CCI Thermal Technologies: Solutions for Industry Heat

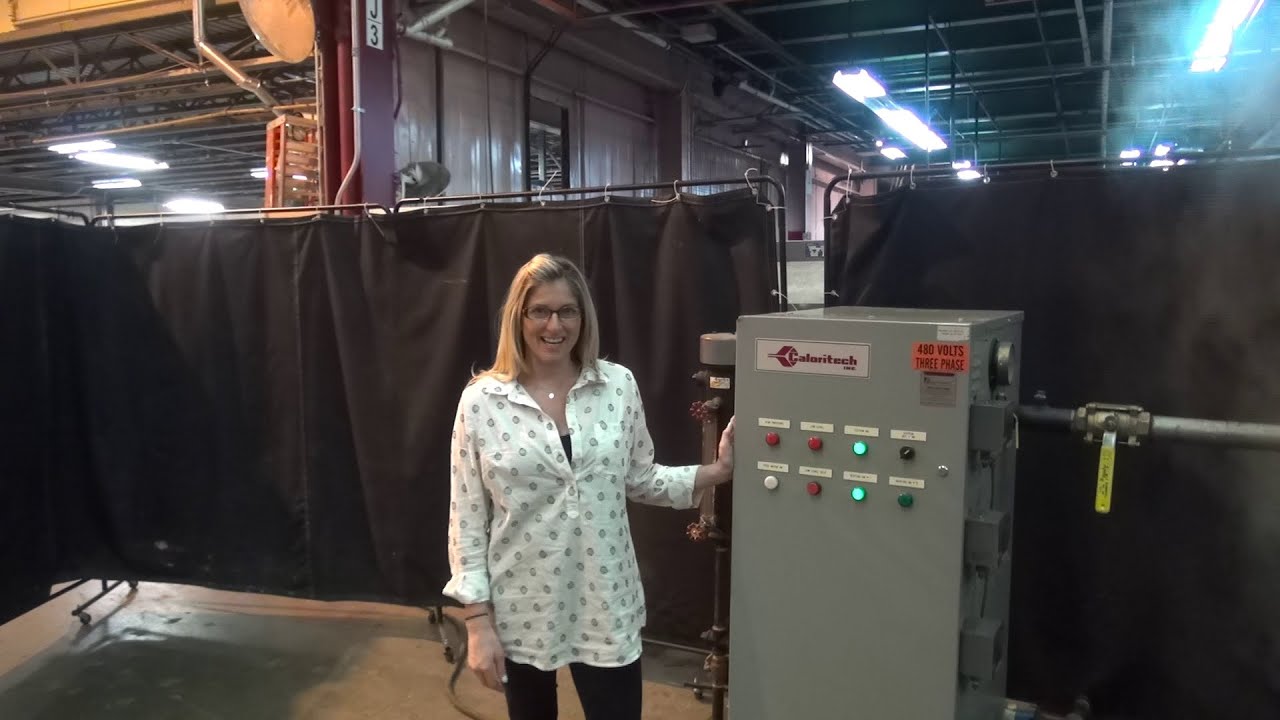

CCI Thermal Technologies is a leading provider of innovative thermal solutions for a wide range of industries. From industrial heating and cooling to process optimization, CCI’s expertise in thermal engineering […]

CCI Thermal Technologies is a leading provider of innovative thermal solutions for a wide range of industries. From industrial heating and cooling to process optimization, CCI’s expertise in thermal engineering and technology helps businesses achieve greater efficiency, productivity, and sustainability.

Founded on a commitment to innovation, CCI Thermal Technologies has a rich history of developing and implementing cutting-edge thermal solutions. Their team of engineers and scientists continuously pushes the boundaries of thermal technology, resulting in groundbreaking advancements that benefit clients across various sectors.

CCI Thermal Technologies

CCI Thermal Technologies is a leading provider of thermal solutions for a wide range of industries. The company specializes in designing, manufacturing, and installing custom thermal systems that meet the unique needs of its clients.

