Brewing Technology: From Tradition to Innovation

Brewing technology sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset. The art […]

Brewing technology sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset. The art of brewing, a practice dating back millennia, has undergone a remarkable evolution, driven by human ingenuity and a relentless pursuit of quality. This journey through time explores the fascinating evolution of brewing technology, from its humble beginnings to the sophisticated techniques employed in modern craft breweries.

This exploration delves into the intricacies of modern brewing methods, highlighting the distinct approaches that define the craft beer landscape. From the all-grain brewing process, celebrated for its control and customization, to the convenience of extract brewing, each method offers unique advantages and challenges. Understanding these techniques provides a deeper appreciation for the diverse flavors and styles that characterize the world of craft beer.

Evolution of Brewing Technology

The art of brewing, dating back thousands of years, has witnessed a fascinating evolution in technology. From rudimentary methods to sophisticated modern processes, the journey reflects human ingenuity and a constant pursuit of improved quality and efficiency. This evolution has been marked by significant innovations that have transformed the brewing landscape, impacting the taste, consistency, and accessibility of our favorite beverages.

Timeline of Key Innovations, Brewing technology

The history of brewing technology is rich with innovations that have significantly impacted the industry. These innovations have led to increased efficiency, improved quality control, and expanded production capabilities, making beer more accessible and diverse than ever before.

- Early Brewing: The earliest forms of brewing likely involved simple fermentation techniques, using natural yeast and rudimentary vessels. This period saw the development of basic brewing methods, including the use of open vats and earthenware containers. The discovery of hops, which added bitterness and preservation qualities, revolutionized brewing and paved the way for the evolution of beer as we know it.

- 19th Century: The 19th century witnessed significant advancements in brewing technology. The invention of the steam engine revolutionized the brewing process, enabling larger-scale production. The development of refrigeration allowed for better temperature control during fermentation, leading to more consistent and reliable brewing results. The introduction of the hydrometer allowed brewers to measure the specific gravity of the wort, providing a more precise way to monitor fermentation progress.

- 20th Century: The 20th century saw further advancements in brewing technology. The development of stainless steel tanks and pipes led to improved sanitation and hygiene, reducing the risk of contamination. The invention of the centrifuge enabled brewers to efficiently separate yeast from the beer, improving clarity and stability. The introduction of modern filtration techniques further enhanced the clarity and purity of beer. The development of automated brewing systems streamlined the brewing process, increasing efficiency and reducing human error.

- 21st Century: The 21st century has seen a continued focus on automation, precision, and innovation in brewing technology. The adoption of computer-controlled systems allows for precise control over fermentation parameters, resulting in more consistent and predictable results. The use of sensors and data analysis provides real-time insights into the brewing process, enabling brewers to optimize their techniques and make informed decisions. The emergence of craft brewing has also fueled innovation, with brewers experimenting with new ingredients, techniques, and styles.

Traditional vs. Contemporary Brewing Methods

Traditional brewing methods, often passed down through generations, rely on time-tested techniques and natural ingredients. These methods typically involve open fermentation vessels, allowing for a greater interaction with the environment and the development of unique flavor profiles.

Traditional brewing methods often emphasize a slower, more natural process, allowing for the development of complex flavors and aromas.

Contemporary brewing methods, on the other hand, utilize modern technology to control and optimize every stage of the brewing process. This includes the use of closed fermentation tanks, temperature-controlled environments, and advanced filtration systems.

Contemporary brewing methods focus on consistency, efficiency, and precision, allowing for the production of large quantities of beer with consistent quality.

- Fermentation: Traditional brewing often employs open fermentation vessels, exposing the wort to the surrounding environment. This can lead to the development of unique yeast strains and flavor profiles, often characteristic of the region. Contemporary brewing, however, relies on closed fermentation tanks, providing a controlled environment for fermentation. This allows for precise temperature control and the use of specific yeast strains, resulting in more consistent and predictable results.

