Jobs in Mechanical Engineering Technology: A Career Path

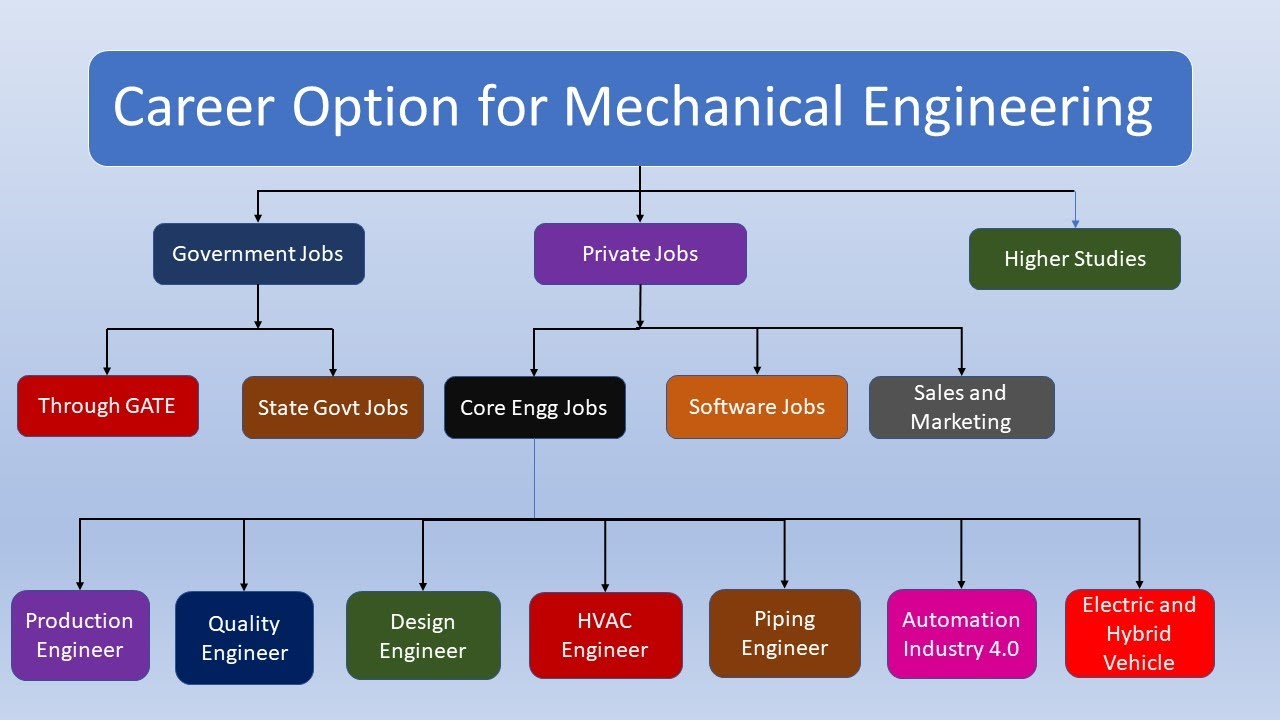

Jobs in mechanical engineering technology are a gateway to a world of innovation and problem-solving. This field combines the principles of engineering with practical applications, allowing professionals to design, build, […]

Jobs in mechanical engineering technology are a gateway to a world of innovation and problem-solving. This field combines the principles of engineering with practical applications, allowing professionals to design, build, and improve the machines and systems that power our modern world. From designing intricate components for automobiles to developing sustainable energy solutions, mechanical engineering technologists play a vital role in shaping the future of industries across the globe.

