Intelligent Weighing Technology: Revolutionizing Industries

Intelligent weighing technology is transforming industries by integrating advanced sensors, data processing, and communication systems into traditional weighing scales. This evolution goes beyond simply measuring weight, offering a comprehensive understanding […]

Intelligent weighing technology is transforming industries by integrating advanced sensors, data processing, and communication systems into traditional weighing scales. This evolution goes beyond simply measuring weight, offering a comprehensive understanding of materials, processes, and environments.

From manufacturing plants optimizing production lines to logistics companies streamlining supply chains, intelligent weighing systems are empowering businesses with real-time insights, improved accuracy, and increased efficiency. The impact extends to various sectors, including agriculture, healthcare, and even scientific research.

Introduction to Intelligent Weighing Technology

Intelligent weighing technology represents a significant advancement in the field of measurement, incorporating advanced sensors, data processing, and communication capabilities to provide accurate and insightful weighing data. This technology goes beyond simply displaying weight values, offering real-time monitoring, analysis, and automation capabilities for various applications.

Evolution of Weighing Technology

The evolution of weighing technology has witnessed a gradual shift from rudimentary mechanical scales to sophisticated intelligent systems. Traditional scales, often relying on mechanical levers and weights, provided basic weight measurements. The advent of electronic scales brought about increased accuracy and digital displays. However, intelligent weighing technology marks a paradigm shift, integrating advanced features and functionalities.

- Traditional Scales: These scales were typically mechanical, using levers and weights to determine weight. They were often bulky, prone to wear and tear, and provided limited accuracy.

- Electronic Scales: Electronic scales introduced digital displays, enhanced accuracy, and simplified operation. However, they primarily focused on basic weight measurements.

- Intelligent Weighing Systems: These systems incorporate sensors, data processing, and communication capabilities, offering real-time monitoring, analysis, and automation features.

Benefits of Intelligent Weighing Technology

Intelligent weighing technology offers several advantages over traditional methods, enhancing efficiency, accuracy, and data utilization.

- Enhanced Accuracy: Intelligent systems utilize advanced sensors and algorithms to ensure highly precise weight measurements.

- Real-Time Monitoring: Data can be monitored and analyzed in real time, providing instant insights into weighing processes.

- Automation and Integration: Intelligent weighing systems can be integrated with other systems, automating processes and streamlining workflows.

- Data Analysis and Insights: Collected data can be analyzed to identify trends, patterns, and anomalies, enabling data-driven decision-making.

- Improved Efficiency: Automation and data analysis capabilities enhance operational efficiency, reducing manual tasks and minimizing errors.

Applications of Intelligent Weighing Technology

Intelligent weighing technology has revolutionized various industries by providing real-time, accurate, and efficient data for improved decision-making and process optimization. These technologies have a wide range of applications, from manufacturing and logistics to agriculture and healthcare.

Manufacturing

Intelligent weighing technology plays a crucial role in optimizing manufacturing processes.

- Material Handling and Inventory Management: Real-time weighing data allows for precise tracking of raw materials and finished goods, improving inventory management and reducing waste.

- Quality Control: Intelligent weighing systems can detect variations in product weight, ensuring consistent quality and compliance with regulations.

- Process Control: Integration with control systems enables automated adjustments to production lines based on weight data, optimizing efficiency and reducing downtime.

Logistics

Intelligent weighing technology streamlines logistics operations by providing accurate weight data for efficient transportation and delivery.

- Load Optimization: Intelligent weighing systems help optimize truck loading, ensuring maximum capacity utilization and minimizing transportation costs.

- Freight Management: Accurate weight data enables efficient freight billing and reduces disputes related to weight discrepancies.

- Real-time Tracking: Integration with GPS systems allows for real-time tracking of goods in transit, providing valuable insights into delivery schedules and potential delays.

Agriculture

Intelligent weighing technology plays a vital role in modern agriculture, improving efficiency and sustainability.

