CA Technologies Air Assisted Airless: A Spraying Revolution

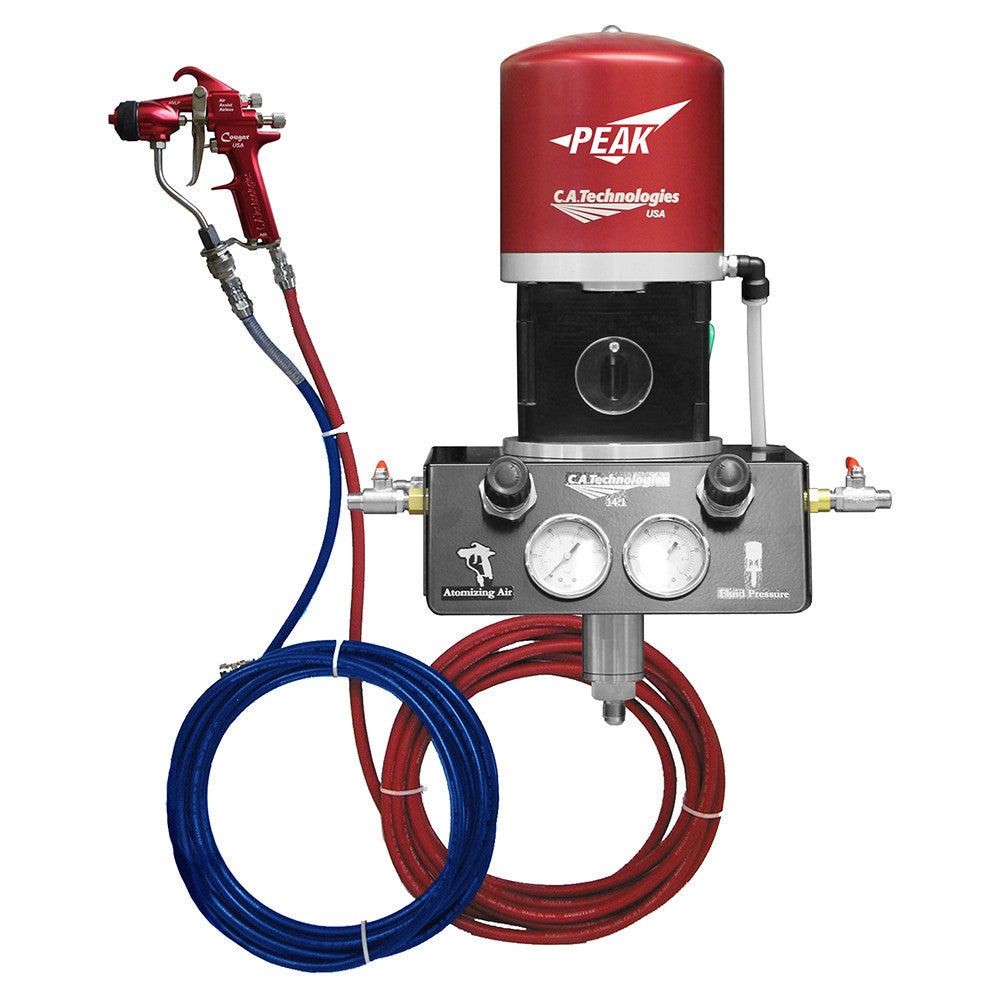

CA Technologies air assisted airless, a game-changer in the world of spraying, combines the efficiency of airless technology with the precision of air-assisted systems. This innovative approach offers a unique […]

CA Technologies air assisted airless, a game-changer in the world of spraying, combines the efficiency of airless technology with the precision of air-assisted systems. This innovative approach offers a unique blend of power and control, delivering superior results across a wide range of applications.

The technology employs a specialized air-assisted nozzle that atomizes the material with compressed air, ensuring a fine and even spray pattern. This results in less overspray, reduced material waste, and improved finish quality. The air assisted airless system also boasts enhanced transfer efficiency, allowing for greater material savings and reduced environmental impact.

Considerations for Implementing CA Technologies Air Assisted Airless

Implementing CA Technologies Air Assisted Airless technology can significantly enhance your painting processes, offering improved efficiency, reduced material waste, and a higher quality finish. However, careful consideration of several factors is crucial for a successful implementation.

