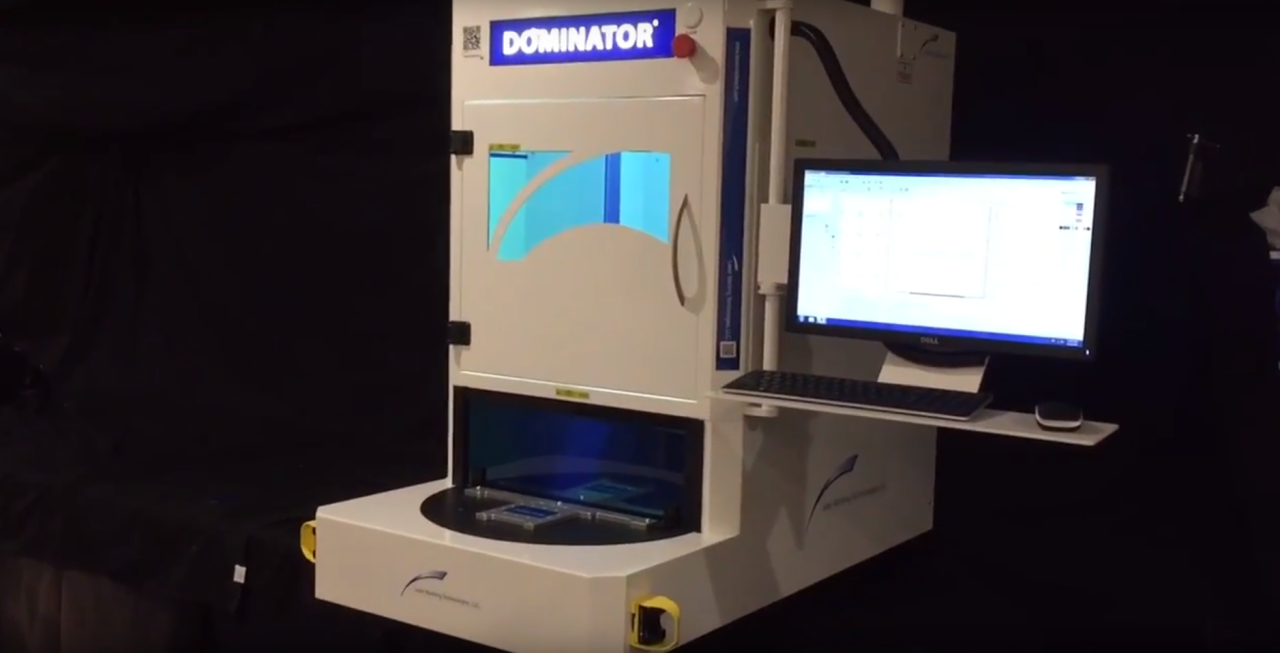

Laser Marking Technologies Dominator: Shaping Industries

Laser marking technologies dominator, a revolution in precision and versatility, is reshaping industries across the globe. From manufacturing to electronics, aerospace to automotive, laser marking has become an indispensable tool […]

Laser marking technologies dominator, a revolution in precision and versatility, is reshaping industries across the globe. From manufacturing to electronics, aerospace to automotive, laser marking has become an indispensable tool for product identification, traceability, and quality control. This technology utilizes focused laser beams to permanently mark materials, offering unparalleled accuracy and efficiency.

The principles behind laser marking are rooted in the interaction of light and matter. Laser beams, concentrated beams of light, interact with the surface of a material, altering its properties to create a permanent mark. This process can be tailored to achieve various marking styles, including text, graphics, and even barcodes.

Laser Marking Technologies: Laser Marking Technologies Dominator

Laser marking technologies are a versatile and widely used set of techniques for permanently marking various materials. They offer high precision, durability, and flexibility, making them suitable for a wide range of applications across different industries.

Fundamentals of Laser Marking

Laser marking involves using a focused laser beam to alter the surface properties of a material, creating a permanent mark. The laser beam interacts with the material, either removing material (ablation) or modifying its properties (e.g., color change, surface hardening). The process is based on the principle of selective absorption of laser energy by the material. Different laser wavelengths and pulse durations are used to achieve specific marking effects.

