Electro Mechanical Technology Course: A Comprehensive Guide

Electro Mechanical Technology Course delves into the fascinating world where electricity and mechanics converge, forming the backbone of modern technology. This course explores the fundamental principles, applications, and emerging trends […]

Electro Mechanical Technology Course delves into the fascinating world where electricity and mechanics converge, forming the backbone of modern technology. This course explores the fundamental principles, applications, and emerging trends in this dynamic field, providing a solid foundation for understanding how electrical and mechanical systems work together to power our world.

From the intricate workings of motors and generators to the sophisticated design of robotic systems, this course covers a wide range of topics. You’ll gain insights into the historical evolution of electromechanical technology, learn about the key components that make up these systems, and explore the diverse applications that shape various industries.

Introduction to Electromechanical Technology

Electromechanical technology is a fascinating field that blends the principles of electrical engineering and mechanical engineering to design, develop, and operate systems that utilize both electrical and mechanical components. These systems are crucial to our modern world, powering everything from simple household appliances to complex industrial machinery.

Electromechanical systems are found in a wide range of industries, including:

* Automotive: Electric vehicles, hybrid cars, and advanced driver-assistance systems (ADAS) rely heavily on electromechanical technology.

* Aerospace: Aircraft control systems, landing gear, and flight control systems utilize electromechanical components.

* Manufacturing: Industrial robots, automated assembly lines, and CNC machines all employ electromechanical technology.

* Energy: Wind turbines, solar power systems, and electric grids utilize electromechanical components for energy generation and distribution.

* Healthcare: Medical imaging equipment, surgical robots, and prosthetic devices rely on electromechanical technology.

Historical Development of Electromechanical Systems

The development of electromechanical systems can be traced back to the 19th century with the invention of the electric motor. The electric motor revolutionized industries by providing a new source of power that was more efficient and reliable than steam engines. The invention of the telegraph and telephone further fueled the development of electromechanical systems.

The 20th century saw significant advancements in electromechanical technology, with the development of:

* Electronics: The invention of the transistor and integrated circuits led to the miniaturization of electromechanical systems.

* Computerization: The rise of computers enabled the automation of complex electromechanical processes.

* Robotics: The development of robots revolutionized manufacturing and other industries.

Common Electromechanical Devices and Applications

Electromechanical devices are everywhere in our daily lives. Here are some common examples:

* Electric Motors: Electric motors convert electrical energy into mechanical energy, powering a wide range of devices, including fans, pumps, compressors, and power tools.

* Generators: Generators convert mechanical energy into electrical energy, powering homes, businesses, and industries.

* Sensors: Sensors are devices that detect physical quantities, such as temperature, pressure, and light, and convert them into electrical signals. They are used in a wide range of applications, including automotive systems, industrial control, and medical devices.

