Electrostatic Technology: A Force Shaping Our World

Electrostatic technology sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset. Imagine a […]

Electrostatic technology sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset. Imagine a world where static electricity, often dismissed as a nuisance, becomes a powerful force driving innovation across industries. This is the realm of electrostatic technology, a fascinating field that harnesses the power of static charges to create groundbreaking solutions.

From the miniature world of electronics to the vast expanse of space exploration, electrostatic technology has permeated our lives in ways we might not even realize. Its principles, rooted in the fundamental laws of physics, have been meticulously studied and refined over centuries, leading to remarkable advancements in various fields.

Introduction to Electrostatic Technology

Electrostatic technology is a branch of physics and engineering that deals with the study and application of static electricity. It explores the behavior of electric charges at rest and the forces they exert on each other. The fundamental principle behind electrostatic technology is Coulomb’s Law, which states that the force between two stationary charged particles is directly proportional to the product of their charges and inversely proportional to the square of the distance between them.

Electrostatic technology has a rich history dating back to ancient civilizations. The Greeks observed static electricity by rubbing amber with fur, which attracted light objects. In the 17th century, William Gilbert conducted extensive research on magnetism and electricity, laying the foundation for modern electrostatics. The 18th century saw significant advancements with the invention of the Leyden jar, a device for storing static electricity, and Benjamin Franklin’s famous kite experiment, which demonstrated the electrical nature of lightning.

Key Applications of Electrostatic Technology

Electrostatic technology finds widespread applications across various industries. Its versatility stems from its ability to manipulate and control electric charges, leading to numerous practical applications.

Electrostatic technology plays a crucial role in various industries. Some of the key applications include:

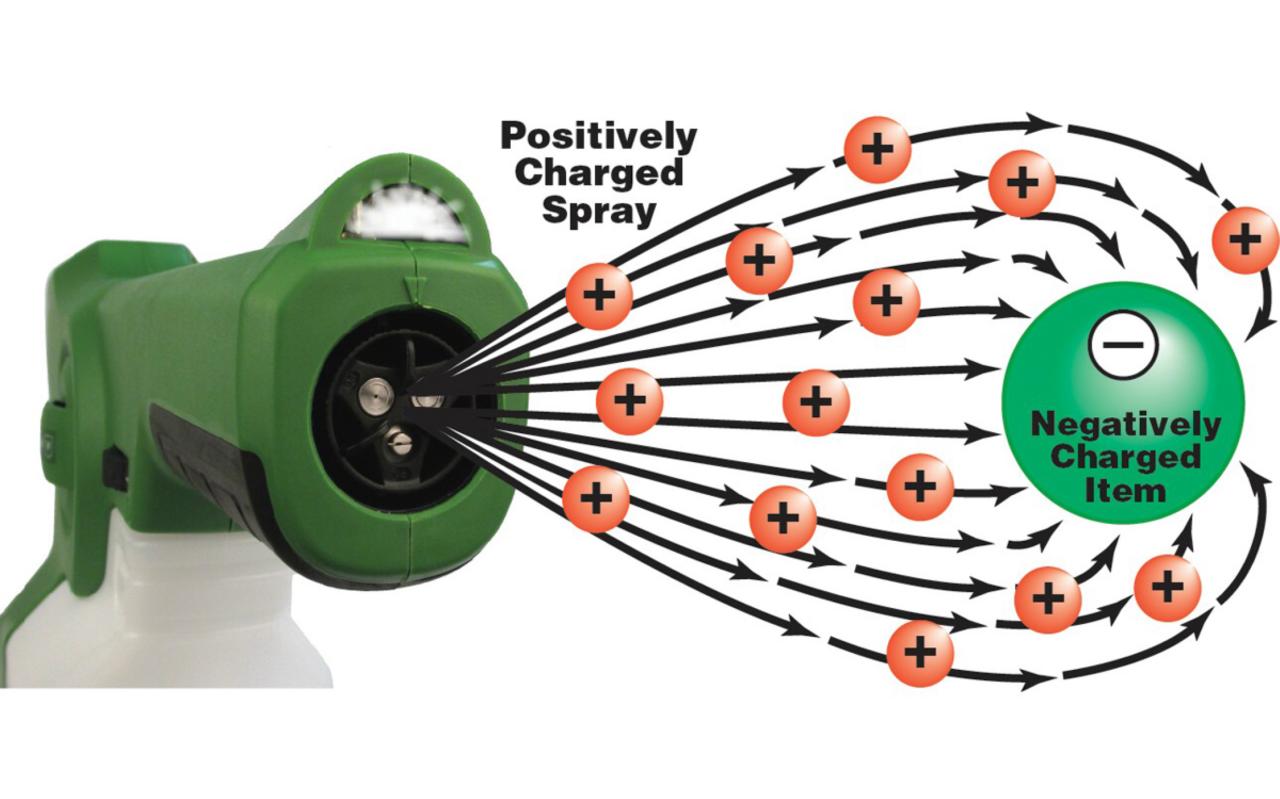

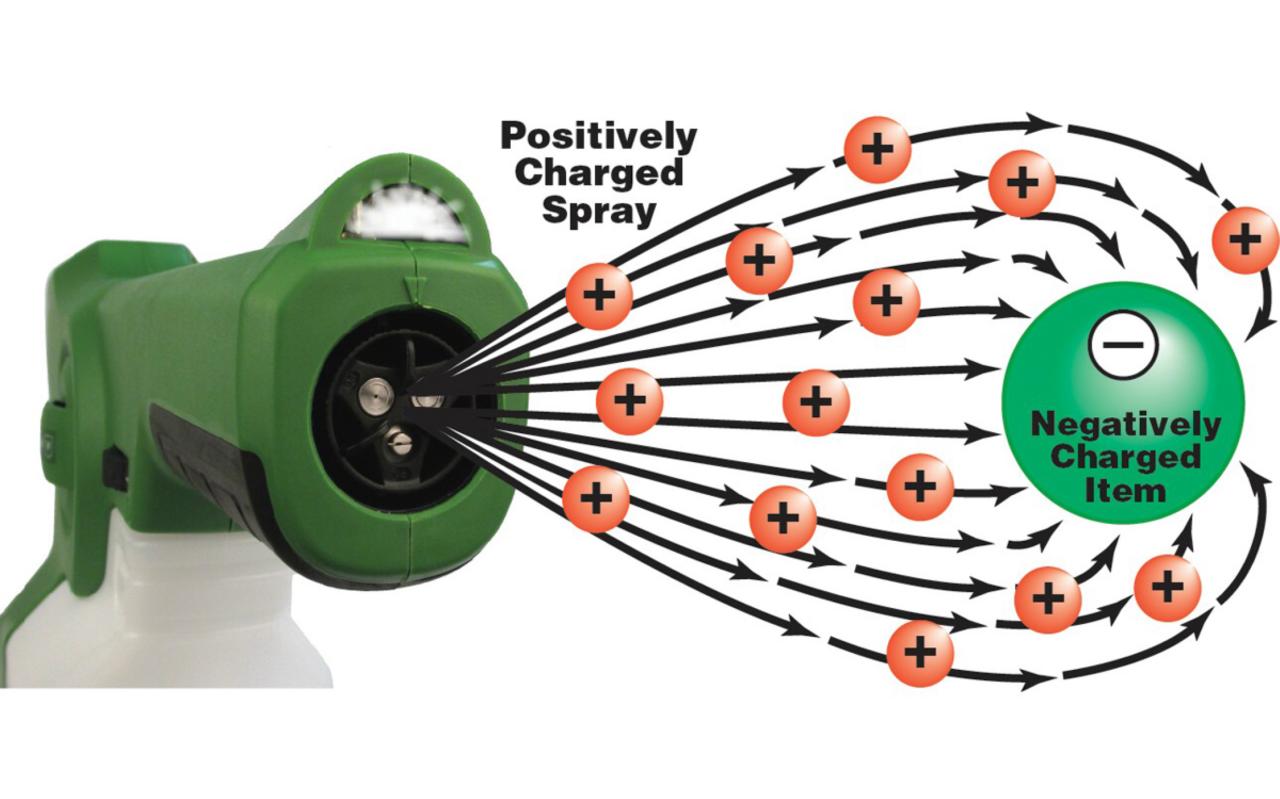

- Electrostatic Painting: Electrostatic painting utilizes the principle of electrostatic attraction to deposit paint evenly and efficiently onto objects. The paint particles are charged, and the object to be painted is grounded. This creates an electrostatic field that attracts the charged paint particles, resulting in a uniform coating.

