GE Water & Process Technologies: Solutions for a Sustainable Future

GE Water & Process Technologies is a global leader in providing innovative solutions for water treatment, process optimization, and sustainable operations. With a rich history and unwavering commitment to environmental […]

GE Water & Process Technologies is a global leader in providing innovative solutions for water treatment, process optimization, and sustainable operations. With a rich history and unwavering commitment to environmental responsibility, GE Water & Process Technologies has established itself as a trusted partner for industries worldwide. Their expertise spans a wide range of technologies, including membrane filtration, ion exchange, reverse osmosis, and advanced process control systems, all designed to meet the unique needs of their clients.

From ensuring clean drinking water for communities to optimizing industrial processes and minimizing environmental impact, GE Water & Process Technologies plays a crucial role in addressing some of the world’s most pressing challenges. Their solutions are tailored to specific industries, including power generation, manufacturing, mining, and agriculture, empowering businesses to achieve operational efficiency, reduce costs, and contribute to a sustainable future.

Introduction to GE Water & Process Technologies

GE Water & Process Technologies is a leading global provider of water and process technologies, solutions, and services. It plays a crucial role in the industry by offering innovative and sustainable solutions to address the world’s most pressing water and process challenges.

The company’s history dates back to the early 20th century, with its roots in the General Electric Company. GE Water & Process Technologies has evolved over the years, expanding its portfolio and expertise to meet the growing demand for water treatment and process solutions.

Mission and Core Values

GE Water & Process Technologies is committed to providing innovative and sustainable solutions that improve water quality, enhance industrial processes, and protect the environment. The company’s mission is to “help our customers succeed by providing the most reliable and sustainable water and process technologies in the world.” Its core values include:

- Customer Focus: GE Water & Process Technologies prioritizes customer satisfaction and strives to meet their unique needs.

- Innovation: The company invests heavily in research and development to deliver cutting-edge technologies and solutions.

- Sustainability: GE Water & Process Technologies is committed to environmental responsibility and strives to minimize its environmental impact.

- Integrity: The company operates with the highest ethical standards and maintains transparency in all its dealings.

Key Areas of Expertise

GE Water & Process Technologies has a wide range of expertise in various areas, including:

- Water Treatment: The company offers a comprehensive range of water treatment solutions, from source water treatment to wastewater treatment.

- Process Technologies: GE Water & Process Technologies provides solutions for various industrial processes, including power generation, oil and gas, mining, and chemical processing.

- Digital Solutions: The company leverages digital technologies to optimize water and process operations, enhance efficiency, and improve performance.

- Services: GE Water & Process Technologies offers a range of services, including maintenance, repair, and optimization, to ensure the optimal performance of its solutions.

Water Treatment Solutions

GE Water & Process Technologies provides a comprehensive range of water treatment solutions tailored to address the unique needs of various industries. These solutions encompass a variety of technologies, including membrane filtration, ion exchange, and reverse osmosis, all aimed at delivering clean and safe water for diverse applications.

Membrane Filtration

Membrane filtration is a versatile water treatment technology that utilizes semi-permeable membranes to separate contaminants from water. These membranes act as barriers, allowing water molecules to pass through while rejecting larger particles, including bacteria, viruses, and suspended solids. The effectiveness of membrane filtration depends on the pore size of the membrane, with smaller pore sizes capable of removing smaller contaminants.

Membrane filtration technologies are widely used in various industries, including:

- Municipal water treatment: Membrane filtration plays a crucial role in producing safe drinking water for communities by removing contaminants such as bacteria, viruses, and parasites.

- Industrial water treatment: Membrane filtration is employed in industrial processes to remove impurities from water used in manufacturing, cooling, and other applications, ensuring product quality and process efficiency.

- Wastewater treatment: Membrane filtration can be used to treat wastewater, removing contaminants and producing clean water for reuse or discharge into the environment.

Ion Exchange

Ion exchange is a water treatment process that utilizes specialized materials called ion exchangers to remove dissolved ions from water. These ion exchangers typically consist of resins with charged functional groups that attract and exchange ions present in the water.

Ion exchange is particularly effective in removing:

- Hardness ions: Calcium and magnesium ions, responsible for water hardness, can be removed by ion exchange, preventing scale formation in pipes and appliances.

- Heavy metals: Ion exchange effectively removes heavy metals such as lead, mercury, and arsenic, ensuring water safety for consumption and industrial use.

- Dissolved salts: Ion exchange can remove dissolved salts, such as sodium chloride, from water, making it suitable for various applications, including boiler feedwater and pharmaceutical production.