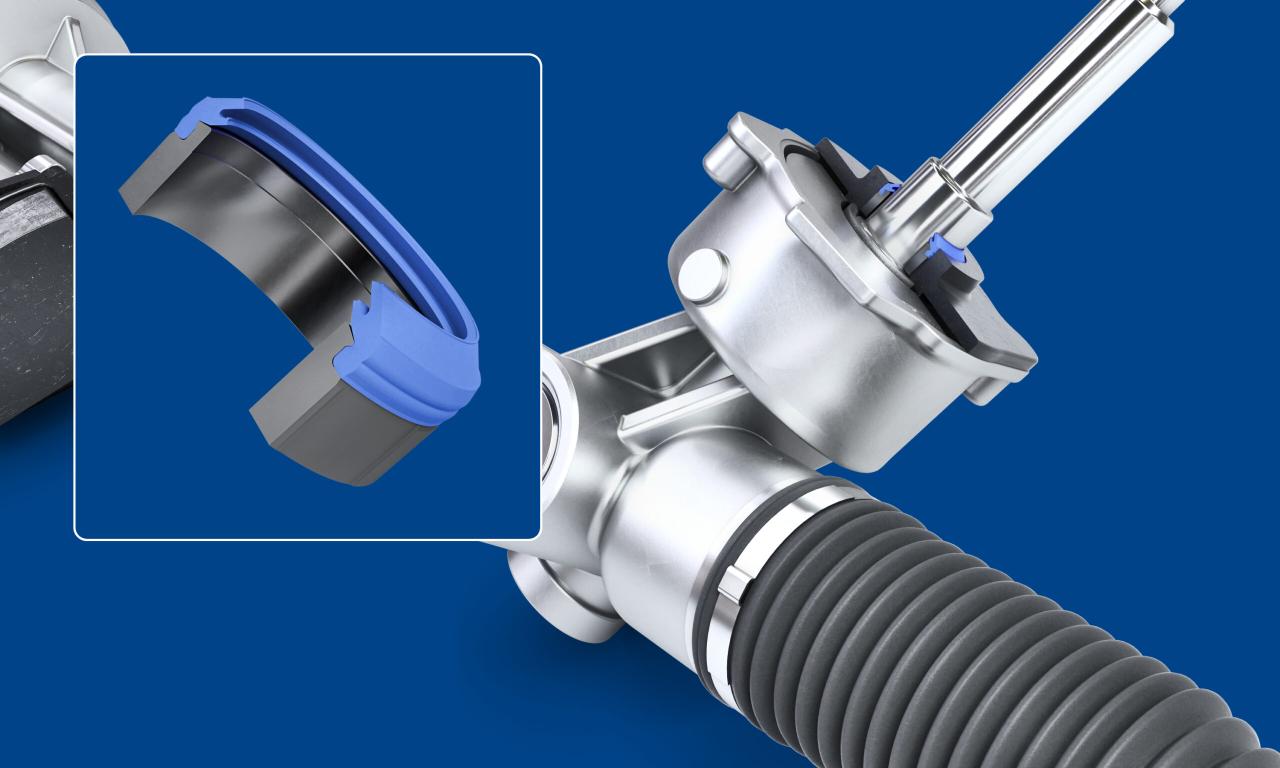

* Actuators: Actuators are devices that convert electrical signals into mechanical motion, controlling valves, doors, and other mechanical systems.

* Relays: Relays are electromechanical switches that use an electrical signal to control a larger electrical circuit. They are commonly used in automotive systems, industrial control, and telecommunications.

* Solenoids: Solenoids are electromagnetic devices that convert electrical energy into linear motion, used in a wide range of applications, including door locks, automotive systems, and industrial control.

* Transformers: Transformers are devices that transfer electrical energy between circuits with different voltages. They are essential for power distribution systems and other applications.

* Circuit Breakers: Circuit breakers are safety devices that protect electrical circuits from overloads and short circuits. They are used in homes, businesses, and industrial settings.

Fundamental Concepts

Electromechanical technology is a fascinating field that combines principles from both electrical and mechanical engineering. Understanding the fundamental concepts of electricity, magnetism, and mechanics is essential for comprehending how electromechanical systems function.

Electricity

The flow of electrons through a conductor constitutes an electric current. This flow is driven by an electromotive force (EMF), often provided by a battery or generator. The relationship between voltage, current, and resistance is described by Ohm’s law:

Voltage (V) = Current (I) x Resistance (R)

.

Voltage represents the electrical potential difference between two points, current is the rate of electron flow, and resistance opposes the flow of current.

Magnetism

Magnetism is a fundamental force that arises from the movement of electric charges. Moving electric charges generate magnetic fields, which can exert forces on other magnetic materials. The strength of a magnetic field is measured in Tesla (T).

- The interaction between electric currents and magnetic fields is described by Faraday’s law of electromagnetic induction, which states that a changing magnetic field induces an electromotive force (EMF) in a conductor.

- This principle is crucial for the operation of electric motors and generators, as it allows for the conversion of electrical energy into mechanical energy and vice versa.

Mechanics

Mechanics deals with the motion of objects and the forces that cause them to move. The basic concepts of mechanics include force, mass, acceleration, and momentum.

- Newton’s laws of motion govern the relationship between force, mass, and acceleration. The first law states that an object at rest will remain at rest, and an object in motion will remain in motion at a constant velocity unless acted upon by an external force.

