Levil Technology Aviation: Transforming Flight

Levil Technology Aviation is revolutionizing the way we fly. From its humble beginnings, this technology has become an integral part of modern aircraft design, manufacturing, and flight operations. Levil Technology, […]

Levil Technology Aviation is revolutionizing the way we fly. From its humble beginnings, this technology has become an integral part of modern aircraft design, manufacturing, and flight operations. Levil Technology, encompassing advanced materials, innovative designs, and sophisticated systems, enhances safety, efficiency, and performance, paving the way for a new era in aviation.

This article delves into the fascinating world of Levil Technology, exploring its historical evolution, current applications, and exciting future prospects. We will uncover the key components of Levil Technology, examine its impact on various aspects of aviation, and discuss the challenges and opportunities it presents.

Introduction to Levil Technology in Aviation

Levil Technology, a crucial aspect of modern aviation, plays a vital role in ensuring safe and efficient flight operations. This technology encompasses various systems and techniques that help maintain aircraft stability and control, especially during challenging conditions like turbulence or engine failure.

Levil Technology has a rich history, evolving alongside the development of aircraft. Early forms of levil technology focused on mechanical systems like ailerons and elevators, manually controlled by the pilot. Over time, advancements in electronics and computing led to the development of more sophisticated systems like autopilots and flight control computers.

Evolution of Levil Technology

The evolution of levil technology can be traced back to the early days of aviation. The Wright brothers, pioneers of flight, utilized basic control surfaces like ailerons and elevators to maintain stability and control their aircraft.

- Early Aviation (1903-1930s): Mechanical control systems, like ailerons and elevators, were the primary means of maintaining aircraft stability. Pilots manually controlled these systems to adjust the aircraft’s attitude and direction.

- Mid-20th Century (1940s-1960s): The introduction of hydraulic and electrical systems significantly improved control response and reduced pilot workload. Autopilots, initially developed for long-haul flights, emerged during this period.

- Late 20th Century and Beyond (1970s-Present): Advancements in electronics and computing led to the development of sophisticated flight control systems. Flight control computers, capable of processing vast amounts of data and making real-time adjustments, revolutionized aircraft control.

Levil Technology Applications

Levil Technology finds applications in various aircraft types, from small general aviation aircraft to large commercial airliners.

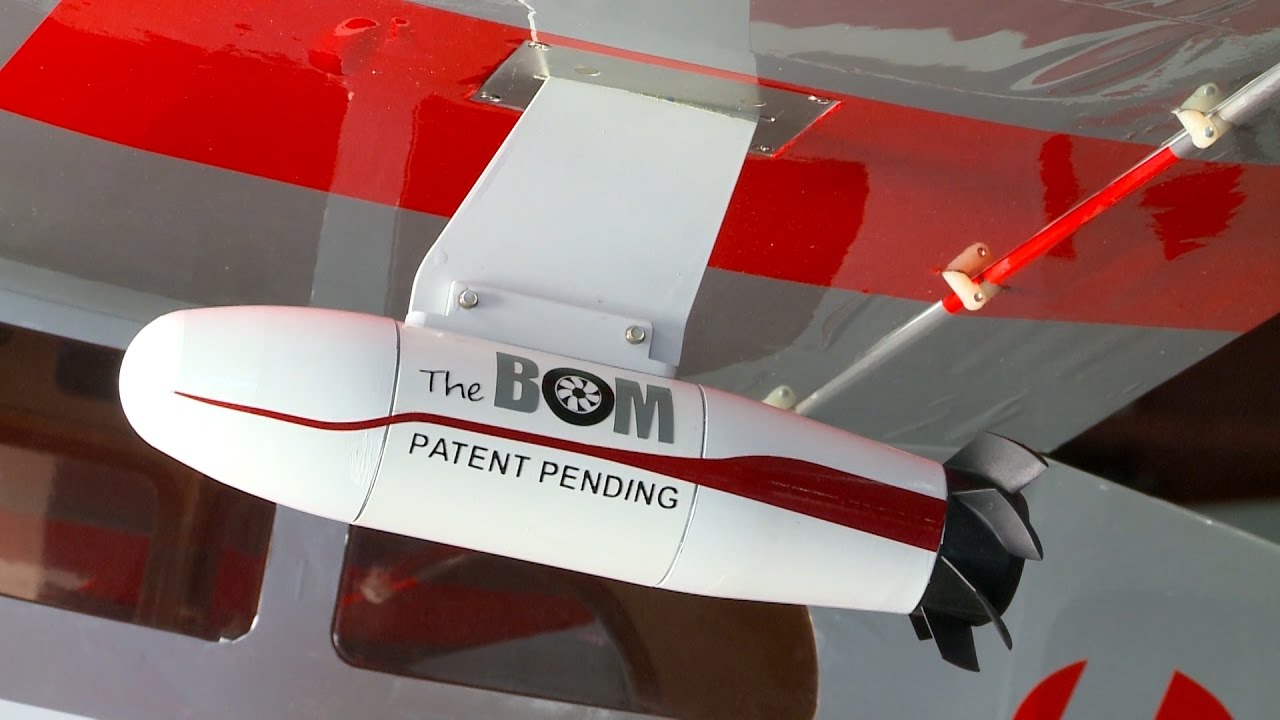

- General Aviation Aircraft: Smaller aircraft often utilize basic levil technology, such as ailerons, elevators, and rudders, controlled manually by the pilot.

