Battery Watering Technologies: Optimizing Performance

Battery watering technologies play a crucial role in maintaining optimal performance and extending the lifespan of batteries. From traditional manual methods to advanced automated systems, the evolution of battery watering […]

Battery watering technologies play a crucial role in maintaining optimal performance and extending the lifespan of batteries. From traditional manual methods to advanced automated systems, the evolution of battery watering techniques has significantly impacted various industries. This article delves into the intricacies of battery watering, exploring its importance, challenges, and the diverse technologies available to ensure efficient and reliable battery operation.

While manual battery watering has long been the standard practice, it presents several challenges, including time-consuming procedures, potential for human error, and safety risks. The introduction of automatic battery watering systems has revolutionized the industry, offering numerous benefits such as reduced labor costs, improved safety, and enhanced efficiency. These systems utilize various methods to monitor and maintain water levels, ensuring optimal battery performance and minimizing the risk of damage.

Introduction to Battery Watering Technologies

Battery watering is a crucial maintenance task for lead-acid batteries, especially those used in stationary applications like backup power systems, electric vehicles, and industrial equipment. It ensures optimal performance and extends the battery’s lifespan.

Regular watering keeps the electrolyte levels topped up, preventing the plates from becoming exposed to air. This exposure can lead to sulfation, which reduces the battery’s capacity and shortens its lifespan.

Challenges of Manual Battery Watering

Manual battery watering can be a tedious and time-consuming task, especially for large battery banks. It also poses several challenges:

- Safety Risks: Handling battery acid requires caution and proper safety gear. Accidental spills can cause burns and damage equipment.

- Inconsistent Watering: Manual watering often leads to inconsistencies in electrolyte levels, as it depends on human judgment and attention. This can negatively impact battery performance.

- Time-Consuming: Checking and watering each battery individually can take significant time, especially for large installations.

- Accessibility Issues: In some cases, batteries might be located in hard-to-reach areas, making manual watering difficult and potentially dangerous.

Types of Battery Watering Technologies

To overcome the challenges of manual battery watering, several automated technologies have been developed. These technologies provide a safer, more efficient, and consistent way to maintain electrolyte levels in batteries.