- Electrostatic Precipitators: Electrostatic precipitators are widely used in industries like power generation and manufacturing to remove particulate matter from flue gases. The principle involves charging the dust particles and collecting them on grounded electrodes, effectively reducing air pollution.

- Xerography: Xerography, the technology behind photocopiers and laser printers, relies on electrostatic principles. The process involves charging a photoconductive drum with light, creating a latent image that is then developed using toner particles, which are attracted to the charged areas.

- Electrostatic Discharge (ESD) Protection: ESD protection is crucial in electronics manufacturing and handling sensitive electronic devices. Electrostatic discharge can damage sensitive components, and ESD protection measures, such as grounding mats and anti-static packaging, are employed to prevent such damage.

Principles of Electrostatics

Electrostatics is the study of stationary or slow-moving electric charges and their interactions. It’s a fundamental branch of physics that underpins various technologies, from everyday devices like photocopiers to advanced applications in microelectronics and medical imaging. Understanding the principles of electrostatics is crucial for comprehending the behavior of electric charges and their effects on matter.

Static Electricity and its Generation

Static electricity refers to the accumulation of electric charges on the surface of an object. This accumulation can occur when two materials are rubbed together, causing electrons to transfer from one material to the other. The material that gains electrons becomes negatively charged, while the material that loses electrons becomes positively charged.

Here are some common ways static electricity is generated:

- Friction: Rubbing two materials together, such as rubbing a balloon on your hair, can transfer electrons, creating static charges.

- Contact: When two objects with different charges come into contact, electrons can flow from one object to the other, resulting in a static charge on both objects.

- Induction: Bringing a charged object near a neutral object can cause a redistribution of charges within the neutral object, inducing a static charge.

Types of Electrostatic Charges and their Interactions

There are two types of electrostatic charges: positive and negative. Like charges repel each other, while opposite charges attract. This fundamental principle governs the interactions between charged objects.

- Positive Charge: An object with a positive charge has a deficiency of electrons.

- Negative Charge: An object with a negative charge has an excess of electrons.

Laws of Electrostatics

Electrostatic phenomena are governed by specific laws that describe the behavior of electric charges. These laws provide a framework for understanding and predicting electrostatic interactions.

Coulomb’s Law

Coulomb’s law quantifies the force between two point charges. It states that the force between two point charges is directly proportional to the product of the charges and inversely proportional to the square of the distance between them.

The force F between two point charges q1 and q2 separated by a distance r is given by:

F = k * (q1 * q2) / r2

where k is Coulomb’s constant.

Gauss’s Law

Gauss’s law relates the electric flux through a closed surface to the enclosed electric charge. It provides a powerful tool for calculating electric fields in various situations.

The electric flux Φ through a closed surface S is proportional to the enclosed electric charge Q:

Φ = Q / ε0

where ε0 is the permittivity of free space.

Electrostatic Phenomena

Electrostatic phenomena arise from the interactions of stationary electric charges. These phenomena are ubiquitous in our daily lives, influencing everything from the way we interact with technology to the behavior of dust particles in the air. Understanding these phenomena is crucial for various applications, from designing high-voltage equipment to controlling static electricity in manufacturing processes.

Electrostatic Induction

Electrostatic induction is the phenomenon where a charged object, without direct contact, influences the distribution of charges within a neutral object. This redistribution of charges occurs due to the electric field generated by the charged object. When a charged object is brought near a neutral object, the charges within the neutral object rearrange themselves to oppose the electric field of the charged object. This results in an accumulation of opposite charges on the surface of the neutral object facing the charged object.

Electrostatic induction has several real-world applications, including:

- Electrostatic Precipitators: These devices use electrostatic induction to remove dust and other particulate matter from industrial exhaust gases. They work by charging the particles and then collecting them on charged plates.

- Electrets: Electrets are materials that retain a permanent electric polarization, similar to permanent magnets. These materials are used in various applications, such as microphones, speakers, and air filters.

