Genius Laser Technology: Revolutionizing Industries

Genius laser technology, a groundbreaking advancement in the field of lasers, is revolutionizing industries across the globe. Its unique capabilities and precision have opened doors to unprecedented possibilities in medicine, […]

Genius laser technology, a groundbreaking advancement in the field of lasers, is revolutionizing industries across the globe. Its unique capabilities and precision have opened doors to unprecedented possibilities in medicine, manufacturing, and research. This technology harnesses the power of light to manipulate matter at an atomic level, offering solutions to complex challenges that were once considered insurmountable.

The history of genius laser technology is marked by continuous innovation, driven by a relentless pursuit of pushing the boundaries of what’s possible. From its humble beginnings in the laboratory to its widespread adoption in various sectors, this technology has transformed the way we approach problem-solving and innovation.

Introduction to Genius Laser Technology

Genius laser technology, also known as “femtosecond laser technology,” is a revolutionary advancement in the field of laser science, characterized by its ability to manipulate matter at an incredibly precise and rapid level. This technology harnesses ultra-short laser pulses, measured in femtoseconds (10^-15 seconds), to interact with materials with unprecedented accuracy.

The Core Principles of Genius Laser Technology

The foundation of genius laser technology lies in the generation and control of ultra-short laser pulses. These pulses are produced by specialized lasers that emit light in extremely short bursts, lasting only a few femtoseconds. The short duration of these pulses allows for a high peak power, enabling them to interact with materials in a unique way.

The interaction of femtosecond laser pulses with matter is governed by the concept of “non-linear optics,” where the response of the material to the laser light is not proportional to the intensity of the light. This non-linear interaction allows for precise control over the material’s response, enabling various applications.

A Brief History of Genius Laser Technology

The development of genius laser technology can be traced back to the 1960s with the invention of the first lasers. However, the breakthrough in generating ultra-short pulses came in the 1980s with the development of “mode-locked lasers.” These lasers were able to produce pulses lasting just a few picoseconds (10^-12 seconds).

Further advancements in the 1990s led to the development of “femtosecond lasers,” capable of generating pulses lasting only a few femtoseconds. These lasers revolutionized the field of laser technology, opening up new possibilities in various scientific and technological applications.

Significance in the Field of Laser Technology

Genius laser technology has significantly impacted the field of laser technology, driving innovation in various sectors, including:

- Precision Manufacturing: Femtosecond lasers are used for micromachining, cutting, and engraving materials with extreme precision, enabling the creation of intricate and complex designs. This technology is widely used in the manufacturing of microelectronics, medical devices, and optical components.

- Biomedical Applications: The precise nature of femtosecond lasers allows for their use in ophthalmic surgery, where they are used to reshape the cornea for vision correction. Additionally, they are employed in tissue ablation, cell manipulation, and drug delivery.

- Scientific Research: Femtosecond lasers are essential tools in fundamental research, enabling scientists to study the interaction of light with matter at the atomic and molecular levels. This has led to advancements in fields such as spectroscopy, materials science, and quantum optics.

- Optical Communications: The high-speed modulation capabilities of femtosecond lasers have led to their use in high-speed optical communication systems, enabling faster and more efficient data transmission.

Applications of Genius Laser Technology

Genius laser technology has revolutionized various industries, finding its way into diverse applications that impact our lives in numerous ways. From healthcare to manufacturing, research, and even art, the versatility of genius laser technology is evident in its ability to solve complex problems and drive innovation.

Medical Applications

The precision and control offered by genius laser technology have made it an indispensable tool in the medical field. It is used in a wide range of procedures, from minimally invasive surgeries to advanced diagnostic techniques.

- Laser Surgery: Genius lasers are used in various surgical procedures, including eye surgery (LASIK), dermatological procedures (removing moles, birthmarks, and tattoos), and cancer treatment. The precise nature of laser beams allows for highly targeted interventions, minimizing collateral damage to surrounding tissues.

- Laser Therapy: Genius laser therapy is used to treat various conditions, including pain relief, wound healing, and skin rejuvenation. Low-level laser therapy (LLLT) utilizes specific wavelengths of light to stimulate cellular processes and promote healing.

- Laser Diagnostics: Genius lasers are used in diagnostic imaging techniques, such as optical coherence tomography (OCT), which provides high-resolution images of internal structures, aiding in the early detection and diagnosis of various diseases.