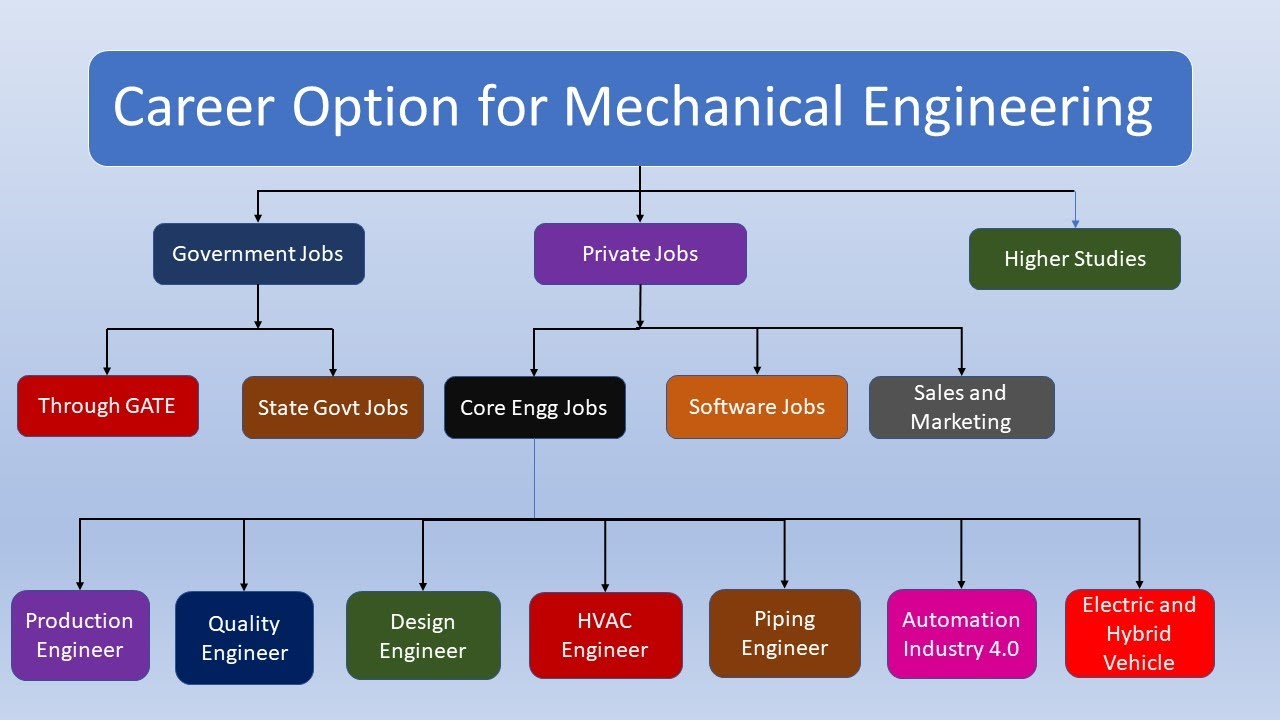

The field encompasses a wide range of specialties, each demanding a unique blend of technical skills and knowledge. Whether you’re interested in automotive engineering, robotics, or biomedical technology, there’s a niche within mechanical engineering technology that can ignite your passion. With its diverse applications and ever-evolving landscape, a career in mechanical engineering technology offers a rewarding path for those seeking to make a tangible impact on the world.

Introduction to Mechanical Engineering Technology

Mechanical engineering technology is a vital field that plays a crucial role in shaping the modern world. It encompasses the application of scientific principles and engineering techniques to design, develop, and manufacture mechanical systems. Mechanical engineering technologists work across diverse industries, contributing to advancements in transportation, energy, manufacturing, and more.

Key Areas of Focus

Mechanical engineering technology is a broad field, encompassing several key areas of focus. These areas are interconnected and often involve collaboration among professionals.

- Design and Development: This area focuses on the conceptualization, design, and development of mechanical systems and components. It involves using computer-aided design (CAD) software, understanding materials science, and applying principles of mechanics and thermodynamics.