- The second law states that the acceleration of an object is directly proportional to the net force acting on it and inversely proportional to its mass.

- The third law states that for every action, there is an equal and opposite reaction.

Relationship Between Electrical and Mechanical Energy

Electromechanical systems are designed to convert energy between electrical and mechanical forms.

- Motors convert electrical energy into mechanical energy, using the interaction between magnetic fields and electric currents to produce rotational motion.

- Generators, conversely, convert mechanical energy into electrical energy, using the principle of electromagnetic induction to generate an EMF.

Basic Components of Electromechanical Systems, Electro mechanical technology course

Electromechanical systems are comprised of various components that work together to perform a specific function.

- Motors: Motors are the heart of many electromechanical systems, converting electrical energy into rotational motion. They are classified based on their operating principles, such as DC motors, AC motors, and stepper motors.

- Generators: Generators convert mechanical energy into electrical energy. They are used in power plants to generate electricity and in vehicles to charge batteries.

- Sensors: Sensors are devices that detect physical parameters such as temperature, pressure, position, and velocity. They convert these parameters into electrical signals that can be processed by control systems.

- Actuators: Actuators are devices that convert electrical signals into mechanical motion. They are used to control the position, velocity, and force of mechanical systems.

Types of Electromechanical Systems

Electromechanical systems are ubiquitous in modern society, playing a crucial role in various industries and aspects of our daily lives. They combine the principles of electrical and mechanical engineering to create devices and systems that perform a wide range of functions. Understanding the different types of electromechanical systems and their working principles is essential for comprehending their applications and potential impact.

Classification of Electromechanical Systems

Electromechanical systems can be classified based on their functionality and applications. This classification helps to understand the diverse range of systems that exist and their specific roles in different industries.

- Servo Systems: Servo systems are closed-loop control systems that use feedback to precisely control the position, velocity, or acceleration of a mechanical component. They are widely used in applications requiring precise motion control, such as robotics, automation, and machine tools.

- Robotic Systems: Robotic systems are electromechanical systems that are capable of performing tasks autonomously or semi-autonomously. They typically consist of a manipulator arm, sensors, actuators, and a control system. Robotics find applications in manufacturing, healthcare, exploration, and many other fields.

- Control Systems: Control systems are designed to regulate and manage the behavior of other systems. They use sensors to monitor system variables and actuators to adjust system parameters. Control systems are found in a wide range of applications, including process control, transportation, and energy management.

- Actuators: Actuators are devices that convert electrical energy into mechanical motion. They are used in electromechanical systems to perform tasks such as linear or rotational movement, gripping, and clamping. Common types of actuators include electric motors, solenoids, and pneumatic cylinders.

- Sensors: Sensors are devices that measure physical quantities and convert them into electrical signals. They provide feedback to control systems, allowing them to monitor system variables and make adjustments. Common types of sensors include position sensors, speed sensors, and force sensors.

Working Principles of Electromechanical Systems

Each type of electromechanical system operates based on specific principles that govern its functionality. Understanding these principles is crucial for designing, analyzing, and troubleshooting electromechanical systems.

Servo Systems

Servo systems are closed-loop control systems that use feedback to achieve precise motion control. They consist of a motor, a sensor, a controller, and a feedback loop. The sensor measures the actual position or velocity of the motor shaft, and the controller compares this information to the desired setpoint. The difference between the actual and desired values is used to generate an error signal, which is fed back to the motor to adjust its output. This continuous feedback loop ensures that the motor maintains the desired position or velocity with high accuracy.

Servo systems are essential for applications requiring precise motion control, such as robotics, automation, and machine tools.

Robotic Systems

Robotic systems are electromechanical systems that combine sensors, actuators, and control systems to perform tasks autonomously or semi-autonomously. The manipulator arm, typically consisting of multiple joints, is driven by actuators, which are controlled by a central control system. Sensors provide information about the robot’s environment and its own position and orientation. This information is processed by the control system to generate commands for the actuators, enabling the robot to move and interact with its environment.