- Ingredients: Traditional brewing often relies on locally sourced ingredients and natural processes. This can lead to variations in flavor and quality depending on the specific region and season. Contemporary brewing, on the other hand, often uses standardized ingredients and processes, ensuring consistent quality and taste.

- Quality Control: Traditional brewing often relies on sensory evaluation and experience to assess quality. Contemporary brewing, however, utilizes laboratory testing and advanced analytical techniques to monitor and control every stage of the brewing process, ensuring consistent quality and safety.

Modern Brewing Techniques

Modern brewing techniques encompass a spectrum of methods, each offering unique advantages and catering to diverse brewing preferences. These methods range from the meticulous all-grain brewing, where brewers exercise complete control over every aspect of the process, to the convenience of extract brewing, which simplifies the brewing process while maintaining quality.

All-Grain Brewing

All-grain brewing is the most traditional and technically advanced method, offering brewers complete control over the entire process, from mashing to boiling. This method involves using whole grains, such as barley, wheat, or oats, which are milled and then steeped in hot water to extract fermentable sugars.

The principles behind all-grain brewing are rooted in the precise control of the mashing process, where temperature and time are critical for optimal sugar extraction and enzyme activity.

- The process begins with milling the grains to expose the starch, which is then mixed with hot water in a mash tun, a vessel designed for controlled temperature regulation.

- The mash is held at specific temperatures for specific durations, allowing enzymes to break down the starch into fermentable sugars.

- After mashing, the liquid, known as wort, is separated from the grains through a process called sparging, where hot water is used to rinse remaining sugars from the grains.

- The wort is then boiled for an extended period to sterilize it, extract bitterness from hops, and concentrate its flavor.

- After cooling, the wort is pitched with yeast, which ferments the sugars into alcohol and carbon dioxide.

All-grain brewing requires specialized equipment, including a mash tun, a kettle for boiling, a chiller to cool the wort, and fermentation vessels. This method demands a significant investment in equipment and time commitment, but it allows for unparalleled creativity and control over the final product.

Extract Brewing

Extract brewing offers a simplified and faster alternative to all-grain brewing, utilizing pre-made malt extracts that contain concentrated sugars. These extracts are available in various forms, including liquid and dry extracts.

- Extract brewing eliminates the need for mashing, reducing the time and complexity involved.

- Brewers simply dissolve the extract in hot water, boil it with hops, and then cool it before pitching yeast.

- The process is significantly shorter than all-grain brewing, making it an ideal option for beginners or those seeking a more streamlined approach.

While extract brewing offers convenience, it sacrifices some control over the brewing process. The use of pre-made extracts limits the brewer’s ability to customize the grain bill and adjust the mashing process. However, extract brewing remains a popular choice due to its ease of use and affordability.

Partial Mash Brewing

Partial mash brewing bridges the gap between all-grain and extract brewing, allowing brewers to control specific aspects of the mashing process while utilizing pre-made extracts for convenience.

- In this method, brewers mash a portion of the grain bill, typically a base malt, while using extracts for the remaining portion.

- This approach offers a balance between control and convenience, allowing brewers to customize the flavor profile and complexity of their beer while minimizing the time commitment associated with full-grain brewing.

Partial mash brewing requires some specialized equipment, such as a mash tun for the grain portion, but it is less demanding than all-grain brewing. This method is a popular choice for brewers who want to explore the nuances of all-grain brewing without committing to the full process.