- Commercial Airliners: Large commercial airliners employ advanced levil technology, including flight control computers, autopilots, and stability augmentation systems. These systems provide enhanced control and stability, even in challenging conditions.

- Military Aircraft: Military aircraft often utilize sophisticated levil technology, including fly-by-wire systems and advanced stability augmentation systems. These systems enable pilots to perform complex maneuvers and maintain control during high-speed flight and combat situations.

Examples of Levil Technology in Action

- Autopilot: An autopilot system is a key component of levil technology. It automatically controls the aircraft’s pitch, roll, and yaw, reducing pilot workload and improving flight efficiency. For instance, during long-haul flights, the autopilot can maintain a steady altitude and heading, allowing the pilots to focus on other tasks.

- Stability Augmentation Systems: These systems enhance aircraft stability by automatically adjusting control surfaces to counter disturbances like turbulence. This technology significantly improves the aircraft’s ride quality and reduces pilot workload.

- Fly-by-Wire Systems: Fly-by-wire systems utilize electronic signals to control the aircraft’s flight surfaces. This technology allows for more precise and responsive control, enabling pilots to perform complex maneuvers with greater ease.

Levil Technology Applications in Aircraft Design

Levil Technology, with its emphasis on lightweight materials and advanced manufacturing techniques, has significantly impacted aircraft design, enabling the creation of more efficient, fuel-saving, and environmentally friendly aircraft. This section delves into the specific applications of Levil Technology in aircraft design, exploring its advantages and disadvantages, and examining its impact on aircraft performance, efficiency, and safety.

Levil Technology Components in Aircraft Design

Levil Technology components are integral to modern aircraft design, contributing to enhanced performance, efficiency, and safety.

- Lightweight Composites: Levil Technology leverages advanced composite materials, such as carbon fiber reinforced polymers (CFRP), which offer exceptional strength-to-weight ratios. These composites are extensively used in aircraft structures, including fuselage, wings, and tail sections, leading to weight reduction and improved fuel efficiency. For example, the Boeing 787 Dreamliner extensively utilizes CFRP, resulting in a 20% reduction in fuel consumption compared to previous models.

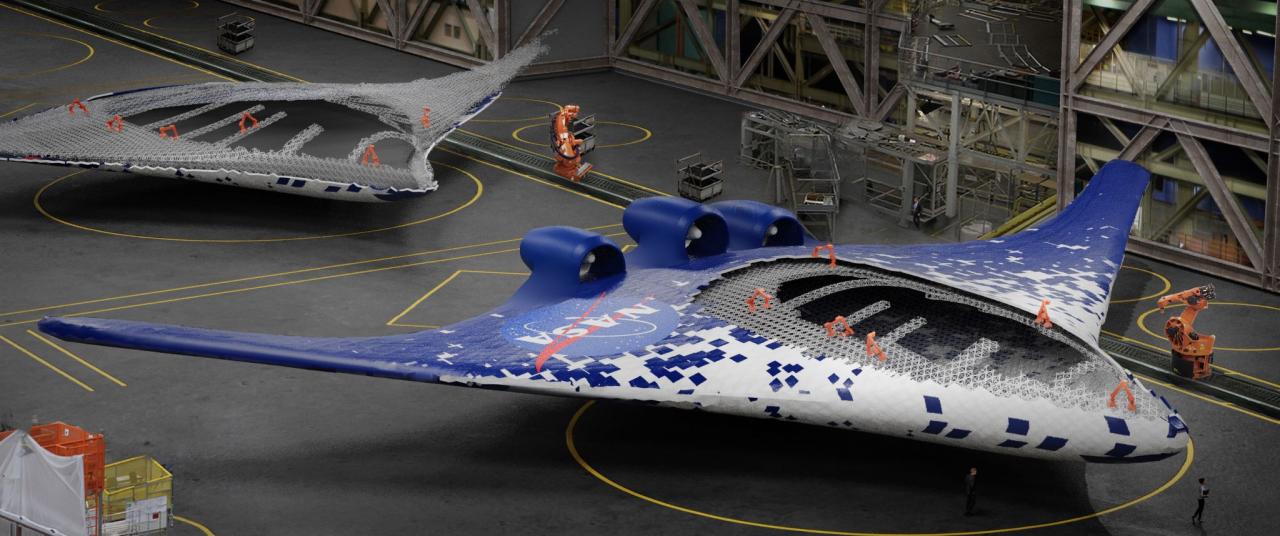

- Additive Manufacturing: Also known as 3D printing, additive manufacturing plays a crucial role in Levil Technology. It allows for the creation of complex and intricate components with precise geometries, reducing material waste and lead times. Additive manufacturing enables the production of customized parts, optimized for specific aircraft designs, contributing to weight reduction and improved performance.

