Eriks Hose Technology: Innovation in Fluid Transfer

Eriks hose technology – Erik’s Hose Technology sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality […]

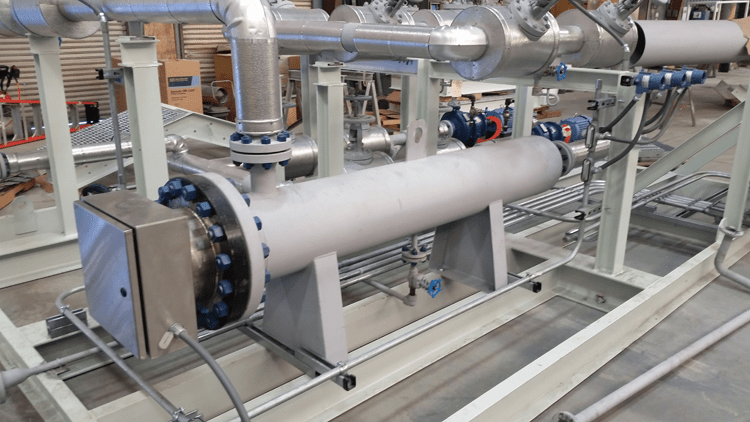

Eriks hose technology – Erik’s Hose Technology sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset. The company’s history and innovative approach to fluid transfer solutions have made them a leader in the industry. From the construction of durable and reliable hoses to the development of specialized applications, Erik’s Hose Technology has consistently pushed the boundaries of what’s possible.

This comprehensive exploration delves into the diverse world of Erik’s Hose Technology, uncovering the key features and benefits that have made them a trusted name in various industries. We’ll examine the different types of hoses available, their unique applications, and the challenges they address. Additionally, we’ll explore the company’s commitment to sustainability and safety, highlighting their role in creating a more responsible and secure future.

Types of Erik’s Hoses: Eriks Hose Technology

Erik’s hoses are a popular choice for various applications, from gardening to industrial use. The brand offers a wide range of hoses, each with its unique characteristics and benefits. Understanding the different types of Erik’s hoses can help you choose the right one for your needs.

Types of Erik’s Hoses, Eriks hose technology

Erik’s hoses are available in various materials, including:

- PVC: Polyvinyl chloride (PVC) is a common material for hoses due to its durability, flexibility, and affordability. PVC hoses are lightweight and easy to handle, making them suitable for general-purpose applications like gardening, watering, and cleaning.

- Rubber: Rubber hoses are known for their flexibility and resistance to kinks. They are often used in applications requiring high pressure and temperature resistance, such as industrial settings or for heavy-duty tasks.

- Reinforced PVC: This type of hose combines the advantages of PVC with the added strength of a reinforcement layer. It is typically made of PVC with a braided nylon or polyester layer for extra durability and resistance to pressure. Reinforced PVC hoses are ideal for demanding applications like irrigation, construction, and industrial use.

- Expandable Hose: These hoses are made from a flexible material that expands when water flows through it. They are lightweight, compact, and easy to store, making them a popular choice for gardening and outdoor activities.

| Hose Type | Material | Applications | Advantages/Disadvantages |

|---|---|---|---|

| PVC Hose | Polyvinyl Chloride (PVC) | Gardening, watering, cleaning | Advantages: Durable, flexible, affordable, lightweight. Disadvantages: Prone to kinking, may not be suitable for high pressure or temperature applications. |

| Rubber Hose | Rubber | Industrial settings, heavy-duty tasks | Advantages: Flexible, kink-resistant, high pressure and temperature resistance. Disadvantages: Can be heavy and bulky, may not be as durable as other materials. |

| Reinforced PVC Hose | PVC with nylon or polyester reinforcement | Irrigation, construction, industrial use | Advantages: Durable, resistant to pressure, kink-resistant. Disadvantages: May be more expensive than standard PVC hoses. |

| Expandable Hose | Flexible material | Gardening, outdoor activities | Advantages: Lightweight, compact, easy to store. Disadvantages: May not be as durable as other hoses, can be prone to leaks. |

Erik’s Hose Technology

Erik’s Hose Technology is committed to sustainability and minimizing its environmental impact throughout its operations. This commitment extends to the design, production, use, and end-of-life management of its hoses.

Environmental Impact of Erik’s Hose Technology

Erik’s Hose Technology strives to minimize its environmental footprint throughout the lifecycle of its products. This includes:

- Raw Material Sourcing: Erik’s Hose Technology prioritizes the use of recycled and sustainable materials whenever possible. This reduces the demand for virgin materials, which often have a higher environmental impact due to extraction and processing.

- Manufacturing Processes: Erik’s Hose Technology utilizes efficient manufacturing processes that minimize waste and energy consumption. This includes implementing lean manufacturing principles and adopting energy-saving technologies.

- Product Design: Erik’s Hose Technology designs its hoses to be durable and long-lasting, reducing the need for frequent replacements and minimizing waste. The company also focuses on designing hoses that are lightweight and efficient, minimizing transportation emissions.

- End-of-Life Management: Erik’s Hose Technology encourages responsible disposal of its products. The company offers recycling programs for its hoses, promoting their reuse or repurposing.

