Gloves Technology: A History of Innovation

Gloves technology sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset. From the […]

Gloves technology sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset. From the simple protection of early designs to the sophisticated capabilities of modern smart gloves, the evolution of gloves has mirrored humanity’s journey toward innovation and advancement.

This exploration delves into the fascinating world of glove technology, tracing its historical roots, examining the diverse materials and manufacturing processes involved, and showcasing the wide range of applications across various industries. We’ll also delve into the latest technological breakthroughs, exploring how smart gloves, haptic feedback systems, and biometric integration are revolutionizing the way we interact with the world.

Evolution of Glove Technology

Gloves, a seemingly simple piece of apparel, have played a significant role in human history, providing protection, warmth, and functionality across diverse cultures and eras. Their evolution reflects the ingenuity of human innovation, driven by necessity and evolving technological advancements.

Early Gloves and Their Purposes

Gloves, in their earliest forms, emerged as a practical necessity for protection and warmth. Archaeological evidence suggests that gloves were worn as early as the Stone Age, primarily for protection against harsh elements and hazardous tasks.

- Early Glove Designs: Early gloves were often crafted from animal hides, furs, and woven materials, offering rudimentary protection against cold and rough surfaces. For instance, ancient Egyptians utilized linen gloves for protection during manual labor, while the Romans employed leather gloves for warmth and protection in colder climates.

- Specific Purposes: Gloves also served specialized purposes in ancient societies. Leather gloves, with reinforced fingertips, were used by archers to protect their hands from the string’s recoil. Similarly, gloves made of thick fabric or metal were worn by warriors to shield their hands during combat.

Technological Advancements in Glove Design

The development of gloves has been closely intertwined with advancements in materials science and manufacturing techniques. From the introduction of new fabrics to the incorporation of advanced technologies, these innovations have significantly enhanced glove functionality and performance.

- Materials Science: The advent of synthetic fabrics, such as nylon, polyester, and Kevlar, revolutionized glove design. These materials offered superior durability, resistance to abrasion, and protection against heat and chemicals.

- Manufacturing Techniques: The development of advanced manufacturing techniques, including knitting, weaving, and laser cutting, enabled the creation of gloves with intricate designs, precise fit, and enhanced dexterity.

- Technological Integration: The integration of advanced technologies, such as sensors, microprocessors, and conductive materials, has led to the development of smart gloves. These gloves can monitor physiological data, provide tactile feedback, and even enable users to interact with virtual reality environments.

Materials and Manufacturing

The materials and manufacturing processes employed in glove production play a crucial role in determining the gloves’ performance, durability, and suitability for specific applications.

Materials Used in Glove Production

The choice of materials depends on the intended use of the gloves, considering factors such as protection requirements, comfort, and cost. Here’s a breakdown of common materials:

- Leather: A natural material known for its durability, flexibility, and breathability. Commonly used in work gloves, driving gloves, and equestrian gloves.

- Textiles: A wide range of fabrics, including cotton, polyester, nylon, and blends, are used in glove production. These materials offer varying levels of comfort, durability, and protection.

- Synthetic Materials: Materials like nitrile, neoprene, and PVC are popular choices for gloves due to their resistance to chemicals, oils, and abrasions. They are often used in industrial settings, medical applications, and food handling.

- Natural Rubber: A versatile material that provides excellent grip and protection against various hazards. Commonly used in household gloves, work gloves, and medical gloves.

- Polyurethane (PU): A synthetic material known for its flexibility, durability, and resistance to abrasion. Often used in gloves for sports, mechanics, and construction.

- Kevlar: A high-performance fiber known for its exceptional strength and heat resistance. Used in gloves for high-risk applications like welding, cutting, and handling hot materials.

Manufacturing Processes

Gloves are produced using various manufacturing processes, each suited for specific materials and designs.

- Knitting: A process that interloops yarn to create a fabric. Commonly used for gloves made from textiles like cotton, polyester, and wool.