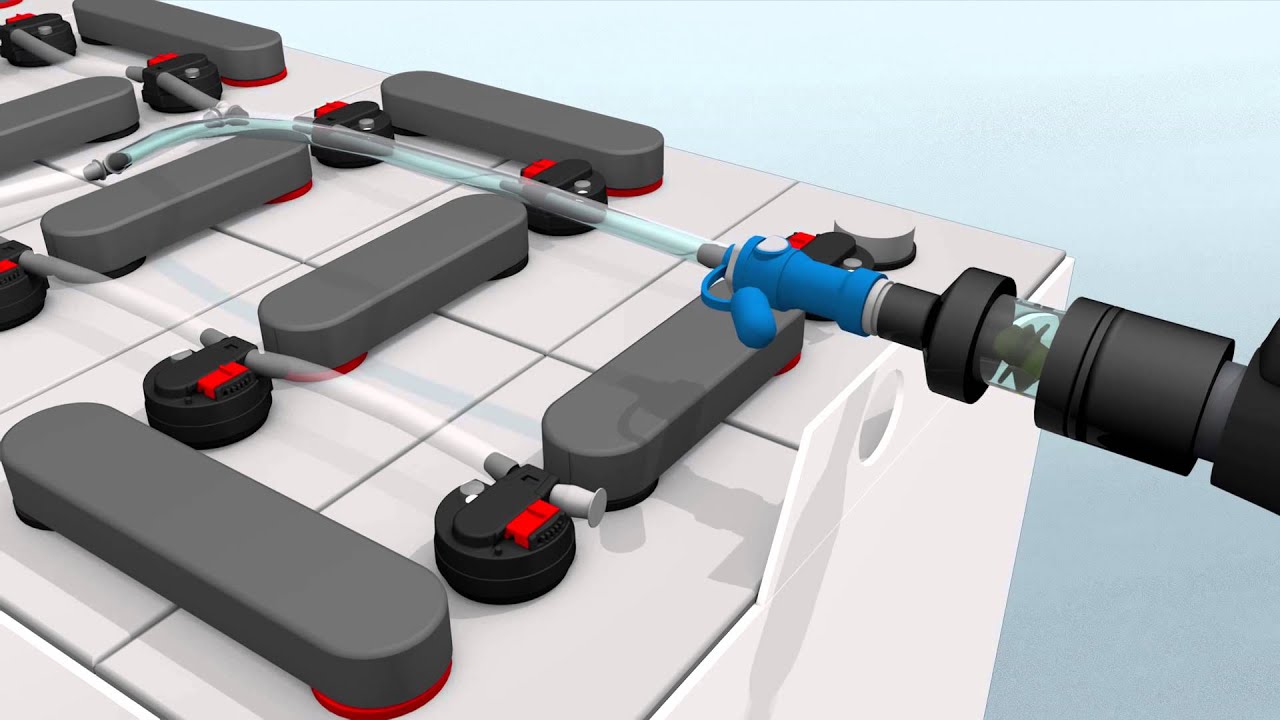

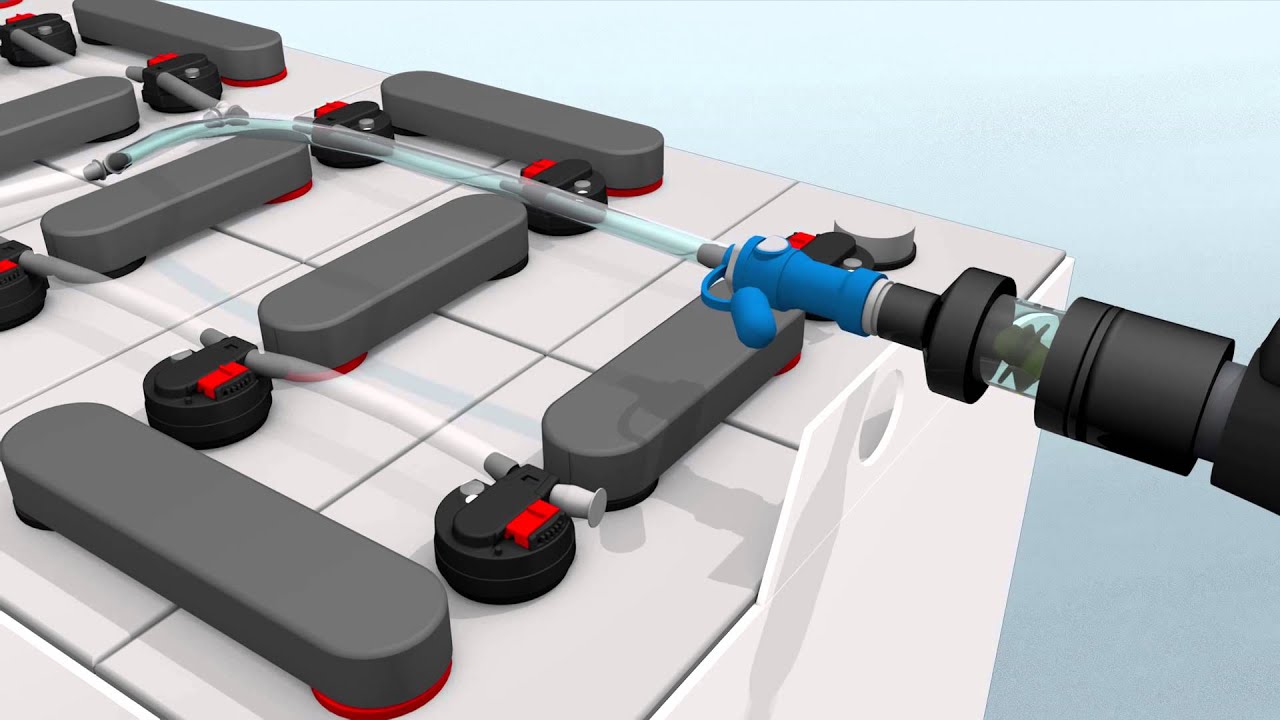

- Automatic Watering Systems: These systems use sensors to monitor electrolyte levels and automatically add water as needed. They typically consist of a water reservoir, a pump, and a control unit.

- Centralized Watering Systems: These systems allow for the watering of multiple batteries from a single location. They are often used in large battery installations and can significantly reduce the time and effort required for watering.

- Remote Monitoring and Control: Some advanced watering systems offer remote monitoring and control capabilities. This allows operators to track battery performance and manage watering remotely.

Automatic Battery Watering Systems

Automatic battery watering systems are designed to maintain the electrolyte levels in batteries without manual intervention. These systems use various technologies to sense the electrolyte level and automatically add water as needed. They are essential for ensuring optimal battery performance, prolonging battery life, and reducing maintenance costs.

Working Principle of Automatic Battery Watering Systems

Automatic battery watering systems operate based on the principle of sensing the electrolyte level in the battery cells and automatically adding water to maintain the desired level. The systems typically consist of a water source, a sensor, a control unit, and a water delivery system.

- The sensor continuously monitors the electrolyte level in the battery cells.

- When the electrolyte level falls below a predefined threshold, the sensor sends a signal to the control unit.

- The control unit activates the water delivery system, which pumps water from the source into the battery cells.

- The water delivery system can be a simple gravity-fed system or a more sophisticated pump-based system.

Benefits of Automatic Battery Watering Systems

Automatic battery watering systems offer several advantages over manual watering methods:

- Reduced Labor Costs: Automatic systems eliminate the need for manual watering, freeing up valuable time and resources for other tasks. This can significantly reduce labor costs, especially in large battery installations.

