Aviation Repair Technologies: From Past to Future

Aviation repair technologies have evolved dramatically since the dawn of flight, transforming how we maintain and repair aircraft. From the early days of rudimentary tools and manual labor to the […]

Aviation repair technologies have evolved dramatically since the dawn of flight, transforming how we maintain and repair aircraft. From the early days of rudimentary tools and manual labor to the modern era of advanced composites, robotics, and artificial intelligence, the field has witnessed a remarkable transformation. This evolution has been driven by a relentless pursuit of safety, efficiency, and sustainability in the aviation industry.

This exploration delves into the history of aviation repair, examines modern techniques, and explores emerging technologies that are poised to revolutionize the industry. We will uncover the challenges and opportunities presented by these advancements, ultimately envisioning a future where aircraft maintenance is more efficient, cost-effective, and environmentally responsible.

Evolution of Aviation Repair Technologies

The history of aviation repair technologies is deeply intertwined with the evolution of aircraft design and materials. From the early days of rudimentary wooden and fabric aircraft to the sophisticated composite and advanced metal alloys used in modern aircraft, repair techniques have continuously adapted to meet the changing demands of the industry.

Traditional Repair Methods

Traditional aviation repair methods, prevalent in the early decades of flight, relied heavily on manual labor and simple tools. These methods, often involving extensive use of rivets, welding, and patching, were effective in repairing the relatively simple structures of early aircraft. However, as aircraft became more complex and materials evolved, traditional methods faced limitations in terms of efficiency, accuracy, and the ability to handle intricate repairs.

Modern Advancements

Modern aviation repair technologies have witnessed a dramatic shift, driven by advancements in materials science, manufacturing processes, and computer-aided engineering.

- Composite Repair: The widespread adoption of composite materials in aircraft construction has revolutionized repair techniques. Composites, like carbon fiber reinforced plastic (CFRP), offer superior strength-to-weight ratios and enhanced durability compared to traditional materials. Repairing composites requires specialized techniques, such as bonding, stitching, and resin infusion, to restore the structural integrity of damaged areas.

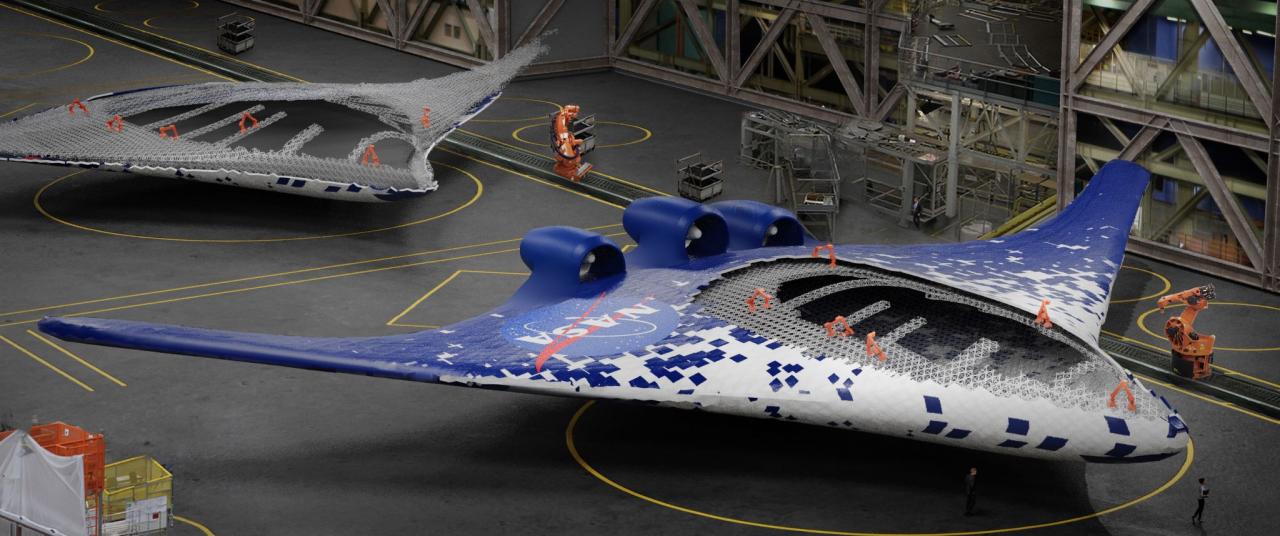

- Additive Manufacturing: Additive manufacturing, also known as 3D printing, has emerged as a transformative technology in aviation repair. This technology allows for the creation of complex, customized parts directly from digital designs, eliminating the need for traditional tooling and molds. 3D printing offers significant advantages in repair scenarios, including the ability to create lightweight, durable, and complex parts, reducing lead times and minimizing waste.

- Robotics and Automation: Robotics and automation play a crucial role in modern aviation repair, enhancing efficiency, precision, and safety. Robots can perform repetitive tasks with high accuracy, reducing human error and improving consistency in repair operations. Automated systems can also assist in tasks such as drilling, riveting, and surface preparation, contributing to faster turnaround times and improved quality.