- Weaving: A process that interlaces two sets of yarns to create a fabric. Used for gloves made from textiles, often for thicker and more durable gloves.

- Dipping: A process where a form is dipped into a liquid material, which then solidifies to form the glove. Commonly used for gloves made from synthetic materials like nitrile, neoprene, and PVC.

- Sewing: A process used to assemble glove parts and create seams. Used in various glove types, including leather gloves, textile gloves, and synthetic gloves.

Glove Types, Materials, and Manufacturing Methods

| Glove Type | Material | Manufacturing Method |

|---|---|---|

| Work Gloves | Leather, textiles, nitrile, neoprene | Knitting, weaving, dipping, sewing |

| Medical Gloves | Nitrile, latex, vinyl | Dipping |

| Household Gloves | Latex, nitrile, vinyl | Dipping |

| Driving Gloves | Leather, textiles | Knitting, sewing |

| Sports Gloves | Textiles, PU | Knitting, sewing |

Types of Gloves and Their Applications

Gloves are an essential piece of protective gear used in various industries and activities, providing protection against hazards, enhancing grip, and improving dexterity. The type of glove used depends on the specific task and the risks involved. This section explores the different types of gloves and their applications.

Work Gloves

Work gloves are designed to protect hands from hazards encountered in various work environments. These gloves are made from a wide range of materials, including leather, cotton, nylon, and synthetic materials, depending on the specific application and required protection.

- Leather Gloves: Leather gloves are durable and offer excellent protection against abrasion, punctures, and cuts. They are commonly used in construction, manufacturing, and heavy-duty tasks.

- Cotton Gloves: Cotton gloves are lightweight and breathable, making them suitable for tasks that require dexterity and comfort. They offer basic protection against minor abrasions and cuts.

- Nylon Gloves: Nylon gloves provide good abrasion resistance and flexibility, making them suitable for tasks involving handling tools and materials.

- Synthetic Gloves: Synthetic gloves are made from materials like nitrile, neoprene, and PVC, offering varying levels of protection against chemicals, solvents, and other hazards. They are commonly used in industries like automotive, healthcare, and food processing.

Medical Gloves

Medical gloves are essential for healthcare professionals, providing a barrier between the wearer’s hands and potential contaminants. These gloves are typically made from latex, nitrile, or vinyl, each offering different properties and advantages.

- Latex Gloves: Latex gloves are known for their sensitivity and dexterity, making them suitable for tasks requiring fine motor skills. However, some individuals may experience allergic reactions to latex.

- Nitrile Gloves: Nitrile gloves are highly resistant to punctures and chemicals, making them suitable for handling hazardous materials. They are also hypoallergenic and less likely to cause allergic reactions.

- Vinyl Gloves: Vinyl gloves are the most economical option, offering basic protection against contaminants. They are often used for non-invasive procedures and general medical tasks.

Sports Gloves

Sports gloves are designed to enhance grip, protect hands, and improve performance in various sports. These gloves are made from materials like leather, synthetic fabrics, and specialized materials like gel padding and shock-absorbing technology.

- Baseball Gloves: Baseball gloves are large and padded, designed to catch and throw baseballs. They are typically made from leather and feature a deep pocket to secure the ball.

- Golf Gloves: Golf gloves are designed to improve grip and control on the club. They are usually made from leather or synthetic materials, with a textured surface for enhanced grip.

- Cycling Gloves: Cycling gloves provide padding and protection for hands during long rides. They often feature gel padding in the palm area to absorb vibrations and reduce hand fatigue.

- Weightlifting Gloves: Weightlifting gloves are designed to improve grip and protect hands during weight training. They are typically made from leather or synthetic materials, with reinforced areas for added durability.

Technological Innovations in Gloves

Gloves have evolved from simple protective barriers to sophisticated tools that enhance human capabilities. Recent advancements in materials science, electronics, and sensor technology have led to the development of innovative gloves with remarkable functionalities. These innovations have opened up new possibilities in various fields, including healthcare, manufacturing, virtual reality, and more.