- Improved Safety: Manual watering can be a hazardous task, especially in enclosed spaces. Automatic systems eliminate the risk of spills and accidents, improving safety for personnel.

- Increased Battery Life: Proper electrolyte levels are crucial for battery performance and longevity. Automatic systems ensure consistent electrolyte levels, leading to longer battery life and reduced replacement costs.

- Enhanced Battery Performance: Maintaining the correct electrolyte level optimizes battery performance, leading to increased efficiency and reduced downtime.

Types of Automatic Battery Watering Systems

Automatic battery watering systems can be broadly categorized into three main types:

- Float-Based Systems: These systems use a float that rises and falls with the electrolyte level. When the float drops below a certain level, it activates a valve that allows water to flow into the battery cells. This system is relatively simple and cost-effective, but it may be less accurate than other types.

- Level-Sensing Systems: These systems use sensors to directly measure the electrolyte level. The sensors can be based on various technologies, such as conductivity, pressure, or ultrasonic measurements. Level-sensing systems are generally more accurate than float-based systems, but they can be more complex and expensive.

- Electronic Systems: These systems use electronic controllers to monitor and manage the watering process. Electronic systems offer the highest level of accuracy and control, but they can be more complex and require specialized expertise for installation and maintenance.

Advantages and Disadvantages of Each Type of System

Each type of automatic battery watering system has its own advantages and disadvantages:

Float-Based Systems

- Advantages: Simple design, low cost, easy to install and maintain.

- Disadvantages: Less accurate than other types, prone to mechanical failure, may not be suitable for all battery types.

Level-Sensing Systems

- Advantages: More accurate than float-based systems, less prone to mechanical failure, suitable for a wider range of battery types.

- Disadvantages: More complex than float-based systems, higher cost, may require specialized expertise for installation and maintenance.

Electronic Systems

- Advantages: Highest level of accuracy and control, can be integrated with other battery management systems, allows for remote monitoring and control.

- Disadvantages: Most complex and expensive, requires specialized expertise for installation and maintenance, susceptible to electronic failure.

Water Quality and Battery Watering

Using pure water for battery watering is crucial for optimal performance and longevity. Contaminated water can lead to various problems, affecting the battery’s efficiency, lifespan, and even safety. This section delves into the importance of water quality, explores the consequences of using impure water, and discusses methods for purifying water for battery use.

Consequences of Using Contaminated Water

Using contaminated water for battery watering can lead to several adverse effects, including:

- Reduced Battery Life: Impurities in water can build up on battery plates, hindering the flow of electricity and reducing the battery’s capacity. This can lead to premature battery failure.

- Corrosion: Impurities like minerals and salts can accelerate corrosion of battery components, leading to leaks and eventual failure.

- Reduced Efficiency: Contaminated water can increase internal resistance within the battery, leading to reduced efficiency and lower power output.

- Safety Hazards: Contaminated water can contribute to the formation of hydrogen gas, a flammable and explosive gas. This can pose a significant safety risk, especially in enclosed spaces.

Methods for Purifying Water for Battery Use, Battery watering technologies

Several methods can be employed to purify water for battery use, ensuring optimal performance and safety.

- Distillation: This process involves heating water to its boiling point, separating it from impurities that have a higher boiling point. The steam is then condensed to produce pure water.

- Deionization: This method removes ions from water using ion exchange resins. The resins exchange their ions for the ions in the water, effectively removing impurities.

- Reverse Osmosis: This process uses a semi-permeable membrane to separate water molecules from impurities. Water is forced through the membrane under pressure, leaving behind dissolved salts and other contaminants.

Maintaining Water Quality in Battery Watering Systems

Maintaining the purity of water in battery watering systems is crucial to ensure optimal performance and longevity.

- Use High-Quality Water: Start with the purest water possible. Consider using distilled, deionized, or reverse osmosis water.

- Regular Cleaning: Clean the watering system regularly to prevent the buildup of impurities. This includes cleaning the water reservoir, hoses, and any other components that come into contact with water.

- Proper Storage: Store water in clean, sealed containers to prevent contamination. Avoid using containers that have previously held chemicals or other substances that could contaminate the water.

Last Point: Battery Watering Technologies

In conclusion, battery watering technologies are essential for ensuring optimal battery performance, extending their lifespan, and enhancing safety. The advancements in automated systems have significantly improved efficiency, reduced labor costs, and minimized the risk of human error. By understanding the various technologies available and implementing appropriate maintenance practices, individuals and businesses can ensure the reliable operation of their battery systems.

Battery watering technologies are crucial for maintaining the longevity of lead-acid batteries, often found in mobility devices like golden technologies scooters. Regular watering ensures proper electrolyte levels, preventing premature failure and maximizing the battery’s lifespan. By understanding these technologies, users can ensure their scooters continue to provide reliable transportation for years to come.