- Capacitors: Capacitors store electrical energy using electrostatic induction. When a voltage is applied across the capacitor plates, charges accumulate on the plates, creating an electric field between them.

Corona Discharge

Corona discharge is a phenomenon that occurs when a high electric field is applied to a conductor, causing ionization of the surrounding air molecules. This ionization results in a luminous glow around the conductor, accompanied by a hissing sound. The electric field strength required for corona discharge depends on the shape and size of the conductor, as well as the surrounding air pressure and humidity.

Corona discharge is a common occurrence in high-voltage equipment, such as power lines and transformers. It can cause energy loss, radio interference, and even damage to equipment. However, corona discharge also has some beneficial applications, such as:

- Ozone Generation: Corona discharge can be used to generate ozone, which is a powerful oxidizer used for water purification and air disinfection.

- Electrostatic Precipitation: Corona discharge can be used to charge dust particles in electrostatic precipitators, making them easier to collect.

- Laser Printing: Corona discharge is used in laser printers to charge the toner particles, allowing them to adhere to the paper.

Dielectric Breakdown

Dielectric breakdown is the phenomenon where a dielectric material, typically an insulator, loses its insulating properties and becomes conductive under a high electric field. This occurs when the electric field strength exceeds the dielectric strength of the material, causing electrons to be ripped from their atoms and creating a conductive path through the material.

Dielectric breakdown is a critical concern in electrical engineering, as it can lead to short circuits and equipment failure. However, it also has some beneficial applications, such as:

- High-Voltage Capacitors: Dielectric breakdown is used in high-voltage capacitors to create a thin layer of dielectric material between the capacitor plates, allowing for high energy storage.

- Lightning Protection: Lightning rods use dielectric breakdown to divert lightning strikes away from buildings and other structures.

- Gas Discharge Lamps: Dielectric breakdown is used in gas discharge lamps, such as neon lights and fluorescent lamps, to initiate the ionization of the gas within the lamp.

Factors Influencing Electrostatic Phenomena

The occurrence and intensity of electrostatic phenomena are influenced by several factors, including:

- Charge Magnitude: The amount of charge present on an object directly influences the strength of the electric field it generates, which in turn affects the electrostatic phenomena that occur.

- Distance: The distance between charged objects influences the strength of the electric field and the forces of attraction or repulsion between them.

- Material Properties: The properties of the materials involved, such as their conductivity, permittivity, and dielectric strength, play a significant role in determining the occurrence and intensity of electrostatic phenomena.

- Environmental Conditions: Factors like temperature, humidity, and air pressure can affect the occurrence and intensity of electrostatic phenomena, especially those involving ionization, such as corona discharge.

Electrostatic Devices and Components

Electrostatic devices utilize the principles of electrostatics to perform specific functions. These devices leverage the forces and interactions between static electric charges to achieve various applications, ranging from energy storage to air purification. Understanding the working principles of these devices is crucial for appreciating their role in diverse technological fields.

Capacitors

Capacitors are fundamental electrostatic devices that store electrical energy in an electric field. They consist of two conductive plates separated by a non-conductive material called a dielectric. The dielectric material’s ability to store electrical energy is quantified by its permittivity.

Here’s a table summarizing the key aspects of capacitors:

| Device Name | Working Principle | Applications |

|—|—|—|

| Capacitor | Stores electrical energy in an electric field created between two conductive plates separated by a dielectric material. | Energy storage in electronic circuits, filtering out unwanted frequencies in electrical signals, and timing circuits. |

The capacitance of a capacitor, denoted by ‘C’, is determined by the area of the plates (A), the distance between them (d), and the permittivity of the dielectric material (ε):

C = εA/d

When a voltage is applied across the capacitor’s plates, electric charges accumulate on the plates, creating an electric field within the dielectric. This stored electrical energy can be released later when needed.

Electrets

Electrets are materials that exhibit a persistent electric polarization, similar to permanent magnets. They retain their electric charge even after the external electric field is removed.

Here’s a table summarizing the key aspects of electrets:

| Device Name | Working Principle | Applications |

|—|—|—|

| Electret | Materials that exhibit a persistent electric polarization, retaining their electric charge even after the external electric field is removed. | Microphones, speakers, air filters, and sensors. |

Electrets are created by subjecting certain materials to a strong electric field during their manufacturing process. This field aligns the dipoles within the material, resulting in a permanent electric polarization.