Industries Served

CCI Thermal Technologies serves a diverse range of industries, each with its own specific challenges and requirements related to thermal technologies. The company’s expertise in thermal engineering and its commitment to innovation enable it to provide solutions that meet the demands of these industries.

| Industry | Challenges | CCI Solutions |

|---|---|---|

| Food Processing | Maintaining consistent temperatures for food safety and quality, preventing spoilage, and reducing energy consumption. | High-efficiency heating and cooling systems, precise temperature control, and energy-saving technologies. |

| Pharmaceutical | Strict adherence to GMP regulations, maintaining sterile environments, and ensuring product stability. | Cleanroom-compliant thermal systems, validation services, and specialized temperature control solutions. |

| Chemical | Handling hazardous materials, managing temperature fluctuations, and optimizing process efficiency. | Robust and reliable thermal systems, corrosion-resistant materials, and safety features. |

| Data Centers | Maintaining optimal temperatures for server operation, preventing overheating, and ensuring high uptime. | Precision cooling systems, energy-efficient designs, and monitoring and control systems. |

| Automotive | Meeting stringent emissions standards, optimizing engine performance, and improving fuel efficiency. | Advanced thermal management systems, lightweight materials, and innovative cooling technologies. |

CCI Thermal Technologies

CCI Thermal Technologies is a leading provider of thermal solutions for a wide range of industries. The company specializes in the design, manufacture, and installation of custom-engineered thermal systems. CCI Thermal Technologies leverages various thermal technologies to meet the unique needs of its clients, ensuring optimal performance and efficiency.

Key Thermal Technologies

CCI Thermal Technologies utilizes several key thermal technologies, each offering distinct advantages and disadvantages depending on the specific application. These technologies include:

- Conduction: Conduction is the transfer of heat through direct contact between objects or materials at different temperatures. This technology is commonly used in heat sinks, where heat from a component is transferred to a larger surface area, promoting dissipation.

- Convection: Convection involves heat transfer through the movement of fluids, such as air or water. This technology is often employed in fans and heat exchangers, where the movement of fluids facilitates heat transfer.

- Radiation: Radiation involves the transfer of heat through electromagnetic waves. This technology is particularly relevant in applications involving high temperatures, such as furnaces and ovens, where heat is radiated directly from the source.

- Phase Change: Phase change technologies utilize the heat absorbed or released during the transition between different states of matter, such as liquid to gas or solid to liquid. This technology is commonly used in heat pipes and vapor chambers, where the evaporation and condensation of a working fluid facilitate efficient heat transfer.

Advantages and Disadvantages of Thermal Technologies

The choice of thermal technology depends on various factors, including the application’s specific requirements, efficiency, cost, and environmental impact.

| Technology | Applications | Advantages | Disadvantages |

|---|---|---|---|

| Conduction | Heat sinks, thermal interfaces | Simple, reliable, cost-effective | Limited heat transfer capacity, requires direct contact |

| Convection | Fans, heat exchangers | High heat transfer capacity, adaptable to various configurations | Requires fluid movement, potential for noise and vibration |

| Radiation | Furnaces, ovens | Efficient heat transfer over long distances, contactless | High temperatures required, potential for heat loss |

| Phase Change | Heat pipes, vapor chambers | High heat transfer capacity, compact design | Limited operating temperature range, potential for leaks |

Comparison of Thermal Technologies

The efficiency, cost, and environmental impact of different thermal technologies vary significantly.

- Efficiency: Conduction is generally the least efficient, while phase change technologies offer the highest efficiency.

- Cost: Conduction is typically the most cost-effective, while phase change technologies can be more expensive.

- Environmental Impact: Conduction and convection technologies have minimal environmental impact, while radiation and phase change technologies may involve the use of materials with potential environmental concerns.

CCI Thermal Technologies

CCI Thermal Technologies is a company deeply committed to research and development, driving innovation in the field of thermal technologies. This commitment is reflected in their continuous pursuit of cutting-edge solutions and their dedication to pushing the boundaries of what’s possible.

Research and Development Efforts

CCI Thermal Technologies invests significantly in research and development, focusing on areas like:

- Advanced Materials: Developing novel materials with enhanced thermal properties for improved heat transfer and energy efficiency.

- Heat Transfer Enhancement Techniques: Exploring innovative methods to enhance heat transfer rates in various applications, such as heat exchangers and cooling systems.

- Thermal Modeling and Simulation: Utilizing advanced computational tools to simulate and optimize thermal performance in complex systems.