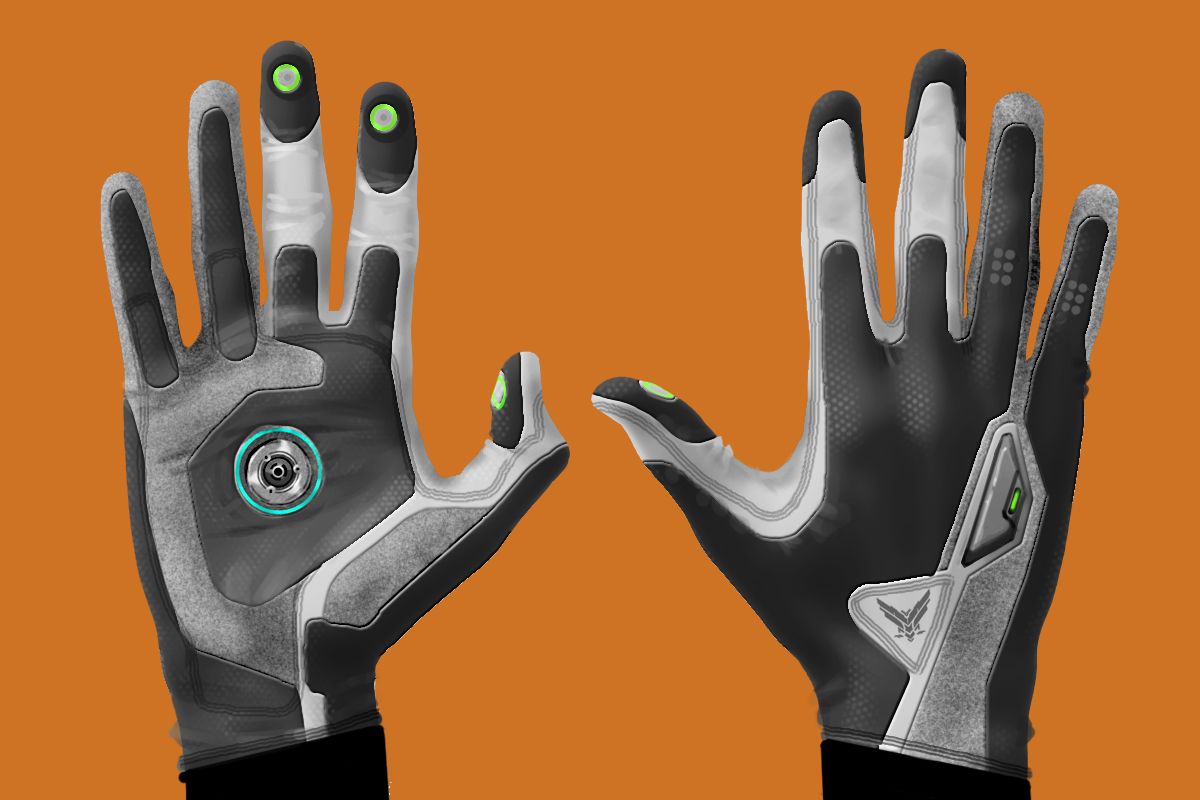

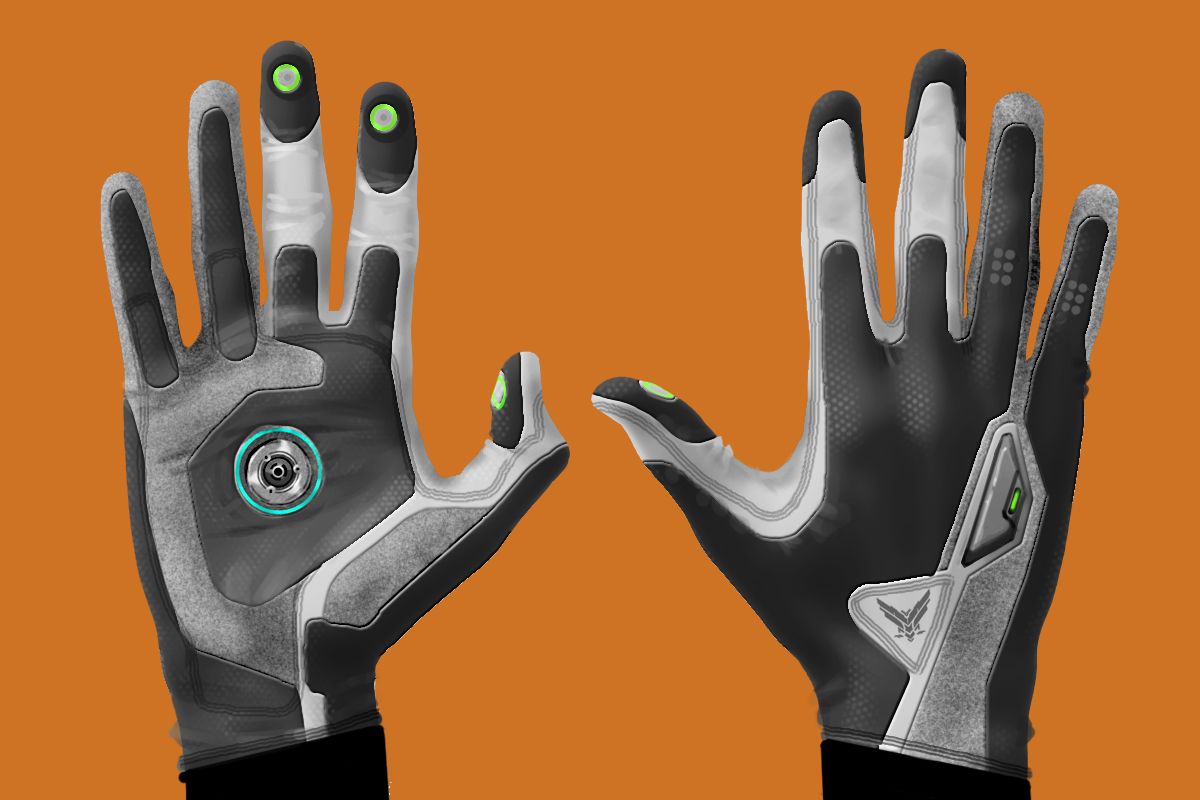

Smart Gloves with Integrated Sensors and Actuators

Smart gloves are equipped with sensors and actuators that allow them to gather data, interact with their environment, and provide feedback to the wearer. These gloves can be used in a wide range of applications, from controlling robotic devices to enhancing human performance.

- Gesture Recognition: Smart gloves can detect hand movements and gestures, enabling users to control devices or software without using a keyboard or mouse. This technology is being explored for applications in gaming, virtual reality, and assistive technology for people with disabilities.

- Haptic Feedback: Haptic feedback gloves provide users with realistic tactile sensations, enhancing their experience in virtual reality applications. They can simulate the feeling of touching objects, manipulating virtual tools, and even experiencing physical feedback in response to virtual events.

- Health Monitoring: Biometric sensors embedded in smart gloves can monitor vital signs such as heart rate, blood pressure, and body temperature. This data can be used for health monitoring, early disease detection, and personalized fitness tracking.

Haptic Feedback Gloves for Virtual Reality Applications

Haptic feedback gloves are a crucial component of immersive virtual reality experiences. They allow users to feel virtual objects and environments, enhancing their sense of presence and realism.

- Realistic Interactions: Haptic feedback gloves enable users to feel the texture, weight, and shape of virtual objects, making virtual interactions more realistic and engaging. This technology is particularly valuable for training simulations, where users need to practice manipulating virtual tools or performing complex tasks.

- Enhanced Immersion: By providing tactile feedback, haptic gloves contribute to a more immersive VR experience. They can create a sense of presence and embodiment in the virtual world, making it feel more real and engaging.