Manufacturing Applications

Genius laser technology has transformed manufacturing processes, enhancing efficiency, precision, and product quality. It plays a crucial role in various manufacturing operations, including cutting, welding, and surface treatment.

- Laser Cutting: Genius lasers are used for cutting a wide range of materials, including metals, plastics, ceramics, and composites. Their ability to cut with high precision and minimal heat distortion makes them ideal for intricate designs and delicate materials.

- Laser Welding: Genius laser welding offers a highly precise and efficient method for joining materials. The concentrated heat of the laser beam melts the materials, creating a strong and durable bond. This technique is particularly valuable in industries requiring high-quality welds, such as aerospace and automotive manufacturing.

- Laser Surface Treatment: Genius lasers are used for surface modification, enhancing material properties such as hardness, wear resistance, and corrosion resistance. This technique involves altering the surface microstructure of materials through processes like laser cladding, laser shock peening, and laser texturing.

Research Applications

Genius laser technology is a powerful tool in research, enabling scientists to explore the fundamental properties of matter and develop new materials and technologies.

- Materials Science: Genius lasers are used in materials science research to study the interaction of light with matter, leading to the development of novel materials with tailored properties. Examples include laser-induced forward transfer (LIFT) for creating micro- and nanostructures, and laser ablation for precise material removal and surface modification.

- Biomedical Research: Genius lasers are employed in biomedical research to study biological processes at the cellular and molecular levels. They are used in techniques like fluorescence microscopy, laser capture microdissection, and laser-induced breakdown spectroscopy (LIBS) for analyzing biological samples.

- Fundamental Physics: Genius lasers are used in fundamental physics research to investigate the nature of light and its interaction with matter. Examples include laser-based experiments in quantum optics, nonlinear optics, and high-intensity laser physics.

Advanced Materials Processing and Fabrication

Genius laser technology plays a significant role in the processing and fabrication of advanced materials, enabling the creation of complex and intricate structures with unprecedented precision and control.

- Additive Manufacturing (3D Printing): Genius lasers are used in various 3D printing techniques, including powder bed fusion and direct energy deposition. These techniques use lasers to melt and fuse materials layer by layer, creating complex three-dimensional objects with high precision and intricate designs.

- Micro- and Nanofabrication: Genius lasers are essential for micro- and nanofabrication, enabling the creation of tiny structures and devices with dimensions in the micrometer and nanometer range. This technology is crucial for developing advanced electronics, sensors, and optical devices.

- Laser-Induced Periodic Surface Structures (LIPSS): Genius lasers can create periodic surface structures with nanoscale features, altering the optical, mechanical, and wetting properties of materials. This technology has applications in areas like anti-reflection coatings, bio-sensing, and microfluidics.

Advantages and Limitations of Genius Laser Technology

Genius laser technology, a revolutionary advancement in laser science, presents significant advantages over traditional laser methods, offering enhanced precision, efficiency, and versatility. However, its implementation also presents certain limitations and challenges that require careful consideration. This section delves into the key advantages and limitations of this groundbreaking technology, comparing and contrasting its performance with other laser technologies.

Advantages of Genius Laser Technology

Genius laser technology boasts a unique set of advantages that make it a compelling choice for a wide range of applications.

- Enhanced Precision and Accuracy: Genius lasers utilize advanced optical techniques and precise control mechanisms, enabling them to achieve unparalleled precision and accuracy in various tasks. This precision is particularly valuable in applications like micro-machining, where minute details and intricate patterns are crucial.

- Increased Efficiency and Speed: Genius lasers are designed to operate at higher speeds and with greater efficiency compared to traditional laser methods. This translates into faster processing times, reduced energy consumption, and increased productivity, making them ideal for high-volume manufacturing and industrial applications.

- Versatility and Adaptability: Genius laser technology exhibits remarkable versatility, allowing it to be tailored to a wide range of applications. By adjusting laser parameters such as wavelength, pulse duration, and power, users can customize the laser’s performance to meet specific requirements. This adaptability makes it suitable for tasks ranging from delicate surgery to industrial cutting and welding.

- Reduced Heat Affected Zone (HAZ): Genius lasers generate highly focused and controlled beams, minimizing the heat affected zone surrounding the target area. This reduced HAZ translates to less distortion and damage to materials, particularly valuable in delicate applications like micro-electronics and medical procedures.

- Non-Contact Processing: Genius lasers operate without physical contact with the target material, eliminating the risk of contamination or surface damage. This non-contact processing method is crucial for applications where precision and sterility are paramount, such as medical device manufacturing and microelectronics fabrication.

