Custom Sensors & Technologies: Shaping Industries

Custom sensors & technologies are revolutionizing industries by providing tailored solutions for specific needs. From healthcare to manufacturing, these specialized sensors are enabling unprecedented levels of precision, efficiency, and innovation. […]

Custom sensors & technologies are revolutionizing industries by providing tailored solutions for specific needs. From healthcare to manufacturing, these specialized sensors are enabling unprecedented levels of precision, efficiency, and innovation. Imagine a world where medical devices can monitor vital signs in real-time, factories can optimize production lines based on sensor data, and smart cities can manage resources effectively through interconnected networks. This is the future that custom sensors are paving the way for.

The significance of custom sensors lies in their ability to address unique challenges and opportunities that off-the-shelf solutions often fail to meet. By designing sensors specifically for a particular application, engineers can achieve optimal performance, accuracy, and reliability. This tailored approach is crucial for industries that demand high-precision measurements, real-time data acquisition, and seamless integration with existing systems.

Introduction to Custom Sensors & Technologies

Custom sensors and technologies play a crucial role in shaping various industries by providing tailored solutions to specific needs. These specialized tools offer a unique advantage over generic, off-the-shelf solutions, allowing for greater accuracy, efficiency, and innovation.

Industries Utilizing Custom Sensors, Custom sensors & technologies

Custom sensors are essential in numerous industries where precise data collection and analysis are crucial. These sensors are designed to meet specific requirements, offering tailored solutions that enhance efficiency, safety, and productivity.

- Healthcare: Custom sensors are used in medical devices to monitor vital signs, detect abnormalities, and provide personalized treatments. For example, wearable sensors can track heart rate, blood pressure, and sleep patterns, enabling proactive healthcare management.

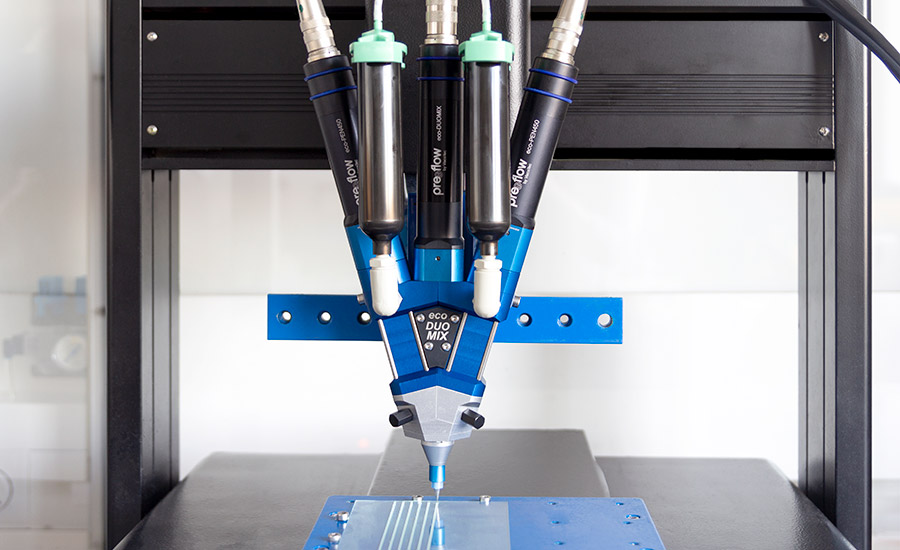

- Manufacturing: In manufacturing, custom sensors monitor production processes, optimize machinery performance, and ensure quality control. For instance, sensors can detect vibrations, temperature fluctuations, and pressure changes, providing real-time insights into machine health and potential issues.

- Environmental Monitoring: Custom sensors are deployed to monitor environmental conditions, such as air quality, water pollution, and soil health. These sensors provide valuable data for environmental protection and sustainable practices.

- Automotive: In the automotive industry, custom sensors are integrated into vehicles to enhance safety, performance, and fuel efficiency. For example, sensors detect obstacles, monitor tire pressure, and optimize engine performance.

- Agriculture: Custom sensors play a vital role in precision agriculture, enabling farmers to monitor soil conditions, weather patterns, and crop health. This data helps optimize irrigation, fertilization, and pest control, leading to increased yields and reduced environmental impact.

Advantages of Custom Sensors

Custom sensors offer several advantages over off-the-shelf solutions, making them an ideal choice for various applications.