- Improved User Experience: Haptic feedback gloves can enhance user experience in VR games and applications. They can add a new layer of realism and interactivity, making the experience more enjoyable and engaging.

Biometric Gloves for Health Monitoring and Data Collection, Gloves technology

Biometric gloves integrate sensors that can measure physiological parameters, providing valuable insights into the wearer’s health and performance.

- Real-Time Health Monitoring: Biometric gloves can continuously monitor vital signs such as heart rate, blood pressure, and skin temperature, providing real-time feedback on the wearer’s health status. This information can be used for early disease detection, personalized healthcare, and athletic performance optimization.

- Data Collection and Analysis: Biometric gloves can collect a wide range of data, including muscle activity, joint movement, and physiological responses. This data can be analyzed to understand human movement patterns, assess the effectiveness of rehabilitation programs, and develop personalized training plans.

- Remote Healthcare: Biometric gloves can facilitate remote healthcare by enabling healthcare professionals to monitor patients’ vital signs and receive real-time data from their homes or workplaces. This technology has the potential to improve patient care and reduce healthcare costs.

Gloves with Enhanced Protection Against Hazards

Gloves designed with enhanced protection against hazards are crucial for workers in industries where they are exposed to extreme conditions or hazardous materials.

- Heat Resistance: Heat-resistant gloves are designed to protect workers from burns and injuries caused by high temperatures. They are commonly used in industries such as manufacturing, welding, and firefighting.

- Chemical Resistance: Chemical-resistant gloves are made from materials that resist the penetration of chemicals, protecting workers from skin irritation, burns, and other harmful effects. They are used in industries such as chemical processing, healthcare, and laboratory work.

- Radiation Protection: Radiation-resistant gloves are designed to shield workers from the harmful effects of radiation, protecting them from skin damage, cancer, and other health risks. They are used in industries such as nuclear power, medical imaging, and aerospace.

Future Trends in Glove Technology

The future of glove technology is poised for significant advancements, driven by the convergence of emerging technologies and evolving market demands. From enhanced safety and performance to innovative functionalities and personalized experiences, the gloves of tomorrow will be a testament to the boundless possibilities of human ingenuity.

Impact of Emerging Technologies

Emerging technologies are set to revolutionize glove design and production, ushering in a new era of functionality and sophistication. Advancements in artificial intelligence, nanotechnology, and 3D printing will reshape the landscape of glove technology, enabling the creation of gloves that are smarter, more adaptable, and more personalized than ever before.

Artificial Intelligence

Artificial intelligence (AI) will play a pivotal role in the future of glove technology, enhancing safety, performance, and user experience. AI-powered gloves will leverage machine learning algorithms to analyze data from sensors embedded within the glove, providing real-time insights into user activity, environmental conditions, and potential hazards.

- Enhanced Safety: AI-powered gloves can detect and alert users to potential hazards, such as sharp objects, extreme temperatures, or hazardous materials, improving workplace safety and reducing the risk of injuries.

- Performance Optimization: AI algorithms can analyze user movements and provide feedback on technique, helping users improve their performance in various tasks, from sports and surgery to manufacturing and construction.

- Personalized Fit and Comfort: AI can analyze user hand anatomy and preferences to create customized gloves that provide a perfect fit and optimal comfort, enhancing performance and reducing fatigue.

Nanotechnology

Nanotechnology will enable the development of gloves with enhanced properties, such as improved durability, water resistance, and breathability. Nanomaterials, with their unique properties at the nanoscale, will revolutionize glove materials, offering superior performance and functionality.

- Enhanced Durability: Nanomaterials can be incorporated into glove materials to create a more robust and durable barrier against abrasion, punctures, and tears, extending the lifespan of gloves and reducing waste.

- Improved Water Resistance: Nano-coatings can provide water-resistant properties to gloves, protecting users from moisture and enhancing their performance in wet environments.

