Ballast Technologies: Shaping Industries and the Environment

Ballast technologies, a crucial element in various industries, play a vital role in maintaining stability and ensuring safe operations. From shipping and construction to renewable energy, these technologies are essential […]

Ballast technologies, a crucial element in various industries, play a vital role in maintaining stability and ensuring safe operations. From shipping and construction to renewable energy, these technologies are essential for balancing loads, mitigating risks, and optimizing performance.

The evolution of ballast technologies has been driven by the need for efficient and reliable solutions across diverse sectors. These systems, often employing water, sand, or other materials, serve to adjust weight distribution and enhance stability, ensuring safety and efficiency in dynamic environments.

Ballast Technologies

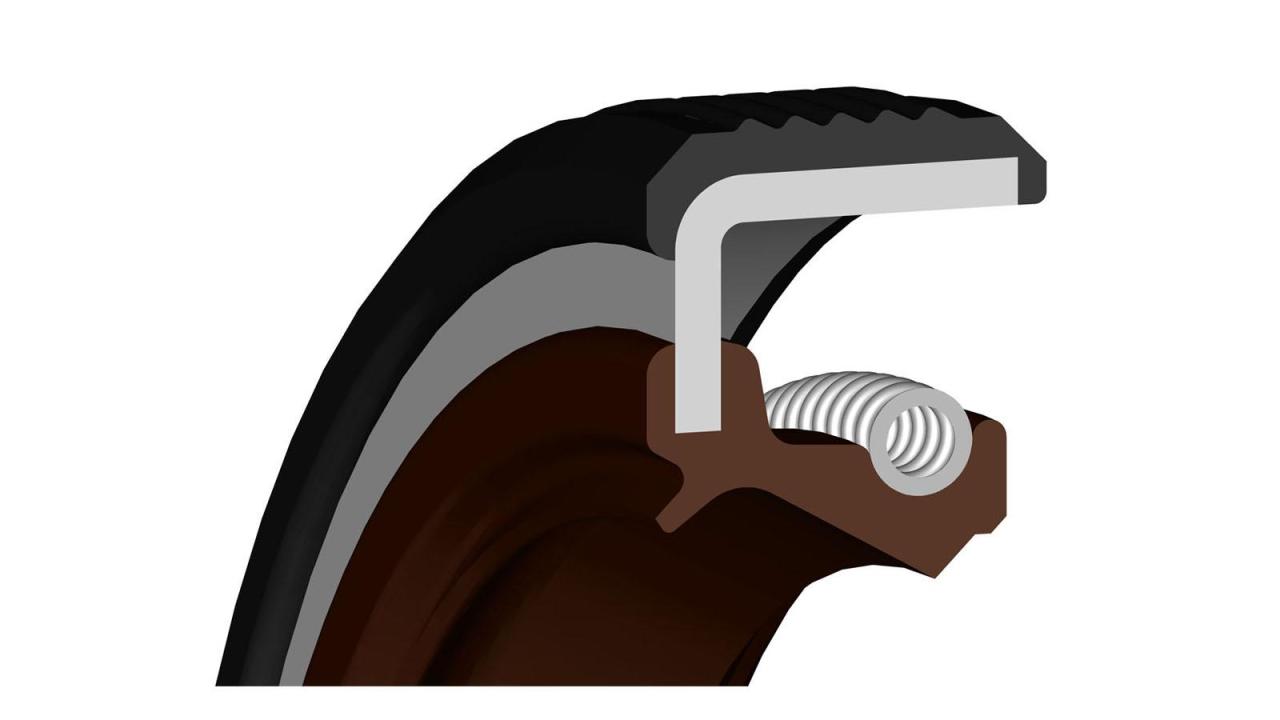

Ballast technologies are systems designed to enhance stability and control in various applications, particularly in maritime and construction sectors. They involve the strategic placement and adjustment of weight, often in the form of water, sand, or other materials, to counterbalance forces and maintain equilibrium.

The Role of Ballast Technologies

Ballast technologies play a crucial role in maintaining stability and control in diverse applications. Their primary function is to adjust the center of gravity and buoyancy of an object, thereby influencing its equilibrium. In the maritime industry, ballast systems are essential for ships to navigate safely and efficiently. They allow vessels to adapt to varying cargo loads, weather conditions, and water depths.

A Brief History of Ballast Technologies

The concept of ballast has been utilized for centuries. Ancient mariners used stones and sand as ballast to stabilize their ships. The evolution of ballast technologies has been driven by advancements in materials, design, and automation. In the 19th century, the use of water as ballast became more common, leading to the development of ballast tanks. The 20th century saw the introduction of sophisticated ballast systems, including automated control systems and advanced materials.