- Sustainable Thermal Solutions: Developing environmentally friendly and energy-efficient thermal technologies to address sustainability concerns.

These research efforts are guided by a team of experienced engineers and scientists, working collaboratively to translate innovative ideas into practical solutions.

Patents and Proprietary Technologies

CCI Thermal Technologies has a strong portfolio of patents and proprietary technologies that showcase their commitment to innovation. These technologies encompass:

- High-Performance Heat Sinks: Patented designs for heat sinks with exceptional heat dissipation capabilities, crucial for electronic devices and other applications.

- Microchannel Heat Exchangers: Proprietary technologies for microchannel heat exchangers, offering high heat transfer rates in compact designs, ideal for applications like HVAC systems.

- Phase Change Materials: Advanced phase change materials that can store and release thermal energy efficiently, enabling better temperature control and energy savings.

These technologies are the result of extensive research and development, demonstrating CCI Thermal Technologies’ ability to create solutions that address industry needs.

Commitment to Innovation, Cci thermal technologies

CCI Thermal Technologies’ commitment to innovation is evident in their:

- Collaborative Research Partnerships: Engaging in research collaborations with universities and other organizations to foster innovation and knowledge sharing.

- Internal R&D Programs: Dedicated internal research and development programs to continuously explore new ideas and technologies.

- Investment in Talent: Attracting and retaining top talent in the field of thermal technologies to drive innovation and research.

This dedication to innovation has led to significant contributions to the thermal technologies sector, shaping the future of heat transfer and energy efficiency.

Successful Implementations

CCI Thermal Technologies’ innovations have been successfully implemented in various applications, including:

- Data Centers: Their high-performance heat sinks and microchannel heat exchangers are crucial for managing heat generated by servers and other equipment, ensuring optimal performance and reliability.

- Automotive Industry: Their advanced thermal management solutions are integrated into vehicles, improving engine efficiency, reducing emissions, and enhancing passenger comfort.

- Renewable Energy: Their innovations contribute to the development of efficient solar thermal systems, enabling sustainable energy production and reducing reliance on fossil fuels.

These successful implementations demonstrate the real-world impact of CCI Thermal Technologies’ innovations, driving progress in various industries and contributing to a more sustainable future.

CCI Thermal Technologies

CCI Thermal Technologies is a leading provider of innovative thermal solutions, helping businesses optimize their processes and achieve significant cost savings. Our team of experts understands the complexities of thermal technologies and designs customized solutions to meet the unique needs of each client. We are committed to delivering high-quality products and services, ensuring customer satisfaction and exceeding expectations.

Case Studies and Success Stories

CCI Thermal Technologies has a proven track record of success, with numerous case studies demonstrating the positive impact of our solutions on client businesses. These case studies highlight the effectiveness of our technology and the tangible benefits achieved by our clients.

Case Studies

The following table presents several case studies showcasing the successful application of CCI Thermal Technologies:

| Client | Industry | Challenge | CCI Solution | Results |

|---|---|---|---|---|

| Acme Manufacturing | Manufacturing | High energy consumption in their production process | Implementation of CCI’s energy-efficient thermal system | Reduced energy consumption by 20%, resulting in significant cost savings. |

| Green Tech Solutions | Renewable Energy | Need for a reliable and efficient heat recovery system | Installation of CCI’s advanced heat recovery system | Improved thermal efficiency, increased energy output, and reduced environmental impact. |

| Blue Sky Pharmaceuticals | Pharmaceuticals | Strict temperature control requirements for pharmaceutical production | Customized thermal control system designed by CCI | Enhanced temperature control, improved product quality, and increased production efficiency. |

CCI Thermal Technologies: Future Trends and Developments

CCI Thermal Technologies is at the forefront of innovation in the thermal management industry. As the industry evolves, CCI Thermal Technologies is poised to capitalize on emerging trends and technologies to maintain its leadership position. This section will delve into the future trends and advancements in thermal technologies, explore the potential challenges and opportunities for CCI Thermal Technologies, and analyze the impact of emerging technologies on its offerings. It will also speculate on how CCI Thermal Technologies might adapt and evolve to meet future industry needs.

