Camstar Technology: Empowering Manufacturing Excellence

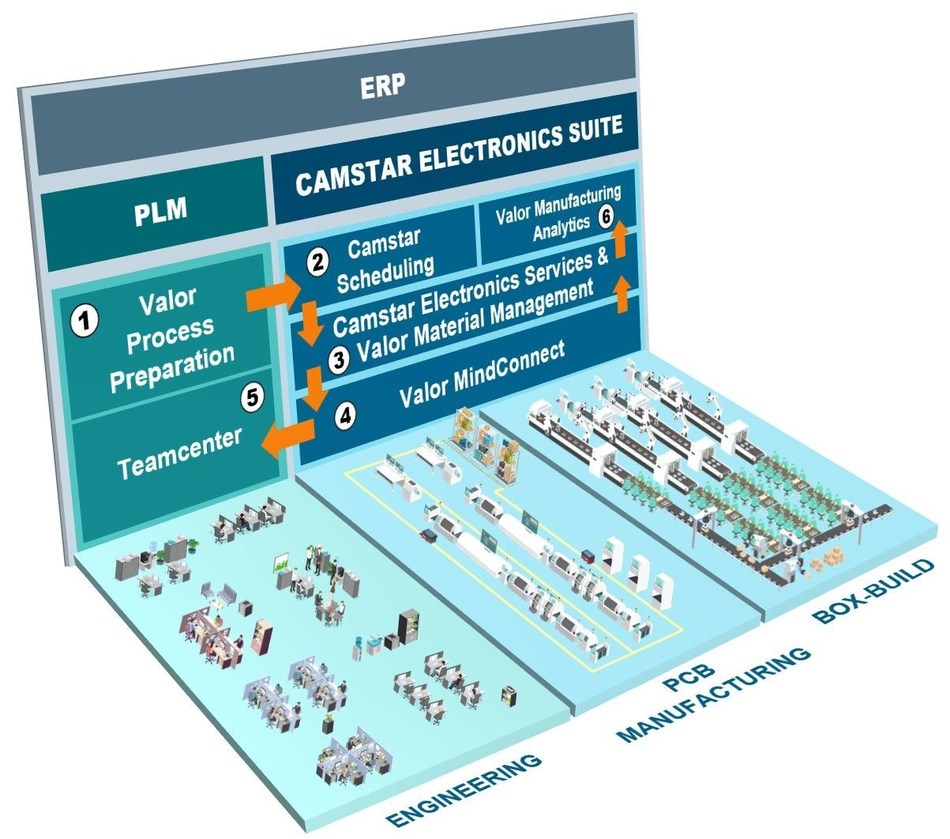

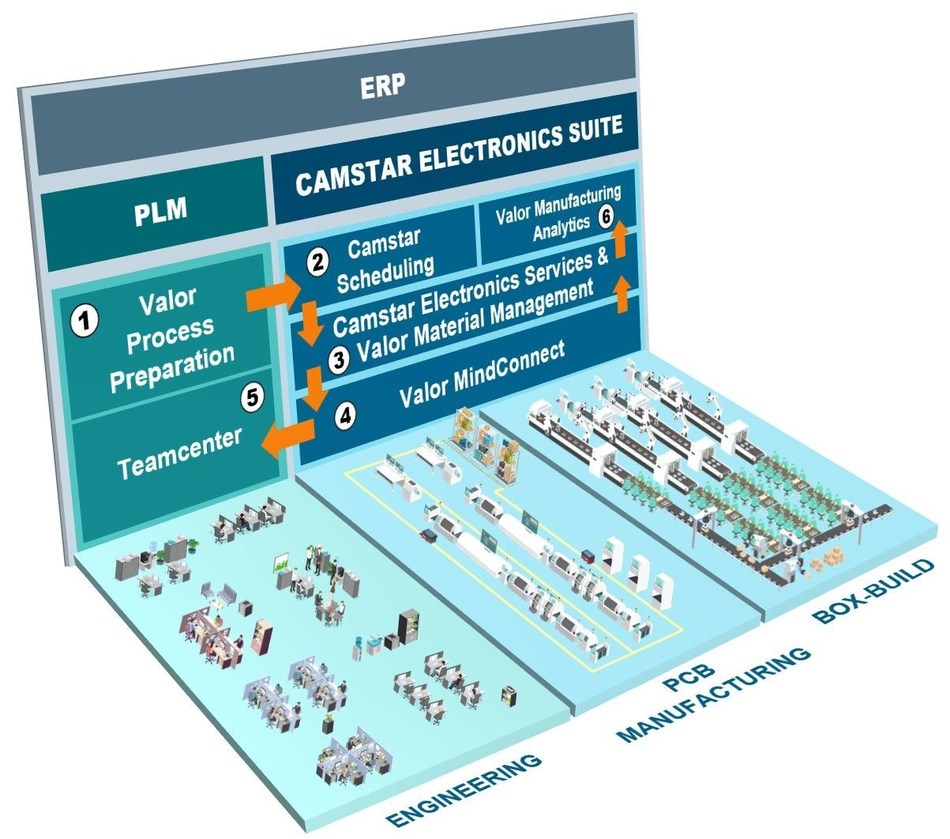

Camstar Technology is a powerful suite of manufacturing execution system (MES) solutions designed to optimize production processes, enhance efficiency, and drive innovation across various industries. Its roots lie in the […]

Camstar Technology is a powerful suite of manufacturing execution system (MES) solutions designed to optimize production processes, enhance efficiency, and drive innovation across various industries. Its roots lie in the early days of manufacturing software, with Camstar evolving over the years to become a leading provider of comprehensive solutions that cater to the complex demands of modern manufacturing environments.

From managing production schedules and tracking materials to controlling quality and ensuring regulatory compliance, Camstar empowers businesses to achieve operational excellence by streamlining workflows, improving data visibility, and facilitating real-time decision-making. This technology has found its place in a wide range of industries, including automotive, aerospace, electronics, pharmaceuticals, and more, helping organizations to overcome challenges and unlock new possibilities in their manufacturing operations.