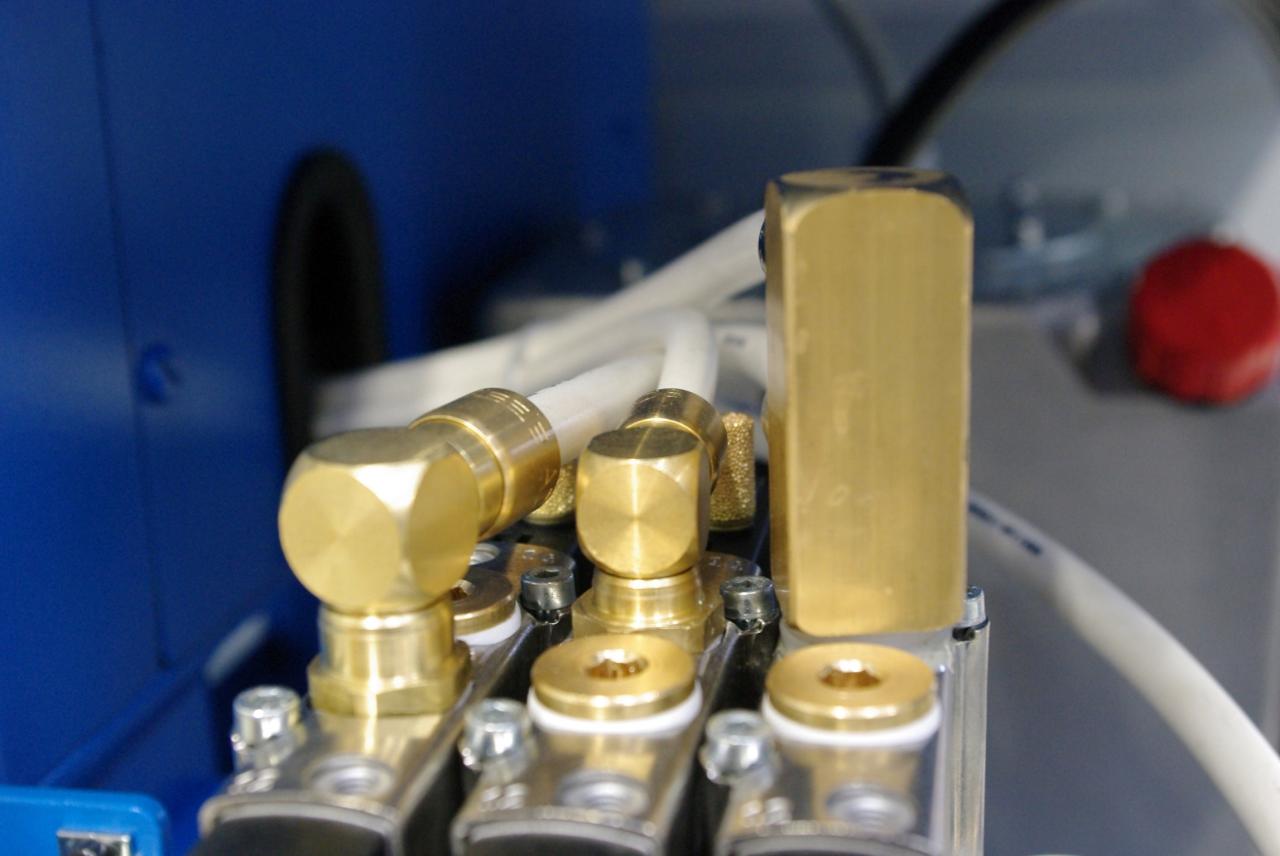

- Manufacturing and Production: This area focuses on the processes involved in producing mechanical systems and components. It includes understanding manufacturing techniques, such as machining, welding, and casting, as well as quality control and process optimization.

- Testing and Evaluation: This area involves conducting experiments and simulations to evaluate the performance, reliability, and safety of mechanical systems. It requires understanding measurement techniques, data analysis, and interpreting results.

- Automation and Robotics: This area focuses on the integration of automation and robotics into manufacturing and other processes. It involves understanding control systems, programming, and the application of robotic systems in various tasks.

Real-World Applications

Mechanical engineering technology has a wide range of applications in various industries, impacting our daily lives in numerous ways. Here are some examples:

- Transportation: From designing fuel-efficient cars and airplanes to developing advanced robotics for autonomous vehicles, mechanical engineering technology plays a vital role in shaping the future of transportation.

- Energy: Mechanical engineering technologists contribute to the development of renewable energy sources, such as wind turbines and solar panels, as well as the optimization of traditional energy systems.

- Manufacturing: Mechanical engineering technology is essential for designing and manufacturing products ranging from consumer goods to complex machinery, driving innovation and efficiency in manufacturing processes.

