Camstar Technology: Streamlining Manufacturing Operations

Camstar Technology, a leading manufacturing execution system (MES), revolutionizes the way businesses manage and optimize their production processes. From its inception, Camstar has evolved to meet the ever-changing needs of […]

Camstar Technology, a leading manufacturing execution system (MES), revolutionizes the way businesses manage and optimize their production processes. From its inception, Camstar has evolved to meet the ever-changing needs of industries like manufacturing, aerospace, and beyond, offering a comprehensive solution for streamlining operations, enhancing efficiency, and improving overall productivity.

At its core, Camstar Technology empowers organizations to gain real-time visibility into their production data, enabling them to make informed decisions, identify bottlenecks, and optimize resource allocation. Its robust functionalities, including production scheduling, quality control, and inventory management, empower businesses to achieve operational excellence and deliver exceptional results.

Benefits of Implementing Camstar Technology

Camstar Technology offers a comprehensive suite of solutions designed to optimize manufacturing processes and enhance overall business performance. By leveraging its advanced capabilities, businesses can achieve significant improvements in efficiency, cost reduction, and decision-making.

Streamlined Operations and Cost Reduction

Camstar Technology empowers businesses to streamline their operations and reduce costs by automating key processes, eliminating manual tasks, and optimizing resource allocation.

- Automated Process Management: Camstar’s automated process management capabilities eliminate manual data entry, reduce errors, and ensure consistency across operations. This streamlines workflows, reduces bottlenecks, and improves overall efficiency.

- Inventory Optimization: Camstar’s inventory management module helps businesses track inventory levels in real-time, predict demand, and optimize stock levels. This minimizes inventory holding costs, reduces waste, and ensures timely delivery of products.

- Production Scheduling and Optimization: Camstar’s production scheduling and optimization features enable businesses to plan and schedule production runs efficiently, maximizing resource utilization and minimizing downtime. This leads to improved production throughput and reduced costs.

Enhanced Data Visibility and Analytics

Camstar Technology provides real-time data visibility and powerful analytics capabilities, enabling businesses to gain actionable insights into their operations and make informed decisions.

- Real-time Data Monitoring: Camstar’s real-time data monitoring capabilities provide instant access to key performance indicators (KPIs) and operational metrics, allowing businesses to track progress, identify potential issues, and take corrective action promptly.

- Advanced Analytics and Reporting: Camstar’s advanced analytics and reporting features enable businesses to analyze data trends, identify areas for improvement, and make data-driven decisions. This helps optimize processes, improve quality, and enhance overall performance.

- Predictive Analytics: Camstar’s predictive analytics capabilities leverage historical data to forecast future trends, anticipate potential problems, and optimize resource allocation. This allows businesses to proactively address challenges and avoid costly disruptions.

Increased Agility and Responsiveness

Camstar Technology enables businesses to become more agile and responsive to changing market conditions and customer demands.

- Rapid Response to Customer Orders: Camstar’s automated order management and fulfillment processes enable businesses to respond to customer orders quickly and efficiently, improving customer satisfaction and loyalty.

- Flexible Manufacturing Capabilities: Camstar’s flexible manufacturing capabilities allow businesses to adapt quickly to changing production requirements, such as new product introductions or changes in customer demand.

- Improved Supply Chain Visibility: Camstar’s supply chain visibility features provide real-time insights into the movement of materials and products throughout the supply chain, enabling businesses to respond quickly to disruptions and optimize logistics.