- Precision Farming: Real-time weighing data allows for precise application of fertilizers and pesticides, minimizing waste and maximizing yield.

- Livestock Management: Intelligent weighing systems monitor animal weight, providing insights into animal health and feeding requirements.

- Harvest Optimization: Real-time weighing data helps optimize harvesting processes, ensuring efficient collection and transportation of crops.

Healthcare

Intelligent weighing technology is increasingly used in healthcare settings to improve patient care and safety.

- Patient Monitoring: Real-time weight monitoring is essential for managing patients with conditions such as obesity, diabetes, and heart disease.

- Medication Dosage: Intelligent weighing systems ensure accurate medication dosage based on patient weight, minimizing errors and improving treatment outcomes.

- Surgical Procedures: Intelligent weighing systems can be used in surgical procedures to ensure accurate placement of implants and other medical devices.

Components of Intelligent Weighing Systems

Intelligent weighing systems are sophisticated technological solutions that integrate various components to provide accurate, efficient, and automated weighing processes. These systems rely on a carefully orchestrated interplay of sensors, data acquisition and processing units, and communication protocols to deliver reliable and actionable insights.

Sensors in Intelligent Weighing Systems

Sensors play a crucial role in intelligent weighing systems by converting physical quantities, such as weight, into electrical signals that can be processed and interpreted. The accuracy and reliability of these systems are directly dependent on the performance of the sensors.

- Strain Gauge Sensors: These sensors are commonly used in weighing scales and load cells. They operate based on the principle of resistance change in a conductor under strain. When a force is applied to the sensor, the strain gauge’s resistance changes proportionally, allowing for accurate weight measurement.

- Load Cells: Load cells are specialized sensors that measure force or weight. They are often integrated into weighing systems for industrial applications. Load cells are typically designed to withstand heavy loads and provide high accuracy in weight measurements.

- Pressure Sensors: Pressure sensors measure the force exerted by a fluid per unit area. They are used in weighing systems that involve liquids or gases, such as tank weighing or pressure-based weighing systems.

Sensors in intelligent weighing systems are carefully chosen based on the specific application, the range of weights to be measured, and the required accuracy. For instance, in high-precision applications, sensors with a high degree of accuracy and sensitivity are preferred.

Data Acquisition and Processing Units

Data acquisition and processing units are the brains of intelligent weighing systems. They collect raw data from sensors, process it, and generate meaningful insights.

- Data Collection: Data acquisition units are responsible for collecting data from sensors at regular intervals. This data typically includes weight readings, time stamps, and other relevant information.

- Data Analysis: The collected data is then processed and analyzed using various algorithms and techniques. This involves filtering, calibration, and statistical analysis to ensure data accuracy and identify trends or anomalies.

- Data Interpretation: Once the data is processed, the system interprets the results and generates reports or alerts. This interpretation might involve calculating total weight, identifying overloads, or detecting deviations from pre-set parameters.