Key Components of Brewing Technology

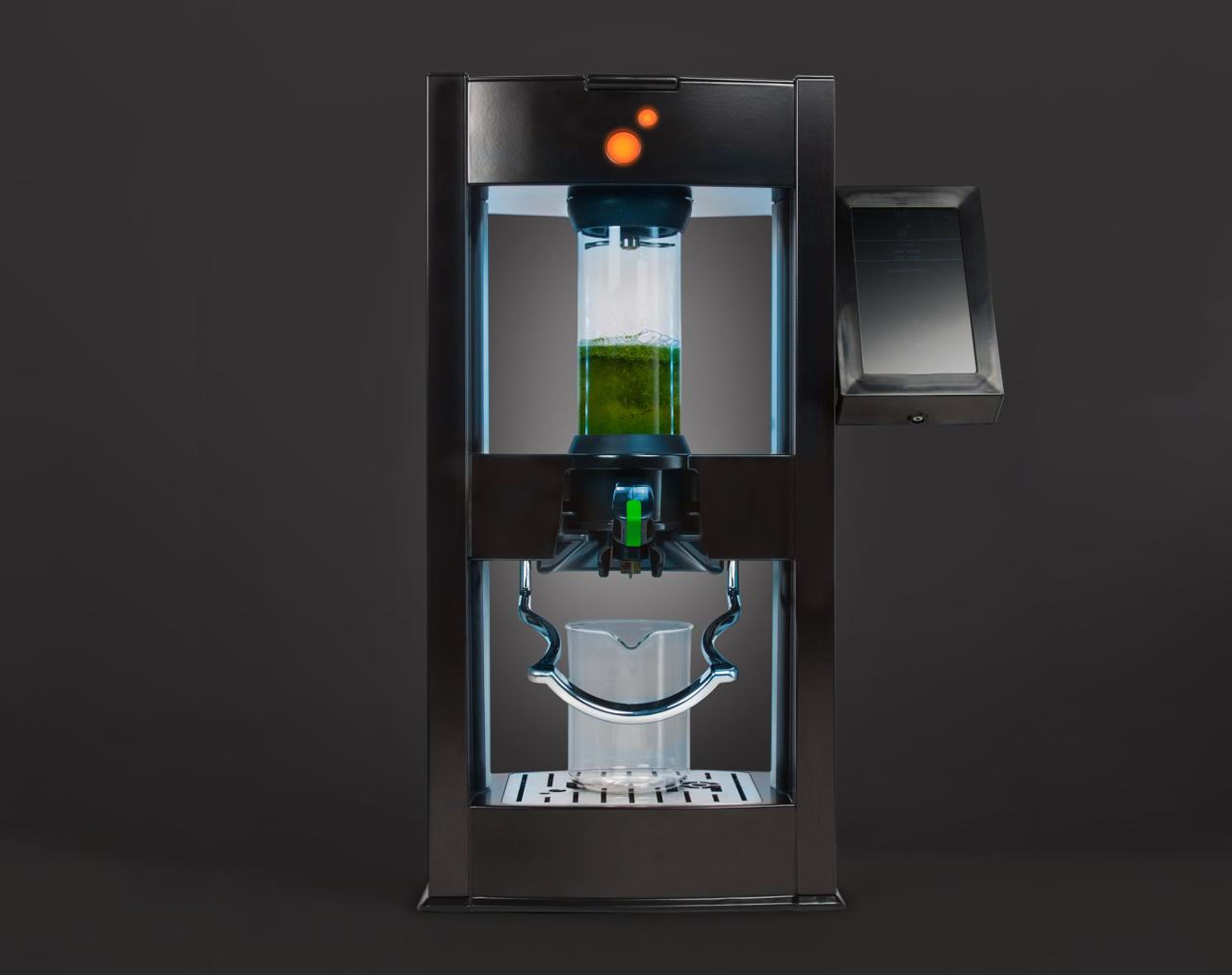

A modern brewing system is a complex and intricate network of equipment designed to transform raw ingredients into delicious beer. Each component plays a crucial role in the brewing process, from extracting sugars from grains to fermenting the wort and packaging the finished product.

The Mash Tun

The mash tun is the first vessel in the brewing process where the starches in the grains are converted into fermentable sugars. The process involves mixing crushed grains (grist) with hot water (mash) to create a slurry called the mash. This process is known as mashing. The temperature of the mash is carefully controlled to activate enzymes that break down the starches.

- Function: The mash tun is responsible for converting the starches in the grains into fermentable sugars, a crucial step in the brewing process.