Robotic systems are revolutionizing various industries, from manufacturing and healthcare to exploration and logistics.

Control Systems

Control systems are designed to regulate and manage the behavior of other systems. They use sensors to monitor system variables and actuators to adjust system parameters. Control systems can be classified as open-loop or closed-loop. Open-loop systems do not use feedback, while closed-loop systems use feedback to adjust their output based on the system’s current state.

Control systems are crucial for maintaining stability, efficiency, and safety in a wide range of applications, including process control, transportation, and energy management.

Design and Analysis of Electromechanical Systems

Designing and analyzing electromechanical systems involves a systematic approach to create and optimize systems that effectively integrate electrical and mechanical components. This process encompasses understanding the requirements, selecting suitable components, performing simulations, and evaluating the system’s performance.

Computer-Aided Design (CAD) and Simulation Tools

Computer-aided design (CAD) and simulation tools play a crucial role in the design and analysis of electromechanical systems. These tools enable engineers to create virtual prototypes, test different design configurations, and analyze system performance before physical implementation.

CAD software allows engineers to create detailed 3D models of electromechanical systems, including components, assemblies, and wiring diagrams. This enables visualization and evaluation of the system’s geometry, clearances, and accessibility.

Simulation tools, such as finite element analysis (FEA) and circuit simulation software, help analyze the system’s behavior under various operating conditions. FEA can be used to predict stress distribution, deformation, and thermal behavior. Circuit simulation tools can be used to analyze electrical circuits, predict performance characteristics, and identify potential problems.

Design Considerations

Several design considerations are crucial in optimizing electromechanical systems. These considerations include:

- Efficiency: Electromechanical systems should be designed to minimize energy loss and maximize efficiency. This involves selecting components with low resistance, minimizing friction, and optimizing system control. For example, using high-efficiency motors and reducing mechanical friction can significantly improve system efficiency.

- Reliability: The reliability of an electromechanical system refers to its ability to function consistently over time. This requires selecting robust components, implementing redundancy where necessary, and performing regular maintenance. For example, using components with a proven track record of reliability and incorporating redundant sensors or actuators can enhance system reliability.

- Safety: Safety is paramount in the design of electromechanical systems. This involves implementing measures to prevent hazards such as electrical shocks, mechanical injuries, and fire. This includes using appropriate safety devices, implementing fail-safe mechanisms, and adhering to safety standards. For example, incorporating overload protection circuits, implementing emergency stop buttons, and using safety guards can mitigate potential hazards.

Applications of Electromechanical Technology: Electro Mechanical Technology Course

Electromechanical technology finds widespread applications across various industries, revolutionizing the way we live, work, and interact with the world around us. From the mundane to the extraordinary, electromechanical systems power our daily lives, driving innovation and shaping the future.

Manufacturing

Electromechanical systems are indispensable in manufacturing, playing a crucial role in automating production processes, enhancing efficiency, and improving product quality.

- Robotics: Robots equipped with electromechanical actuators and sensors are extensively used in manufacturing for tasks like assembly, welding, painting, and material handling. They offer increased precision, speed, and consistency compared to manual labor. For instance, in automotive manufacturing, robots are employed for tasks such as welding car bodies, painting vehicles, and assembling engines.

- Computer Numerical Control (CNC) Machines: CNC machines, controlled by computer programs, utilize electromechanical systems to perform precise cutting, drilling, and milling operations. These machines are essential for producing components with high accuracy and repeatability, widely used in industries like aerospace, automotive, and electronics.

- Automated Guided Vehicles (AGVs): AGVs are self-guided vehicles that navigate through factories and warehouses, transporting materials and goods without human intervention. They employ electromechanical systems for navigation, guidance, and load handling, enhancing efficiency and reducing labor costs.

Transportation

Electromechanical technology is transforming the transportation sector, leading to the development of cleaner, more efficient, and safer vehicles.

- Electric Vehicles (EVs): EVs utilize electric motors and batteries, powered by electricity, to propel the vehicle. Electromechanical systems control the motor speed, braking, and other vehicle functions. EVs offer reduced emissions, lower operating costs, and improved performance compared to traditional gasoline-powered vehicles.