- Tailored Solutions: Custom sensors are designed to meet specific requirements, providing a perfect fit for the intended application. This ensures optimal performance and accuracy.

- Enhanced Accuracy: By tailoring the sensor design and calibration, custom sensors can achieve higher accuracy than generic solutions, leading to more reliable data and improved decision-making.

- Increased Efficiency: Custom sensors can be integrated seamlessly into existing systems, streamlining operations and improving overall efficiency. They can also be designed to collect specific data, eliminating unnecessary information and reducing processing time.

- Cost Savings: While custom sensors may have higher initial costs, they can ultimately save money by improving efficiency, reducing waste, and preventing costly failures. This long-term cost-effectiveness makes them a valuable investment.

- Innovation and Advancement: Custom sensors enable the development of innovative technologies and solutions. By pushing the boundaries of sensor design and capabilities, custom sensors drive progress in various fields.

Design & Development Process: Custom Sensors & Technologies

The design and development process for custom sensors involves a series of steps that ensure the sensor meets the specific requirements of the application. This process includes defining the sensor’s purpose, selecting appropriate materials and fabrication techniques, conducting simulations and prototyping, and finally testing and refining the sensor.

Material Selection and Fabrication Techniques

Selecting appropriate materials and fabrication techniques is crucial for achieving the desired sensor performance and ensuring its reliability. The choice of materials depends on the sensor’s operating environment, the measured parameter, and the required sensitivity and accuracy. For example, a sensor for high-temperature applications would require materials with high melting points and resistance to oxidation. Similarly, a sensor for measuring chemical concentrations would need materials that are compatible with the target analyte and have a high sensitivity to its presence.

- Materials: Common materials used in sensor fabrication include silicon, polymers, ceramics, and composites. Silicon is often used in microelectromechanical systems (MEMS) due to its excellent electrical and mechanical properties. Polymers offer flexibility and low cost, making them suitable for disposable sensors. Ceramics are known for their high temperature stability and chemical resistance. Composites, combining different materials, can provide unique properties tailored to specific applications.

- Fabrication Techniques: The fabrication technique chosen depends on the desired sensor design and material properties. Common techniques include photolithography, etching, thin-film deposition, and micromachining. Photolithography involves using light to pattern materials, allowing for precise control over the sensor’s geometry. Etching removes material from a substrate, creating specific features. Thin-film deposition adds layers of materials to a substrate, enabling the creation of multi-layered sensors. Micromachining involves using tools to shape materials with high precision, often used for creating three-dimensional structures.

Simulations and Prototyping

Simulations and prototyping play a vital role in the development process by allowing engineers to test different designs and materials before committing to expensive fabrication. Simulations use computer models to predict the sensor’s performance under various conditions, helping optimize its design and identify potential issues early in the development cycle. Prototyping involves creating physical models of the sensor to test its functionality and refine its design based on experimental data.

- Simulations: Finite element analysis (FEA) and computational fluid dynamics (CFD) are commonly used simulation tools. FEA allows engineers to analyze the sensor’s mechanical behavior under stress and strain, while CFD helps predict fluid flow patterns and heat transfer within the sensor.

- Prototyping: Prototyping can be done using various methods, including 3D printing, laser cutting, and microfabrication. 3D printing offers rapid prototyping capabilities and allows for the creation of complex geometries. Laser cutting provides precision and speed in creating prototypes from thin materials. Microfabrication techniques are used to create highly integrated and miniaturized prototypes, especially for MEMS sensors.

Final Thoughts

As custom sensors & technologies continue to evolve, we can expect to see even more groundbreaking applications emerge. The integration of artificial intelligence, miniaturization, and wireless communication is pushing the boundaries of what’s possible. From personalized healthcare solutions to advanced environmental monitoring systems, the future of custom sensors is bright and full of promise. As we delve deeper into the realm of data-driven decision-making, these specialized sensors will play a pivotal role in shaping the world around us.

Custom sensors and technologies are increasingly being used in a wide range of applications, from monitoring environmental conditions to controlling industrial processes. One innovative approach that is gaining traction in this field is the use of click technologies , which offer a unique combination of simplicity and versatility.

By leveraging these technologies, developers can create custom sensor solutions that are tailored to specific needs, enabling more efficient and effective data collection and analysis.