Types of Laser Marking Technologies

Laser marking technologies can be broadly classified into several categories based on the marking mechanism:

- Laser Ablation Marking: This technique uses a high-power laser beam to remove material from the surface, creating a permanent mark. It is suitable for marking metals, plastics, ceramics, and other materials.

- Laser Engraving: A variation of laser ablation marking where the laser beam is scanned across the surface to create a three-dimensional mark. It is often used for creating intricate designs and patterns.

- Laser Marking by Surface Modification: This technique involves using a laser beam to modify the surface properties of a material, such as color, texture, or hardness.

- Laser Marking by Heat Treatment: This technique uses a laser beam to heat the surface of a material, causing a change in its properties. This is often used for marking metals, where the laser heat can induce a color change or hardening of the surface.

Applications of Laser Marking Technologies

Laser marking technologies have found widespread applications in various industries, including:

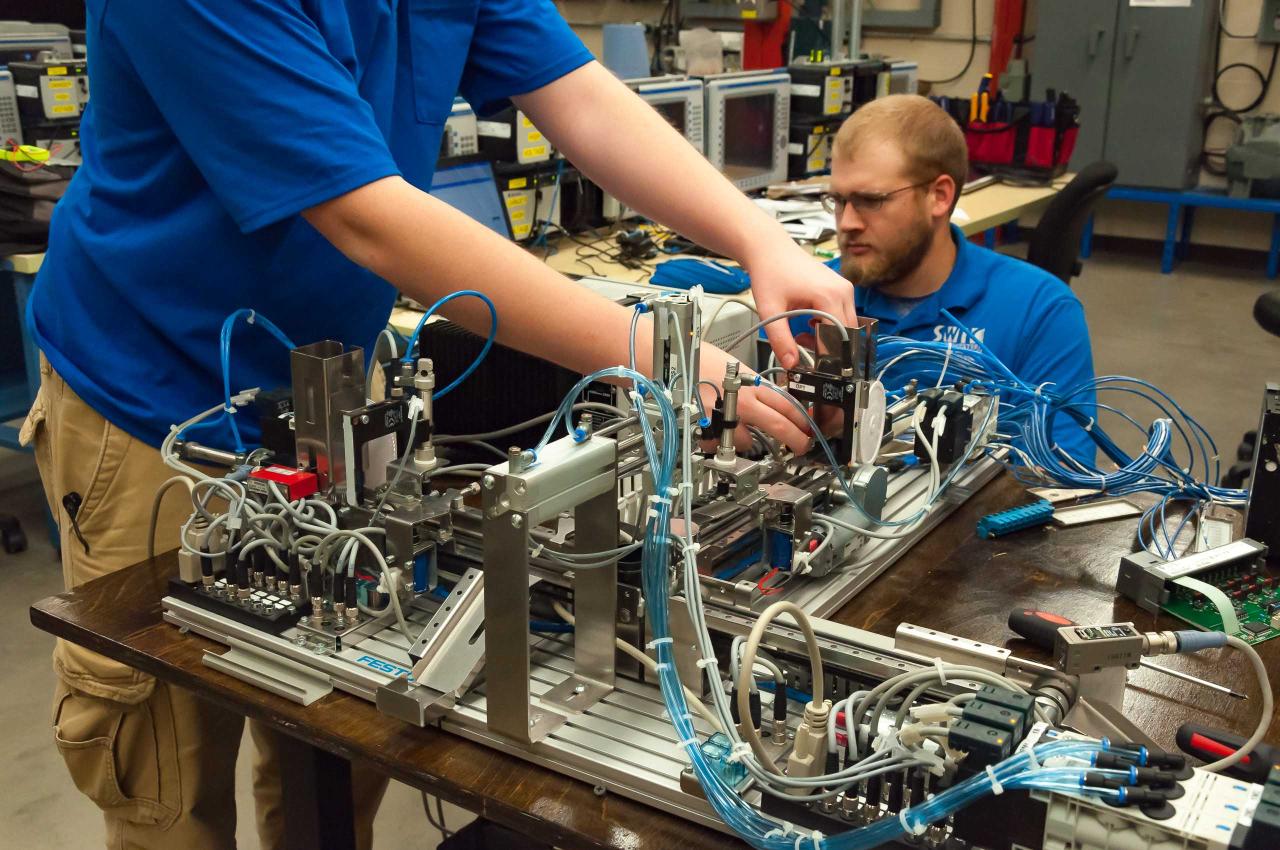

- Manufacturing: Laser marking is used for marking parts, components, and products for identification, traceability, and quality control.

- Electronics: Laser marking is used for marking circuit boards, integrated circuits, and other electronic components.

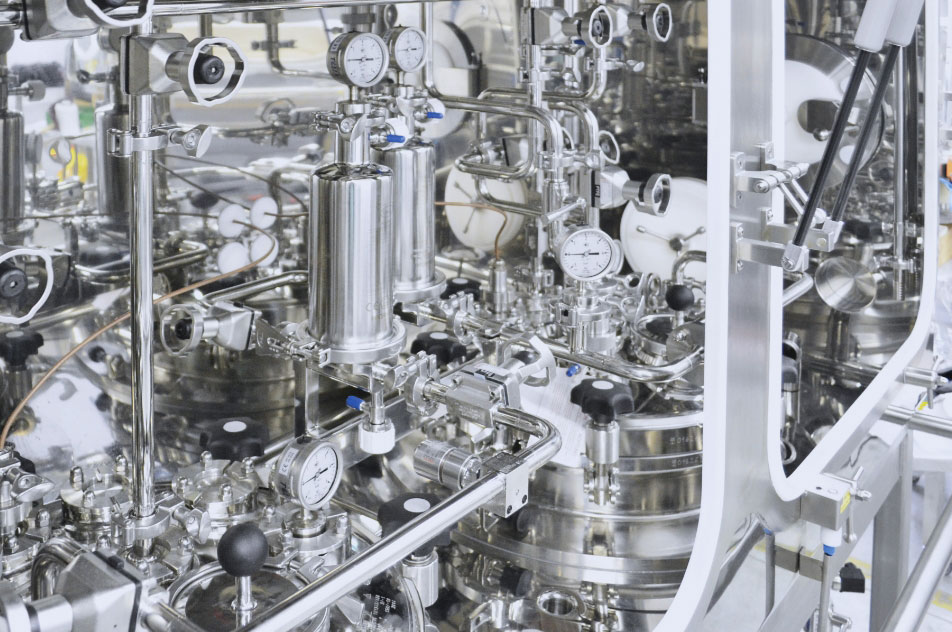

- Medical Devices: Laser marking is used for marking medical devices for identification, sterilization, and regulatory compliance.

- Automotive: Laser marking is used for marking automotive parts, components, and vehicles for identification, traceability, and safety.

- Aerospace: Laser marking is used for marking aerospace components, such as turbine blades, for identification, traceability, and quality control.

- Jewelry: Laser marking is used for engraving designs and inscriptions on jewelry, creating unique and personalized pieces.

Dominant Players in the Laser Marking Industry

The laser marking industry is a competitive landscape with several key players vying for market share. These companies are constantly innovating to develop advanced laser marking technologies, cater to specific industry needs, and expand their global reach. Understanding the key players and their competitive strategies is crucial for businesses seeking to implement laser marking solutions.

Market Share and Competitive Landscape

The laser marking industry is characterized by a mix of established players and emerging companies. Some of the dominant players in the market include:

- Trumpf: A German multinational company, Trumpf is a leading provider of laser marking systems for various industries, including automotive, aerospace, and electronics. Trumpf is known for its high-quality laser marking systems, extensive product portfolio, and strong global presence.

