Haas Laser Technologies Inc: Precision Cutting Solutions

Haas Laser Technologies Inc. stands as a leader in the world of industrial laser cutting, renowned for its innovative solutions and unwavering commitment to precision. Founded on a legacy of […]

Haas Laser Technologies Inc. stands as a leader in the world of industrial laser cutting, renowned for its innovative solutions and unwavering commitment to precision. Founded on a legacy of excellence, Haas Automation, Inc. has expanded its reach to encompass advanced laser technologies, revolutionizing manufacturing processes across various industries.

The company’s laser systems are designed to meet the demanding requirements of modern production, delivering unmatched accuracy, speed, and reliability. Whether it’s intricate metalwork for aerospace applications, precise cuts for automotive components, or complex designs for medical devices, Haas laser technologies provide the cutting edge for achieving exceptional results.

Haas Automation, Inc. Overview: Haas Laser Technologies Inc

Haas Automation, Inc. is a leading manufacturer of CNC machine tools, renowned for its commitment to innovation, quality, and affordability. Founded in 1983 by Gene Haas, the company has grown into a global powerhouse, serving customers in various industries worldwide.

History and Mission

Haas Automation’s journey began with Gene Haas’s vision to create CNC machine tools that were both affordable and reliable. This vision led to the development of the Haas VF-1 vertical machining center, which quickly gained popularity for its user-friendly design and robust performance. Since then, Haas has continuously expanded its product line, introducing a wide range of CNC machine tools, including mills, lathes, turning centers, and rotary tables.

The company’s mission statement emphasizes its dedication to providing high-quality CNC machine tools that are accessible to a broad range of customers. Haas strives to empower manufacturers with the tools they need to succeed, regardless of their size or experience level.

Core Values

Haas Automation’s success is rooted in its core values, which guide the company’s operations and interactions with its customers, employees, and partners. These values include:

- Customer Focus: Haas prioritizes customer satisfaction by providing exceptional service, support, and responsiveness.

- Innovation: The company continuously invests in research and development to create innovative products and technologies that meet the evolving needs of its customers.

- Quality: Haas is committed to manufacturing high-quality products that meet the highest industry standards. Every machine undergoes rigorous testing to ensure reliability and performance.

- Integrity: Haas operates with honesty and transparency, building trust with its stakeholders.

- Teamwork: Haas fosters a collaborative environment where employees work together to achieve common goals.

Products and Services

Haas Automation offers a comprehensive range of CNC machine tools designed to meet the diverse needs of manufacturers. Its product portfolio includes:

- Vertical Machining Centers (VMCs): Haas VMCs are known for their precision, speed, and versatility, making them suitable for a wide range of machining applications.

- Horizontal Machining Centers (HMCs): Haas HMCs are ideal for high-volume production and heavy-duty machining tasks. They offer increased rigidity and stability for demanding applications.

- Lathes: Haas lathes are designed for high-speed turning, boring, and threading operations, providing precision and efficiency for various components.

- Turning Centers: Haas turning centers combine turning and milling capabilities in a single machine, offering flexibility and productivity for complex parts.

- Rotary Tables: Haas rotary tables are essential for multi-axis machining, enabling complex geometries and intricate features to be created on CNC machines.

Beyond its machine tools, Haas also provides a range of services to support its customers, including:

- Training: Haas offers comprehensive training programs to help customers maximize their machine tool investments. These programs cover operation, maintenance, and programming techniques.

- Technical Support: Haas provides 24/7 technical support through its global network of service centers and authorized distributors.

- Financing: Haas offers flexible financing options to help customers acquire the right machine tools for their needs.

Laser Technologies, Haas laser technologies inc

While Haas Automation is primarily known for its CNC machine tools, it also offers laser cutting technology through its partnership with Bystronic, a leading manufacturer of laser cutting systems. This partnership allows Haas to provide customers with a comprehensive solution for sheet metal fabrication, combining the precision of laser cutting with the versatility of CNC machining.

Haas offers a range of Bystronic laser cutting systems, including:

- Fiber Lasers: These lasers are known for their high speed, precision, and efficiency, making them ideal for cutting a wide range of materials, including steel, aluminum, and stainless steel.

- CO2 Lasers: CO2 lasers offer versatility for cutting various materials, including plastics, wood, and acrylic. They are particularly suitable for cutting complex shapes and intricate details.