Electrostatic Precipitators

Electrostatic precipitators are devices used to remove particulate matter from gas streams, primarily in industrial applications. They operate on the principle of electrostatic attraction.

Here’s a table summarizing the key aspects of electrostatic precipitators:

| Device Name | Working Principle | Applications |

|—|—|—|

| Electrostatic Precipitator | Removes particulate matter from gas streams by using an electric field to charge the particles and then collect them on grounded electrodes. | Industrial air pollution control, flue gas cleaning in power plants, and dust removal in various industries. |

Electrostatic precipitators use a high-voltage electrode to generate a strong electric field. As the gas stream containing particulate matter passes through this field, the particles become charged. These charged particles are then attracted to grounded collection plates, where they are collected.

Applications of Electrostatic Technology

Electrostatic technology finds widespread applications in various industries, impacting our daily lives in numerous ways. This section explores the diverse applications of electrostatics, highlighting its significance in shaping modern technologies and industries.

Electronics

Electrostatics plays a crucial role in the development and operation of electronic devices. The principles of electrostatics are fundamental to the design and functionality of various electronic components, including capacitors, transistors, and printed circuit boards.

Capacitors, essential components in electronic circuits, store electrical energy by accumulating charges on their plates separated by a dielectric material. The capacitance of a capacitor, a measure of its ability to store charge, is directly related to the electrostatic field between its plates. Electrostatic forces govern the movement of charge carriers in transistors, enabling amplification and switching operations. Transistors, the building blocks of modern electronics, rely on electrostatic fields to control the flow of current. Printed circuit boards (PCBs), the foundation of electronic devices, utilize electrostatic principles for component placement and soldering. Electrostatic discharge (ESD) protection measures are crucial in electronics manufacturing to prevent damage to sensitive components caused by static electricity.