- Advanced Joining Techniques: Levil Technology emphasizes advanced joining techniques, such as laser welding and adhesive bonding, which replace traditional mechanical fasteners, further reducing weight and improving structural integrity. These techniques enable seamless integration of different materials, enhancing the overall strength and durability of the aircraft.

Advantages of Levil Technology in Aircraft Design

The application of Levil Technology in aircraft design offers numerous advantages:

- Weight Reduction: By employing lightweight materials and advanced manufacturing techniques, Levil Technology significantly reduces aircraft weight. This leads to lower fuel consumption, reduced emissions, and improved payload capacity.

- Improved Fuel Efficiency: The reduction in weight translates into improved fuel efficiency, enabling aircraft to travel longer distances with less fuel, thereby reducing operational costs and environmental impact.

- Enhanced Performance: Lighter aircraft experience improved acceleration, climb rate, and maneuverability, leading to enhanced overall performance.

- Increased Safety: The use of advanced materials and manufacturing techniques contributes to improved structural integrity and enhanced safety. For instance, composite materials exhibit high impact resistance, enhancing crashworthiness.

- Reduced Maintenance Costs: Levil Technology often results in components with longer service lives, requiring less frequent maintenance, thereby reducing overall operational costs.

Disadvantages of Levil Technology in Aircraft Design

While Levil Technology offers numerous advantages, it also presents certain challenges:

- Higher Initial Costs: Advanced materials and manufacturing processes associated with Levil Technology can result in higher initial costs compared to traditional aircraft construction methods. However, these costs are often offset by long-term savings in fuel and maintenance.

- Complexity of Design and Manufacturing: Levil Technology requires specialized expertise and sophisticated manufacturing processes, adding complexity to the design and manufacturing phases.

- Limited Repair Capabilities: Damage to composite structures can be challenging to repair, requiring specialized expertise and facilities. However, advancements in repair techniques are continuously being made.

Impact of Levil Technology on Aircraft Performance, Efficiency, and Safety, Levil technology aviation

Levil Technology has had a profound impact on aircraft performance, efficiency, and safety.

- Performance: Levil Technology has enabled the development of aircraft with improved acceleration, climb rate, and maneuverability. For example, the Airbus A350, which incorporates extensive use of composites, boasts a 25% reduction in fuel consumption compared to previous models, contributing to enhanced performance and range.

- Efficiency: Levil Technology’s emphasis on weight reduction and advanced manufacturing techniques has significantly improved fuel efficiency, leading to lower operating costs and reduced environmental impact. For instance, the Boeing 787 Dreamliner, with its extensive use of composites, has achieved a 20% reduction in fuel consumption compared to previous models.

- Safety: Levil Technology has enhanced aircraft safety by improving structural integrity and crashworthiness. Composite materials, with their high impact resistance, have contributed to enhanced safety in aircraft design. For example, the use of composites in the Airbus A380 has contributed to its exceptional crashworthiness.

Levil Technology in Aircraft Manufacturing

Levil Technology’s integration into aircraft manufacturing presents a unique set of challenges and opportunities, influencing the design, production, and overall efficiency of aircraft. This section delves into the specific manufacturing processes involved, the associated challenges and opportunities, and highlights successful examples of Levil Technology integration in aircraft manufacturing.

Manufacturing Processes

Levil Technology’s integration into aircraft manufacturing involves adapting existing manufacturing processes and developing new ones to accommodate the unique characteristics of Levil materials. These processes include:

- Material Handling: Levil materials are often lighter and more delicate than traditional materials, requiring specialized handling equipment and procedures to prevent damage during transportation and storage.

- Cutting and Shaping: Levil materials require specialized cutting and shaping techniques, often employing laser cutting, waterjet cutting, or other precision methods to achieve the desired geometry.

- Joining and Assembly: Levil materials may require unique joining techniques, such as adhesive bonding, riveting, or specialized welding processes, to ensure structural integrity.

- Surface Finishing: Levil materials often require specific surface finishing processes, such as anodizing, painting, or coating, to enhance their durability and aesthetics.

