Cummins Turbo Technologies: Powering Performance

Cummin turbo technologies – Cummins turbo technologies set the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality […]

Cummin turbo technologies – Cummins turbo technologies set the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset. Cummins, a global leader in power solutions, has long been synonymous with innovation and reliability, and its turbocharger technology is a testament to this commitment.

From the bustling highways to the rugged terrains of off-road applications, Cummins turbochargers have revolutionized engine performance and efficiency. Their intricate designs, leveraging advanced materials and electronic control systems, have pushed the boundaries of what’s possible in power generation and transportation. This exploration delves into the history, evolution, and applications of Cummins turbo technologies, highlighting their impact on various industries and the future they hold.

Introduction to Cummins Turbo Technologies

Cummins Turbo Technologies, a subsidiary of Cummins Inc., is a global leader in the design, manufacture, and distribution of turbochargers for various industries. The company has a rich history spanning over 70 years, with a constant focus on innovation and technological advancements.

History and Evolution of Cummins Turbo Technologies

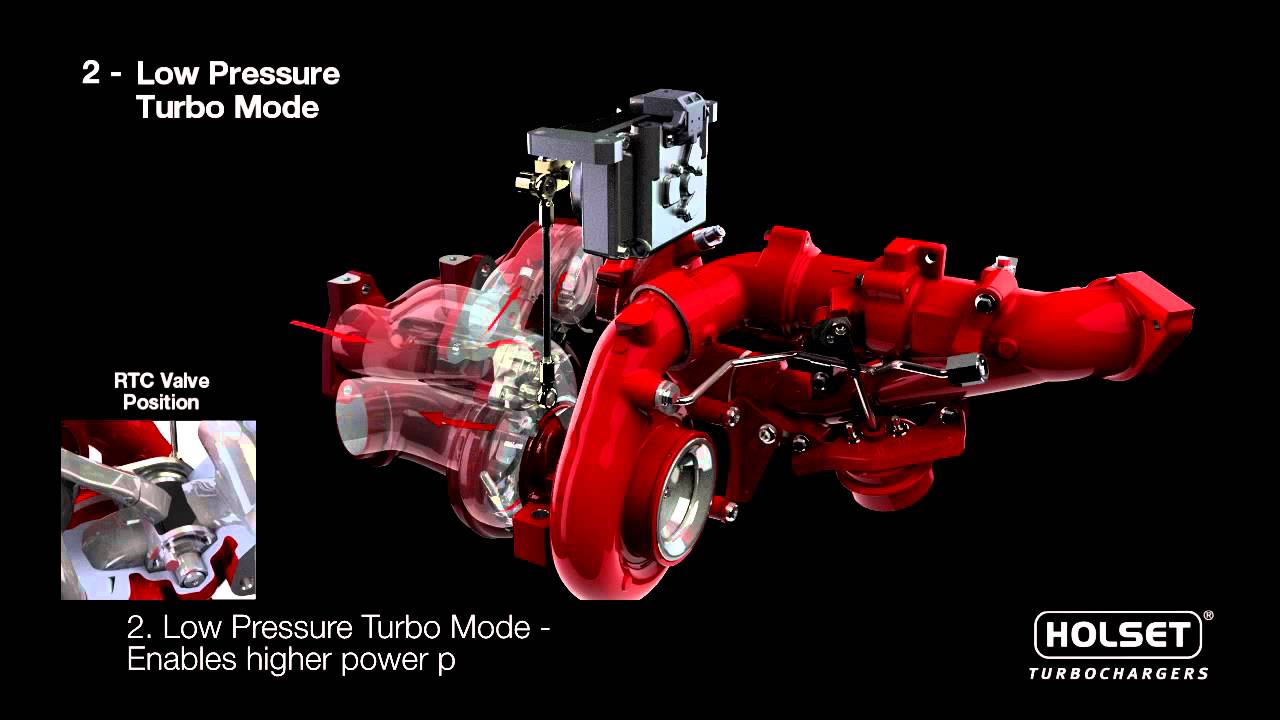

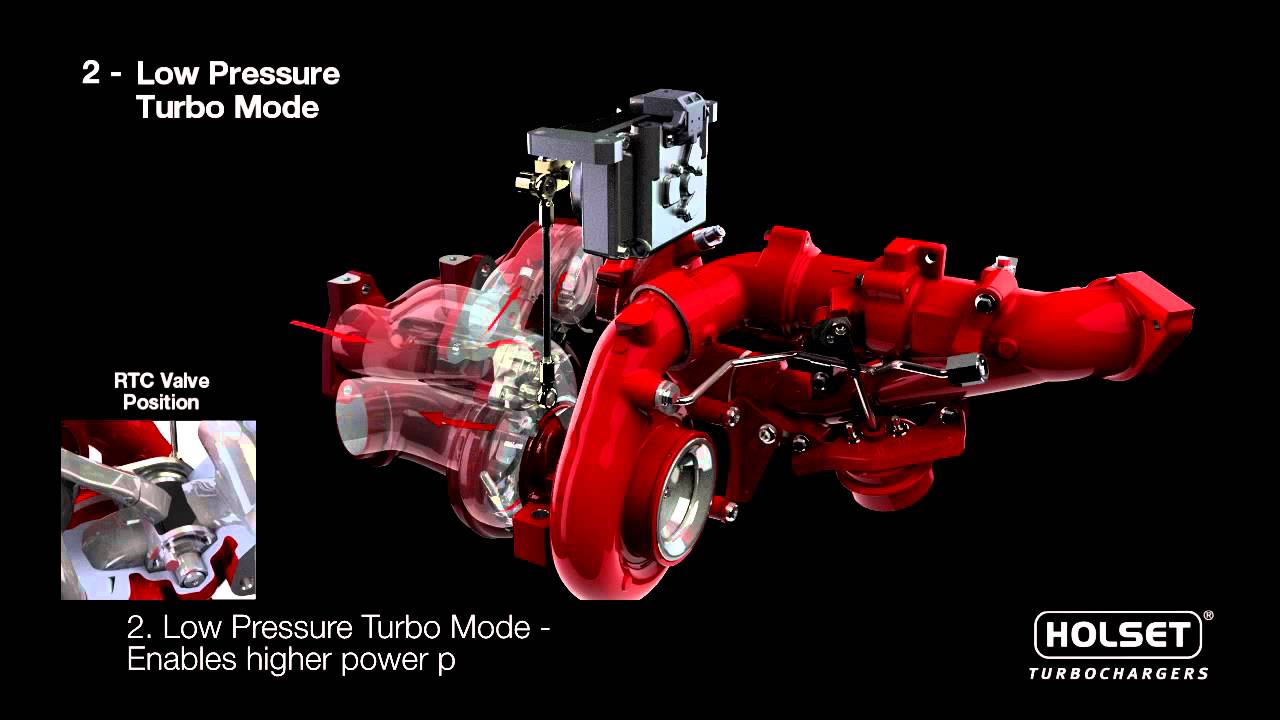

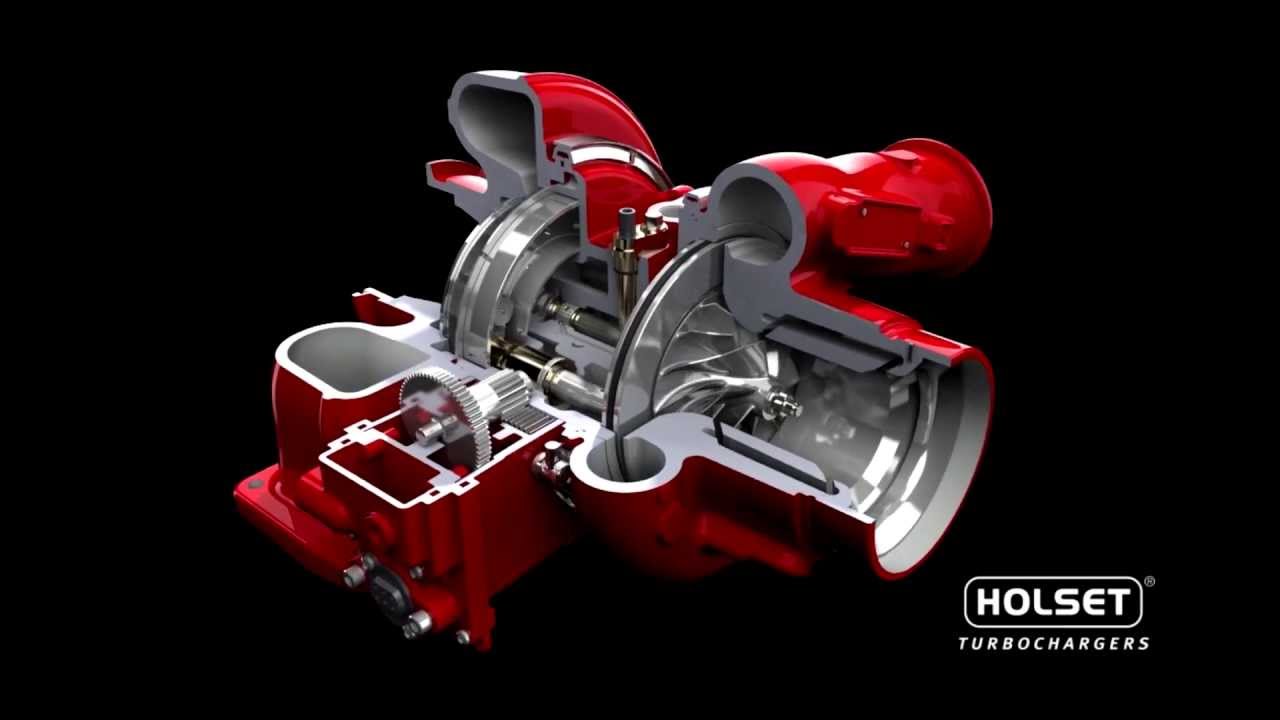