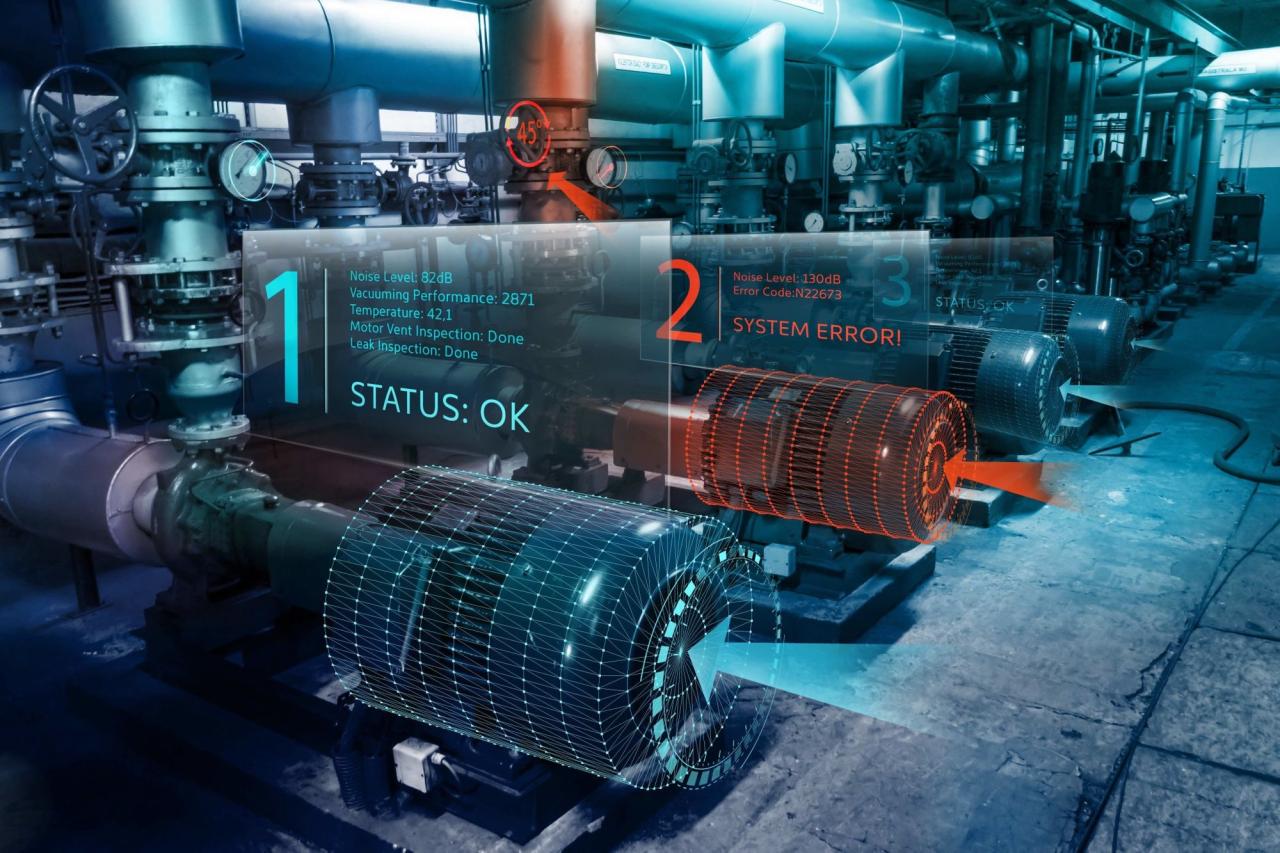

Modern intelligent weighing systems often incorporate advanced data analysis techniques, such as machine learning and artificial intelligence, to enhance accuracy and identify patterns that may not be easily discernible through traditional methods.

Communication Protocols in Intelligent Weighing Systems

Communication protocols are essential for transmitting data between different components of the intelligent weighing system and integrating it with other systems.

- Data Transmission: Communication protocols facilitate the transfer of data from sensors to the data acquisition and processing unit. This data transfer can be wireless or wired, depending on the system’s requirements.

- System Integration: Intelligent weighing systems often need to communicate with other systems, such as enterprise resource planning (ERP) systems, inventory management systems, or process control systems. Communication protocols enable seamless data exchange between these systems, ensuring efficient workflow and data consistency.

- Common Protocols: Some commonly used communication protocols in intelligent weighing systems include:

- RS-232: A serial communication protocol commonly used for connecting weighing scales to computers or other devices.

- RS-485: A serial communication protocol that offers better noise immunity and longer communication distances compared to RS-232.

- Ethernet: A widely used network protocol that enables high-speed data transfer over local area networks (LANs).

- Wireless Protocols: Bluetooth, Wi-Fi, and cellular networks are increasingly used for wireless data transmission in intelligent weighing systems, offering flexibility and remote monitoring capabilities.