Manufacturing

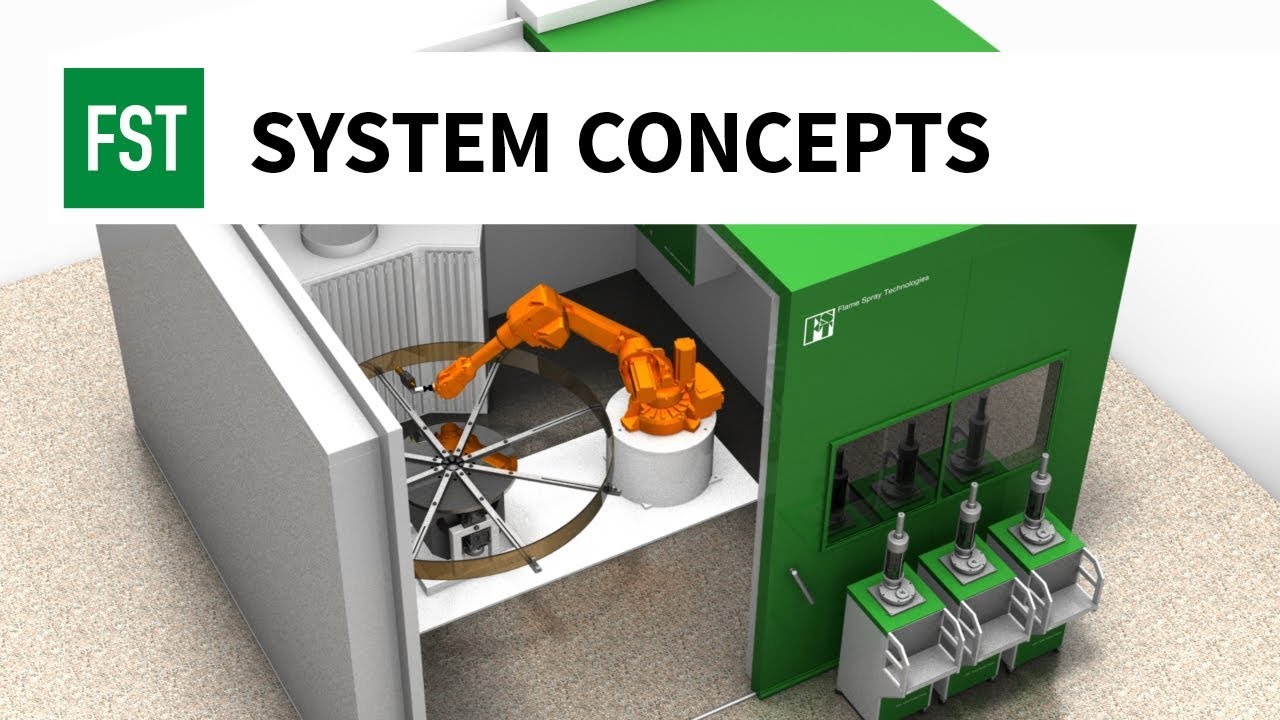

Electrostatic technology finds diverse applications in manufacturing processes, enhancing efficiency and product quality. Electrostatic painting, powder coating, and electrostatic separation are prime examples of how electrostatic principles are employed in various manufacturing industries.

Electrostatic painting utilizes the attraction between opposite charges to deposit paint onto a workpiece. The paint particles, charged with one polarity, are attracted to the workpiece with the opposite polarity, resulting in a uniform and efficient paint application. Powder coating, a similar process, utilizes charged powder particles instead of liquid paint, leading to a durable and environmentally friendly coating. Electrostatic separation is a technique used to separate materials based on their different electrostatic properties. In this process, materials with different electrical conductivities are charged differently, allowing for their separation based on their electrostatic attraction or repulsion.

Healthcare

Electrostatic technology has revolutionized healthcare by enabling advancements in medical imaging, drug delivery, and other critical areas.

Medical imaging techniques, such as X-ray imaging, rely on the interaction of electromagnetic radiation with the body’s tissues. Electrostatic forces play a role in the generation and detection of X-rays, allowing for the visualization of internal structures. Electrostatic forces are also utilized in drug delivery systems, where charged drug particles are targeted to specific cells or tissues, enhancing drug efficacy and reducing side effects.

Energy

Electrostatic technology holds immense potential in the energy sector, contributing to both energy harvesting and air purification.

Electrostatic energy harvesting utilizes the principles of electrostatics to convert mechanical energy into electrical energy. This technology involves the use of triboelectric materials that generate static electricity when subjected to mechanical vibrations or friction. Electrostatic air cleaners utilize electrostatic fields to remove dust, pollen, and other airborne particles from the air. These devices use charged plates to attract and capture airborne pollutants, improving air quality and reducing health risks.

Advantages and Disadvantages of Electrostatic Technology

Electrostatic technology, with its unique ability to manipulate charges, offers a wide range of applications. While it presents a promising future, it also comes with its own set of advantages and disadvantages that must be carefully considered.

Advantages of Electrostatic Technology

Electrostatic technology presents several advantages that make it a valuable tool in various fields.

- High Efficiency: Electrostatic processes often operate with high efficiency, minimizing energy losses. This is particularly true in applications like electrostatic painting and powder coating, where the charged particles directly adhere to the target surface, reducing material waste.

- Low Energy Consumption: Electrostatic processes typically require relatively low energy consumption compared to other technologies. This is attributed to the use of static electric fields, which do not involve significant heat generation or mechanical forces.

- Precision: Electrostatic technology allows for precise control over the movement and deposition of charged particles. This precision is particularly valuable in applications like microelectronics fabrication, where the accurate placement of materials is crucial.

- Versatility: Electrostatic technology finds applications in diverse fields, ranging from manufacturing and healthcare to environmental monitoring and energy generation. This versatility makes it a valuable tool for addressing various challenges.

Disadvantages of Electrostatic Technology

While electrostatic technology offers several advantages, it also has some drawbacks that need to be considered.

- Safety Concerns: Electrostatic discharges can be hazardous, especially in environments with flammable materials or sensitive electronic equipment. This necessitates careful design and implementation of electrostatic safety measures.

- Potential for Damage: High electrostatic fields can damage sensitive materials or components. This is particularly relevant in applications involving delicate electronic devices or biological samples.

- Limitations in Certain Applications: Electrostatic technology may not be suitable for all applications. For instance, in environments with high humidity or conductivity, the effectiveness of electrostatic processes can be significantly reduced.