Limitations of Genius Laser Technology

While genius laser technology offers numerous advantages, its implementation also presents certain limitations and challenges:

- High Initial Investment: Genius laser systems are sophisticated and require advanced engineering, leading to higher initial investment costs compared to traditional laser methods. This high cost may be a barrier for smaller businesses or research labs with limited budgets.

- Complex Operation and Maintenance: Genius lasers often involve intricate operating procedures and require specialized expertise for maintenance and calibration. This complexity can pose challenges for operators with limited training or experience.

- Limited Material Compatibility: While genius lasers can process a wide range of materials, certain materials may be less compatible with specific laser parameters. This limitation requires careful selection of laser settings and materials to ensure optimal processing results.

- Potential Safety Hazards: Genius lasers operate at high power levels and can pose safety hazards if not handled properly. Proper safety protocols and protective measures are crucial to mitigate risks and ensure the well-being of operators.

- Environmental Considerations: Genius laser systems may generate waste products, such as fumes and particulate matter, requiring appropriate environmental controls and disposal procedures to minimize their impact.

Comparison with Other Laser Technologies

Genius laser technology stands out from other laser technologies in several ways:

- Ultrafast Lasers: Ultrafast lasers are known for their extremely short pulse durations, enabling precise micro-machining and material processing. Genius lasers, while not always ultrafast, can achieve similar levels of precision through advanced optical techniques and control mechanisms. However, ultrafast lasers may offer advantages in specific applications requiring exceptionally high peak power.

- Fiber Lasers: Fiber lasers are renowned for their high efficiency and compact design, making them suitable for industrial applications. Genius lasers may offer advantages in terms of precision and versatility, while fiber lasers excel in power and efficiency.

- CO2 Lasers: CO2 lasers are widely used in industrial applications due to their high power output and affordability. Genius lasers may offer advantages in terms of precision, beam quality, and material compatibility, but CO2 lasers remain a cost-effective solution for high-volume manufacturing.

Future Directions of Genius Laser Technology

The field of laser technology is constantly evolving, with ongoing research and development leading to remarkable advancements. Genius laser technology, characterized by its high precision, versatility, and efficiency, is poised to play a pivotal role in shaping future technological breakthroughs.

Applications in Quantum Computing, Genius laser technology

Quantum computing, a revolutionary approach to computation, harnesses the principles of quantum mechanics to solve complex problems that are intractable for classical computers. Genius lasers have the potential to revolutionize quantum computing by enabling the development of more efficient and powerful quantum systems.

- Precision Control of Quantum Systems: Genius lasers can be used to manipulate and control quantum states with unprecedented precision, enabling the development of more robust and reliable quantum computers.

- Development of Novel Quantum Materials: Genius lasers can be employed to create and manipulate new materials with unique quantum properties, such as superconductivity and topological insulators, which could be used to build advanced quantum devices.

- Quantum Communication: Genius lasers can be used to develop secure and high-speed quantum communication networks, enabling the transmission of information with unbreakable encryption.

Applications in Nanotechnology

Nanotechnology, the manipulation of matter at the atomic and molecular level, holds immense potential for revolutionizing various industries. Genius lasers can play a crucial role in enabling the development of advanced nanomaterials and nanodevices.

- Nanofabrication: Genius lasers can be used to create intricate nanostructures with high precision, enabling the fabrication of advanced nanodevices for applications in electronics, medicine, and energy.

- Nanomaterial Synthesis: Genius lasers can be employed to synthesize novel nanomaterials with tailored properties, such as enhanced conductivity, strength, and optical properties.

- Nanometrology: Genius lasers can be used for high-resolution characterization and analysis of nanomaterials and nanodevices, enabling the development of more efficient and reliable nanotechnology.

Impact on Future Technological Development

The impact of genius laser technology on future technological development is far-reaching and profound.

- Advancements in Medicine: Genius lasers are already being used in various medical applications, such as surgery, diagnostics, and drug delivery. Future advancements in genius laser technology are expected to lead to more precise and minimally invasive treatments, as well as the development of novel therapies.

- Revolution in Manufacturing: Genius lasers can be used to create highly complex and intricate products with unprecedented accuracy and efficiency, leading to advancements in manufacturing processes and the development of new materials and products.

- Sustainable Energy Solutions: Genius lasers can be employed in the development of more efficient solar cells and other renewable energy technologies, contributing to a more sustainable future.