Aircraft Maintenance and Repair Techniques

Aircraft maintenance and repair techniques are essential for ensuring the safe and reliable operation of aircraft. These techniques involve a wide range of procedures, from routine inspections to complex structural repairs. They are crucial for identifying and rectifying potential problems before they escalate into serious safety hazards.

Types of Aircraft Maintenance and Repair

There are different types of aircraft maintenance and repair, categorized based on their scope and frequency. These include:

- Line Maintenance: This is routine maintenance performed daily or before each flight. It includes tasks such as pre-flight inspections, refueling, and checking fluid levels.

- Scheduled Maintenance: This involves more extensive inspections and repairs, conducted at specific intervals as Artikeld in the aircraft’s maintenance manual. It includes tasks such as engine overhauls, component replacements, and structural inspections.

- Unscheduled Maintenance: This is performed when a problem arises that requires immediate attention. It can range from minor repairs to major structural work.

Common Repair Procedures

Common repair procedures include:

- Troubleshooting: This involves identifying the root cause of a problem. It involves examining symptoms, analyzing data, and using diagnostic tools to determine the source of the issue.

- Component Replacement: This involves replacing defective components with new or refurbished ones. It requires careful removal and installation procedures to ensure proper fit and functionality.

- Structural Repairs: These involve repairing damage to the aircraft’s structure, such as cracks, dents, or corrosion. It requires specialized techniques and materials to restore the structural integrity of the aircraft.

Tools and Equipment

Aviation repair technicians use a wide range of specialized tools and equipment to perform their work. These tools are designed for specific tasks and are essential for ensuring the quality and safety of repairs.

| Tool/Equipment | Application |

|---|---|

| Torque Wrenches | Applying precise torques to fasteners, ensuring proper tightness |

| Pneumatic Riveting Guns | Fastening aircraft skin panels and other components |

| Hydraulic Jacks | Lifting and supporting aircraft during maintenance |

| Inspection Mirrors | Accessing hard-to-reach areas for inspection |

| Borescopes | Inspecting internal components and cavities |

Emerging Technologies in Aviation Repair: Aviation Repair Technologies

The aviation industry is constantly evolving, with new technologies emerging that are transforming the way aircraft are maintained and repaired. These advancements are not only improving efficiency and safety but also paving the way for a more sustainable future for aviation.

Artificial Intelligence and Machine Learning

Artificial intelligence (AI) and machine learning (ML) are revolutionizing aircraft maintenance by automating tasks, predicting potential issues, and improving decision-making. AI-powered systems can analyze vast amounts of data from sensors, flight logs, and maintenance records to identify patterns and predict potential failures before they occur. This proactive approach to maintenance significantly reduces downtime and ensures aircraft safety.

- Predictive Maintenance: AI algorithms can analyze data from various sources, such as engine vibration sensors, flight data recorders, and maintenance records, to identify patterns and predict potential failures. This allows maintenance teams to schedule repairs proactively, preventing unscheduled downtime and reducing the risk of catastrophic events. For instance, an AI system could analyze engine vibration data and predict a potential bearing failure, prompting maintenance personnel to replace the bearing before it fails in flight.

- Automated Inspection and Repair: AI-powered robots can perform routine inspections and repairs, reducing the need for human intervention in hazardous or repetitive tasks. These robots can access hard-to-reach areas, inspect for damage, and even perform simple repairs like replacing bolts or sealing leaks. This not only improves efficiency but also reduces the risk of human error. For example, an AI-powered robot could be deployed to inspect the underside of an aircraft wing for cracks, identifying potential issues that might otherwise go unnoticed.

- Enhanced Decision-Making: AI can assist maintenance technicians in making informed decisions by providing real-time data analysis and expert recommendations. For instance, an AI system could analyze a pilot’s report of a strange noise during flight and suggest potential causes and recommended actions, helping the technician diagnose the issue more quickly and efficiently.

Virtual Reality and Augmented Reality, Aviation repair technologies

Virtual reality (VR) and augmented reality (AR) are transforming aviation training and repair processes by providing immersive and interactive experiences. VR allows trainees to simulate real-world scenarios, such as engine maintenance or aircraft troubleshooting, in a safe and controlled environment. AR overlays digital information onto the real world, providing technicians with real-time guidance and instructions during repairs.

- Immersive Training: VR training programs provide realistic simulations of aircraft maintenance tasks, allowing trainees to practice procedures and gain experience without the risk of damaging real equipment. This reduces training costs and improves the quality of training by allowing trainees to learn at their own pace and repeat tasks until they are proficient. For example, a trainee could use a VR headset to simulate the process of replacing an engine component, gaining hands-on experience without the need for a real aircraft.

- Guided Repairs: AR can overlay digital information onto the real world, providing technicians with real-time guidance during repairs. This could include step-by-step instructions, 3D models of components, and access to repair manuals and technical data. This technology reduces the risk of errors and improves repair efficiency by providing technicians with the information they need at the point of need. For instance, an AR system could overlay a digital model of an engine onto the real engine, highlighting the specific component that needs to be replaced and providing step-by-step instructions for the repair process.

