Dustless Technology: A Cleaner Future

Dustless technology is revolutionizing industries by tackling the challenges of dust and particulate matter. From construction sites to manufacturing plants, dustless technology ensures a cleaner, safer, and more productive work […]

Dustless technology is revolutionizing industries by tackling the challenges of dust and particulate matter. From construction sites to manufacturing plants, dustless technology ensures a cleaner, safer, and more productive work environment. This technology encompasses a range of solutions, including vacuum systems, air filtration, and wet methods, each tailored to specific applications.

The benefits of dustless technology are multifaceted. It improves worker health by reducing exposure to harmful dust particles, minimizing environmental impact through controlled dust containment, and enhancing product quality by eliminating contamination. Furthermore, dustless technology contributes to increased productivity by streamlining operations and reducing downtime associated with dust-related issues.

Introduction to Dustless Technology

Dustless technology encompasses a range of methods and tools designed to minimize or eliminate dust generation during various processes. It plays a crucial role in maintaining clean and safe working environments, improving product quality, and protecting workers’ health.

Dustless technology is essential in various industries where dust poses significant challenges. It helps to mitigate the risks associated with dust exposure, such as respiratory problems, explosions, and product contamination.

Industries Employing Dustless Technology

Dustless technology finds widespread application across numerous industries, including:

- Construction: Dustless cutting, drilling, and demolition techniques are employed to minimize dust generation during building projects, ensuring cleaner work environments and reduced exposure for workers.

- Manufacturing: Dustless sanding, grinding, and polishing methods are essential in industries like woodworking, metalworking, and automotive manufacturing to maintain product quality and worker safety.

- Mining: Dust suppression systems are vital in mining operations to control dust levels, protecting workers from respiratory illnesses and improving air quality.

- Demolition: Dustless demolition techniques are employed to minimize dust generation during building demolition projects, ensuring cleaner work environments and reduced exposure for workers.

- Agriculture: Dustless farming practices, such as using no-till farming techniques and dust suppressants, help to reduce dust generation and improve soil health.

Challenges Associated with Dust and Particulate Matter

Dust and particulate matter pose significant challenges in various settings, impacting human health, product quality, and environmental sustainability.

- Respiratory Health: Dust inhalation can lead to respiratory problems such as asthma, bronchitis, and lung disease. Fine particulate matter can penetrate deep into the lungs, causing inflammation and damage.

- Product Contamination: Dust can contaminate products, reducing their quality and affecting their performance. This is particularly critical in industries like pharmaceuticals, food processing, and electronics manufacturing.

- Fire and Explosion Hazards: Dust accumulation can create fire and explosion hazards, especially in industries handling combustible materials. Dust explosions can cause significant damage and injuries.

- Environmental Impact: Dust can contribute to air pollution, affecting visibility, causing respiratory problems, and contributing to climate change.

Types of Dustless Technology

Dustless technology encompasses various methods and techniques designed to minimize or eliminate dust generation during construction, demolition, and other industrial processes. These technologies play a crucial role in improving air quality, worker safety, and overall project efficiency.