Sustainability Practices and Initiatives

Erik’s Hose Technology has implemented various sustainability practices and initiatives, demonstrating its commitment to environmental responsibility:

- Water Conservation: Erik’s Hose Technology has invested in water-efficient technologies and processes within its manufacturing facilities. This includes implementing water-saving fixtures and utilizing recycled water for non-potable applications.

- Energy Efficiency: Erik’s Hose Technology has adopted energy-saving measures throughout its operations, including the use of LED lighting, efficient HVAC systems, and renewable energy sources.

- Waste Reduction: Erik’s Hose Technology has implemented comprehensive waste management programs to minimize waste generation. This includes promoting recycling, composting, and reducing packaging materials.

- Carbon Footprint Reduction: Erik’s Hose Technology is actively working to reduce its carbon footprint by optimizing transportation routes, utilizing fuel-efficient vehicles, and exploring alternative transportation modes.

Contribution to a Sustainable Future

Erik’s Hose Technology’s sustainability efforts contribute to a more sustainable future in several ways:

- Reduced Resource Consumption: Erik’s Hose Technology’s focus on using recycled materials and minimizing waste helps conserve natural resources and reduce the environmental impact of its operations.

- Reduced Greenhouse Gas Emissions: Erik’s Hose Technology’s commitment to energy efficiency and carbon footprint reduction contributes to mitigating climate change.

- Enhanced Product Durability: Erik’s Hose Technology’s focus on designing durable and long-lasting hoses reduces the need for frequent replacements, minimizing waste and environmental impact.

- Promoting Circular Economy: Erik’s Hose Technology’s recycling programs encourage the reuse and repurposing of its products, promoting a circular economy model.

Wrap-Up

Erik’s Hose Technology stands as a testament to innovation and ingenuity, constantly evolving to meet the ever-changing needs of industries worldwide. Their dedication to sustainability, safety, and cutting-edge solutions ensures that their hoses continue to play a vital role in fluid transfer applications for years to come. As we look toward the future, Erik’s Hose Technology is poised to remain a leading force, shaping the landscape of hose technology and driving progress in various sectors.

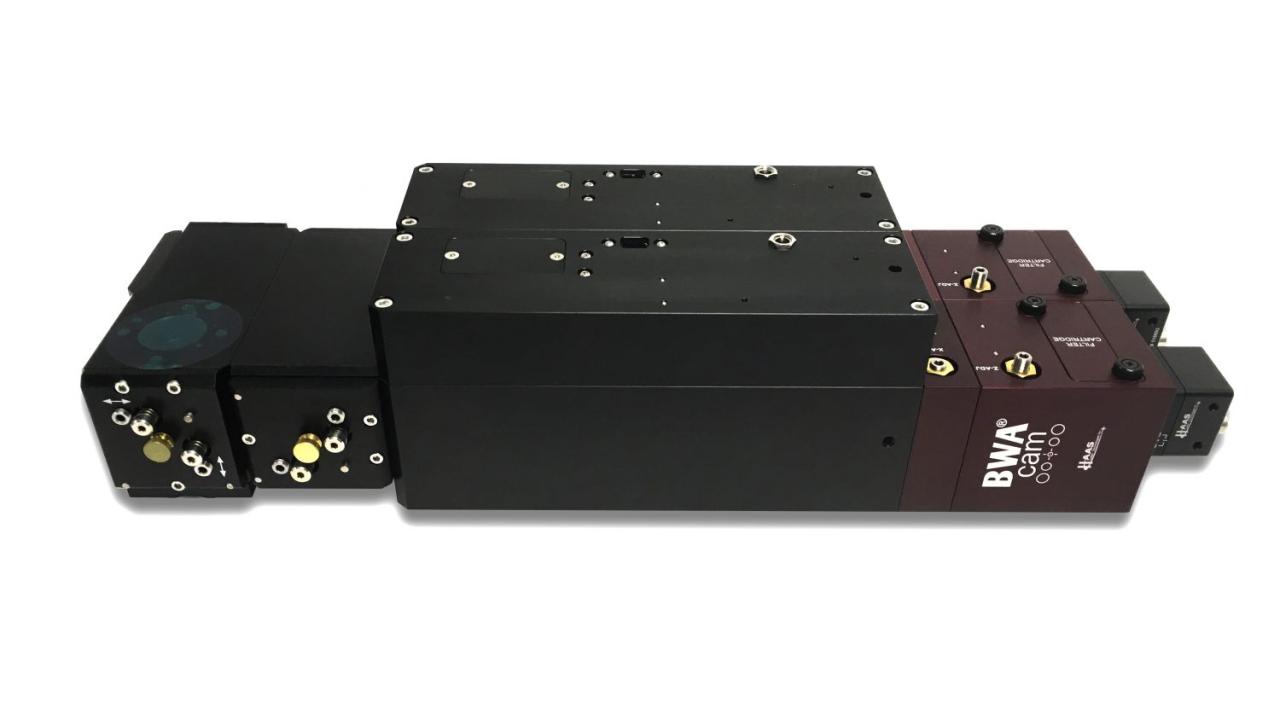

Erik’s Hose Technology has been a leader in the industry for decades, known for its innovative solutions and commitment to quality. They recently expanded their offerings to include advanced PCO technology , a cutting-edge system that provides precise control and efficiency for various applications.

This integration showcases Erik’s dedication to staying ahead of the curve and providing comprehensive solutions for a wide range of needs.