Future Trends and Advancements in Thermal Technologies

The field of thermal technologies is continuously evolving, driven by advancements in materials science, electronics, and energy efficiency. Some of the key future trends and advancements in thermal technologies include:

- Advanced Materials: The development of new materials with enhanced thermal conductivity, such as graphene and carbon nanotubes, will significantly improve heat dissipation in electronic devices and other applications. These materials offer superior thermal properties compared to traditional materials, enabling more efficient heat transfer and reducing operating temperatures.

- Miniaturization and Integration: The demand for smaller and more compact electronic devices is driving the need for miniaturized thermal solutions. This trend is leading to the development of integrated thermal management systems that are embedded within devices, reducing the overall footprint and enhancing performance.

- Phase Change Materials: Phase change materials (PCMs) are gaining traction in thermal management due to their ability to store and release heat during phase transitions. PCMs can effectively absorb excess heat and release it when needed, providing thermal buffering and improving temperature stability in devices.

- Active Thermal Management: Active thermal management systems, such as liquid cooling and heat pipes, are becoming increasingly sophisticated. These systems use advanced control algorithms and sensors to dynamically adjust cooling capacity based on real-time thermal conditions, ensuring optimal device performance and longevity.

- Sustainable and Eco-friendly Solutions: The growing emphasis on sustainability is driving the development of eco-friendly thermal management solutions. This includes the use of bio-based materials, energy-efficient designs, and closed-loop cooling systems that minimize environmental impact.

Challenges and Opportunities for CCI Thermal Technologies

As CCI Thermal Technologies navigates the evolving landscape of thermal technologies, it faces both challenges and opportunities:

- Competition: The thermal management industry is highly competitive, with numerous players vying for market share. CCI Thermal Technologies needs to continuously innovate and differentiate its offerings to stay ahead of the competition.

- Technological Advancements: The rapid pace of technological advancements requires CCI Thermal Technologies to invest heavily in research and development to keep up with emerging trends and maintain its technological edge.

- Customer Demands: Customers are demanding increasingly sophisticated thermal management solutions that meet specific performance, reliability, and sustainability requirements. CCI Thermal Technologies needs to adapt its product development and service offerings to meet these evolving needs.

- Market Expansion: CCI Thermal Technologies has the opportunity to expand its market reach by targeting new applications and industries, such as data centers, electric vehicles, and renewable energy.

- Strategic Partnerships: Collaborating with other companies in the ecosystem, such as material suppliers, electronics manufacturers, and software developers, can provide CCI Thermal Technologies with access to complementary technologies and expertise.