Key Principles and Mechanisms of Ballast Technologies

Ballast technologies operate based on fundamental principles of physics, particularly buoyancy and center of gravity. The key mechanisms include:

- Buoyancy: Ballast systems utilize the principle of buoyancy, which states that an object submerged in a fluid experiences an upward force equal to the weight of the fluid displaced. By adjusting the amount of ballast, the buoyancy of the object can be controlled.

- Center of Gravity: The center of gravity (CG) of an object is the point where its weight is concentrated. Ballast systems manipulate the CG by shifting weight, thereby influencing the object’s stability.

Types of Ballast Technologies

Ballast technologies are essential components in lighting systems, playing a crucial role in regulating the flow of electricity to lamps and ensuring optimal performance. They are categorized based on their function, construction, and operating principles.

Types of Ballast Technologies

Ballast technologies are broadly classified into three main categories: magnetic, electronic, and LED drivers.

- Magnetic ballasts are the traditional type, utilizing electromagnetic coils to control the current flow. They are known for their simplicity and robustness but are less efficient than other types.

- Electronic ballasts utilize electronic circuitry to regulate the current flow, resulting in higher efficiency and better light output compared to magnetic ballasts.

- LED drivers are specifically designed for LED lighting, providing constant current to the LEDs and ensuring optimal performance.

Magnetic Ballasts, Ballast technologies

Magnetic ballasts are the oldest type of ballast technology, relying on electromagnetic induction to regulate the current flow to the lamp.

- Advantages:

- Simple and robust design, making them reliable and long-lasting.

- Lower initial cost compared to electronic ballasts.

- Disadvantages:

- Lower efficiency, leading to higher energy consumption and heat generation.

- Limited dimming capabilities, making them unsuitable for applications requiring adjustable light levels.

- Higher ballast factor, which affects the lamp’s light output.

- Larger size and weight compared to electronic ballasts.

Electronic Ballasts

Electronic ballasts utilize electronic circuitry to control the current flow, providing a more efficient and versatile alternative to magnetic ballasts.

- Advantages:

- Higher efficiency, leading to lower energy consumption and reduced heat generation.

- Improved light output and color rendering compared to magnetic ballasts.

- Dimming capabilities, allowing for adjustable light levels.

- Faster lamp starting time.

- Smaller size and lighter weight compared to magnetic ballasts.

- Disadvantages:

- Higher initial cost compared to magnetic ballasts.

- More complex design, potentially leading to higher maintenance costs.

- Can generate electromagnetic interference (EMI) if not properly shielded.

LED Drivers

LED drivers are specifically designed for LED lighting, providing a constant current to the LEDs and ensuring optimal performance.

- Advantages:

- High efficiency, leading to significant energy savings.

- Long lifespan, contributing to reduced maintenance costs.

- Wide range of dimming options, allowing for precise light control.

- Compact size and lightweight design.

- Low heat generation, promoting longer LED lifespan and improved safety.

- Disadvantages:

- Higher initial cost compared to traditional ballasts.

- Requires specialized knowledge for installation and maintenance.

Comparison of Ballast Technologies

| Type | Advantages | Disadvantages | Applications |

|---|---|---|---|

| Magnetic Ballasts | Simple and robust, low initial cost | Low efficiency, limited dimming, high ballast factor | Traditional lighting applications where energy efficiency is not a primary concern |

| Electronic Ballasts | Higher efficiency, improved light output, dimming capabilities | Higher initial cost, more complex design | Commercial and industrial lighting, applications requiring dimming and energy efficiency |

| LED Drivers | High efficiency, long lifespan, wide dimming range | Higher initial cost, specialized installation and maintenance | Residential, commercial, and industrial LED lighting applications |

Environmental Impact of Ballast Technologies

Ballast water, the water taken on by ships to maintain stability and balance, can have significant environmental impacts. The introduction of non-native species, known as invasive species, through ballast water discharge is a major concern. These species can outcompete native organisms, disrupt ecosystems, and cause significant economic damage.

Ecological Impacts of Ballast Water

Invasive species introduced through ballast water can have far-reaching ecological consequences. They can:

- Outcompete native species for food, habitat, and resources, leading to population declines and even extinctions.

- Introduce diseases and parasites that can harm native species.

- Alter food webs and ecosystem dynamics, disrupting the balance of natural communities.

- Cause significant damage to infrastructure, such as clogging water intake pipes and fouling boat hulls.