- Hybrid Electric Vehicles (HEVs): HEVs combine a gasoline engine with an electric motor, offering fuel efficiency and reduced emissions. The electromechanical system manages the power flow between the engine and the motor, optimizing fuel consumption and performance.

- Autonomous Vehicles: Autonomous vehicles, or self-driving cars, rely heavily on electromechanical systems for navigation, perception, and control. Sensors, actuators, and control algorithms work together to enable the vehicle to perceive its surroundings, make decisions, and navigate safely without human intervention.

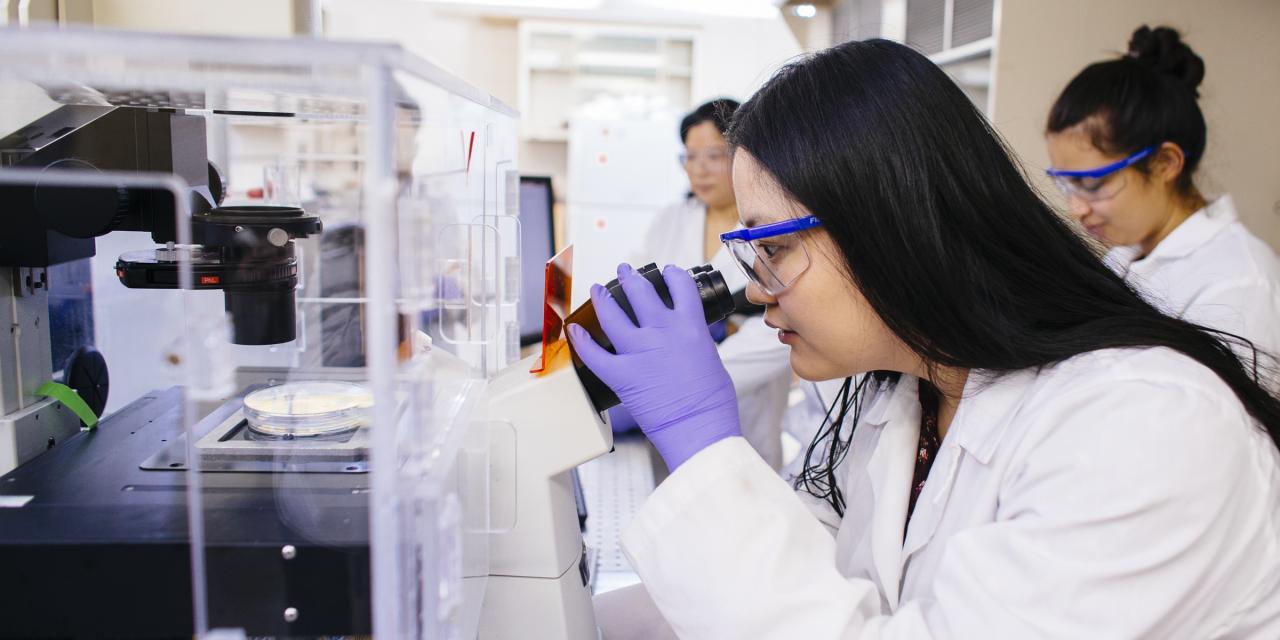

Healthcare

Electromechanical technology plays a vital role in healthcare, improving diagnosis, treatment, and patient care.

- Medical Imaging: Medical imaging technologies, such as X-ray, MRI, and CT scans, utilize electromechanical systems to generate and analyze images of the human body. These technologies aid in diagnosing diseases, monitoring patient conditions, and guiding surgical procedures.

- Surgical Robots: Surgical robots, equipped with electromechanical actuators and sensors, assist surgeons in performing complex procedures with greater precision and minimally invasive techniques. They provide surgeons with a magnified view of the surgical field and allow for more precise movements, leading to faster recovery times and reduced complications.