Camstar Technology Architecture and Integration

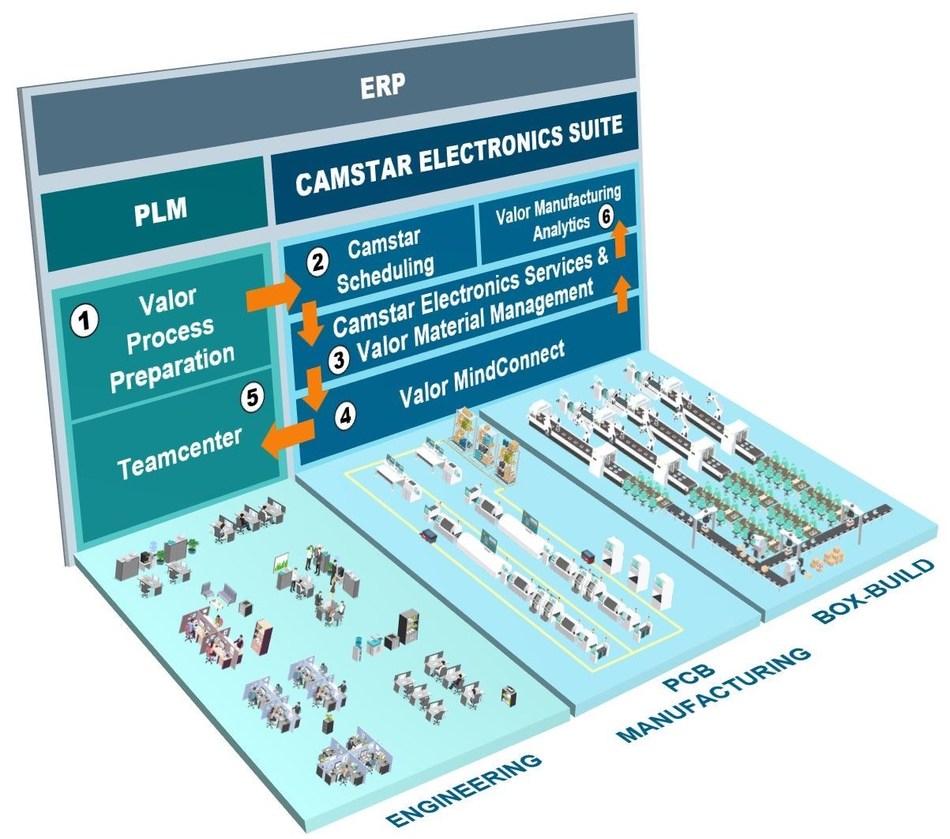

Camstar Technology is designed with a modular and scalable architecture that enables seamless integration with various systems and platforms within a manufacturing environment. This robust architecture ensures flexibility and adaptability, allowing businesses to leverage Camstar’s capabilities effectively while maintaining existing workflows and data.

Architecture of Camstar Technology

Camstar Technology’s architecture is built upon a layered approach, incorporating key components that work together to provide a comprehensive manufacturing execution system (MES) solution. The core components include:

- Manufacturing Execution Engine: The heart of Camstar Technology, responsible for managing and orchestrating all manufacturing operations, including scheduling, production tracking, and quality control.

- Data Repository: A central database that stores all manufacturing data, including product information, process parameters, and production history. This ensures data consistency and accessibility across the system.

- User Interface: A user-friendly interface that provides access to all functionalities of Camstar Technology, enabling operators, managers, and engineers to monitor and manage production processes.

- Integration Layer: This layer facilitates communication and data exchange with other systems and applications, enabling seamless integration with existing enterprise resource planning (ERP), product lifecycle management (PLM), and other business systems.

Integration Capabilities of Camstar Technology

Camstar Technology offers extensive integration capabilities, allowing businesses to connect their manufacturing processes with other systems and platforms. This integration is achieved through various mechanisms, including:

- Pre-built Connectors: Camstar provides pre-built connectors for popular ERP and PLM systems, simplifying the integration process and reducing development time.

- Open APIs: Camstar’s open APIs allow developers to create custom integrations with specific applications or systems, providing flexibility and tailored solutions.

- Middleware: Camstar Technology can leverage middleware solutions to facilitate data exchange between different systems, ensuring smooth data flow and synchronization.

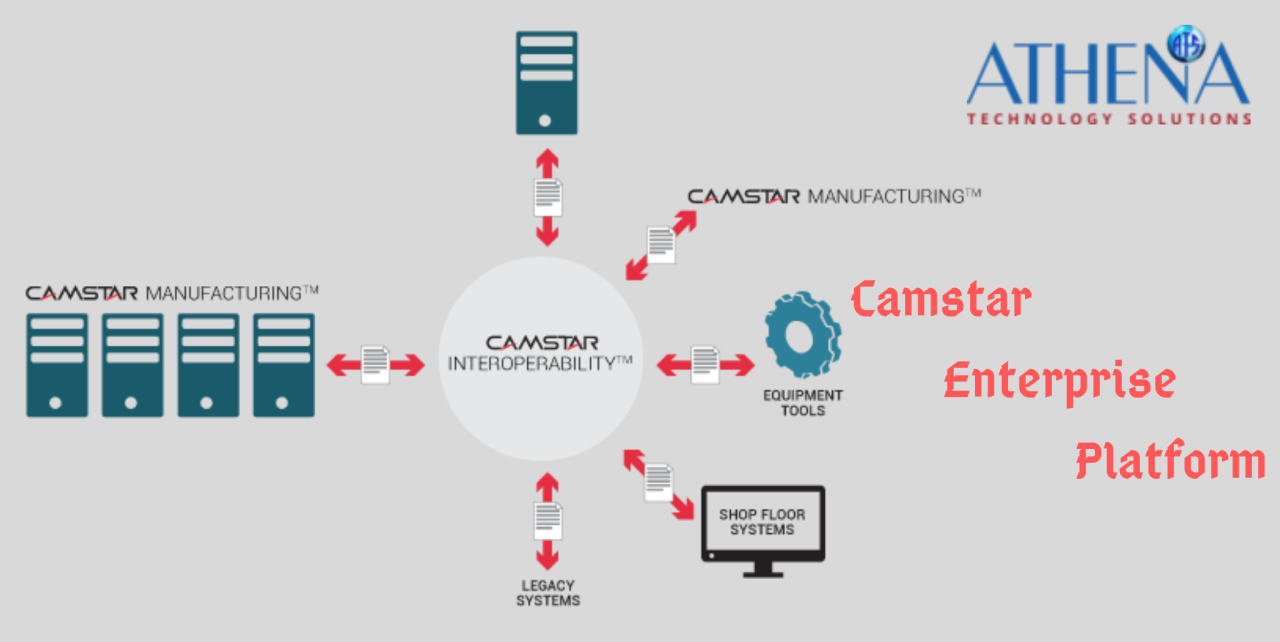

Role of APIs and Middleware

APIs (Application Programming Interfaces) and middleware play crucial roles in enabling seamless integration between Camstar Technology and other applications. APIs act as communication channels, allowing different systems to interact and exchange data in a standardized format. Middleware, on the other hand, acts as a bridge between disparate systems, facilitating data translation and synchronization.