Water Quality Impacts of Ballast Water

Ballast water can also introduce pollutants and contaminants into receiving waters, impacting water quality. These pollutants can include:

- Nutrients, such as nitrates and phosphates, which can lead to algal blooms and oxygen depletion.

- Pathogens, such as bacteria and viruses, which can pose health risks to humans and wildlife.

- Heavy metals, such as mercury and lead, which can accumulate in the food chain and cause toxicity.

- Organic chemicals, such as pesticides and herbicides, which can have harmful effects on aquatic life.

Sustainable Ballast Technologies

To mitigate the environmental risks associated with ballast water, sustainable ballast technologies have been developed. These technologies aim to:

- Prevent the uptake of organisms and pollutants during ballast water filling.

- Treat ballast water to eliminate or reduce the number of organisms and pollutants before discharge.

- Optimize ballast water management practices to minimize the risk of introductions.

Best Practices for Responsible Ballast Management

To minimize the environmental damage caused by ballast water, it is crucial to adopt best practices for responsible ballast management. These practices include:

- Ballast water exchange: This involves replacing ballast water with clean ocean water far from shore, reducing the risk of introducing organisms.

- Ballast water treatment: This involves using physical, chemical, or biological methods to eliminate or reduce the number of organisms and pollutants in ballast water.

- Ballast water management plans: Ships should have detailed plans outlining procedures for ballast water management, including filling, emptying, and treatment.

- Reporting and monitoring: Ships should report ballast water operations to relevant authorities and participate in monitoring programs to track the effectiveness of management practices.

Future Trends in Ballast Technologies

Ballast technologies are rapidly evolving, driven by innovation and a growing focus on sustainability. This evolution is driven by advancements in materials science, digital technologies, and a growing awareness of the environmental impact of traditional ballast systems. These advancements are shaping the future of ballast technologies and their applications across various industries.

Advancements in Materials Science

The development of new materials is playing a crucial role in shaping the future of ballast technologies. For example, researchers are exploring the use of lightweight and high-strength composites, such as carbon fiber reinforced polymers, to replace traditional steel ballast. These composites offer several advantages, including reduced weight, improved corrosion resistance, and enhanced durability. This trend is particularly significant in the transportation industry, where reducing weight can lead to fuel efficiency and lower emissions.

- Lightweight Composites: Lightweight composites, such as carbon fiber reinforced polymers (CFRP), are increasingly being explored as alternatives to traditional steel ballast. CFRP offers advantages like reduced weight, improved corrosion resistance, and enhanced durability, making them ideal for applications in transportation, aerospace, and marine industries.

- Self-Healing Materials: Researchers are developing self-healing materials that can repair damage to ballast systems, extending their lifespan and reducing maintenance costs. These materials incorporate microcapsules filled with healing agents that are released when a crack or damage occurs, promoting self-repair.

- Smart Materials: Smart materials, such as shape memory alloys and piezoelectric materials, are being integrated into ballast systems to provide adaptive and responsive functionalities. These materials can change their shape or properties in response to external stimuli, enabling dynamic ballast adjustments based on environmental conditions or load variations.

Digital Technologies and Automation

Digital technologies are transforming ballast systems, enabling greater efficiency, precision, and real-time monitoring. The integration of sensors, data analytics, and artificial intelligence (AI) is revolutionizing ballast management, allowing for more informed decisions and proactive maintenance.

- Smart Ballast Systems: Smart ballast systems utilize sensors to monitor ballast conditions, such as weight distribution, stability, and environmental factors. This data is then processed using AI algorithms to optimize ballast adjustments and ensure optimal performance.

- Automated Ballast Control: Automated ballast control systems are being developed to automate ballast adjustments, reducing human error and improving efficiency. These systems use AI algorithms to analyze data from sensors and make real-time adjustments to ballast configurations, ensuring optimal stability and performance.

- Remote Monitoring and Diagnostics: Remote monitoring and diagnostics allow for real-time tracking of ballast system performance and early detection of potential issues. This enables proactive maintenance, reducing downtime and improving safety.

Ending Remarks

Ballast technologies are an integral part of our modern world, contributing to the stability and functionality of numerous industries. As we move towards a more sustainable future, the development and application of environmentally conscious ballast solutions are becoming increasingly critical. Understanding the principles, applications, and environmental considerations of ballast technologies is crucial for shaping a safer, more efficient, and sustainable future.

Ballast technologies, essential for regulating electrical current in lighting systems, are constantly evolving. You can find comprehensive training programs on these technologies at the northeast technology center pryor oklahoma , a leading institution in vocational education. Their courses cover everything from basic principles to advanced applications, ensuring students are well-equipped to enter the growing field of ballast technology.