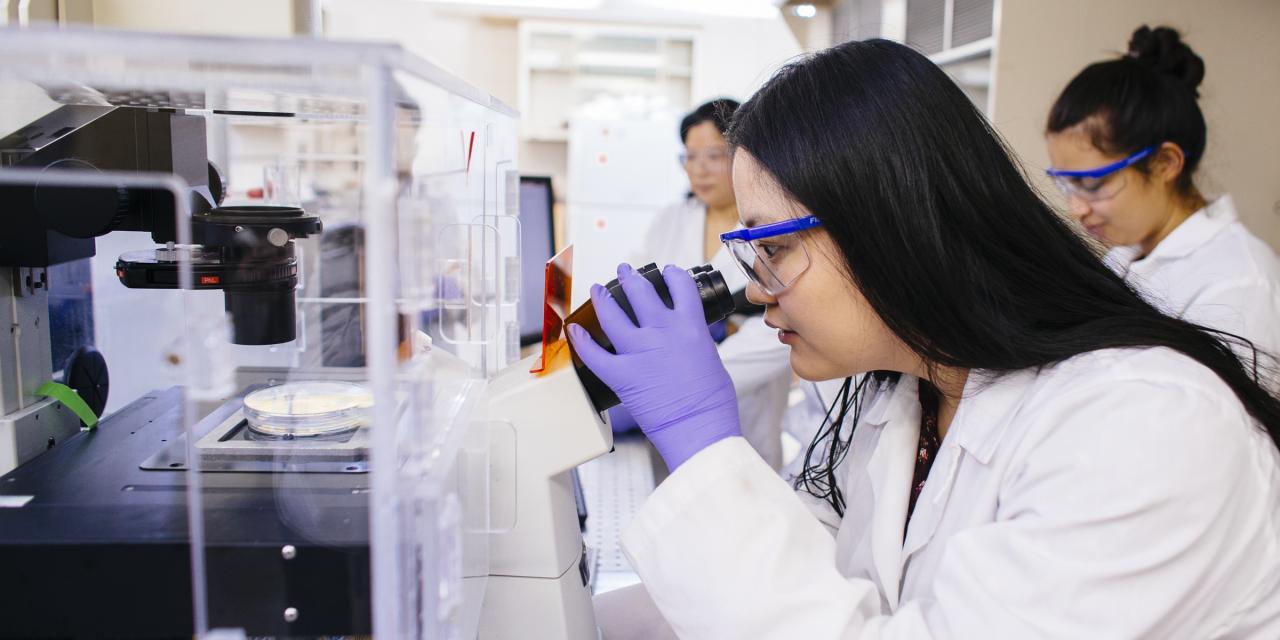

- Medical Devices: Mechanical engineering technologists are involved in the design and development of medical devices, such as prosthetics, surgical instruments, and imaging equipment, improving healthcare outcomes.

Education and Training Requirements

Becoming a mechanical engineering technologist typically requires a combination of formal education and practical experience. Aspiring professionals can choose from various educational pathways, each offering unique advantages and specializations. The specific skills and knowledge gained in these programs are essential for success in the field.

Educational Pathways

The most common educational pathways for aspiring mechanical engineering technologists include:

- Associate Degree in Mechanical Engineering Technology: This two-year program provides a strong foundation in mechanical engineering principles, including design, manufacturing, and analysis. It prepares graduates for entry-level positions in various industries.

- Bachelor of Science in Mechanical Engineering Technology: This four-year program offers a more comprehensive education, covering advanced topics like computer-aided design (CAD), robotics, and automation. Graduates are equipped for more complex roles and have the potential for career advancement.

- Certificate Programs: Specialized certificate programs can provide focused training in specific areas of mechanical engineering technology, such as CAD software, welding, or machine operation. These programs are ideal for individuals seeking to enhance their skills or transition into a new field.

Skills and Knowledge Acquired

Mechanical engineering technology programs emphasize the practical application of engineering principles. Students develop a wide range of skills and knowledge, including:

- Technical Skills: This includes proficiency in using CAD software, drafting, machining, and other manufacturing processes. Students learn to design, analyze, and create mechanical systems.

- Problem-Solving Skills: Mechanical engineering technologists are skilled at identifying and solving technical problems. They use their knowledge of engineering principles and practical experience to develop creative solutions.

- Communication Skills: Effective communication is essential for success in this field. Students learn to present technical information clearly and concisely, both verbally and in writing.

- Teamwork Skills: Mechanical engineering technologists often work in collaborative teams. They learn to communicate effectively, share ideas, and contribute to a common goal.

Certifications and Professional Development

While not always mandatory, certifications can enhance career prospects and demonstrate a commitment to professional development. Some popular certifications for mechanical engineering technologists include:

- Certified Engineering Technologist (CET): This certification, offered by the American Society for Engineering Education (ASEE), recognizes individuals who meet specific educational and experience requirements. It demonstrates a commitment to professional standards and ethical conduct.

- Certified Manufacturing Engineer (CMfgE): This certification, offered by the American Society of Mechanical Engineers (ASME), recognizes individuals with expertise in manufacturing processes, quality control, and production management.

- Certified SolidWorks Professional (CSWP): This certification, offered by Dassault Systèmes, validates proficiency in using SolidWorks CAD software. It demonstrates expertise in 3D modeling, design, and analysis.

Continuing education and professional development are crucial for staying current with industry trends and advancements. Mechanical engineering technologists can participate in workshops, conferences, and online courses to enhance their skills and knowledge.

Skills and Abilities

Mechanical engineering technology is a field that requires a blend of technical skills and soft skills to succeed. These skills are crucial for solving problems, designing and creating new products, and collaborating effectively with other professionals.