Reverse Osmosis

Reverse osmosis is a pressure-driven membrane filtration process that forces water molecules through a semi-permeable membrane, leaving behind contaminants. This process relies on the principle of osmotic pressure, where water naturally flows from a region of high concentration to a region of low concentration. By applying pressure to the water, the flow is reversed, pushing water through the membrane and leaving behind contaminants.

Reverse osmosis is a highly effective water treatment technology used in a wide range of applications, including:

- Drinking water production: Reverse osmosis is widely used in municipal water treatment plants to produce safe and palatable drinking water.

- Industrial process water: Reverse osmosis is essential for various industrial processes, providing high-purity water for manufacturing, pharmaceutical production, and power generation.

- Wastewater reuse: Reverse osmosis can be used to treat wastewater, producing clean water that can be reused for irrigation, industrial processes, or even drinking water.

Process Technologies: Ge Water & Process Technologies

GE Water & Process Technologies offers a wide range of process technologies that address various challenges faced by industries. These technologies are designed to improve process efficiency, reduce environmental impact, and optimize resource utilization.

Process Optimization and Efficiency

These process technologies play a crucial role in enhancing operational efficiency and reducing costs. By optimizing processes, industries can achieve significant improvements in:

- Energy consumption: Process technologies help reduce energy consumption by optimizing heat transfer, improving separation efficiency, and minimizing waste generation.

- Water consumption: Technologies like membrane filtration and reverse osmosis minimize water usage by reusing and recycling water, contributing to water conservation efforts.

- Waste generation: By minimizing waste generation and maximizing resource recovery, process technologies help reduce environmental impact and comply with regulatory requirements.

- Productivity: Optimized processes lead to improved productivity by increasing throughput, reducing downtime, and improving product quality.

Industries Where Process Technologies Are Implemented

GE Water & Process Technologies’ process technologies are implemented across a wide range of industries, including:

- Power generation: Power plants use these technologies for cooling water treatment, steam generation, and wastewater treatment, ensuring efficient and reliable power production.

- Oil and gas: Process technologies are used in oil and gas production for water treatment, gas processing, and wastewater management, contributing to safe and sustainable operations.

- Chemical and pharmaceutical: These industries rely on process technologies for water purification, separation, and purification of chemicals, ensuring product quality and safety.

- Food and beverage: Process technologies play a vital role in food and beverage production, ensuring water quality, product safety, and efficient resource utilization.

- Mining and metals: Process technologies are used in mining and metals processing for water treatment, mineral recovery, and wastewater management, contributing to sustainable resource extraction.

Sustainable Solutions

GE Water & Process Technologies is committed to sustainability, integrating it into every aspect of its business. The company recognizes the importance of protecting the environment and conserving resources for future generations. GE Water & Process Technologies’ sustainability efforts aim to minimize environmental impact, promote resource efficiency, and contribute to a more sustainable future.

Environmental Protection and Resource Conservation

GE Water & Process Technologies actively contributes to environmental protection and resource conservation through its innovative water and process technologies. The company’s solutions help industries reduce their water consumption, minimize waste generation, and improve overall environmental performance.

- Water Conservation: GE Water & Process Technologies offers advanced water treatment technologies that enable industries to reuse and recycle water, reducing their reliance on fresh water sources. This approach helps conserve valuable water resources and minimize the environmental impact of industrial operations.

- Waste Minimization: The company’s process technologies help industries reduce waste generation by optimizing processes, recovering valuable resources from waste streams, and minimizing emissions. This approach contributes to a cleaner environment and promotes resource circularity.

- Energy Efficiency: GE Water & Process Technologies focuses on developing energy-efficient solutions that reduce the energy footprint of water and process operations. This includes optimizing equipment design, integrating renewable energy sources, and implementing energy-saving technologies.

Case Studies

GE Water & Process Technologies has a rich history of successfully implementing innovative solutions for various industries and challenges. Here, we explore a few real-world examples that showcase the company’s capabilities and the impact of its solutions.

Water Treatment Solutions for Municipal Water Systems

The city of [City Name] faced a critical challenge with its aging water infrastructure, resulting in high levels of contaminants and water loss. GE Water & Process Technologies provided a comprehensive solution, including membrane filtration systems, advanced oxidation technologies, and intelligent water management software.

- The implementation of these technologies resulted in a significant reduction in contaminants, ensuring safe and clean drinking water for the city’s residents.

- The intelligent water management software helped optimize water distribution, minimizing water loss and improving operational efficiency.

- The project also contributed to the city’s sustainability goals by reducing its reliance on traditional water treatment methods, which often require high energy consumption.