The choice of communication protocol depends on factors such as data transfer rate, distance, and compatibility with other systems.

Benefits and Challenges of Intelligent Weighing Technology

Intelligent weighing technology offers a transformative approach to weighing processes, bringing numerous benefits while also presenting certain challenges. This section delves into the advantages and obstacles associated with implementing intelligent weighing systems, exploring potential solutions to overcome these challenges.

Advantages of Intelligent Weighing Technology

Intelligent weighing technology provides significant advantages over traditional weighing methods, enhancing accuracy, efficiency, and automation in various industries.

- Improved Accuracy: Intelligent weighing systems utilize advanced sensors and algorithms to achieve high levels of precision. These systems can detect and compensate for environmental factors, such as temperature and humidity, resulting in more accurate weight measurements. This improved accuracy is crucial in industries where precise weighing is essential, such as pharmaceuticals, chemicals, and food processing.

- Increased Efficiency: Intelligent weighing systems streamline weighing processes, reducing manual labor and time spent on data entry. Automated data collection and analysis capabilities eliminate the need for manual data recording, leading to faster turnaround times and increased productivity. This efficiency translates into cost savings and improved operational efficiency.

- Enhanced Automation: Intelligent weighing systems can be integrated with other automation systems, enabling seamless integration with existing workflows. Automated data transfer and analysis allow for real-time monitoring and control of weighing processes, reducing human error and improving overall process efficiency. This level of automation enables industries to optimize their operations and achieve greater productivity.

- Data Analytics and Insights: Intelligent weighing systems generate a wealth of data that can be analyzed to identify trends, optimize processes, and improve decision-making. Data analytics capabilities allow for the identification of patterns and anomalies, providing valuable insights into production processes and potential areas for improvement. This data-driven approach enhances operational efficiency and helps organizations make informed decisions.

Challenges of Implementing Intelligent Weighing Systems

While intelligent weighing technology offers significant advantages, implementing these systems presents certain challenges that need to be addressed.

- Cost: Implementing intelligent weighing systems can involve significant upfront investment, including hardware, software, and installation costs. The complexity of these systems and the need for specialized expertise can contribute to higher costs. However, the long-term benefits of increased efficiency and reduced errors can offset these initial investments.

- Complexity: Intelligent weighing systems are complex and require specialized knowledge to configure, operate, and maintain. Integrating these systems with existing infrastructure can be challenging, requiring careful planning and coordination. However, advancements in user-friendly interfaces and intuitive software are simplifying the implementation and operation of these systems.

- Integration with Existing Infrastructure: Integrating intelligent weighing systems with existing infrastructure can be a complex process, requiring careful planning and coordination. Compatibility issues with existing systems and the need for data synchronization can pose challenges. However, the use of open standards and standardized communication protocols is facilitating seamless integration with existing systems.

- Cybersecurity: Intelligent weighing systems are connected to networks, making them vulnerable to cybersecurity threats. Protecting sensitive data and ensuring system integrity is crucial. Implementing robust cybersecurity measures, such as firewalls, intrusion detection systems, and data encryption, is essential to mitigate these risks.

Solutions and Strategies for Addressing Challenges

To address the challenges associated with implementing intelligent weighing systems, various solutions and strategies can be employed.

- Cost-Effective Solutions: Explore cost-effective solutions, such as cloud-based platforms and modular systems, to reduce upfront investment. Consider leasing or subscription models to spread the cost over time. Leverage government grants or incentives to offset implementation costs.

- Simplified Implementation: Choose systems with user-friendly interfaces and intuitive software to simplify implementation and operation. Seek expert assistance from vendors or consultants to ensure seamless integration with existing infrastructure.

- Enhanced Integration: Utilize open standards and standardized communication protocols to facilitate integration with existing systems. Consider using middleware solutions to bridge compatibility gaps between different systems.