For example, Camstar can utilize APIs to connect with an ERP system to retrieve order information and production schedules. Middleware can then translate this information into a format that Camstar’s Manufacturing Execution Engine can understand, enabling seamless execution of production plans.

Security Measures in Camstar Technology

Camstar Technology incorporates robust security measures to protect sensitive manufacturing data. These measures include:

- Role-based Access Control: Different users have access to specific functionalities and data based on their roles and responsibilities, ensuring data security and integrity.

- Data Encryption: Sensitive data is encrypted both in transit and at rest, protecting it from unauthorized access and data breaches.

- Regular Security Audits: Camstar undergoes regular security audits to identify and address potential vulnerabilities, ensuring continuous security improvement.

Future Trends and Innovations in Camstar Technology

Camstar Technology, a leading manufacturing execution system (MES) platform, is continuously evolving to meet the demands of a rapidly changing manufacturing landscape. This evolution is driven by emerging trends and advancements in the field of MES, the integration of artificial intelligence (AI) and machine learning (ML), and the influence of Industry 4.0 and the Industrial Internet of Things (IIoT). This section explores the potential of these trends to enhance Camstar Technology’s capabilities and shape its future direction.

Impact of AI and Machine Learning

The integration of AI and ML is transforming the manufacturing industry, and Camstar Technology is poised to leverage these technologies to enhance its capabilities. AI and ML can be used to analyze large volumes of data generated by manufacturing processes, identify patterns, and optimize production operations. This can lead to improvements in:

- Predictive Maintenance: AI can analyze sensor data from machines to predict potential failures, allowing for proactive maintenance and minimizing downtime. This can be particularly beneficial for critical equipment, reducing unplanned outages and ensuring production continuity.

- Quality Control: AI-powered vision systems can inspect products for defects, ensuring high-quality output and reducing the need for manual inspection. This can improve efficiency and reduce human error in quality control processes.

- Process Optimization: ML algorithms can analyze historical data and real-time production information to identify areas for improvement in production processes. This can lead to increased efficiency, reduced waste, and improved overall productivity.

Industry 4.0 and the Industrial Internet of Things

Industry 4.0 and the IIoT are driving a shift towards interconnected and intelligent manufacturing systems. Camstar Technology is well-positioned to play a key role in this transformation by providing a platform for integrating and managing data from various sources.

- Real-Time Data Visibility: IIoT enables real-time data collection from sensors, machines, and other devices throughout the manufacturing process. Camstar Technology can leverage this data to provide real-time visibility into production operations, allowing for better decision-making and improved operational efficiency.

- Smart Factories: By integrating with IIoT devices, Camstar Technology can contribute to the development of smart factories, where production processes are automated and optimized through data analysis and intelligent decision-making. This can lead to increased productivity, improved quality, and reduced costs.

- Cloud-Based Solutions: Camstar Technology is moving towards cloud-based solutions, enabling access to data and functionality from anywhere, anytime. This enhances scalability, flexibility, and accessibility for manufacturers of all sizes.

Future Directions and Innovations

Camstar Technology is continuously evolving to address the evolving needs of the manufacturing industry. Some key future directions and innovations include:

- Advanced Analytics: Camstar Technology will continue to invest in advanced analytics capabilities to provide deeper insights into production data. This will enable manufacturers to make more informed decisions and optimize their operations.

- Cybersecurity: As manufacturing systems become increasingly interconnected, cybersecurity is becoming increasingly critical. Camstar Technology will continue to invest in robust cybersecurity measures to protect its platform and the data it manages.

- Digital Twin Technology: Camstar Technology is exploring the potential of digital twin technology, which creates virtual representations of physical assets. This can be used to simulate and optimize production processes, reducing the need for physical prototypes and accelerating time-to-market.

Final Wrap-Up

Camstar Technology stands as a testament to the transformative power of technology in the manufacturing landscape. By seamlessly integrating with existing systems and embracing emerging trends like AI and Industry 4.0, Camstar empowers businesses to embrace digital transformation, unlock new levels of efficiency, and stay ahead of the curve in an increasingly competitive market.

Camstar technology is a powerful tool for streamlining manufacturing processes and improving efficiency. It’s an exciting field that’s constantly evolving, and we’re seeing more and more individuals dedicated to pushing the boundaries of what’s possible. If you’re passionate about using technology to create a better world, consider applying for the a better world spirituality and technology advancement scholarship.

This scholarship supports individuals who are exploring the intersection of technology and spirituality, which is a vital area for the future of Camstar technology.