This project demonstrates GE Water & Process Technologies’ ability to address complex water treatment challenges in municipal water systems, ensuring access to safe and reliable drinking water for communities.

Process Technologies for Industrial Applications

A large manufacturing plant in [Country] was struggling with high energy consumption and wastewater discharge. GE Water & Process Technologies implemented a combination of process technologies, including reverse osmosis, thermal desalination, and wastewater treatment systems.

- The reverse osmosis system helped recover valuable water from the plant’s wastewater, reducing the overall water footprint.

- The thermal desalination technology enabled the plant to use seawater as a source of freshwater, further reducing reliance on freshwater resources.

- The wastewater treatment systems effectively removed contaminants from the plant’s wastewater, ensuring compliance with environmental regulations.

This project exemplifies GE Water & Process Technologies’ expertise in providing sustainable solutions for industrial applications, minimizing environmental impact and maximizing resource efficiency.

Sustainable Solutions for the Mining Industry

A mining operation in [Country] was facing significant challenges with water scarcity and environmental regulations. GE Water & Process Technologies provided a comprehensive solution, including water reuse systems, desalination technologies, and mine water treatment solutions.

- The water reuse systems helped reduce the mine’s reliance on freshwater resources by treating and reusing wastewater for various operations.

- The desalination technologies enabled the mine to access a reliable source of freshwater from seawater, further reducing its water footprint.

- The mine water treatment solutions effectively removed contaminants from the mine’s wastewater, ensuring compliance with environmental regulations and protecting local ecosystems.

This project demonstrates GE Water & Process Technologies’ commitment to providing sustainable solutions for the mining industry, balancing economic development with environmental responsibility.

Industry Trends and Future Directions

The water and process technology industry is constantly evolving, driven by a complex interplay of factors including population growth, urbanization, climate change, and increasing regulatory scrutiny. GE Water & Process Technologies is actively engaged in navigating these trends and shaping the future of the industry through innovative solutions and sustainable practices.

Current Trends and Challenges, Ge water & process technologies

The water and process technology industry faces a number of key trends and challenges, including:

- Growing Demand for Water: Global population growth and urbanization are putting increasing pressure on water resources. This demand is further amplified by the need for water in industrial processes and agriculture.

- Water Scarcity and Drought: Climate change is leading to more frequent and severe droughts in many parts of the world, exacerbating water scarcity issues.

- Water Quality Degradation: Pollution from industrial activities, agricultural runoff, and wastewater discharge is degrading water quality, impacting human health and ecosystems.

- Energy Efficiency and Sustainability: The industry is under increasing pressure to reduce its environmental footprint and improve energy efficiency. This includes reducing greenhouse gas emissions and minimizing water consumption.

