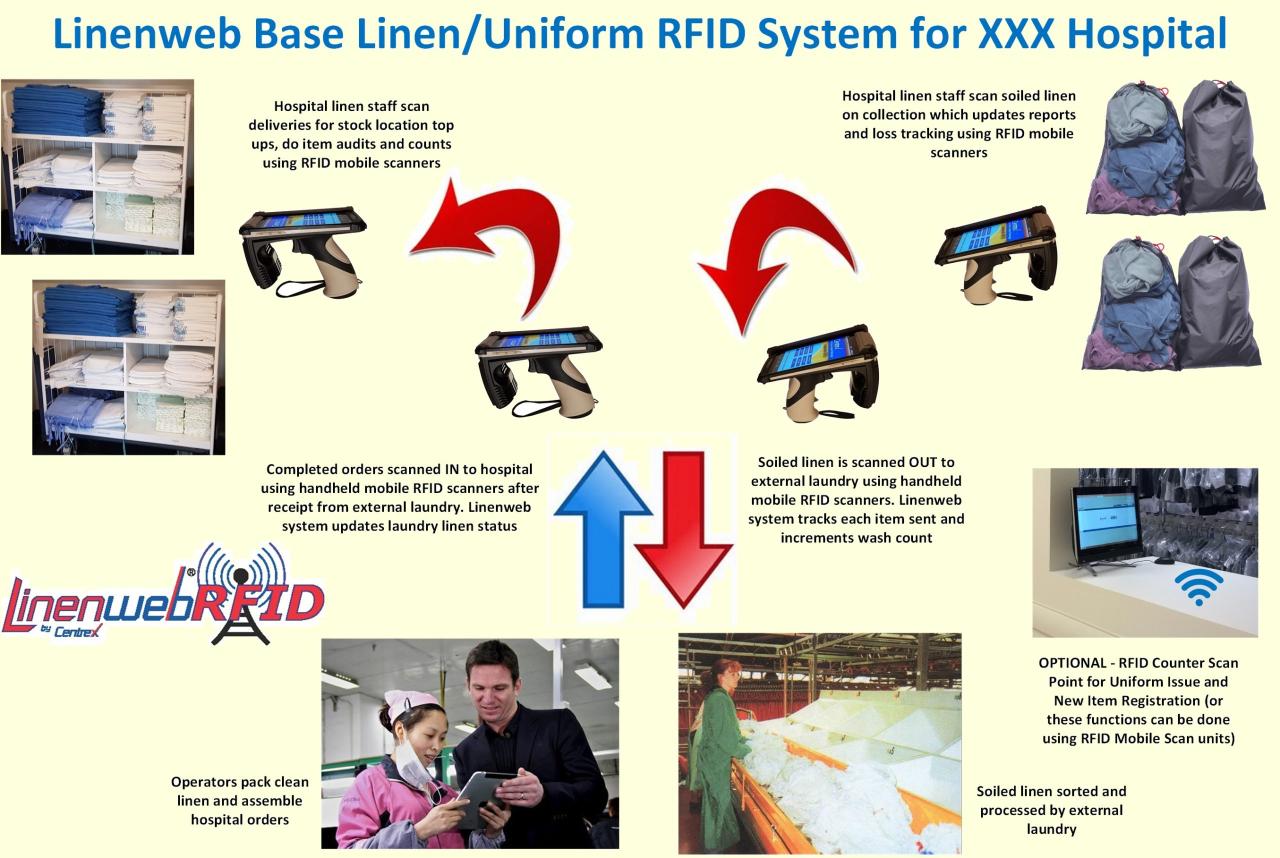

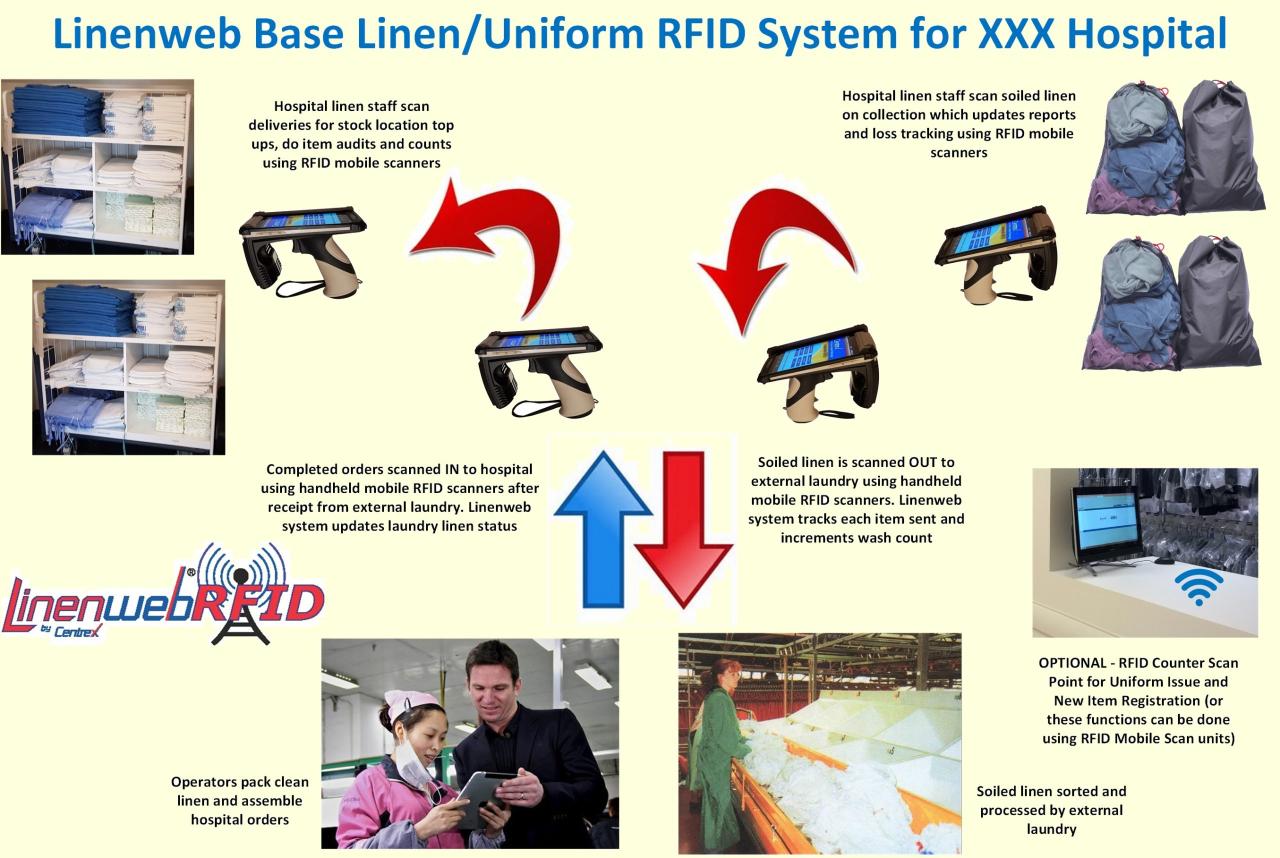

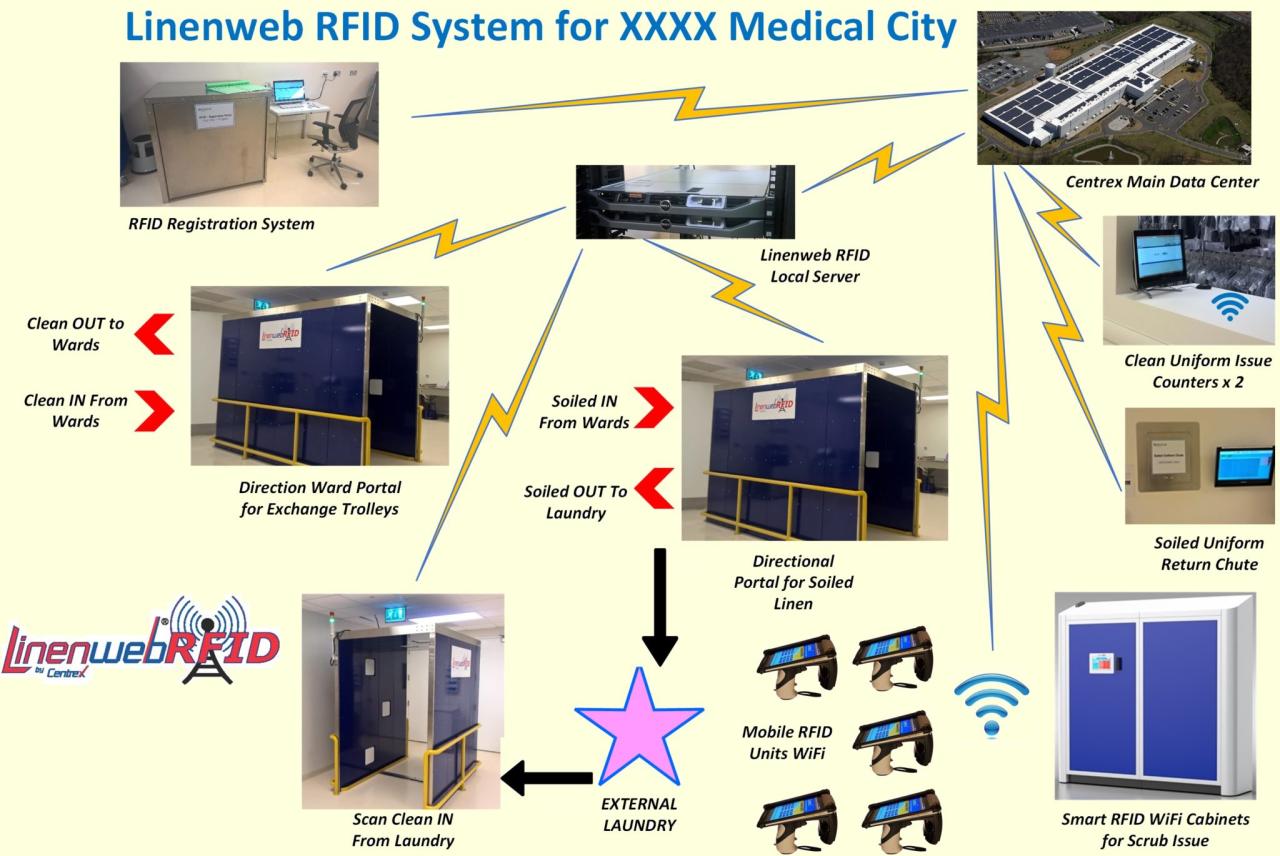

From hospitals and hotels to restaurants and industrial laundries, linen tracking technology plays a crucial role in ensuring efficient and sustainable operations. By leveraging technologies like RFID, barcode scanning, and GPS tracking, businesses can streamline their linen management, minimize losses, and make informed decisions based on data-driven insights.

Types of Linen Tracking Technologies

Linen tracking technologies are essential for maintaining hygiene, optimizing inventory management, and improving operational efficiency in various industries. These technologies provide real-time visibility into linen movement, ensuring timely laundering and reducing losses. This section explores different types of linen tracking technologies, highlighting their features, benefits, limitations, and applications.

RFID Tracking

RFID (Radio-Frequency Identification) technology utilizes electromagnetic fields to automatically identify and track tags attached to linen items.

- Features: RFID tags store unique identification information, enabling automated data capture without line-of-sight requirements. RFID readers can scan multiple tags simultaneously, enhancing efficiency.

- Benefits: RFID offers improved accuracy and speed compared to manual tracking methods. It enables real-time inventory management, automates linen sorting, and reduces human error.

- Limitations: RFID tags can be expensive, and the technology requires infrastructure investment in readers and software. Interference from metal or water can affect tag readability.

- Applications: RFID is widely used in healthcare, hospitality, and laundry services. It helps track linens in hospitals, hotels, and laundries, ensuring proper hygiene and reducing losses.

Barcode Tracking

Barcode tracking involves attaching barcodes to linen items, which are then scanned using barcode readers.

- Features: Barcodes contain unique identification numbers that can be scanned using barcode readers. The information can be stored in a database for tracking and analysis.

- Benefits: Barcode tracking is cost-effective and easy to implement. It provides accurate inventory data and simplifies linen management processes.