Applications and Use Cases

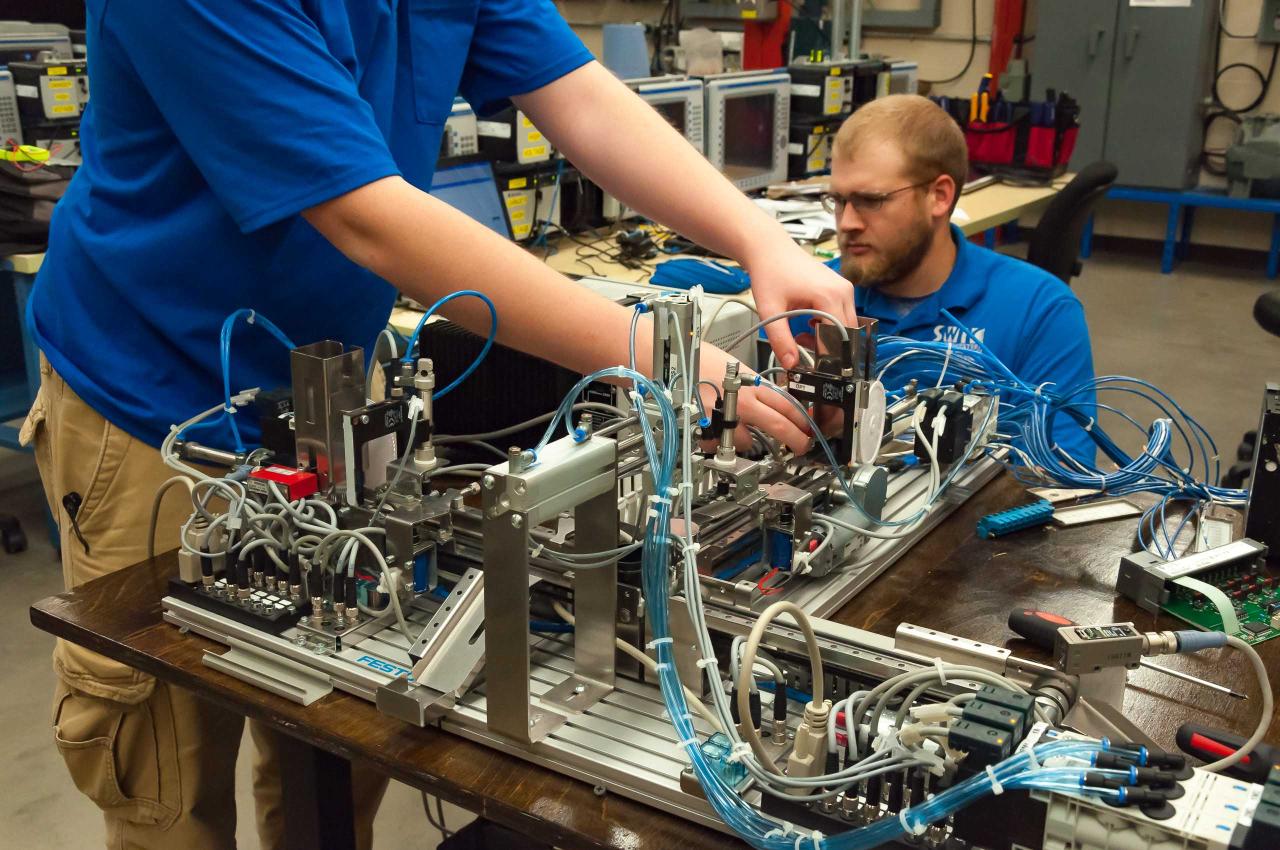

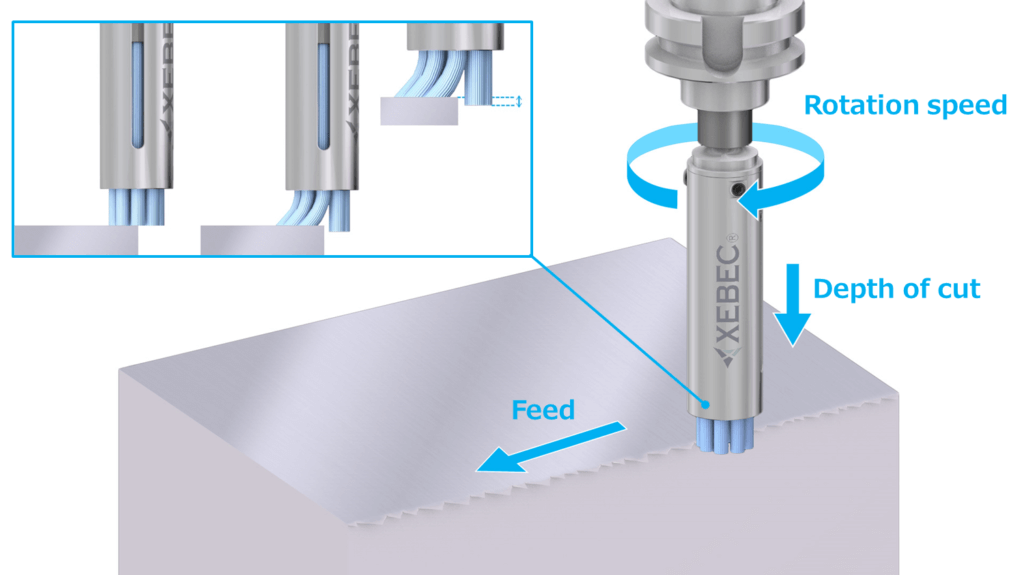

Camstar technology finds extensive application across various industries, streamlining operations and enhancing efficiency. Its comprehensive suite of tools empowers businesses to optimize their manufacturing processes, from planning and scheduling to execution and quality control.

Camstar’s versatility allows it to adapt to diverse business needs, making it a valuable asset for companies seeking to improve their operational efficiency and achieve greater profitability.