- Enhanced Breathability: Nanomaterials can be used to create breathable fabrics that allow air circulation while maintaining a barrier against moisture and contaminants, enhancing user comfort and reducing perspiration.

3D Printing

3D printing, or additive manufacturing, will revolutionize glove production, enabling the creation of customized and highly specialized gloves with complex geometries and intricate designs. 3D printing will allow for the production of gloves tailored to specific applications and user needs, providing a level of personalization previously unattainable.

- Customized Fit: 3D printing allows for the creation of gloves that perfectly fit the user’s hand, enhancing comfort, performance, and dexterity.

- Complex Designs: 3D printing enables the production of gloves with intricate designs and complex geometries, facilitating the integration of sensors, actuators, and other functionalities.

- On-Demand Production: 3D printing enables on-demand production of gloves, reducing inventory costs and lead times, and allowing for the creation of customized gloves tailored to specific needs.

Innovative Glove Concepts

The convergence of emerging technologies will pave the way for innovative glove concepts that address future challenges and opportunities. These concepts will leverage the power of AI, nanotechnology, and 3D printing to create gloves that are smarter, more adaptable, and more personalized than ever before.

Smart Gloves for Industrial Applications

Smart gloves for industrial applications will integrate sensors, actuators, and AI algorithms to enhance safety, performance, and efficiency. These gloves will provide real-time feedback on user movements, environmental conditions, and potential hazards, enabling workers to perform tasks more safely and efficiently.

- Haptic Feedback: Smart gloves can provide haptic feedback to users, simulating the feel of objects and providing guidance on tasks, enhancing precision and accuracy.

- Augmented Reality: Smart gloves can integrate augmented reality (AR) displays, overlaying information on the user’s field of view, providing guidance and instructions for complex tasks.

- Remote Control: Smart gloves can be used to control machinery and equipment remotely, enhancing worker safety and productivity.

Biometric Gloves for Healthcare

Biometric gloves for healthcare will leverage sensors and AI algorithms to monitor vital signs, detect anomalies, and provide real-time feedback to healthcare professionals. These gloves will enhance patient care, improve diagnosis, and enable more effective treatment.

- Vital Sign Monitoring: Biometric gloves can monitor vital signs, such as heart rate, blood pressure, and oxygen saturation, providing real-time data to healthcare professionals.

- Early Disease Detection: Biometric gloves can detect subtle changes in vital signs that may indicate underlying health conditions, enabling early diagnosis and intervention.

- Remote Patient Monitoring: Biometric gloves can enable remote patient monitoring, allowing healthcare professionals to track patient health status from afar.

Personalized Gloves for Everyday Use

Personalized gloves for everyday use will leverage 3D printing and AI algorithms to create gloves that perfectly fit the user’s hand and provide enhanced comfort, functionality, and style. These gloves will cater to individual needs and preferences, offering a more personalized and enjoyable user experience.

- Customized Fit: 3D printing allows for the creation of gloves that perfectly fit the user’s hand, enhancing comfort, performance, and dexterity.

- Integrated Technology: Personalized gloves can integrate technology, such as touchscreens, sensors, and actuators, enhancing functionality and providing a seamless user experience.

- Fashionable Designs: Personalized gloves can be designed with a variety of styles and colors, allowing users to express their individuality and enhance their personal style.

Last Word: Gloves Technology

As we look towards the future, the potential for gloves technology is boundless. With advancements in artificial intelligence, nanotechnology, and 3D printing, the gloves of tomorrow promise to be even more sophisticated, adaptable, and integrated into our lives. From enhancing our senses to protecting us from unseen dangers, gloves are poised to play a vital role in shaping the future of human interaction and performance.

Gloves technology is advancing rapidly, incorporating innovations like haptic feedback and motion tracking. These advancements are finding applications in various fields, including medical procedures and virtual reality experiences. The max air technology actuator is a prime example of this progress, offering precise control and responsiveness for intricate movements.

With such advancements, the future of gloves technology holds immense potential for enhancing human interaction and performance in diverse settings.