Cummins Turbo Technologies’ journey began in 1951 when Holset Engineering Company, a British manufacturer of turbochargers, was established. Holset quickly gained recognition for its innovative turbocharger designs and became a prominent player in the industry. In 1998, Cummins Inc. acquired Holset, marking a significant milestone in the evolution of Cummins Turbo Technologies. This acquisition brought together the expertise of two industry leaders, creating a powerful force in the turbocharger market.

Over the years, Cummins Turbo Technologies has continued to invest heavily in research and development, leading to numerous breakthroughs and advancements in turbocharger technology. The company has been at the forefront of introducing innovative features such as variable geometry turbochargers (VGTs), electronic wastegates, and advanced materials, which have significantly enhanced engine performance and efficiency.

Role of Cummins Turbo Technologies in the Cummins Business

Cummins Turbo Technologies plays a vital role in the overall Cummins business strategy. Turbochargers are an integral component of many Cummins engine platforms, enhancing engine performance, fuel efficiency, and emissions reduction. The company’s expertise in turbocharger technology complements Cummins’ core engine manufacturing capabilities, enabling the development of highly efficient and reliable power solutions for diverse applications.

Applications of Cummins Turbo Technologies

Cummins Turbo Technologies’ turbochargers find applications in a wide range of industries, including:

- On-Highway: Cummins turbochargers are used in heavy-duty trucks, buses, and other commercial vehicles, providing increased power and torque for demanding applications. These turbochargers are designed to meet stringent emissions regulations, contributing to cleaner and more efficient transportation.

- Off-Highway: The company’s turbochargers are also used in off-highway equipment, such as construction machinery, agricultural equipment, and mining vehicles. These turbochargers provide the power and reliability needed for demanding tasks in harsh environments.

- Power Generation: Cummins Turbo Technologies supplies turbochargers for power generation applications, including stationary and mobile generators. These turbochargers enhance engine efficiency and reliability, ensuring consistent power output in various settings.

- Marine: The company’s turbochargers are also used in marine applications, powering vessels of all sizes. These turbochargers are designed to withstand the harsh marine environment and provide reliable performance for long durations.

- Industrial: Cummins Turbo Technologies provides turbochargers for industrial applications, such as pumps, compressors, and other industrial equipment. These turbochargers enhance engine performance and efficiency, contributing to increased productivity and reduced operating costs.