Industry-Specific Applications, Camstar technology

Camstar’s application extends to numerous industries, each with its unique set of challenges and requirements. Here’s a glimpse into some of the industries where Camstar is making a significant impact:

- Aerospace and Defense: Camstar plays a vital role in managing complex manufacturing processes, ensuring compliance with stringent quality standards and regulations. Its advanced features help track materials, manage inventory, and optimize production schedules, ensuring timely delivery of critical components for aerospace and defense projects.

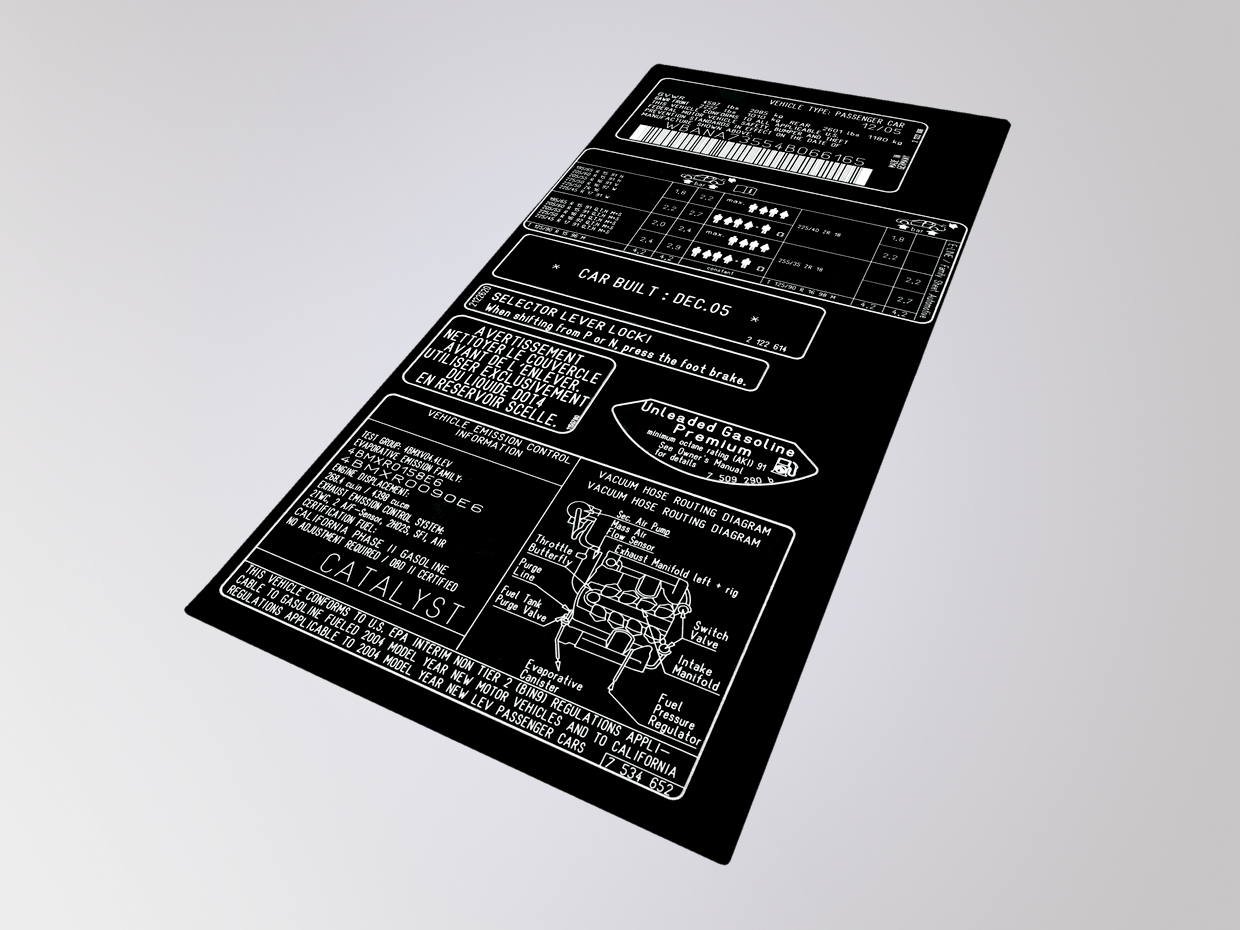

- Automotive: The automotive industry relies heavily on efficient manufacturing processes to meet high production volumes and stringent quality requirements. Camstar empowers automotive manufacturers to manage production lines, track parts, and monitor quality, ultimately contributing to increased productivity and reduced production costs.