- Materials: Mash tuns are typically constructed from stainless steel, which is durable, corrosion-resistant, and easy to clean. Some brewers may opt for copper mash tuns, which can impart subtle flavors to the beer.

- Technologies: Modern mash tuns often feature sophisticated temperature control systems, allowing brewers to precisely adjust the mash temperature for optimal enzyme activity.

The Lauter Tun

The lauter tun is a vessel that separates the liquid wort from the spent grains. It is a cylindrical vessel with a perforated bottom, allowing the wort to drain through while retaining the grains.

- Function: The lauter tun separates the liquid wort from the spent grains, ensuring a clear and flavorful wort for fermentation.

- Materials: Lauter tuns are typically constructed from stainless steel, offering durability and ease of cleaning. Some brewers may use copper lauter tuns, which can contribute subtle flavors to the beer.

- Technologies: Modern lauter tuns often incorporate advanced filtration systems to remove any remaining grain particles from the wort, resulting in a cleaner and clearer product.

The Kettle

The kettle is a large, heated vessel used to boil the wort after it has been separated from the spent grains in the lauter tun.

- Function: The kettle serves several purposes:

- Boiling the wort sterilizes it, killing any harmful bacteria that may have contaminated it.

- Boiling concentrates the wort, increasing its gravity and enhancing its flavor.

- Boiling allows the addition of hops, which impart bitterness and aroma to the beer.

- Materials: Kettles are typically made from stainless steel, offering durability and resistance to corrosion.

- Technologies: Modern kettles often feature advanced heating systems, such as steam or direct fire, providing efficient and precise temperature control.

The Fermenter

The fermenter is a vessel where the wort is inoculated with yeast and allowed to ferment, transforming the sugars into alcohol and carbon dioxide.

- Function: The fermenter is the heart of the brewing process, where the magic of fermentation takes place. Yeast consumes the sugars in the wort, producing alcohol and carbon dioxide, giving the beer its characteristic flavor and aroma.

- Materials: Fermenters are typically made from stainless steel, offering durability, sanitation, and ease of cleaning. Some brewers may use other materials, such as plastic or glass, depending on the specific brewing style and preferences.

- Technologies: Modern fermenters often feature temperature control systems, allowing brewers to maintain optimal fermentation temperatures for specific yeast strains.

Packaging Equipment

After fermentation, the beer is ready for packaging. This involves filling bottles, cans, or kegs.

- Function: Packaging equipment ensures the beer is safely and efficiently filled into its final containers, ready for distribution and consumption.

- Materials: Packaging equipment is typically made from stainless steel, offering durability and sanitation.

- Technologies: Modern packaging equipment often incorporates advanced filling and capping systems, ensuring precise filling volumes and secure closures.

Automation and Control in Brewing

The brewing industry has witnessed a significant shift towards automation and control systems, transforming traditional processes into highly efficient and consistent operations. This integration not only enhances productivity but also ensures the quality and consistency of the final product, making it a crucial aspect of modern brewing technology.

The Role of Automation and Control Systems

Automation and control systems play a vital role in optimizing brewing processes, ensuring consistency, and enhancing efficiency. They are designed to manage and monitor various aspects of the brewing process, from mashing and lautering to fermentation and packaging. These systems automate tasks, reduce manual intervention, and enable precise control over critical brewing parameters, leading to consistent and high-quality beer.

Sensors, Controllers, and Data Analytics

Sensors are the eyes of the automated brewing system, continuously monitoring various parameters like temperature, pressure, pH, and dissolved oxygen levels. These sensors transmit real-time data to controllers, which are the brains of the system. Controllers use this data to adjust and optimize brewing processes based on pre-programmed parameters or user-defined settings.

Data analytics plays a crucial role in analyzing historical data collected from sensors and controllers. This data analysis helps identify trends, patterns, and potential areas for improvement. By leveraging data analytics, brewers can refine their brewing processes, optimize resource utilization, and enhance the overall efficiency of their operations.