Cummins Turbocharger Technology and Innovation

Cummins has been at the forefront of turbocharger technology for decades, constantly innovating to enhance engine performance, fuel efficiency, and emissions reduction. The company’s commitment to research and development has resulted in groundbreaking advancements in turbocharger design, materials, and control systems.

Electronic Control Systems

Electronic control systems have revolutionized turbocharger operation, allowing for precise and dynamic control of boost pressure and engine performance. Cummins has developed sophisticated electronic control units (ECUs) that monitor various engine parameters, such as engine speed, air mass, and exhaust gas temperature, to optimize turbocharger performance in real-time. These ECUs enable adaptive control strategies that adjust turbocharger operation based on driving conditions and engine load, maximizing efficiency and responsiveness.

Advanced Materials

The use of advanced materials in turbocharger components has significantly improved durability, efficiency, and performance. Cummins utilizes high-temperature resistant alloys, ceramics, and composites in critical components such as turbine wheels, compressor wheels, and housings. These materials enable operation at higher temperatures and pressures, reducing wear and tear and extending turbocharger lifespan.

Impact of Innovations

Cummins’ turbocharger innovations have had a profound impact on engine performance, fuel efficiency, and emissions reduction. Electronic control systems have enabled precise boost pressure control, leading to faster engine response, improved fuel economy, and reduced emissions. Advanced materials have enhanced turbocharger durability and efficiency, further contributing to improved fuel consumption and reduced emissions.

Research and Development Focus

Cummins continues to invest heavily in research and development to push the boundaries of turbocharger technology. The company is focusing on areas such as:

- Variable Geometry Turbochargers (VGT): VGTs allow for precise control of exhaust gas flow through the turbine, optimizing performance across the engine speed range. Cummins is developing advanced VGT systems with improved responsiveness and durability.

- Electric Turbochargers (eTCs): eTCs use electric motors to supplement the exhaust gas-driven turbine, providing faster boost response and improved low-speed performance. Cummins is actively exploring the potential of eTCs for various engine applications.

- Turbocharger Integration with Aftertreatment Systems: Integrating turbochargers with aftertreatment systems, such as diesel particulate filters (DPFs) and selective catalytic reduction (SCR) systems, optimizes exhaust gas flow and improves emissions control efficiency. Cummins is developing integrated solutions that enhance both performance and emissions reduction.

Benefits of Cummins Turbo Technologies

Cummins turbochargers offer a range of benefits that contribute to improved engine performance, efficiency, and longevity. These benefits are achieved through the innovative design and engineering of Cummins turbochargers, which are specifically tailored to meet the demanding requirements of various applications.

Improved Fuel Efficiency

Cummins turbochargers play a crucial role in enhancing fuel efficiency by optimizing engine performance. The turbocharger utilizes exhaust gases to spin a turbine, which in turn drives a compressor. This compressed air is then delivered to the engine’s combustion chamber, increasing the amount of oxygen available for combustion. The result is more efficient combustion, leading to improved fuel economy.

“By utilizing exhaust gases to compress air, Cummins turbochargers enable engines to burn fuel more efficiently, resulting in significant fuel savings.”

For instance, a Cummins-powered truck equipped with a turbocharger can achieve a fuel efficiency improvement of up to 10% compared to a non-turbocharged engine. This translates into significant cost savings for operators over the long term.

Reduced Emissions

Cummins turbochargers contribute to cleaner emissions by promoting more efficient combustion. The increased oxygen intake provided by the turbocharger allows for a more complete combustion process, resulting in lower levels of harmful emissions such as nitrogen oxides (NOx) and particulate matter (PM).

“Cummins turbochargers help reduce emissions by promoting more efficient combustion, resulting in lower levels of NOx and PM.”

For example, Cummins turbochargers have been instrumental in helping meet stringent emissions regulations, such as the Euro VI standard, which sets strict limits on NOx and PM emissions.

Enhanced Performance

Cummins turbochargers deliver a significant boost in engine performance, providing more power and torque across a wider RPM range. The increased air intake provided by the turbocharger allows the engine to burn more fuel, generating greater power output.

“Cummins turbochargers enhance engine performance by increasing air intake, leading to greater power and torque.”