- IPG Photonics: A US-based company, IPG Photonics is a global leader in high-power fiber lasers. The company offers a wide range of laser marking systems, including fiber lasers, diode lasers, and ultrafast lasers. IPG Photonics is known for its innovative laser technologies, high-performance systems, and strong customer support.

- Coherent: A US-based company, Coherent is a leading manufacturer of laser systems for various applications, including laser marking. Coherent offers a diverse range of laser marking systems, including fiber lasers, diode lasers, and ultrafast lasers. Coherent is known for its high-precision laser marking systems, advanced technology, and global reach.

- Universal Laser Systems (ULS): A US-based company, ULS is a leading provider of laser marking systems for industrial applications. ULS offers a wide range of laser marking systems, including CO2 lasers, fiber lasers, and diode lasers. ULS is known for its user-friendly laser marking systems, comprehensive software solutions, and strong customer support.

- Daetwyler: A Swiss multinational company, Daetwyler is a leading provider of laser marking systems for the electronics and automotive industries. Daetwyler offers a range of laser marking systems, including fiber lasers, diode lasers, and ultrafast lasers. Daetwyler is known for its high-precision laser marking systems, innovative technologies, and global reach.

These companies hold significant market share and are constantly striving to innovate and expand their product offerings.

Strengths and Weaknesses of Laser Marking Technology Companies

Each laser marking technology company has its strengths and weaknesses, which contribute to their competitive positioning.

- Trumpf:

- Strengths: Extensive product portfolio, strong global presence, high-quality laser marking systems, strong customer support.

- Weaknesses: Relatively high pricing compared to some competitors, limited focus on niche markets.

- IPG Photonics:

- Strengths: Innovative laser technologies, high-performance systems, strong customer support, competitive pricing.

- Weaknesses: Limited product portfolio compared to some competitors, less emphasis on software solutions.

- Coherent:

- Strengths: High-precision laser marking systems, advanced technology, strong global reach, diverse product portfolio.

- Weaknesses: Relatively high pricing, complex system configurations, limited focus on certain niche markets.

- Universal Laser Systems (ULS):

- Strengths: User-friendly laser marking systems, comprehensive software solutions, strong customer support, competitive pricing.

- Weaknesses: Limited product portfolio compared to some competitors, less focus on high-power laser marking systems.

- Daetwyler:

- Strengths: High-precision laser marking systems, innovative technologies, strong global reach, focus on specific industries (electronics, automotive).

- Weaknesses: Limited product portfolio compared to some competitors, relatively high pricing, less emphasis on software solutions.

Factors Contributing to Dominance

Several factors contribute to the dominance of certain laser marking technology providers.

- Innovation and Technology Leadership: Companies that invest heavily in research and development and consistently introduce innovative laser marking technologies often gain a competitive advantage.

- Product Portfolio and Customization: Offering a wide range of laser marking systems, including different laser types and power levels, allows companies to cater to diverse customer needs.

- Global Reach and Distribution Network: Companies with a strong global presence and extensive distribution networks can reach a wider customer base and provide efficient service and support.

- Customer Support and Service: Providing excellent customer support, including technical assistance, training, and maintenance services, is crucial for building customer loyalty and satisfaction.

- Pricing and Value Proposition: Companies that offer competitive pricing and a compelling value proposition, such as high-quality products, reliable performance, and excellent customer service, can attract a larger customer base.

Technological Advancements in Laser Marking

Laser marking technologies have witnessed remarkable advancements in recent years, pushing the boundaries of precision, speed, and versatility. These innovations have significantly impacted various industries, from manufacturing and electronics to healthcare and aerospace.

Advancements in Laser Sources

The development of new laser sources has played a crucial role in enhancing laser marking capabilities.

- Fiber Lasers: These lasers offer high efficiency, excellent beam quality, and long operational life. Their compact size and high power output make them suitable for a wide range of marking applications, particularly in high-volume production environments.

- Ultrafast Lasers: Ultrafast lasers generate extremely short pulses of laser light, measured in femtoseconds or picoseconds. This allows for highly precise marking with minimal heat input, making them ideal for delicate materials and intricate designs. They also enable micromachining and surface modification applications.