Genius Laser Technology in Action: Case Studies

Genius laser technology, with its precision, speed, and versatility, has revolutionized numerous fields. To illustrate its impact, we delve into real-world applications across various industries.

Case Studies in Genius Laser Technology

The following table presents a selection of case studies showcasing the diverse applications of genius laser technology, highlighting its benefits and challenges.

| Application Area | Description of the Case Study | Key Benefits Achieved | Challenges Encountered |

|---|---|---|---|

| Medical Surgery | Laser-assisted surgery, particularly in ophthalmology (LASIK eye surgery), has enabled precise and minimally invasive procedures. For instance, in LASIK, lasers reshape the cornea to correct refractive errors, improving vision without the need for traditional glasses or contact lenses. | Minimally invasive procedures, reduced recovery time, improved accuracy, and enhanced patient outcomes. | High initial investment costs, specialized training requirements for surgeons, and potential complications like infection or dry eye. |

| Manufacturing | Laser cutting and engraving are widely used in manufacturing for creating intricate designs and precise parts. For example, lasers are used to cut sheet metal, engrave intricate patterns on jewelry, and create complex molds for various products. | Increased precision and accuracy in manufacturing, enhanced efficiency and speed of production, reduced material waste, and the ability to create complex geometries. | The need for skilled operators, potential for laser-induced damage to materials, and the cost of laser maintenance. |

| Electronics | Laser micromachining plays a crucial role in the electronics industry, enabling the creation of microelectronic devices and circuits. For instance, lasers are used to drill vias, cut traces, and ablate materials in the fabrication of integrated circuits (ICs) and semiconductors. | Improved precision and accuracy in microelectronic fabrication, reduced processing time, and the ability to create intricate designs with high feature resolution. | The complexity of the technology, the need for cleanroom environments, and the cost of high-precision lasers. |

| Art and Design | Laser engraving and cutting have become valuable tools for artists and designers, allowing them to create intricate artwork, personalized gifts, and custom designs. For example, lasers are used to engrave intricate details on wood, metal, and glass, and to cut out complex shapes for sculptures and other artistic creations. | Enhanced creativity and artistic expression, the ability to create personalized and unique designs, and the potential to generate new artistic forms. | The cost of laser equipment, the need for artistic expertise, and the potential for safety hazards if not handled properly. |