In heavy-duty applications, such as trucks and construction equipment, Cummins turbochargers enable engines to deliver more power for hauling heavier loads and operating in challenging terrain.

Increased Engine Life

Cummins turbochargers contribute to increased engine life by reducing wear and tear. The turbocharger’s ability to optimize combustion reduces stress on engine components, extending their lifespan.

“Cummins turbochargers contribute to increased engine life by reducing stress on engine components, promoting smoother operation and minimizing wear and tear.”

In demanding applications, such as off-road equipment, Cummins turbochargers play a vital role in ensuring long-term reliability and reducing maintenance costs.

Future Trends in Cummins Turbo Technologies

Cummins Turbo Technologies is at the forefront of innovation, constantly adapting to the evolving landscape of the automotive industry. The future holds exciting possibilities for the company as it navigates emerging trends and technologies.

Timeline of Anticipated Evolution, Cummin turbo technologies

The future of Cummins turbocharger technology is marked by a continuous evolution towards increased efficiency, reduced emissions, and enhanced performance. Here’s a timeline outlining key anticipated advancements:

- 2025-2030: Advancements in variable geometry turbochargers (VGT) will focus on optimizing performance across a wider engine operating range, further improving fuel efficiency and reducing emissions.

- 2030-2035: The integration of advanced materials, such as ceramics and composites, will enable the development of lighter and more durable turbochargers, enhancing engine responsiveness and reducing friction losses.

- 2035-2040: The development of electric turbochargers (e-boosters) will revolutionize engine performance, offering instant torque and improved fuel economy, particularly in hybrid and electric vehicle applications.

Emerging Trends and Their Impact

The automotive industry is undergoing a significant transformation, driven by the need for sustainable and efficient transportation solutions. Cummins Turbo Technologies is actively exploring and adapting to these trends:

Electrification and Hybridization

The increasing adoption of electric and hybrid vehicles presents both challenges and opportunities for Cummins Turbo Technologies. While electric motors offer instant torque and efficiency, internal combustion engines still play a vital role in range and performance. Cummins is developing electric turbochargers (e-boosters) that can be integrated into hybrid and electric powertrains to enhance performance and efficiency. These e-boosters can provide instant torque, improving acceleration and responsiveness, while also enhancing fuel economy.

Alternative Fuels

The shift towards alternative fuels, such as biofuels, hydrogen, and synthetic fuels, presents a significant opportunity for Cummins Turbo Technologies. These fuels offer potential for reduced emissions and improved sustainability. Cummins is actively researching and developing turbocharger technologies that are compatible with these alternative fuels, ensuring its products remain relevant in the evolving fuel landscape.

Challenges and Opportunities

The future of Cummins Turbo Technologies is not without its challenges. The transition to electric and hybrid vehicles could potentially reduce the demand for traditional turbochargers. However, the company is well-positioned to capitalize on the growing market for electric turbochargers and other technologies that enhance the performance of hybrid and electric powertrains.

The development of alternative fuels also presents both challenges and opportunities. Cummins is actively researching and developing turbocharger technologies that are compatible with these fuels, ensuring its products remain relevant in the evolving fuel landscape.

Cummins Turbo Technologies is committed to staying at the forefront of innovation, continuously developing and adapting its products to meet the evolving needs of the automotive industry. The company’s focus on efficiency, sustainability, and performance ensures its continued success in the years to come.

Closure: Cummin Turbo Technologies

Cummins turbo technologies stand as a testament to the power of innovation, pushing the boundaries of performance and efficiency while minimizing environmental impact. As we look towards the future, Cummins continues to invest in research and development, exploring new frontiers in electrification, hybridization, and alternative fuels. The legacy of Cummins turbochargers is one of power, precision, and progress, ensuring that the future of transportation and power generation is driven by cutting-edge technology and a commitment to sustainability.

Cummins Turbo Technologies, a leading provider of advanced turbocharger solutions, is committed to innovation. Their expertise extends beyond the automotive industry, as they also collaborate with institutions like the MCI Institute of Technology to foster the next generation of engineers.

This partnership allows for knowledge exchange and research development, ensuring Cummins Turbo Technologies remains at the forefront of turbocharger technology.