Factors to Consider Before Implementation, Ca technologies air assisted airless

Before integrating CA Technologies Air Assisted Airless technology into your operations, it’s essential to assess various factors that can influence the success of your implementation. These factors include:

- Project Scope and Requirements: Determine the specific needs and objectives of your project. This includes the type of coating being applied, the surface area to be covered, the desired finish quality, and any environmental considerations. This assessment helps in selecting the right equipment and materials for your project.

- Existing Infrastructure and Equipment: Evaluate your current infrastructure, including air compressors, paint circulation systems, and existing spray equipment. Compatibility with the new technology is crucial for a smooth transition. Consider if upgrades or modifications are required to accommodate the new system.

- Training and Operator Skill: Air Assisted Airless technology requires specialized training for operators to ensure safe and efficient operation. Evaluate the skill level of your existing workforce and plan for appropriate training programs to ensure proper handling and maintenance of the equipment.

- Material Compatibility: Not all coatings are compatible with Air Assisted Airless technology. Research and ensure that the coatings you intend to use are suitable for the specific system. Consider factors like viscosity, solids content, and potential for clogging.

- Cost-Benefit Analysis: Conduct a thorough cost-benefit analysis to determine the financial viability of implementing Air Assisted Airless technology. Consider the initial investment in equipment, training, and any potential modifications to your infrastructure. Compare these costs with the potential benefits, such as reduced material waste, increased productivity, and improved finish quality.

Potential Challenges and Solutions

While Air Assisted Airless technology offers numerous benefits, potential challenges might arise during implementation. Understanding these challenges and having solutions in place can ensure a smooth transition and successful integration:

- Training and Operator Skill: Lack of proper training can lead to inefficient operation, material waste, and potential safety hazards. Invest in comprehensive training programs for your operators, covering equipment operation, safety procedures, and troubleshooting techniques. This ensures a skilled workforce capable of maximizing the benefits of the technology.

- Material Compatibility: Using incompatible coatings can result in clogging, poor finish quality, and equipment damage. Conduct thorough testing and research to ensure that your chosen coatings are compatible with the Air Assisted Airless system. Consult with the coating manufacturer and the equipment supplier for recommendations and guidance.

- Maintenance and Troubleshooting: Regular maintenance and prompt troubleshooting are crucial for maintaining the efficiency and longevity of the equipment. Develop a comprehensive maintenance schedule and train operators to identify and resolve common issues. Consider establishing a service contract with the equipment supplier for regular maintenance and technical support.

- Initial Setup and Integration: Integrating the new technology into your existing infrastructure and processes might require adjustments and modifications. Plan for a smooth integration process, including system configuration, calibration, and testing. Ensure that the equipment is properly installed and connected to your existing infrastructure.

Recommendations for Successful Implementation

To ensure a successful implementation of CA Technologies Air Assisted Airless technology, consider the following recommendations:

- Thorough Planning and Preparation: Invest time in planning and preparation before implementation. This includes a comprehensive needs assessment, cost-benefit analysis, and identification of potential challenges. Develop a detailed implementation plan outlining the steps involved, timelines, and resource allocation.

- Comprehensive Training: Prioritize training for your operators. Provide comprehensive training programs covering equipment operation, safety procedures, troubleshooting techniques, and material compatibility. Consider hands-on training sessions to familiarize operators with the equipment and its functionalities.

- Regular Maintenance and Monitoring: Establish a regular maintenance schedule for the equipment. Train operators to perform routine maintenance tasks and identify potential issues. Implement a system for monitoring the equipment’s performance and addressing any problems promptly.

- Continuous Improvement: Continuously evaluate the performance of the Air Assisted Airless system and identify areas for improvement. Gather feedback from operators and monitor key performance indicators (KPIs) such as material usage, productivity, and finish quality. Implement changes and adjustments as needed to optimize the system’s efficiency and effectiveness.

Final Review

CA Technologies air assisted airless technology represents a significant advancement in spraying technology. Its unique combination of power, precision, and efficiency offers numerous benefits for both applicators and end users. With its adaptability to various industries and applications, this technology is poised to become the industry standard for high-quality, cost-effective, and environmentally conscious spraying solutions.

CA Technologies’ air-assisted airless technology is a powerful tool for achieving precise and efficient application of coatings. This technology, often used in conjunction with adlogic technology for advanced control and automation, ensures optimal performance in various industrial applications. The combination of these technologies allows for seamless integration and superior results, making CA Technologies’ air-assisted airless systems a leading choice in the industry.