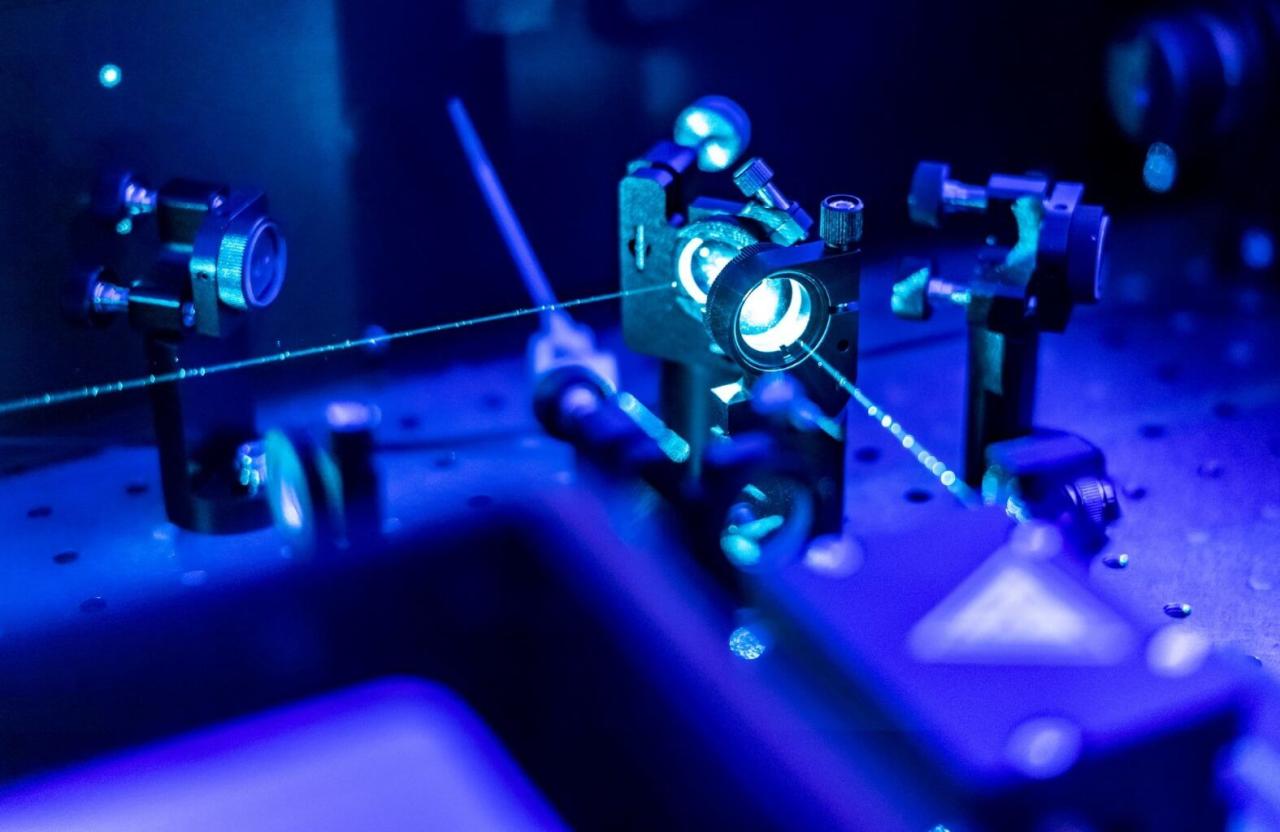

Visual Representations of Genius Laser Technology

Visual representations play a crucial role in understanding complex technologies like genius lasers. These depictions offer a clear and intuitive way to grasp the intricate workings and applications of these advanced systems. By providing a visual framework, these representations facilitate comprehension and promote further exploration.

Visual Depictions of Genius Laser Systems

Visual depictions of genius laser systems are essential for understanding their structure and functionality. These representations often take the form of schematic diagrams, illustrating the various components and their interconnectedness.

| Image Description | Detailed Description |

|---|---|

| A schematic diagram of a genius laser system, highlighting the laser source, optical resonator, and focusing optics. | This schematic depicts the key components of a genius laser system, including the laser source, which generates the coherent light beam. The optical resonator, a crucial element, ensures that the laser beam oscillates and amplifies within the system. Focusing optics are then used to direct and concentrate the laser beam, enabling precise and controlled applications. The diagram illustrates the intricate interplay between these components, showcasing the unique features of genius laser technology. |

| A 3D rendering of a genius laser system, showcasing the spatial arrangement of its components. | This 3D rendering provides a comprehensive view of the genius laser system, depicting the physical arrangement of its components in three dimensions. The rendering emphasizes the spatial relationships between the laser source, optical resonator, and focusing optics, offering a realistic representation of the system’s physical structure. This visualization aids in understanding the system’s physical layout and the interaction between its components. |

Visual Representations of Genius Laser Applications

Visual representations are crucial for showcasing the diverse applications of genius laser technology. These depictions can range from simple diagrams illustrating the interaction of the laser beam with a target material to complex animations depicting the intricate processes involved in specific applications.

| Image Description | Detailed Description |

|---|---|

| A diagram illustrating the use of a genius laser for precision cutting of a metal sheet. | This diagram depicts the process of laser cutting, where a focused laser beam is directed onto a metal sheet, precisely melting and vaporizing the material along the desired path. The diagram highlights the accuracy and controllability of genius lasers, showcasing their ability to achieve intricate cuts with minimal heat-affected zones. |

| An animation demonstrating the use of a genius laser for 3D printing. | This animation visually represents the process of 3D printing using a genius laser. It shows how the laser beam selectively melts and fuses layers of powdered material, building up a three-dimensional object layer by layer. The animation highlights the precision and flexibility of genius lasers in 3D printing, enabling the creation of complex geometries with intricate details. |

Ending Remarks

Genius laser technology is not merely a technological marvel; it represents a paradigm shift in our understanding and manipulation of light. As we continue to explore its potential, the future promises even more transformative applications, pushing the limits of human ingenuity and shaping the world around us in profound ways. The impact of genius laser technology is far-reaching, extending beyond specific industries to influence the very fabric of our society.

Genius laser technology is revolutionizing the way we interact with the world, from precision surgery to intricate manufacturing processes. The technology’s applications are constantly expanding, with companies like b and c technologies at the forefront of innovation. Their expertise in laser systems allows them to push the boundaries of what’s possible, further solidifying the role of genius laser technology in shaping the future.