- Diode Lasers: Diode lasers are known for their affordability and reliability. They are particularly well-suited for marking on plastics, metals, and other materials, offering good marking quality at a competitive cost.

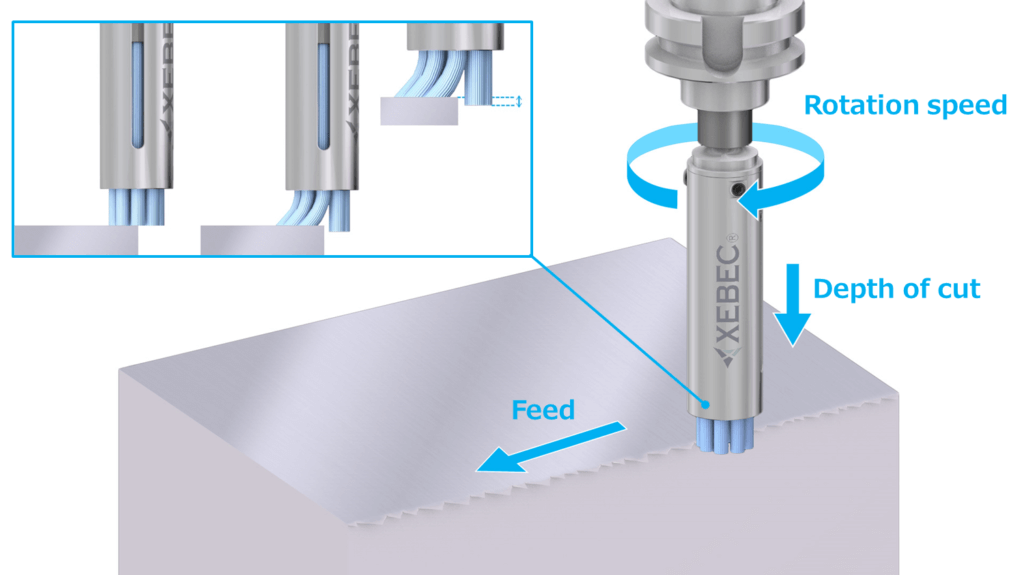

Enhanced Marking Precision and Speed

Advancements in laser optics, control systems, and software have significantly improved the precision and speed of laser marking processes.

- High-Resolution Marking: Improved laser optics and scanning systems enable high-resolution marking, allowing for the creation of intricate and detailed designs with fine features. This is particularly beneficial for applications requiring precise marking of small components or intricate patterns.

- Faster Marking Speeds: Advanced control systems and software algorithms allow for faster marking speeds without compromising quality. This significantly increases production efficiency, particularly in high-volume manufacturing environments.

Versatility and Adaptability, Laser marking technologies dominator

Laser marking technologies are becoming increasingly versatile and adaptable to meet the demands of diverse applications.

- Multi-Material Marking: Laser marking systems are now capable of marking a wide range of materials, including metals, plastics, ceramics, glass, and even wood. This versatility expands the applications of laser marking across various industries.

- Flexible Marking Configurations: Laser marking systems are now available in different configurations, including handheld, stationary, and robotic systems. This flexibility allows for marking on various surfaces and in different environments, adapting to specific needs and production processes.

Emerging Applications and Opportunities

Advancements in laser marking technologies are opening up new opportunities and applications across various industries.

- Medical Device Marking: Laser marking is used for permanent and precise marking of medical devices, ensuring traceability and compliance with regulatory standards. This is crucial for patient safety and device identification.

- Electronics and Semiconductor Marking: Laser marking is essential for marking microchips, circuit boards, and other electronic components. Its high precision and speed enable efficient and reliable marking of intricate features on delicate materials.

- Aerospace and Automotive Marking: Laser marking is used for marking parts and components in aerospace and automotive industries. It ensures durability, traceability, and compliance with stringent industry standards.