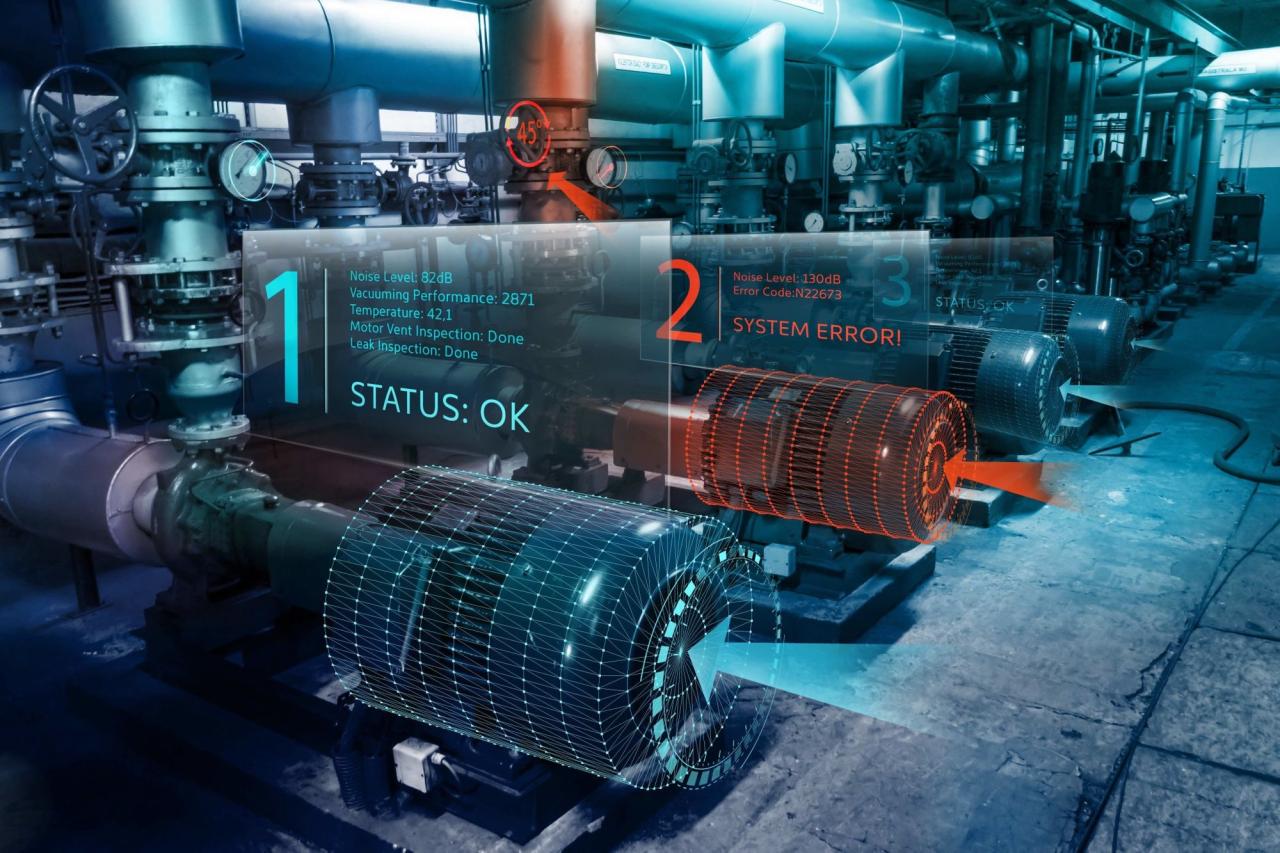

Vacuum Systems

Vacuum systems are a widely used dustless technology that captures dust particles at the source. These systems typically consist of a powerful vacuum unit connected to a specialized tool or attachment.

Vacuum systems work by creating a negative pressure that draws air and dust particles into the vacuum unit. The dust is then collected in a filter bag or container, preventing it from escaping into the surrounding environment.

- Central Vacuum Systems: These systems use a central vacuum unit that is connected to multiple outlets throughout the workspace. They offer high suction power and are suitable for large-scale projects.

- Portable Vacuum Systems: Portable vacuum systems are smaller and more compact, making them ideal for smaller projects or tasks that require mobility. They are often equipped with HEPA filters to capture even the smallest dust particles.

- Wet/Dry Vacuum Systems: These systems can handle both dry and wet debris, making them versatile for various applications. They are often used in areas where water or other liquids are present.

Advantages of Vacuum Systems:

- Effective dust control

- Wide range of applications

- Relatively low cost

Disadvantages of Vacuum Systems:

- Can be noisy

- May require regular maintenance

- Limited effectiveness in open areas or with large amounts of dust

Air Filtration

Air filtration systems are another important dustless technology that focuses on cleaning the air after dust particles have been released. These systems use specialized filters to trap dust particles, reducing their concentration in the air.