- Complexity: Implementing and maintaining electrostatic systems can be complex, requiring specialized knowledge and equipment. This can increase the overall cost and time involved in utilizing electrostatic technology.

Comparison with Other Technologies

Electrostatic technology can be compared to other related technologies, such as electromagnetic technology, based on their advantages and disadvantages.

- Electromagnetic Technology: While electromagnetic technology offers greater power and versatility, it often involves higher energy consumption and can be more complex to implement. Electrostatic technology, on the other hand, offers advantages in terms of energy efficiency and precision, making it suitable for specific applications where these factors are critical.

Future Trends in Electrostatic Technology

Electrostatic technology is rapidly evolving, driven by advancements in materials science, nanotechnology, and microelectronics. The potential applications of electrostatic technology extend far beyond traditional uses in industries like printing and painting, reaching into cutting-edge fields like nanotechnology, robotics, and space exploration.

Electrostatic Applications in Nanotechnology

Electrostatic forces play a crucial role in manipulating and assembling nanoscale materials. The ability to control and direct the movement of charged particles at the nanoscale opens up possibilities for creating novel materials with unique properties.

- Electrostatic self-assembly: This technique uses electrostatic interactions to assemble nanoscale building blocks into complex structures. By precisely controlling the charges of individual nanoparticles, researchers can create ordered arrays, films, and even three-dimensional structures with tailored properties. This has applications in areas like electronics, energy storage, and biomedicine.

- Electrospinning: This process uses electrostatic forces to generate fibers with diameters ranging from nanometers to micrometers. The high surface area and unique properties of electrospun fibers make them ideal for applications in filtration, tissue engineering, and energy harvesting.

- Electrostatic manipulation of nanoparticles: Electrostatic fields can be used to manipulate and control the movement of nanoparticles. This capability is essential for developing nanoscale devices, such as sensors, actuators, and drug delivery systems.

Electrostatic Applications in Robotics

Electrostatic forces offer a unique approach to robotic manipulation and actuation. Their ability to operate in contact-free and non-invasive ways provides advantages in delicate tasks and environments where conventional mechanical methods are limited.

- Electrostatic grippers: These grippers utilize electrostatic forces to grasp and manipulate objects without physical contact. This allows for handling delicate objects, such as biological samples or electronic components, without causing damage.

- Electrostatic actuators: These actuators use electrostatic forces to generate motion. They are compact, lightweight, and have high force-to-weight ratios, making them suitable for applications in micro-robotics and micro-actuation.

- Electrostatic levitation: This technique uses electrostatic forces to levitate objects, eliminating friction and enabling frictionless motion. This has applications in robotics for precision positioning and manipulation.

Electrostatic Applications in Space Exploration

Electrostatic technology has significant potential in space exploration, particularly in areas like propulsion, material processing, and dust mitigation.

- Electrostatic propulsion: This technology uses electrostatic forces to accelerate charged particles, creating thrust for spacecraft. Electrostatic propulsion systems offer high efficiency and specific impulse, making them ideal for long-duration missions and deep-space exploration.

- Electrostatic dust mitigation: In the harsh environment of space, dust can pose a significant threat to spacecraft. Electrostatic dust mitigation systems use electric fields to neutralize or deflect dust particles, protecting spacecraft from damage and ensuring mission success.

- Electrostatic material processing: Electrostatic fields can be used to process materials in space, such as for creating advanced alloys, composites, and coatings. The microgravity environment of space enhances the effectiveness of electrostatic processing techniques.

Challenges and Opportunities in Electrostatic Technology

Despite the vast potential of electrostatic technology, several challenges need to be addressed to fully realize its applications.

- Scaling up: Scaling up electrostatic devices and processes for industrial applications can be challenging due to the limitations of current materials and fabrication techniques.

- Power consumption: Electrostatic devices can require significant power, limiting their use in certain applications. Research is ongoing to develop more energy-efficient electrostatic systems.

- Environmental considerations: Electrostatic fields can interact with surrounding environments, potentially causing interference or damage. Careful design and implementation are crucial to minimize environmental impact.

Emerging Trends in Electrostatic Technology

The field of electrostatic technology is constantly evolving, with new advancements emerging regularly.