Technical Skills

Technical skills are the foundational elements of mechanical engineering technology. These skills are acquired through formal education and hands-on experience.

- Computer-Aided Design (CAD): CAD software, such as SolidWorks, AutoCAD, and Inventor, is used to create detailed drawings, models, and simulations of mechanical systems. These programs are essential for visualizing and analyzing designs, and for generating manufacturing instructions.

- Computer-Aided Manufacturing (CAM): CAM software integrates with CAD data to control and automate manufacturing processes. This includes CNC machining, 3D printing, and robotics, allowing for precise and efficient production.

- Mechanical Analysis and Simulation: Mechanical engineers use simulation software like ANSYS and ABAQUS to analyze the performance of designs under various conditions. This involves applying principles of mechanics, thermodynamics, and fluid dynamics to predict stress, strain, heat transfer, and fluid flow. This helps identify potential problems early in the design process, reducing costly rework and improving product reliability.

- Materials Science: Understanding the properties of different materials, such as metals, plastics, and composites, is crucial for selecting the right material for a specific application. Factors like strength, stiffness, durability, and cost must be considered.

- Manufacturing Processes: Knowledge of manufacturing processes, such as machining, welding, casting, and molding, is essential for understanding how products are made. This includes understanding the capabilities and limitations of each process, and how to optimize them for efficiency and quality.

- Fluid Mechanics: Understanding the principles of fluid mechanics is essential for designing and analyzing systems involving liquids and gases, such as pumps, turbines, and pipelines. This includes concepts like pressure, flow rate, viscosity, and turbulence.

- Thermodynamics: Thermodynamics is the study of heat and its relationship to work, energy, and temperature. This knowledge is essential for designing systems involving heat transfer, such as engines, refrigerators, and power plants.

Soft Skills

While technical skills are essential, soft skills are equally important for success in mechanical engineering technology. They enable effective communication, teamwork, and problem-solving in a collaborative environment.

- Communication: Effective communication is vital for conveying technical information to colleagues, clients, and stakeholders. This includes written communication (reports, presentations, emails), verbal communication (meetings, presentations), and the ability to explain complex concepts clearly and concisely.

- Teamwork: Mechanical engineering projects often involve collaboration with other engineers, designers, technicians, and managers. Teamwork skills, such as active listening, conflict resolution, and consensus building, are essential for working effectively in a team environment.

- Problem-Solving: Mechanical engineers are constantly faced with challenges and problems that require creative solutions. Critical thinking, analytical skills, and the ability to break down complex problems into smaller, manageable steps are essential for effective problem-solving.

- Adaptability: The field of mechanical engineering is constantly evolving with new technologies and advancements. Adaptability, including the willingness to learn new skills and embrace change, is crucial for staying competitive and successful in this dynamic field.

Skill Importance in Different Job Roles, Jobs in mechanical engineering technology

The importance of different skills varies depending on the specific job role within mechanical engineering technology. Here’s a table illustrating the relative importance of various skills in different job roles:

| Skill | Design Engineer | Manufacturing Engineer | Project Manager | Research and Development Engineer |

|---|---|---|---|---|

| CAD Software | High | Moderate | Low | High |

| CAM Software | Moderate | High | Low | Moderate |

| Mechanical Analysis | High | Moderate | Low | High |

| Materials Science | High | Moderate | Low | High |

| Manufacturing Processes | Moderate | High | Low | Moderate |

| Communication | Moderate | Moderate | High | Moderate |

| Teamwork | Moderate | Moderate | High | Moderate |

| Problem-Solving | High | High | High | High |

| Adaptability | High | High | High | High |

Wrap-Up: Jobs In Mechanical Engineering Technology

The demand for skilled mechanical engineering technologists is consistently high, making it a promising career choice. As technology continues to advance, the role of these professionals will become even more critical in driving innovation and shaping the future of various industries. Whether you’re drawn to the intricate details of design, the challenge of solving complex problems, or the satisfaction of creating something tangible, a career in mechanical engineering technology offers a fulfilling journey filled with endless opportunities for growth and impact.

Jobs in mechanical engineering technology are diverse, ranging from designing and testing new products to maintaining complex machinery. One fascinating area within this field is the development of innovative solutions for packaging and distribution, like wbox technology , which utilizes advanced materials and automation to optimize product protection and shipping efficiency.

These advancements create exciting opportunities for mechanical engineers to contribute to a more sustainable and efficient supply chain.