Air filtration systems typically consist of a fan that draws air through a series of filters. The filters capture dust particles based on their size and type, effectively purifying the air.

- HEPA Filters: HEPA (High-Efficiency Particulate Air) filters are highly effective at capturing even the smallest dust particles, including those that can be harmful to human health.

- Carbon Filters: Carbon filters are used to remove odors and gases from the air, providing an additional layer of protection.

- UV Filters: UV filters use ultraviolet light to kill bacteria and viruses that may be present in the air.

Advantages of Air Filtration Systems:

- Improve air quality

- Reduce health risks associated with dust exposure

- Can be used in conjunction with other dustless technologies

Disadvantages of Air Filtration Systems:

- May not be effective at capturing all dust particles

- Require regular filter replacement

- Can be expensive to install and maintain

Wet Methods

Wet methods involve using water or other liquids to suppress dust generation. These methods are often used in conjunction with other dustless technologies to provide comprehensive dust control.

Wet methods work by binding dust particles to water molecules, preventing them from becoming airborne. The water also helps to dampen the material being worked on, further reducing dust generation.

- Water Misting: Water misting systems use fine water droplets to create a mist that settles on surfaces and traps dust particles.

- Water Spraying: Water spraying involves using a nozzle to spray water directly onto the material being worked on, effectively suppressing dust generation.

- Water-Based Adhesives: Water-based adhesives can be used to bind dust particles together, preventing them from becoming airborne.

Advantages of Wet Methods:

- Effective at suppressing dust

- Can be used in a variety of applications

- Relatively inexpensive

Disadvantages of Wet Methods:

- Can create slippery surfaces

- May require additional cleanup

- Not suitable for all materials

Comparison of Dustless Technologies

The effectiveness of different dustless technologies varies depending on the specific application. For example, vacuum systems are highly effective at capturing dust particles from small areas, while air filtration systems are better suited for large open spaces. Wet methods are often used in conjunction with other technologies to provide comprehensive dust control.

The choice of dustless technology should be based on a careful assessment of the project requirements, including the type of material being worked on, the size of the workspace, and the level of dust control required.

Applications of Dustless Technology

Dustless technology finds widespread use in various industries, significantly enhancing worker safety, environmental protection, and product quality. This technology is particularly valuable in industries where dust generation is a major concern, such as construction, manufacturing, demolition, and healthcare.

Construction

Dustless technology plays a crucial role in construction, minimizing the hazards associated with dust exposure. Here are some applications:

- Concrete Cutting and Grinding: Dustless concrete cutting and grinding systems employ water or vacuum technology to capture dust generated during these operations. This significantly reduces airborne dust, improving worker safety and minimizing environmental impact.

- Demolition: Dustless demolition techniques, such as controlled demolition with water mist or vacuum systems, effectively contain dust generated during the process. This is particularly important in urban areas where dust can pose a risk to nearby residents and traffic.

- Drywall Installation: Dustless drywall sanding systems utilize specialized sanding tools and vacuum systems to capture dust generated during sanding. This minimizes dust exposure for workers and improves indoor air quality during construction projects.

Manufacturing

Dustless technology is essential in manufacturing, ensuring worker safety and maintaining product quality. Here are some applications:

- Woodworking: Dustless woodworking tools, such as dust collection systems for routers, sanders, and saws, effectively capture dust generated during woodworking operations. This helps prevent respiratory problems for workers and maintains a clean working environment.

- Metalworking: Dustless metalworking equipment, such as dust collection systems for grinders, polishers, and cutting tools, minimize dust exposure for workers. This helps prevent metal dust from contaminating products and ensures worker safety.

- Pharmaceutical Manufacturing: Dustless technology is crucial in pharmaceutical manufacturing, where contamination can affect product quality and safety. Dustless equipment, such as cleanroom technologies and HEPA filtration systems, ensure a dust-free environment for sensitive drug production processes.