- Dielectric elastomers: These materials exhibit significant deformation under an electric field, making them ideal for applications in actuators, sensors, and artificial muscles. The development of new dielectric elastomer materials with improved properties is an active area of research.

- Electrostatic charging of surfaces: The ability to control the surface charge of materials has wide-ranging applications in areas like adhesion, friction, and biocompatibility. New techniques for electrostatic charging are being developed to enhance the performance of various materials.

- Integration with other technologies: Electrostatic technology is increasingly being integrated with other technologies, such as microelectronics, nanotechnology, and photonics, to create hybrid systems with enhanced functionality.

Safety Considerations: Electrostatic Technology

Working with electrostatic equipment requires strict adherence to safety protocols to prevent potential hazards. Electrostatic discharges can cause significant damage to equipment, materials, and even personnel, making it crucial to understand and implement proper safety measures.

Potential Hazards of Electrostatic Discharges, Electrostatic technology

Electrostatic discharges (ESD) can pose several hazards, including:

- Equipment Damage: ESD can damage sensitive electronic components, leading to malfunctions or complete failure. The discharge’s high voltage and current can cause short circuits, component burn-out, and data corruption.

- Material Damage: ESD can also damage non-electronic materials, such as plastics and fabrics. The discharge can cause static cling, surface degradation, and even fire hazards.

- Personnel Safety: ESD can be a safety hazard for personnel, particularly in environments with flammable materials or high-voltage equipment. The discharge can cause burns, electric shock, and even ignite flammable materials.

Mitigating Electrostatic Discharges

To minimize the risk of ESD, several mitigation techniques can be implemented:

- Grounding: Grounding is a fundamental safety practice in electrostatics. It involves providing a path for static charges to flow to the earth, preventing the build-up of potentially harmful voltages.

- Anti-Static Materials: Using anti-static materials, such as conductive flooring, work surfaces, and packaging, can help dissipate static charges and reduce the risk of ESD.

- Ionization: Ionization is a process that introduces ions into the air, neutralizing static charges. Ionizers are often used in sensitive environments to create a static-free zone.

- ESD-Protective Clothing: ESD-protective clothing, such as wrist straps and smocks, helps dissipate static charges from the body, reducing the risk of ESD events.

Safe Handling, Storage, and Disposal of Electrostatic Devices

Proper handling, storage, and disposal of electrostatic devices are essential to ensure safety:

- Handling: Always use ESD-protective tools and wear ESD-protective clothing when handling sensitive components. Avoid touching components with bare hands, and handle them gently to prevent damage.

- Storage: Store electrostatic devices in ESD-protective containers or bags to prevent static build-up. Ensure the storage area is free from static-generating materials and is properly grounded.

- Disposal: Dispose of electrostatic devices properly according to local regulations. Ensure the devices are properly deactivated before disposal to prevent accidental ESD events.

Examples of ESD Safety Practices in Real-World Applications

- Electronics Manufacturing: In electronics manufacturing facilities, ESD-protective mats, work surfaces, and clothing are mandatory for workers handling sensitive components. Ionizers are also commonly used to neutralize static charges in the air.

- Hospital Operating Rooms: Operating rooms are susceptible to ESD due to the presence of flammable materials like oxygen and anesthetic gases. ESD-protective measures, such as grounded equipment and anti-static flooring, are crucial to prevent fires and explosions.

- Aircraft Maintenance: Aircraft maintenance involves handling sensitive electronic systems. ESD-protective measures are implemented to prevent damage to avionics equipment and ensure safe operation.

Epilogue

As we delve deeper into the world of electrostatic technology, it becomes clear that its potential is far from exhausted. The future holds exciting possibilities for this versatile field, with advancements in nanotechnology, robotics, and space exploration poised to further revolutionize its applications. From the meticulous design of capacitors to the intricate workings of electrostatic precipitators, the journey through this fascinating field reveals a tapestry of innovation, revealing how static electricity has become a driving force in shaping our world.

Electrostatic technology, with its focus on manipulating charges, has found its way into a variety of applications, including the fascinating world of videocomm technologies. This is particularly evident in touchscreens, where electrostatic fields play a crucial role in detecting finger input.

The same principles are also applied in electrostatic speakers, offering a unique and efficient way to generate sound.