- Electronics: The electronics industry demands precision and speed in manufacturing, with rapid product cycles and constant innovation. Camstar helps electronics manufacturers manage complex assembly processes, track components, and optimize production flows, enabling them to meet the demanding requirements of this fast-paced industry.

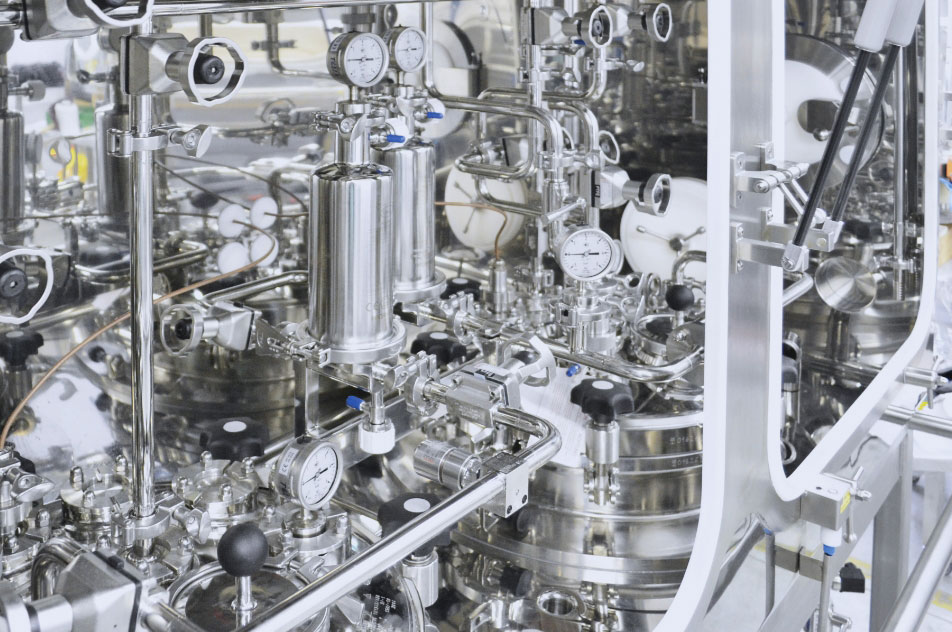

- Pharmaceuticals: The pharmaceutical industry operates under strict regulations and requires meticulous attention to quality control. Camstar’s capabilities in managing batch processes, tracking materials, and ensuring compliance with regulatory requirements make it an invaluable tool for pharmaceutical manufacturers.

- Food and Beverage: The food and beverage industry demands efficient production processes and stringent quality controls to ensure product safety and meet consumer expectations. Camstar helps food and beverage manufacturers manage production lines, track ingredients, and monitor quality, contributing to improved efficiency and compliance with safety regulations.

Use Cases in Different Industries

| Industry | Use Case | Description |

|—|—|—|

| Aerospace & Defense | Production Planning and Scheduling | Camstar enables aerospace manufacturers to optimize production schedules, manage complex supply chains, and ensure timely delivery of critical components for aircraft and defense projects. |

| Automotive | Manufacturing Execution System (MES) | Camstar provides real-time visibility into production processes, allowing automotive manufacturers to track production progress, manage work orders, and monitor quality, leading to increased efficiency and reduced production costs. |

| Electronics | Quality Management System (QMS) | Camstar helps electronics manufacturers manage quality processes, track defects, and implement corrective actions, ensuring the production of high-quality electronic devices. |

| Pharmaceuticals | Batch Process Management | Camstar enables pharmaceutical manufacturers to manage complex batch processes, track materials, and ensure compliance with regulatory requirements, ensuring the production of safe and effective pharmaceuticals. |

| Food & Beverage | Product Traceability | Camstar provides comprehensive traceability capabilities, allowing food and beverage manufacturers to track ingredients, products, and production processes, ensuring product safety and compliance with food safety regulations. |

Real-World Scenarios

Camstar is widely utilized in real-world scenarios across various industries, demonstrating its effectiveness in addressing diverse operational challenges.