A Hypothetical Automated Brewing System

A hypothetical automated brewing system would integrate sensors, controllers, and data analytics to manage and optimize the entire brewing process.

Key Features and Functionalities

- Automated Mashing and Lautering: Sensors monitor the temperature and pH of the mash, ensuring optimal conditions for enzyme activity. Controllers adjust the temperature and flow rates of water to achieve the desired mash profile.

- Automated Sparging: Sensors measure the specific gravity of the wort, providing feedback to the controllers for adjusting the flow rate of sparge water to maximize extract recovery.

- Automated Boiling and Hopping: Sensors monitor the wort temperature and adjust the heat input to maintain the desired boiling temperature. Controllers manage the addition of hops, ensuring precise timing and dosage for optimal flavor and aroma extraction.

- Automated Fermentation and Conditioning: Sensors monitor the temperature, pressure, and dissolved oxygen levels in the fermentation tanks. Controllers adjust the temperature and aeration levels to create the ideal environment for yeast growth and beer maturation.

- Automated Packaging and Labeling: Sensors monitor the filling levels and pressure in the packaging line, ensuring consistent and accurate filling. Controllers manage the labeling process, ensuring proper information is printed on each bottle or can.

Benefits of Automation

- Increased Efficiency: Automation reduces manual labor, freeing up brewers to focus on other aspects of the brewing process.

- Improved Consistency: Automated systems ensure consistent brewing parameters, resulting in more uniform and predictable beer quality.

- Enhanced Quality: Precise control over brewing parameters helps to optimize flavor, aroma, and overall beer quality.

- Reduced Waste: Automated systems optimize resource utilization, minimizing waste and reducing production costs.

- Real-Time Data Analysis: Data collected from sensors and controllers provides valuable insights into the brewing process, enabling brewers to identify areas for improvement and optimize production.

Emerging Trends in Brewing Technology

The brewing industry is constantly evolving, driven by advancements in technology, changing consumer preferences, and a growing emphasis on sustainability. This has led to the emergence of innovative brewing techniques and technologies that are transforming the way beer is produced.

Precision Fermentation

Precision fermentation is a revolutionary technology that allows brewers to produce beer ingredients, such as hops, yeast, and even alcohol, in a controlled laboratory environment. This process involves using genetically modified microorganisms to create specific compounds, offering a range of advantages.

- Control and Consistency: Precision fermentation allows brewers to precisely control the production of desired compounds, resulting in consistent quality and flavor profiles.

- Sustainability: By eliminating the need for traditional agricultural practices, precision fermentation reduces the environmental impact of brewing.

- Innovation: It opens up new possibilities for creating unique flavors and ingredients, expanding the boundaries of beer innovation.

| Benefits | Challenges |

|---|---|

| Increased control over ingredient production | High initial investment costs |

| Reduced environmental impact | Regulatory hurdles and public perception |

| Enhanced flavor and aroma profiles | Limited availability of technology |

Bio-Engineered Yeast Strains

Brewers are increasingly utilizing bio-engineered yeast strains to enhance the fermentation process and create unique flavor profiles. These strains are designed to produce specific compounds, such as esters and phenols, that contribute to the distinctive characteristics of different beer styles.

- Flavor Complexity: Bio-engineered yeast strains can produce a wider range of flavors and aromas, leading to more complex and interesting beer styles.

- Efficiency: Some engineered strains can ferment faster and more efficiently, reducing production time and costs.

- Sustainability: Bio-engineered strains can reduce the need for traditional yeast propagation methods, leading to a more sustainable brewing process.

| Benefits | Challenges |

|---|---|

| Enhanced flavor profiles | Ethical concerns about genetic modification |

| Increased fermentation efficiency | Potential for unintended consequences |

| Reduced reliance on traditional yeast propagation | Regulatory approvals and consumer acceptance |

Sustainable Brewing Practices

As the brewing industry faces growing pressure to reduce its environmental footprint, sustainable brewing practices are becoming increasingly important. These practices aim to minimize waste, conserve resources, and reduce greenhouse gas emissions.