- Security and Anti-Counterfeiting: Laser marking can be used to create unique and intricate patterns for security and anti-counterfeiting purposes. This helps in verifying authenticity and protecting brands from counterfeiting.

Applications of Laser Marking Technologies

Laser marking technologies have revolutionized various industries by offering a versatile and precise method for permanently marking materials. This technology finds applications in numerous sectors, from manufacturing and automotive to electronics and aerospace, enabling efficient product identification, traceability, and brand enhancement.

Manufacturing

Laser marking plays a crucial role in manufacturing by providing a reliable and durable method for marking various materials, including metals, plastics, and ceramics. The high precision and flexibility of laser marking systems allow for the creation of intricate designs, logos, serial numbers, and barcodes.

- Part Identification: Laser marking is used to permanently identify components and parts, ensuring traceability throughout the manufacturing process. This helps track production batches, manage inventory, and prevent counterfeiting.

- Quality Control: Laser marking enables manufacturers to integrate quality control measures directly onto components. Marking critical parameters such as dimensions, tolerances, and material specifications directly onto the product surface eliminates the need for separate labels or tags, simplifying inspection processes.

- Product Branding: Laser marking allows manufacturers to brand their products with logos, trademarks, and other branding elements. The permanent nature of laser markings ensures brand integrity and prevents counterfeiting.