Challenges and Opportunities

The integration of Levil Technology in aircraft manufacturing presents both challenges and opportunities.

- Challenges:

- Material Compatibility: Levil materials may have different properties than traditional materials, requiring careful consideration of their compatibility with existing components and systems.

- Manufacturing Expertise: The specialized manufacturing processes required for Levil materials necessitate a skilled workforce with specific expertise.

- Cost Optimization: Levil materials can be more expensive than traditional materials, requiring careful cost optimization strategies to ensure economic viability.

- Certification and Testing: Levil materials require rigorous certification and testing processes to meet aviation safety standards.

- Opportunities:

- Weight Reduction: Levil materials offer significant weight reduction potential, leading to improved fuel efficiency and reduced emissions.

- Enhanced Performance: Levil materials can enhance aircraft performance by providing improved strength-to-weight ratios and aerodynamic characteristics.

- Reduced Maintenance Costs: Levil materials can reduce maintenance costs due to their durability and resistance to corrosion.

- Innovation and Differentiation: Levil Technology provides opportunities for innovation and differentiation in aircraft design, enabling manufacturers to develop unique and competitive products.

Successful Examples

Several aircraft manufacturers have successfully integrated Levil Technology into their products, demonstrating its potential to revolutionize aircraft manufacturing.

- Boeing: Boeing has incorporated Levil materials into various components of its commercial aircraft, including the 787 Dreamliner, contributing to its fuel efficiency and performance.

- Airbus: Airbus has also adopted Levil Technology in its aircraft, such as the A350 XWB, utilizing Levil materials for structural components and enhancing its overall efficiency.

- Embraer: Embraer, a Brazilian aircraft manufacturer, has implemented Levil Technology in its regional jets, resulting in lighter aircraft with improved fuel economy.

Levil Technology and Flight Operations: Levil Technology Aviation

Levil Technology plays a significant role in enhancing flight operations, impacting various stages from takeoff to landing and in-flight procedures. By leveraging data analysis and predictive modeling, Levil Technology contributes to increased safety, efficiency, and sustainability in aviation.

Impact on Takeoff and Landing

Levil Technology assists in optimizing takeoff and landing procedures, ensuring a smoother and safer experience. By analyzing real-time data from various sources, including weather conditions, runway conditions, and aircraft performance, Levil Technology provides pilots with critical insights. This information helps them make informed decisions about takeoff and landing parameters, ensuring optimal performance and minimizing risks. For example, Levil Technology can analyze wind conditions and suggest optimal takeoff and landing headings to minimize crosswind effects, contributing to a more stable and controlled flight.

Enhancement of In-Flight Procedures

Levil Technology significantly enhances in-flight procedures, optimizing flight paths, fuel consumption, and overall efficiency. By analyzing historical flight data, weather patterns, and air traffic conditions, Levil Technology can predict potential delays and suggest alternative routes to minimize disruptions and optimize flight times. Furthermore, it can assist in optimizing fuel consumption by suggesting the most efficient flight path and altitude, contributing to environmental sustainability and cost savings.

Contribution to Flight Safety and Efficiency

Levil Technology plays a crucial role in enhancing flight safety and efficiency by providing pilots and air traffic controllers with valuable information and insights. It can identify potential hazards, such as turbulence, weather anomalies, and potential bird strikes, allowing for proactive measures to be taken. By analyzing flight data and identifying trends, Levil Technology can also contribute to improving aircraft maintenance schedules and detecting potential issues before they become critical.

Impact of Levil Technology on Flight Operations

| Aspect of Flight Operations | Impact of Levil Technology |

|—|—|

| Takeoff and Landing | Optimized takeoff and landing procedures, improved safety and efficiency |

| In-Flight Procedures | Optimized flight paths, fuel consumption, and overall efficiency |

| Flight Safety | Enhanced safety through early hazard detection and proactive measures |

| Flight Efficiency | Increased efficiency through optimized flight paths and fuel consumption |

| Maintenance | Improved maintenance scheduling and early detection of potential issues |

Final Summary

Levil Technology is not just shaping the future of aviation; it’s defining it. As we continue to push the boundaries of what’s possible in flight, Levil Technology will play an increasingly crucial role in creating a safer, more efficient, and sustainable aviation industry. By embracing innovation and leveraging the power of Levil Technology, we can unlock a new era of flight, reaching greater heights and exploring new horizons.

Levil Technology Aviation is known for its innovative approach to aerospace engineering. While they focus on the skies, their commitment to improving accessibility extends to the ground as well. For those seeking comfortable and convenient seating options, golden technologies lift chair prices offer a range of solutions.

Levil Technology Aviation’s dedication to making life easier for everyone, regardless of their physical limitations, aligns with the spirit of accessibility that Golden Technologies embodies.