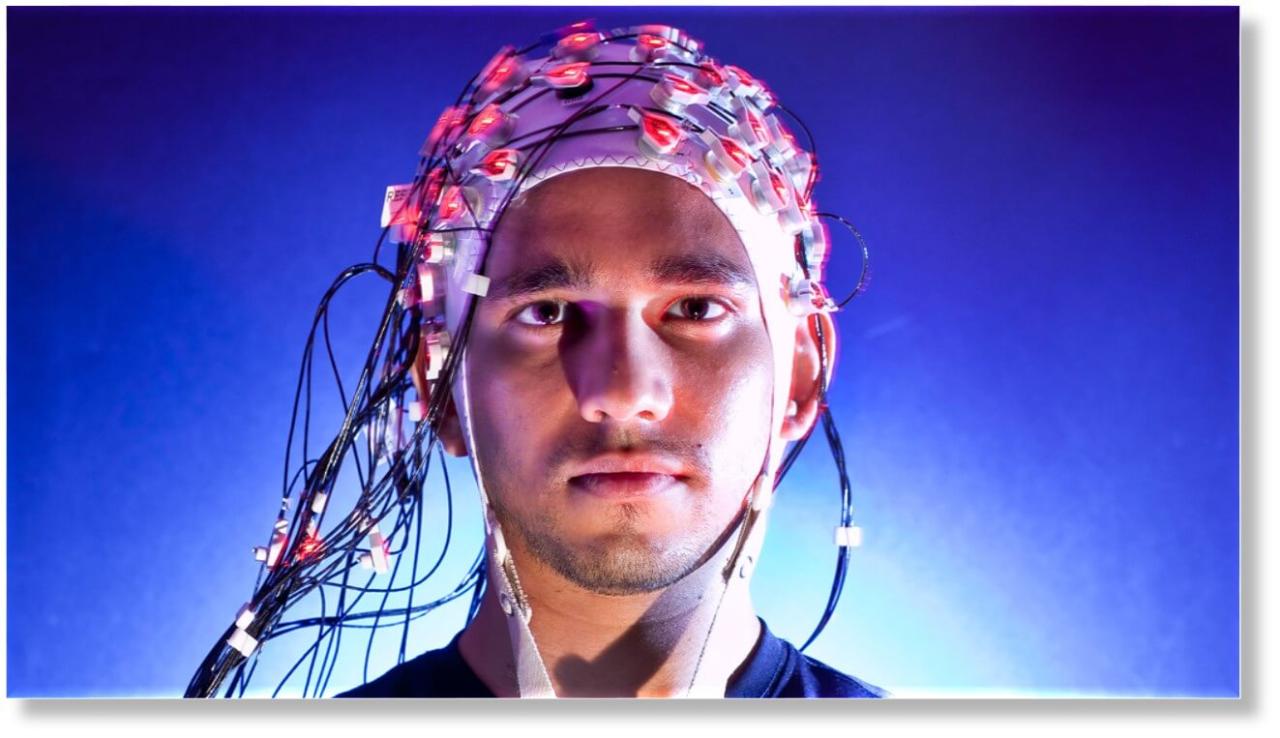

- Prosthetics and Orthotics: Electromechanical systems are used to develop advanced prosthetics and orthotics, providing individuals with disabilities with improved mobility and functionality. These devices use sensors to detect muscle signals and translate them into movements, enabling users to control their prosthetic limbs or orthotic devices.

Energy

Electromechanical technology is crucial in the energy sector, enabling efficient generation, transmission, and distribution of power.

- Power Generation: Electromechanical systems are used in power generation plants to convert mechanical energy into electrical energy. Wind turbines, hydroelectric generators, and fossil fuel power plants all rely on electromechanical systems to produce electricity.

- Power Transmission and Distribution: Electromechanical systems are used in power grids to transmit electricity from generation plants to consumers. Transformers, circuit breakers, and other electromechanical components ensure the efficient and reliable delivery of power.

- Smart Grids: Smart grids utilize electromechanical systems and communication technologies to optimize energy distribution, improve grid reliability, and integrate renewable energy sources. They allow for real-time monitoring and control of energy flow, enhancing grid efficiency and reducing energy waste.