For instance, a leading aerospace manufacturer leveraged Camstar to optimize its production planning and scheduling, reducing lead times and improving overall efficiency. By implementing Camstar, the manufacturer gained real-time visibility into production processes, enabling them to identify bottlenecks and optimize resource allocation.

In the automotive industry, a major automaker implemented Camstar as its Manufacturing Execution System (MES), streamlining production processes and enhancing quality control. Camstar’s real-time data collection and analysis capabilities enabled the automaker to identify and address production issues proactively, resulting in improved productivity and reduced downtime.

In the pharmaceutical industry, a global pharmaceutical company implemented Camstar to manage its batch processes and ensure compliance with regulatory requirements. Camstar’s comprehensive batch management capabilities enabled the company to track materials, manage production processes, and ensure the production of safe and effective pharmaceuticals, meeting the stringent regulations of the industry.

Implementation and Deployment: Camstar Technology

Implementing Camstar technology involves a systematic approach to ensure successful integration into your organization’s operations. This process encompasses various stages, from planning and design to testing and deployment.

Deployment Best Practices

Deploying Camstar effectively requires careful consideration of your specific environment and needs. Here are some best practices to guide the implementation:

- Define Clear Objectives: Clearly define your goals for implementing Camstar. What problems are you aiming to solve? What improvements do you expect to achieve? This will help you prioritize features and ensure that the implementation aligns with your overall business strategy.

- Conduct a Thorough Needs Assessment: Understand your current processes and identify areas where Camstar can add value. Analyze your data, workflows, and existing systems to determine the best way to integrate Camstar seamlessly.

- Pilot Implementation: Start with a pilot project in a specific department or area of your organization. This allows you to test the system, gather feedback, and refine your implementation strategy before rolling it out to the entire organization.

- User Training and Support: Provide comprehensive training for users to ensure they are comfortable and proficient in using Camstar. Offer ongoing support and resources to address any questions or issues that arise.

- Data Migration and Integration: Carefully plan the migration of existing data into Camstar. Ensure that data is accurate, complete, and consistent. Consider using a data migration tool to streamline the process.

- Change Management: Implement change management strategies to minimize disruption and ensure user adoption. Communicate the benefits of Camstar and provide ongoing support to address concerns and promote positive change.

Case Studies of Successful Implementations

- Example 1: Manufacturing Company – A large manufacturing company implemented Camstar to improve its production planning and scheduling. The company achieved significant improvements in efficiency and productivity by optimizing its production processes and reducing downtime. The implementation involved careful planning, thorough training, and ongoing support to ensure successful adoption by employees.

- Example 2: Pharmaceutical Company – A pharmaceutical company implemented Camstar to enhance its quality management system. The implementation helped the company to improve its product quality, reduce defects, and comply with regulatory requirements. The company’s success was attributed to its focus on data integrity, process automation, and continuous improvement.

Final Summary

Camstar Technology stands as a testament to the transformative power of software in the manufacturing landscape. By embracing a holistic approach that encompasses planning, execution, and analysis, Camstar empowers businesses to achieve greater agility, efficiency, and profitability. As manufacturing continues to evolve, Camstar remains at the forefront of innovation, adapting to emerging trends and technologies to ensure its solutions remain relevant and effective for years to come.

Camstar technology is a powerful tool for managing manufacturing processes, offering features like scheduling, production tracking, and quality control. For businesses seeking to optimize their supply chain, integrating with external systems like rn technologies can be a valuable step. By leveraging these complementary technologies, businesses can achieve greater efficiency and streamline their operations.