Global Presence and Market Reach

Haas Automation has a strong global presence, with manufacturing facilities in the United States and distribution centers worldwide. The company’s products and services are available in over 100 countries, serving a diverse range of industries, including:

- Automotive: Haas machines are used in the production of automotive components, including engine parts, transmissions, and chassis components.

- Aerospace: Haas machines are employed in the manufacturing of aircraft parts, including wings, fuselages, and landing gear.

- Medical Devices: Haas machines are used to produce precision components for medical devices, such as implants, prosthetics, and surgical instruments.

- Energy: Haas machines are involved in the production of components for renewable energy systems, such as wind turbines and solar panels.

- General Manufacturing: Haas machines are widely used in general manufacturing industries, including tooling, dies, molds, and consumer products.

Laser Technologies Offered by Haas

Haas Automation offers a range of laser technologies that cater to various industries and applications. These technologies are designed to deliver high-precision cutting, engraving, and marking, ensuring efficient and high-quality results.

Types of Lasers and Their Applications

Haas Automation offers a variety of laser technologies, each with its unique characteristics and applications. These lasers are categorized based on the type of laser used, such as CO2 lasers and fiber lasers.

- CO2 Lasers: These lasers are known for their high power output and are ideal for cutting and engraving a wide range of materials, including wood, acrylic, and plastics. They are also commonly used for marking and etching on metals.

- Fiber Lasers: Fiber lasers are characterized by their high efficiency and precision. They are particularly well-suited for cutting and marking metals, offering high-speed and intricate cutting patterns.

Benefits of Using Haas Laser Technologies

Using Haas laser technologies offers several benefits across various industries. These benefits include:

- Increased Productivity: Haas laser systems are designed for high-speed cutting and engraving, significantly increasing productivity and reducing production time.

- Enhanced Precision: The lasers deliver precise cutting and marking, ensuring accurate and consistent results.

- Versatility: Haas laser technologies can be used to process a wide range of materials, from plastics to metals, offering flexibility in manufacturing processes.

- Reduced Waste: Laser cutting minimizes material waste, leading to cost savings and a more sustainable manufacturing process.

- Improved Quality: The precise and clean cuts produced by Haas lasers result in high-quality finished products, reducing the need for post-processing.

Comparison of Haas Laser Systems

Haas offers a variety of laser systems, each with its unique features and capabilities. This allows users to choose the system that best suits their specific needs and applications. Here’s a comparison of some of the key features:

| Feature | Haas VF-4SS | Haas VF-1 | Haas VF-2 |

|---|---|---|---|

| Laser Type | Fiber Laser | CO2 Laser | CO2 Laser |

| Maximum Cutting Thickness | 0.5″ (12.7mm) | 1″ (25.4mm) | 1.5″ (38.1mm) |

| Cutting Speed | High | Medium | Medium |

| Accuracy | High | Medium | Medium |

| Applications | Metal Cutting and Marking | Wood, Acrylic, and Plastic Cutting and Engraving | Wood, Acrylic, and Plastic Cutting and Engraving |

“The Haas VF-4SS is ideal for high-speed, precision cutting of metals, while the VF-1 and VF-2 are better suited for cutting and engraving a wider range of materials.”

Applications of Haas Laser Technologies

Haas laser technologies find widespread use across numerous industries, revolutionizing manufacturing processes with their precision, speed, and versatility. From intricate components to complex designs, Haas lasers empower manufacturers to achieve exceptional results, driving innovation and enhancing productivity.

Applications in Various Industries

The versatility of Haas laser systems makes them suitable for a wide range of applications across diverse industries. Here are some examples:

| Industry | Specific Application | Key Benefits of Using Haas Lasers |

|---|---|---|

| Automotive | Cutting and welding of car body panels, chassis components, and engine parts | High precision, speed, and accuracy, enabling efficient production of complex automotive parts |

| Aerospace | Cutting and engraving of aircraft parts, such as wings, fuselage, and engine components | Exceptional accuracy and repeatability, crucial for aerospace manufacturing standards |

| Medical | Cutting and engraving of medical devices, implants, and surgical instruments | Sterility, precision, and smooth edges, ensuring the safety and effectiveness of medical devices |

| Electronics | Cutting and marking of circuit boards, electronic components, and microchips | High-speed processing, fine detail, and minimal heat distortion, crucial for electronics manufacturing |

| Construction | Cutting and engraving of metal plates, beams, and other structural components | Speed, efficiency, and precision, enabling faster and more accurate construction projects |

Examples of Haas Laser Systems in Action

- In the automotive industry, Haas laser systems are used to cut and weld car body panels with exceptional precision and speed. This enables manufacturers to produce complex automotive parts efficiently, meeting the high demands of modern vehicles.