- Limitations: Barcode scanning requires line-of-sight, and barcodes can be easily damaged or obscured. It is less efficient than RFID for tracking large volumes of linens.

- Applications: Barcode tracking is commonly used in laundry services, hotels, and restaurants. It facilitates linen inventory management, tracking, and billing.

GPS Tracking, Linen tracking technology

GPS (Global Positioning System) tracking utilizes satellite signals to determine the location of linen items equipped with GPS devices.

- Features: GPS devices track the real-time location of linens, providing detailed movement information. This data can be accessed through software applications.

- Benefits: GPS tracking offers high accuracy and real-time visibility into linen movement. It helps optimize delivery routes and identify potential delays or losses.

- Limitations: GPS tracking is primarily suitable for outdoor applications, as satellite signals may not be available indoors. The technology can be expensive, and battery life can be a concern.

- Applications: GPS tracking is commonly used in linen delivery services, where it provides real-time tracking of linen shipments and optimizes logistics.

Data Management and Analysis: Linen Tracking Technology

![]()

Linen tracking technology generates a wealth of data that provides valuable insights into linen usage patterns, inventory levels, and overall efficiency. By harnessing this data, laundry facilities can optimize their operations and achieve significant cost savings.

Data Generation and Types

Linen tracking technology generates data through various means, including RFID tags, barcode scanners, and sensors. This data encompasses a wide range of information about linen items, including:

- Linen ID: Unique identifier assigned to each linen item, enabling individual tracking.

- Linen Type: Classification of linen items, such as towels, sheets, or uniforms.

- Location: Current location of the linen item, whether in the laundry, on a cart, or in a room.

- Status: Current state of the linen item, such as clean, dirty, or in repair.

- Usage History: Record of the linen item’s past uses, including dates, locations, and associated patients or guests.

- Maintenance History: Tracking of repairs, cleaning, and other maintenance activities performed on the linen item.

Data Analysis Methods

Data analysis methods are crucial for extracting meaningful insights from the vast amount of linen tracking data. Commonly used methods include:

- Descriptive Statistics: Summarizing data using measures like mean, median, and standard deviation to understand linen usage patterns, inventory levels, and efficiency.

- Trend Analysis: Identifying patterns and trends in linen usage over time, such as seasonal fluctuations or changes in demand.

- Regression Analysis: Determining the relationship between linen usage and other factors, such as patient occupancy or room type.

- Clustering Analysis: Grouping similar linen items based on their usage patterns or characteristics, enabling targeted management strategies.

Optimizing Linen Management Practices

Data insights derived from linen tracking technology can be used to optimize linen management practices in several ways:

- Inventory Optimization: Accurately predicting linen demand and adjusting inventory levels to minimize waste and storage costs.

- Par Level Management: Establishing optimal par levels for each linen type in different areas, ensuring adequate supply while minimizing excess inventory.

- Linen Rotation: Implementing efficient linen rotation strategies to maximize linen lifespan and minimize premature wear and tear.

- Laundry Scheduling: Optimizing laundry schedules based on linen usage patterns and demand, reducing downtime and maximizing efficiency.

- Cost Reduction: Identifying areas for cost savings, such as reducing linen loss, minimizing unnecessary laundry cycles, and optimizing linen purchasing.

Final Wrap-Up

The adoption of linen tracking technology signifies a significant shift towards a more data-driven and efficient approach to laundry and textile management. By harnessing the power of real-time data and advanced analytics, businesses can optimize their linen inventory, reduce operational costs, and enhance customer satisfaction. As technology continues to evolve, we can expect even more innovative solutions to emerge, further transforming the landscape of linen management in the years to come.

Linen tracking technology has become increasingly sophisticated, offering real-time insights into the movement and usage of linens. This can be especially beneficial in industries like healthcare, where meticulous tracking is essential. Similar to the need for detailed information in the 2024 Acura MDX Technology Package vs Advance Package , where you can compare features and benefits to make an informed decision, linen tracking systems allow for informed decisions about inventory, cleaning schedules, and potential shortages.

By leveraging technology, both linen tracking and vehicle purchasing processes can be streamlined and optimized.