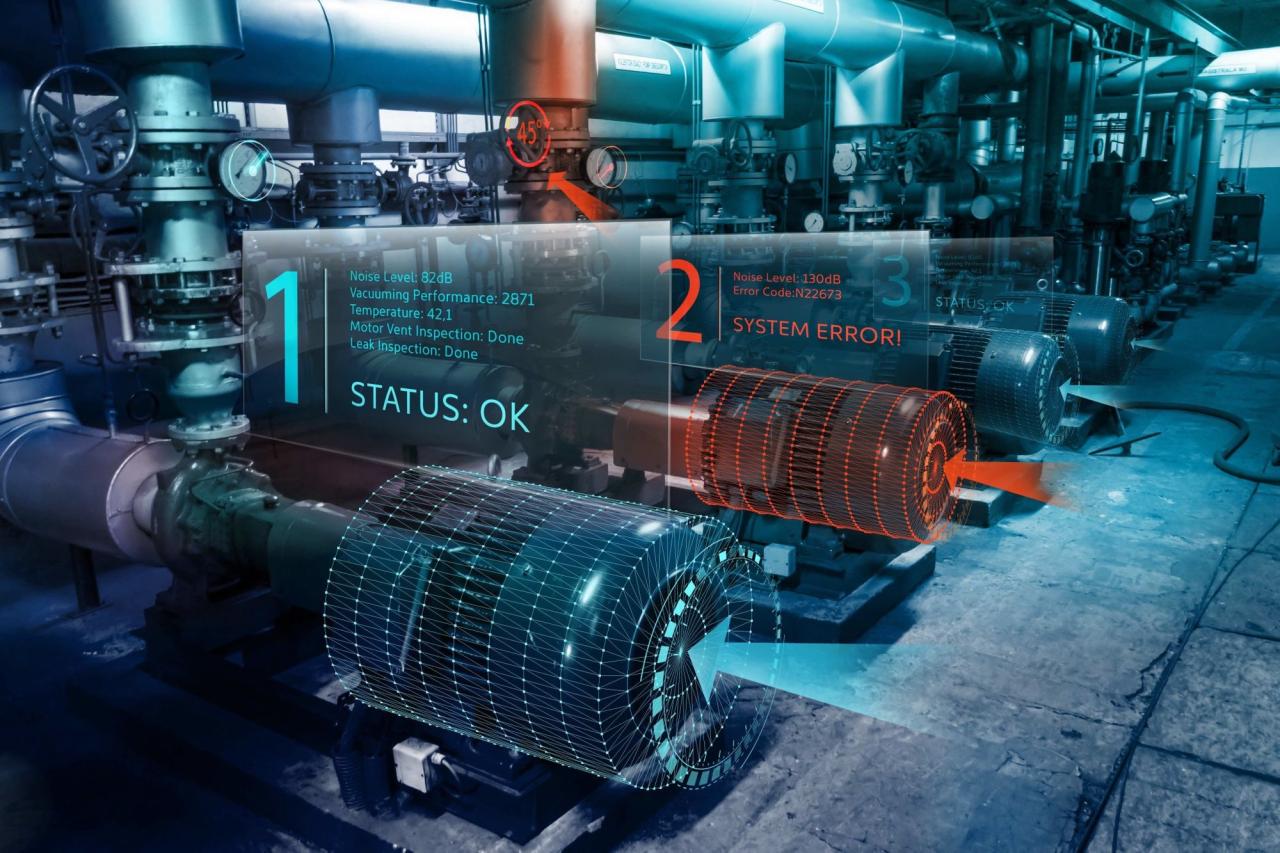

- Digitalization and Automation: Advancements in digital technologies, such as sensors, data analytics, and artificial intelligence (AI), are transforming the industry, enabling more efficient and data-driven operations.

GE Water & Process Technologies’ Role in Shaping the Industry

GE Water & Process Technologies is committed to addressing these challenges and shaping the future of the water and process technology industry through its innovative solutions and sustainable practices. The company focuses on the following key areas:

- Water Treatment Solutions: GE Water & Process Technologies provides a comprehensive range of water treatment solutions, including desalination, membrane filtration, and advanced oxidation processes. These solutions help to ensure access to clean and safe water for communities and industries.

- Process Technologies: The company offers advanced process technologies for a wide range of industries, including power generation, oil and gas, and chemicals. These technologies help to improve efficiency, reduce emissions, and enhance sustainability.

- Sustainable Solutions: GE Water & Process Technologies is committed to developing and deploying sustainable solutions that minimize environmental impact. This includes using renewable energy sources, reducing water consumption, and promoting circular economy principles.

Potential Innovations and Advancements

The water and process technology industry is poised for significant innovation and advancements in the coming years. Some of the key areas of focus include:

- Advanced Materials and Membranes: Research and development in advanced materials and membranes is leading to more efficient and sustainable water treatment processes. For example, new membrane materials with improved selectivity and fouling resistance are being developed for desalination and wastewater treatment.

- Artificial Intelligence (AI) and Machine Learning: AI and machine learning are being used to optimize water treatment processes, predict equipment failures, and improve operational efficiency. These technologies can analyze large datasets and identify patterns that would be difficult or impossible for humans to detect.

- Internet of Things (IoT): The IoT is enabling real-time monitoring and control of water treatment and process systems. Sensors and data analytics provide insights into system performance, allowing for proactive maintenance and optimization.

- Renewable Energy Integration: Integrating renewable energy sources, such as solar and wind power, into water treatment and process systems can significantly reduce reliance on fossil fuels and lower carbon emissions.

- Circular Economy Principles: The industry is embracing circular economy principles, aiming to minimize waste and maximize resource recovery. This includes recycling wastewater and recovering valuable materials from industrial processes.

Ultimate Conclusion

GE Water & Process Technologies stands at the forefront of the water and process technology industry, driving innovation and shaping the future of sustainable operations. Their commitment to research and development ensures that they remain at the cutting edge of technology, offering clients solutions that are both effective and environmentally responsible. As the world faces increasing water scarcity and environmental concerns, GE Water & Process Technologies continues to provide the essential tools and expertise needed to create a more sustainable future for all.

GE Water & Process Technologies provides cutting-edge solutions for water treatment and industrial processes. To ensure the optimal deployment of these technologies, GE relies on a robust framework for technology portfolio management , allowing them to prioritize investments, manage risks, and maximize returns.

This approach helps GE Water & Process Technologies stay ahead of the curve and deliver the most effective solutions to its clients.