Automotive

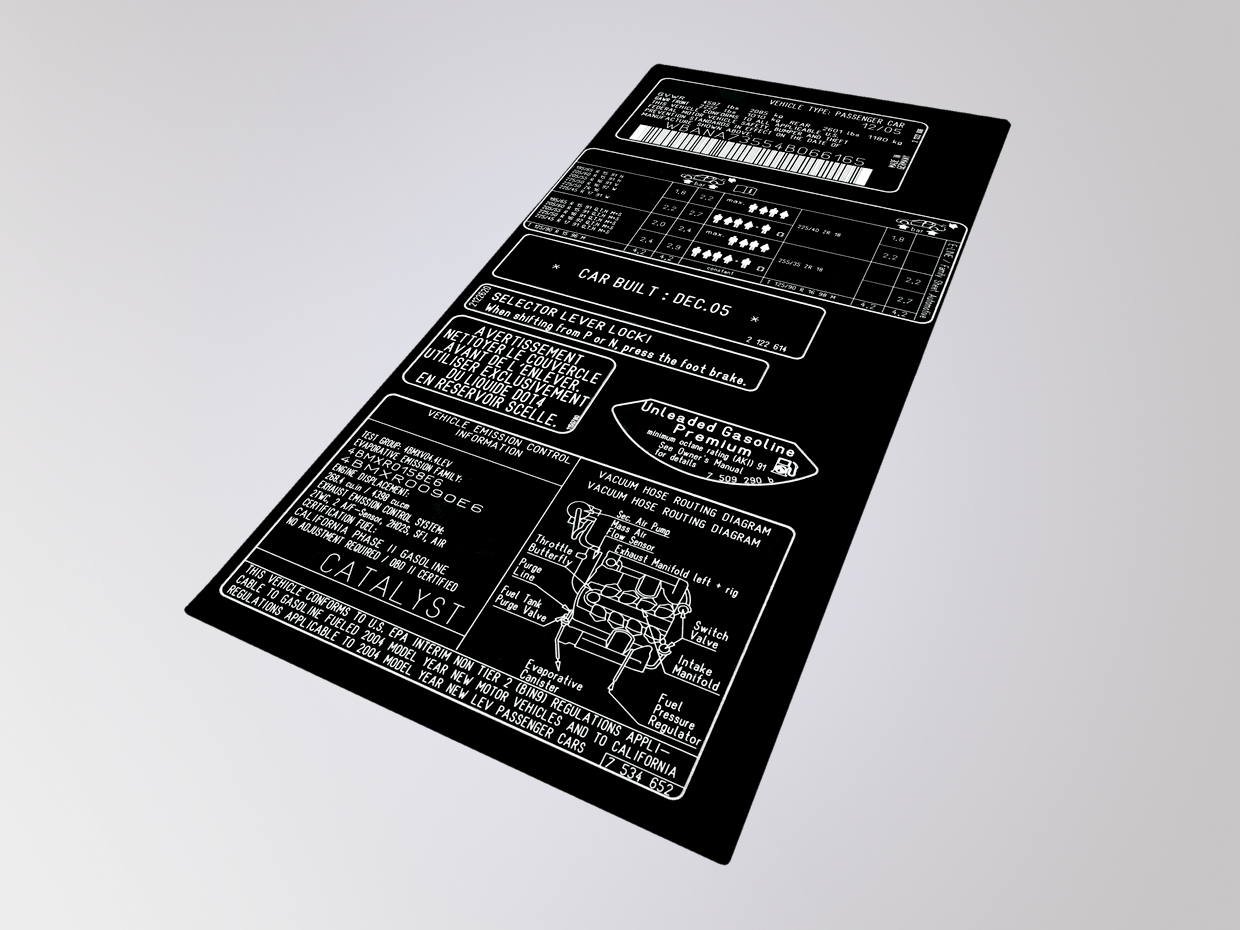

The automotive industry relies heavily on laser marking technologies for a wide range of applications, from component identification and traceability to decorative markings and safety features.

- Engine Components: Laser marking is used to mark engine parts, such as cylinders, pistons, and crankshafts, with unique identification numbers, enabling efficient tracking and maintenance.

- Vehicle Identification Numbers (VINs): Laser marking is the standard method for permanently etching VINs onto vehicle chassis and components. The high durability of laser markings ensures that VINs remain legible throughout the vehicle’s lifetime.

- Safety Features: Laser marking is employed to create safety markings on vehicle components, such as brake calipers and steering wheels. These markings provide essential information for safety inspections and maintenance.

Electronics

The electronics industry utilizes laser marking for marking delicate components and intricate circuitry, ensuring precise identification and traceability.

- Printed Circuit Boards (PCBs): Laser marking is widely used to mark PCBs with component identification, circuit diagrams, and serial numbers. The precision of laser marking allows for the creation of fine details on complex circuitry, enhancing product traceability and quality control.

- Microchips and Semiconductors: Laser marking is employed to mark microchips and semiconductors with unique identification numbers, enabling tracking and authentication. The non-contact nature of laser marking prevents damage to these sensitive components.

- Electronic Devices: Laser marking is used to mark electronic devices such as smartphones, laptops, and tablets with logos, model numbers, and serial numbers. The durability of laser markings ensures that these markings remain legible throughout the device’s lifespan.

Aerospace

The aerospace industry demands high-precision marking solutions for critical components, and laser marking technologies provide the necessary accuracy and durability.

- Aircraft Parts: Laser marking is used to mark aircraft parts, such as engines, wings, and fuselage, with identification numbers, material specifications, and manufacturing dates. The permanent nature of laser markings ensures traceability and safety compliance.

- Satellite Components: Laser marking is employed to mark satellite components with unique identification numbers and operational parameters. The high precision and durability of laser markings ensure that these markings remain legible in harsh space environments.

- Spacecraft Components: Laser marking is used to mark spacecraft components, such as fuel tanks, propulsion systems, and solar panels, with identification numbers, material specifications, and operational parameters. The non-contact nature of laser marking prevents contamination or damage to these critical components.

Final Summary

Laser marking technologies dominator is not just a technological advancement; it is a catalyst for innovation, driving improvements in product quality, traceability, and brand identification. As the industry continues to evolve, laser marking will undoubtedly play an even greater role in shaping the future of manufacturing and beyond. With its versatility, precision, and increasing automation, laser marking technology promises to remain at the forefront of industrial innovation.

Laser marking technologies are revolutionizing industries, and one company leading the charge is shenzhen tong bo wei technology co. ltd. Their expertise in precision laser marking solutions is making a significant impact on the market, proving their commitment to delivering cutting-edge technology that pushes the boundaries of what’s possible in laser marking.