Career Opportunities in Electromechanical Technology

Electromechanical technology is a rapidly growing field, offering diverse and rewarding career paths for individuals with a passion for combining electrical and mechanical principles. With the increasing demand for automation, robotics, and advanced manufacturing, electromechanical professionals are highly sought after across various industries.

Types of Electromechanical Engineering Roles

The skills and qualifications required for different electromechanical engineering roles vary depending on the specific specialization and industry. However, some common roles include:

- Electromechanical Engineer: These professionals design, develop, and test electromechanical systems, ensuring they meet performance requirements and safety standards. They are involved in the entire product lifecycle, from concept to implementation.

- Robotics Engineer: With the increasing adoption of robotics in manufacturing, healthcare, and other sectors, robotics engineers play a crucial role in designing, programming, and maintaining robotic systems.

- Mechatronics Engineer: Mechatronics engineers specialize in integrating mechanical, electrical, and computer systems to create complex and automated solutions. They often work on projects involving sensors, actuators, and control systems.

- Automation Engineer: Automation engineers design and implement automated systems to improve efficiency and productivity in various industries. They are responsible for integrating hardware and software components to create seamless automated processes.

- Control Systems Engineer: Control systems engineers focus on designing and implementing control systems for electromechanical systems. They ensure that systems operate efficiently, accurately, and safely.

Industries and Organizations that Hire Electromechanical Professionals

Electromechanical professionals are in high demand across various industries, including:

- Manufacturing: Automotive, aerospace, consumer electronics, and industrial equipment manufacturers heavily rely on electromechanical engineers for designing and implementing production processes and equipment.

- Robotics and Automation: Companies specializing in robotics and automation technologies require electromechanical engineers to develop and maintain robotic systems, automated guided vehicles (AGVs), and other automated equipment.

- Energy and Utilities: Electromechanical engineers are crucial in designing and maintaining power generation and distribution systems, including wind turbines, solar panels, and power grids.

- Healthcare: Medical device manufacturers and hospitals need electromechanical engineers to develop and maintain medical equipment, such as imaging systems, surgical robots, and diagnostic tools.

- Research and Development: Universities, research institutions, and government agencies hire electromechanical professionals to conduct research, develop new technologies, and advance scientific knowledge.

Skills and Qualifications Required for Electromechanical Engineering Roles

To succeed in electromechanical engineering roles, individuals need a strong foundation in both electrical and mechanical principles, as well as the ability to integrate these disciplines effectively. Some essential skills and qualifications include:

- Technical Skills:

- Electrical Engineering: Understanding of circuits, electronics, power systems, and control systems.

- Mechanical Engineering: Knowledge of mechanics, materials science, thermodynamics, and fluid mechanics.

- Computer Programming: Proficiency in programming languages such as C++, Python, and MATLAB for designing and controlling electromechanical systems.

- CAD/CAM Software: Experience with computer-aided design (CAD) and computer-aided manufacturing (CAM) software for creating and simulating electromechanical systems.

- Problem-Solving and Analytical Skills: Electromechanical engineers need to be able to identify problems, analyze complex systems, and develop innovative solutions.

- Communication and Teamwork Skills: Effective communication skills are essential for collaborating with colleagues, clients, and stakeholders. Teamwork skills are also important for working in multidisciplinary teams on complex projects.

- Continuous Learning: Electromechanical technology is constantly evolving, so it is crucial for professionals to stay up-to-date with the latest advancements and technologies.

Epilogue

The Electro Mechanical Technology Course empowers individuals with a deep understanding of this vital field, preparing them for rewarding careers in a rapidly evolving technological landscape. Whether you’re interested in designing innovative systems, optimizing existing technologies, or pursuing research in emerging areas, this course provides the necessary knowledge and skills to excel in the electromechanical world.

An electro-mechanical technology course provides a solid foundation in understanding how mechanical systems interact with electrical components. This knowledge can be directly applied to the field of assistive technology, where devices are designed to help individuals with disabilities. If you’re interested in pursuing a career as an assistive technology specialist , an electro-mechanical technology course can equip you with the necessary skills to develop, adapt, and maintain these life-changing technologies.