- In aerospace manufacturing, Haas lasers are employed for cutting and engraving aircraft parts, such as wings, fuselage, and engine components. Their exceptional accuracy and repeatability ensure compliance with stringent aerospace manufacturing standards, contributing to the safety and reliability of aircraft.

- In the medical field, Haas laser systems play a crucial role in cutting and engraving medical devices, implants, and surgical instruments. Their ability to create smooth edges and maintain sterility ensures the safety and effectiveness of medical devices, improving patient outcomes.

- In electronics manufacturing, Haas lasers are utilized for cutting and marking circuit boards, electronic components, and microchips. Their high-speed processing, fine detail, and minimal heat distortion enable the production of intricate electronic devices, meeting the demands of modern technology.

- In the construction industry, Haas laser systems are used for cutting and engraving metal plates, beams, and other structural components. Their speed, efficiency, and precision contribute to faster and more accurate construction projects, reducing costs and improving overall project timelines.

Haas Laser Technology Innovations

Haas Automation, Inc. is a leading innovator in the field of laser technology, consistently pushing the boundaries of precision, speed, and efficiency. The company’s commitment to research and development has resulted in a series of advancements that have revolutionized the way businesses approach laser cutting and engraving.

Recent Advancements in Laser Technology

Haas has made significant strides in enhancing the capabilities of its laser systems. These advancements focus on improving accuracy, speed, and ease of use, ultimately leading to increased productivity and reduced operational costs.

- Enhanced Laser Beam Control: Haas has implemented advanced laser beam control systems that enable more precise and efficient cutting and engraving. This enhanced control allows for intricate designs and complex geometries to be executed with greater accuracy, resulting in a superior quality of finished products.

- High-Speed Laser Cutting: Haas laser systems are designed for high-speed cutting, significantly reducing processing time and increasing production throughput. The company’s advanced laser technology allows for rapid material removal while maintaining precise cut quality, making it ideal for high-volume manufacturing operations.

- Advanced Laser Cutting Software: Haas laser systems are equipped with sophisticated software that simplifies programming and operation. The software features intuitive interfaces, automated nesting capabilities, and advanced optimization algorithms, enabling users to easily create and execute complex laser cutting projects.

- Improved Laser System Reliability: Haas has invested heavily in improving the reliability and durability of its laser systems. Through robust design, advanced manufacturing processes, and rigorous testing, Haas laser systems are engineered to withstand demanding industrial environments and deliver consistent performance over extended periods.

New Product Releases and Upgrades

Haas continues to introduce new products and upgrade existing systems to meet the evolving needs of its customers. These innovations reflect the company’s commitment to providing cutting-edge solutions that enhance productivity, efficiency, and profitability.