Demolition

Dustless technology is essential in demolition, minimizing dust hazards and protecting the surrounding environment. Here are some applications:

- Building Demolition: Dustless demolition techniques, such as water-assisted demolition and vacuum systems, effectively capture dust generated during the process. This minimizes dust dispersion and protects nearby residents and traffic.

- Road Demolition: Dustless road demolition methods, such as water-assisted demolition and vacuum systems, minimize dust generated during roadwork. This protects workers and reduces dust pollution in the surrounding environment.

- Bridge Demolition: Dustless bridge demolition techniques, such as controlled demolition with water mist or vacuum systems, effectively contain dust generated during the process. This protects workers and minimizes environmental impact.

Healthcare

Dustless technology plays a crucial role in healthcare, ensuring a clean and safe environment for patients and staff. Here are some applications:

- Operating Rooms: Dustless technology is essential in operating rooms to minimize airborne dust and contaminants. HEPA filtration systems and air purification systems create a sterile environment, reducing the risk of infections and complications.

- Patient Rooms: Dustless cleaning systems, such as vacuum cleaners with HEPA filtration, minimize dust accumulation in patient rooms, improving air quality and reducing the risk of allergies and respiratory problems.

- Laboratories: Dustless technology is crucial in laboratories, where contamination can affect research and testing. HEPA filtration systems and cleanroom technologies create a dust-free environment, ensuring accurate and reliable results.

Benefits of Dustless Technology

Dustless technology offers a wide range of advantages across various industries, leading to improved worker health, reduced environmental impact, enhanced product quality, and increased productivity. This technology has become increasingly popular due to its ability to create a cleaner and safer working environment, making it a valuable asset for businesses seeking to optimize their operations.

Improved Worker Health

Implementing dustless technology significantly improves worker health and safety by minimizing exposure to harmful dust particles. Dust can cause various respiratory problems, skin irritation, and eye irritation, leading to decreased productivity and increased healthcare costs.

- Dustless technology effectively reduces dust levels, protecting workers from these health risks.

- This improved air quality leads to a healthier work environment, reducing absenteeism and improving employee morale.

Reduced Environmental Impact

Dustless technology contributes to a cleaner environment by minimizing dust emissions, which can negatively impact air quality and contribute to respiratory problems in surrounding communities.

- By reducing dust generation, dustless technology helps to improve air quality and reduce the environmental impact of industrial operations.

- This reduction in dust emissions also helps to minimize the risk of dust explosions, which can be hazardous to workers and the surrounding environment.

Enhanced Product Quality

Dustless technology plays a crucial role in maintaining product quality by preventing dust contamination, which can affect the performance and appearance of products.

- In industries like manufacturing and construction, dust can lead to defects, scratches, and other imperfections, reducing product quality and customer satisfaction.

- Dustless technology eliminates these issues by creating a dust-free environment, ensuring products meet quality standards and enhance customer satisfaction.

Increased Productivity

Dustless technology leads to increased productivity by creating a cleaner and safer work environment, reducing downtime caused by dust-related issues.

- By eliminating dust, workers can focus on their tasks without interruptions, leading to increased efficiency and productivity.

- Reduced downtime for cleaning and maintenance further contributes to increased productivity, optimizing overall operations.

Final Conclusion

As we move towards a future focused on sustainability and worker well-being, dustless technology plays a crucial role. Its continuous development, driven by advancements in filtration systems, automation, and nanotechnology, promises even cleaner and more efficient solutions. The integration of dustless technology with other emerging technologies will further shape industries, paving the way for a cleaner and more sustainable future.

Dustless technology is revolutionizing various industries by minimizing airborne particles and improving safety. A key figure in this evolution is the chief product and technology officer , who spearheads the development and implementation of these innovative solutions. Their expertise ensures that dustless technology continues to evolve, offering cleaner, healthier, and more efficient work environments.