- Water Conservation: Brewers are implementing technologies and processes to reduce water usage, such as closed-loop systems and efficient cleaning practices.

- Energy Efficiency: Utilizing renewable energy sources and optimizing energy consumption in brewing operations are key to reducing carbon emissions.

- Waste Reduction: Brewers are exploring innovative ways to reduce and recycle waste generated during the brewing process, such as using spent grains for animal feed or compost.

| Benefits | Challenges |

|---|---|

| Reduced environmental impact | Initial investment costs for sustainable technologies |

| Enhanced brand image and consumer loyalty | Changes to existing processes and practices |

| Cost savings through resource optimization | Limited availability of sustainable solutions |

Brewing Technology and Innovation

Brewing technology is constantly evolving, driven by a relentless pursuit of quality, efficiency, and innovation. Research and development play a crucial role in pushing the boundaries of brewing, leading to new techniques, processes, and equipment that enhance the brewing experience.

Innovative Brewing Technologies

The brewing industry has embraced a range of innovative technologies that have revolutionized the production of beer. These advancements have led to greater control over the brewing process, improved consistency, and enhanced flavor profiles.

- Precision Fermentation: This technology involves using sensors and data analysis to monitor and control fermentation parameters like temperature, pH, and dissolved oxygen levels. This allows brewers to optimize fermentation conditions for specific yeast strains and achieve consistent results.

- Automated Brewing Systems: Automated brewing systems streamline the brewing process, reducing manual labor and minimizing human error. These systems can manage tasks like mashing, lautering, and boiling, ensuring precise control and consistency.

- Sensory Analysis Tools: Advanced sensory analysis tools help brewers objectively assess the aroma, flavor, and appearance of beer. These tools can provide valuable insights into the quality and consistency of beer, enabling brewers to fine-tune their recipes and production processes.

- Biotechnology: Biotechnology is transforming brewing by enabling the development of new yeast strains with specific characteristics. This includes strains that can produce unique flavors, improve fermentation efficiency, and enhance beer quality.

Challenges and Opportunities

While innovative brewing technologies offer significant benefits, their adoption presents challenges for brewers.

- Cost of Implementation: Implementing new technologies can be expensive, requiring significant capital investment. This can be a barrier for smaller breweries with limited resources.

- Training and Expertise: Using new technologies requires specialized training and expertise. Brewers need to adapt to new processes and equipment, which can be time-consuming and demanding.

- Data Management: Innovative brewing technologies generate large amounts of data that need to be effectively managed and analyzed. Brewers need to develop data management strategies to leverage these insights for process optimization.

Despite these challenges, the opportunities presented by innovative brewing technologies are significant.

- Enhanced Efficiency: New technologies can improve efficiency, reduce waste, and lower production costs, making brewing more sustainable and profitable.

- Product Innovation: Innovative brewing technologies enable brewers to experiment with new flavors, styles, and ingredients, expanding the possibilities for product development.

- Improved Quality: Precision control and monitoring offered by new technologies enhance the consistency and quality of beer, ensuring a superior drinking experience for consumers.

Concluding Remarks

The future of brewing is a landscape brimming with exciting possibilities, shaped by the convergence of technology and a passion for creating exceptional beverages. As brewing technology continues to evolve, we can expect to witness a wave of innovation, pushing the boundaries of flavor, sustainability, and efficiency. From the development of bio-engineered yeast strains to the adoption of precision fermentation, the craft beer industry is poised to embrace these advancements, ensuring a future where the pursuit of excellence knows no bounds.

Brewing technology has come a long way, from traditional methods to sophisticated systems that ensure consistent quality and efficiency. One company leading the charge in this technological advancement is Cetrix Technologies , specializing in automation and data management solutions for the brewing industry.

Cetrix’s innovative solutions streamline operations, enhance quality control, and optimize resource utilization, contributing to the ongoing evolution of brewing technology.