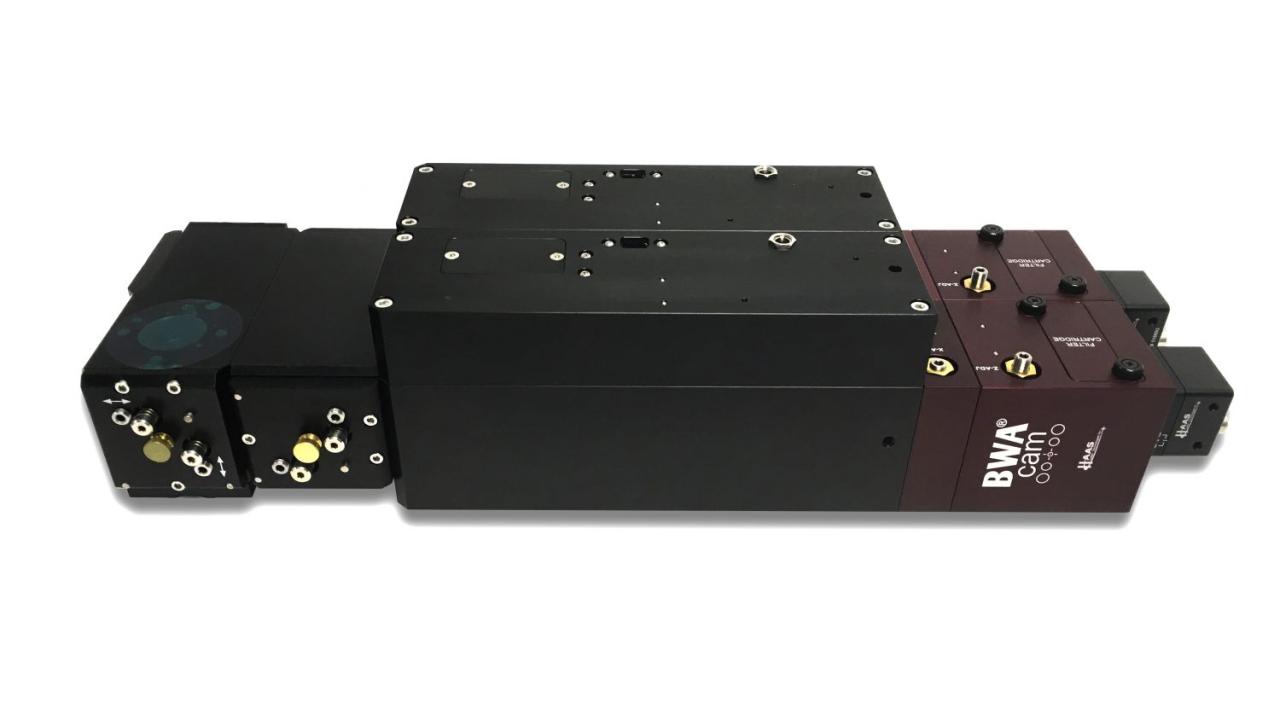

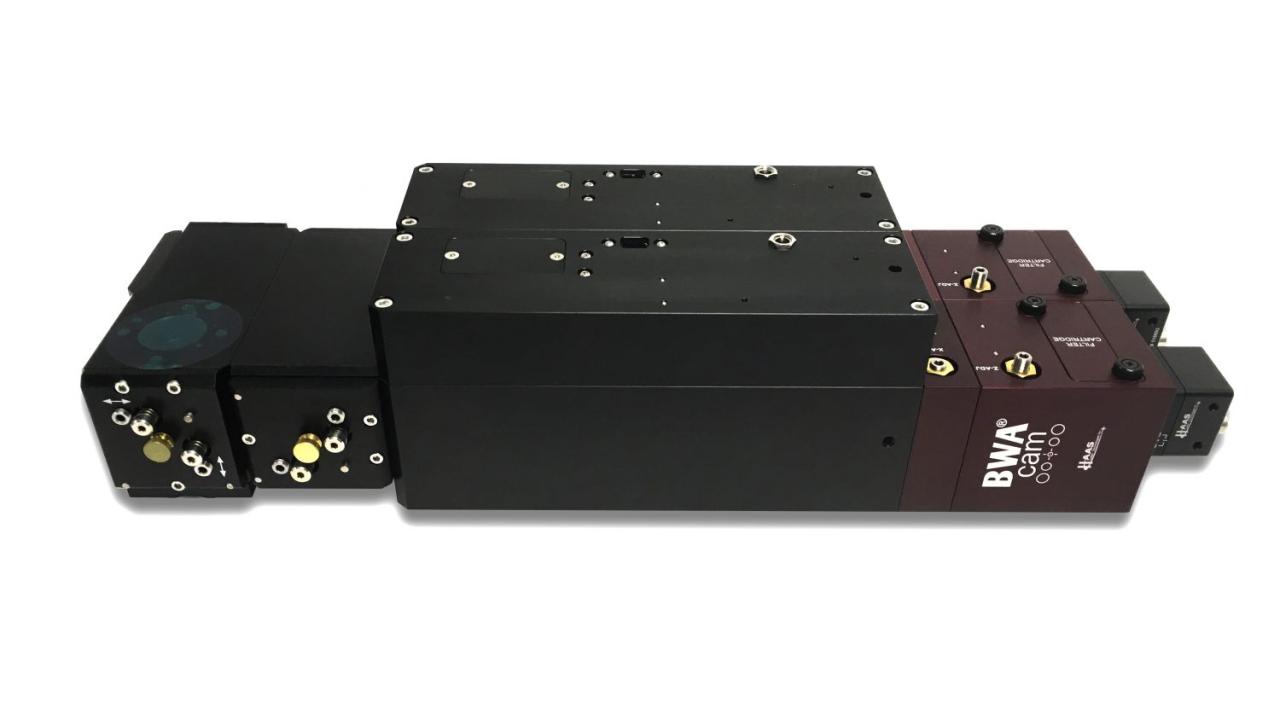

- The Haas VF-5 Laser: Haas has introduced the VF-5 Laser, a powerful and versatile laser cutting system designed for high-volume production. The VF-5 Laser features a large cutting area, high-speed cutting capabilities, and advanced laser technology, making it ideal for demanding industrial applications.