- Robust Cybersecurity Measures: Implement robust cybersecurity measures, such as firewalls, intrusion detection systems, and data encryption, to protect sensitive data and ensure system integrity. Train personnel on cybersecurity best practices and regularly update system software to mitigate vulnerabilities.

Future Trends in Intelligent Weighing Technology

The field of intelligent weighing technology is rapidly evolving, driven by advancements in artificial intelligence (AI), machine learning (ML), and cloud computing. These emerging technologies are transforming the functionality, accuracy, and applications of weighing systems, paving the way for a future where weighing is more precise, efficient, and integrated into various industries.

Impact of Emerging Technologies

The integration of AI, ML, and cloud computing is revolutionizing intelligent weighing systems, leading to significant advancements in functionality, accuracy, and applications.

- Enhanced Accuracy and Precision: AI-powered algorithms can analyze vast amounts of data from weighing sensors, identifying and correcting errors in real-time. This results in highly accurate and precise weight measurements, crucial for industries demanding high levels of accuracy, such as pharmaceuticals and food processing.

- Improved Efficiency and Automation: ML algorithms can learn from historical weighing data, predicting trends and optimizing weighing processes. This automation reduces manual intervention, minimizing human error and improving overall efficiency.

- Real-Time Data Analytics: Cloud computing enables real-time data collection and analysis from multiple weighing systems, providing valuable insights into production processes. This data can be used to identify bottlenecks, optimize resource allocation, and improve decision-making.

Applications of Intelligent Weighing Systems

The advancements in intelligent weighing technology are expanding the applications of weighing systems across various industries.

- Smart Factories: Intelligent weighing systems are playing a crucial role in smart factories, enabling real-time monitoring of production processes, inventory management, and quality control. For example, in automotive manufacturing, weighing systems can track the weight of components throughout the assembly line, ensuring that each vehicle meets specific weight requirements.

- Supply Chain Optimization: Intelligent weighing systems are used to optimize logistics and transportation by providing accurate weight data for efficient load planning and route optimization. This reduces transportation costs, minimizes fuel consumption, and improves delivery times.

- Precision Agriculture: In agriculture, intelligent weighing systems are used to monitor the weight of crops and livestock, providing valuable data for optimizing fertilization, irrigation, and animal feed management. This helps farmers improve crop yields and livestock productivity while reducing environmental impact.

Predictions for the Future of Intelligent Weighing Technology

The future of intelligent weighing technology holds exciting possibilities, with advancements in AI, ML, and cloud computing driving innovation.

- Increased Connectivity and Integration: Intelligent weighing systems will become increasingly connected, seamlessly integrating with other systems and platforms. This will enable real-time data sharing and analysis, fostering greater collaboration and efficiency across industries.

- Advanced Analytics and Predictive Maintenance: AI and ML will play a crucial role in predictive maintenance, analyzing data from weighing systems to anticipate potential failures and schedule preventative maintenance. This will reduce downtime, minimize repair costs, and improve the overall reliability of weighing systems.

- Personalized Weighing Experiences: AI-powered intelligent weighing systems will offer personalized experiences, tailoring weighing processes to specific needs and preferences. This could involve customized weighing units, intelligent calibration, and automated data analysis, enhancing the user experience and improving accuracy.

Closure

As technology continues to evolve, intelligent weighing systems are poised to become even more sophisticated, incorporating artificial intelligence, machine learning, and cloud computing. This will further enhance their capabilities, enabling them to anticipate needs, optimize processes autonomously, and provide actionable data for informed decision-making. The future of intelligent weighing technology promises a world where precision, efficiency, and data-driven insights drive progress across diverse industries.

Intelligent weighing technology plays a crucial role in various industries, ensuring accurate measurements for efficient operations. One such application can be found in the realm of environmental protection, where systems like the abatement technologies predator 750 utilize intelligent weighing to monitor and control emissions, contributing to a cleaner environment.

By integrating such advanced technologies, we can optimize processes and make a positive impact on our planet.