Predictive Maintenance and Data Analytics

Predictive maintenance, powered by data analytics, is a key strategy for preventing aircraft failures and optimizing repair schedules. By analyzing data from sensors, flight logs, and maintenance records, airlines can identify potential issues before they become critical, reducing downtime and improving operational efficiency.

- Early Detection of Issues: Data analytics can identify subtle changes in aircraft performance that may indicate potential problems. For instance, an increase in engine vibration or a slight decrease in fuel efficiency could be early indicators of a developing issue. By detecting these issues early, maintenance teams can address them before they escalate into major problems.

- Optimized Maintenance Schedules: Data analytics can be used to optimize maintenance schedules based on real-time aircraft performance and environmental conditions. This allows airlines to schedule maintenance tasks only when they are truly necessary, reducing unnecessary downtime and maintenance costs.

Challenges and Opportunities in Aviation Repair Technologies

The aviation industry is constantly evolving, driven by advancements in technology and the need for greater efficiency and sustainability. While these advancements present exciting opportunities, they also come with challenges that must be addressed to ensure the smooth implementation and adoption of new repair technologies.

Cost Considerations

The implementation of new repair technologies often involves significant upfront costs, including the purchase of new equipment, software, and training. This can be a major barrier for smaller airlines and maintenance organizations, which may not have the financial resources to invest in cutting-edge technologies. Additionally, the ongoing maintenance and support costs for these technologies can also be substantial. To mitigate these costs, airlines and maintenance organizations can explore partnerships with technology providers, lease or rent equipment, and prioritize technologies that offer a clear return on investment.

Training and Workforce Development

The successful implementation of new repair technologies requires a skilled workforce that can operate and maintain them effectively. This necessitates comprehensive training programs that equip technicians with the necessary knowledge and skills. The rapid pace of technological advancements can make it challenging to keep up with the latest training requirements. To address this challenge, the aviation industry needs to invest in ongoing training and education programs, and consider developing standardized training curricula for new technologies.

Regulatory Compliance

The aviation industry is highly regulated, and any new repair technologies must meet strict safety and compliance standards. The process of obtaining regulatory approval for new technologies can be time-consuming and complex, adding to the overall cost and implementation timeline. To facilitate the adoption of new technologies, regulatory bodies need to streamline the approval process, while ensuring that safety standards are not compromised.

Opportunities for Improvement

While the challenges are real, the opportunities presented by advancements in aviation repair technologies are significant. These technologies offer the potential for:

Enhanced Safety

New repair technologies can enhance aircraft safety by enabling more accurate and efficient inspections and repairs. For example, automated inspection systems can identify potential defects that might be missed during manual inspections, while advanced repair techniques can ensure that repairs are completed to the highest standards.

Reduced Downtime

New repair technologies can reduce aircraft downtime by streamlining the repair process and enabling faster turnaround times. For example, 3D printing can be used to create custom parts on-demand, reducing the need to wait for parts to be shipped from manufacturers.

Enhanced Sustainability

New repair technologies can promote sustainability in the aviation industry by reducing waste, emissions, and fuel consumption. For example, advanced materials and repair techniques can extend the life of aircraft components, reducing the need for replacements.

Future Trends and Advancements

The future of aviation repair technologies is bright, with several emerging trends that are likely to shape the industry in the coming years:

Artificial Intelligence (AI) and Machine Learning

AI and machine learning are expected to play a significant role in aviation repair, enabling predictive maintenance, automated inspections, and real-time performance monitoring. These technologies can help to identify potential problems before they occur, reducing downtime and improving safety.

Augmented and Virtual Reality (AR/VR)

AR/VR technologies can be used to create immersive training simulations for technicians, providing hands-on experience in a safe and controlled environment. AR/VR can also be used to assist technicians during repairs, providing real-time guidance and instructions.

Robotics and Automation

Robotics and automation are increasingly being used in aviation repair, enabling tasks to be performed more efficiently and accurately. For example, robots can be used to perform repetitive tasks, such as drilling and riveting, freeing up technicians to focus on more complex tasks.

Sustainable Materials and Repair Techniques

The aviation industry is committed to reducing its environmental impact, and new repair technologies are playing a key role in this effort. Sustainable materials, such as composites and bio-based materials, are being used to manufacture aircraft components, while new repair techniques are being developed to extend the life of these components.

Final Summary

As aviation repair technologies continue to advance, the future holds immense promise for enhanced safety, reduced downtime, and greater sustainability in the industry. By embracing these advancements, we can ensure that the skies remain safe and accessible for generations to come. The journey ahead is filled with exciting possibilities, and the innovative spirit that has driven aviation repair for decades will continue to shape the industry’s future.

Aviation repair technologies are constantly evolving, requiring sophisticated tools and processes to maintain aircraft safety and efficiency. Similar to the automotive industry, advancements in dealership technology solutions are also transforming the way aircraft repair businesses operate. By implementing solutions like those found at dealership technology solutions , aviation repair shops can streamline their operations, improve communication, and ultimately enhance customer satisfaction.