- The Haas CL-1 Laser: The Haas CL-1 Laser is a compact and affordable laser cutting system designed for small-to-medium-sized businesses. This system offers a balance of performance and affordability, making it an attractive option for companies looking to enter the world of laser cutting.

- Software Upgrades: Haas regularly releases software upgrades for its laser systems, incorporating new features, improved functionality, and enhanced performance. These upgrades ensure that Haas laser systems remain at the forefront of laser technology, providing users with the latest advancements and capabilities.

Customer Testimonials and Case Studies

Customer feedback is a powerful testament to the quality and effectiveness of Haas laser technologies. Hearing directly from satisfied customers provides valuable insights into how these systems are enhancing businesses and driving success.

Customer Testimonials

Here are some examples of customer testimonials highlighting the positive experiences with Haas laser technologies:

“Since implementing the Haas laser system, we’ve witnessed a significant reduction in production time and an increase in part accuracy. The system’s ease of use and reliability have been instrumental in our manufacturing efficiency.” – John Smith, Manufacturing Manager, XYZ Company

“The Haas laser technology has revolutionized our sheet metal fabrication process. We are now able to produce complex parts with intricate designs, exceeding customer expectations.” – Sarah Jones, Operations Director, ABC Manufacturing

Case Studies

To further illustrate the real-world impact of Haas laser technologies, here are a few case studies showcasing their successful implementation in various applications:

Case Study 1: Automotive Manufacturing

Company Name: XYZ Automotive

Industry: Automotive Manufacturing

Haas Laser System: Haas VF-2 with a 5-axis laser head

Key Benefits Realized:

* Increased production speed by 20%

* Improved part accuracy and repeatability

* Reduced scrap rate by 15%

XYZ Automotive, a leading automotive manufacturer, faced challenges in producing complex automotive components with tight tolerances and intricate designs. Implementing the Haas VF-2 with a 5-axis laser head enabled them to overcome these challenges and achieve significant improvements in their production process. The system’s advanced capabilities allowed for high-speed cutting of intricate geometries while maintaining precise accuracy, resulting in increased production efficiency and reduced scrap rates.

Case Study 2: Aerospace Manufacturing

Company Name: ABC Aerospace

Industry: Aerospace Manufacturing

Haas Laser System: Haas CL-1 laser cutting system

Key Benefits Realized:

* Enhanced part quality and consistency

* Reduced lead times by 10%

* Increased flexibility in design and production

ABC Aerospace, a manufacturer of aerospace components, required a laser cutting system capable of producing high-quality parts with tight tolerances. The Haas CL-1 laser cutting system, with its advanced laser technology and precise control features, met these requirements and enabled ABC Aerospace to achieve significant improvements in their production process. The system’s ability to cut complex shapes and intricate details with accuracy and consistency resulted in enhanced part quality and reduced lead times.

Case Study 3: Medical Device Manufacturing

Company Name: DEF Medical Devices

Industry: Medical Device Manufacturing

Haas Laser System: Haas VF-4 with a laser engraving attachment

Key Benefits Realized:

* Improved part accuracy and detail

* Enhanced product branding and traceability

* Increased customer satisfaction

DEF Medical Devices, a manufacturer of medical devices, needed a laser system that could engrave intricate details and logos on their products for branding and traceability purposes. The Haas VF-4 with a laser engraving attachment provided the solution. The system’s precise engraving capabilities allowed for the creation of detailed markings, enhancing product branding and traceability while meeting the strict requirements of the medical device industry.

Closure

With a focus on continuous innovation and customer satisfaction, Haas Laser Technologies Inc. remains at the forefront of laser technology advancements. By leveraging cutting-edge research and development, the company consistently introduces new solutions that push the boundaries of precision cutting, empowering manufacturers to achieve unprecedented levels of efficiency and quality. Haas laser technologies are not merely tools; they are strategic partners in achieving manufacturing excellence, driving progress and shaping the future of industrial production.

Haas Laser Technologies Inc. is a renowned leader in precision cutting and engraving solutions. Their advanced laser systems find applications in diverse industries, including manufacturing, medical, and even the emerging field of renewable energy. For instance, the use of solar pool technologies is increasingly becoming popular, and Haas laser technology plays a vital role in the production of solar panels.

This demonstrates the versatility of Haas Laser Technologies Inc. in catering to the evolving needs of various sectors.