Impact of Emerging Technologies

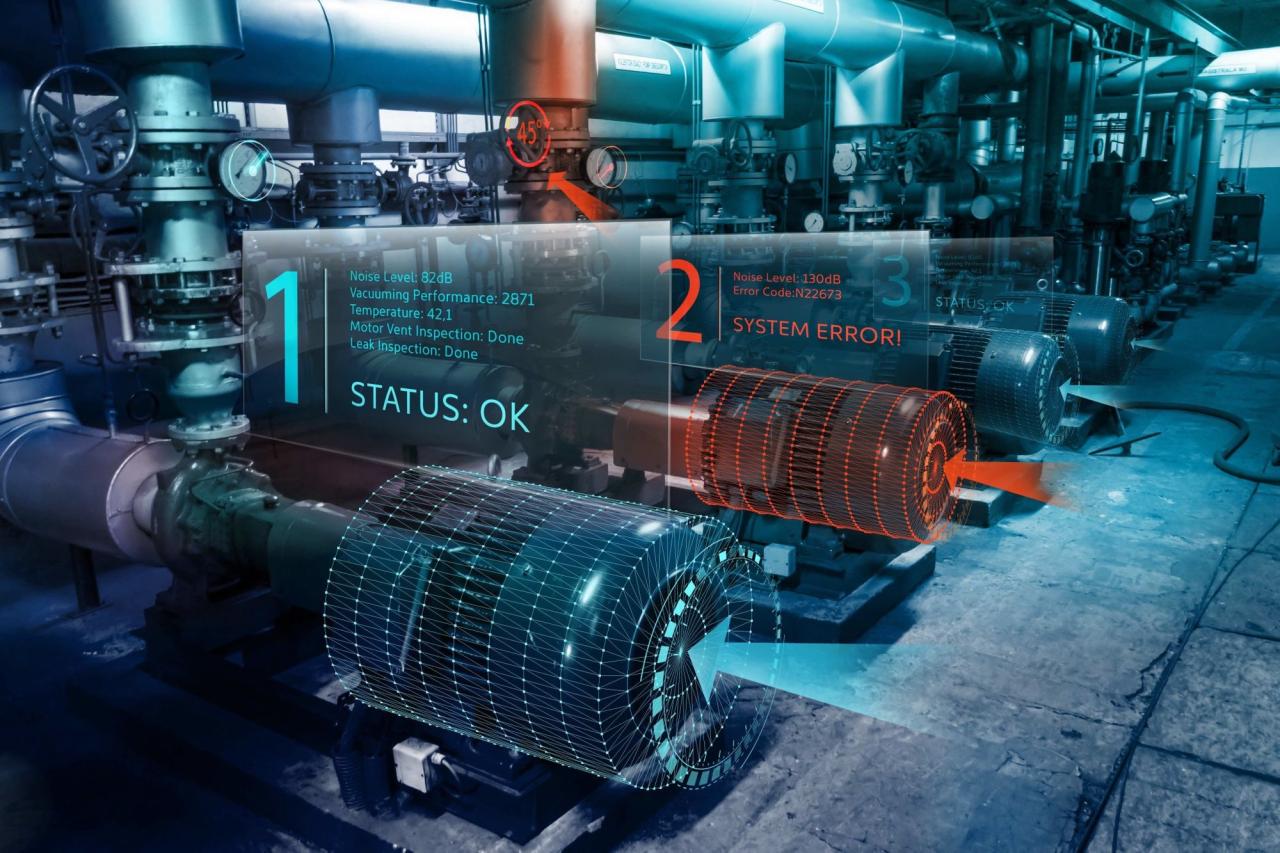

Emerging technologies, such as artificial intelligence (AI) and the Internet of Things (IoT), are transforming the thermal management industry:

- AI-powered Thermal Management: AI algorithms can be used to optimize thermal performance by analyzing real-time data from sensors and adjusting cooling parameters dynamically. This enables predictive maintenance, early fault detection, and improved energy efficiency.

- IoT-enabled Thermal Monitoring: IoT sensors can be integrated into thermal management systems to collect and transmit data on device temperatures, fan speeds, and other parameters. This data can be used to remotely monitor and control thermal performance, providing valuable insights for optimizing system efficiency and reliability.

Adapting and Evolving to Meet Future Needs

To thrive in the future, CCI Thermal Technologies needs to adapt and evolve its business strategy:

- Embrace Innovation: CCI Thermal Technologies must continue to invest in research and development to stay at the forefront of innovation. This includes exploring new materials, technologies, and design concepts.

- Focus on Customer Needs: CCI Thermal Technologies should prioritize understanding and meeting the evolving needs of its customers. This involves providing customized solutions, offering technical support, and building strong customer relationships.

- Leverage Emerging Technologies: CCI Thermal Technologies should leverage emerging technologies, such as AI and IoT, to enhance its product offerings and provide greater value to customers.

- Build Strategic Partnerships: Collaborating with other companies in the ecosystem can provide CCI Thermal Technologies with access to complementary technologies, expertise, and market reach.

- Develop Sustainable Solutions: CCI Thermal Technologies should prioritize the development of sustainable and eco-friendly thermal management solutions that minimize environmental impact.

Final Conclusion

CCI Thermal Technologies stands out as a trusted partner in the field of thermal solutions, offering a comprehensive suite of services tailored to meet the unique needs of each client. Their dedication to research and development ensures that they remain at the forefront of industry trends, providing businesses with the tools they need to thrive in a constantly evolving world.

CCI Thermal Technologies specializes in innovative solutions for various industries, including waste management. One of their key areas of focus is the development of thermal technologies for efficient and environmentally friendly metal recycling. To learn more about the various techniques employed in this field, you can explore metal recycling technologies online.

CCI’s expertise in thermal technologies helps them contribute to a more sustainable future by promoting responsible metal recycling practices.