Agilent Technologies 7890A: A Comprehensive Guide

The Agilent Technologies 7890A Gas Chromatograph stands as a cornerstone of modern analytical chemistry, offering unparalleled precision and versatility for a wide range of applications. This instrument, renowned for its […]

The Agilent Technologies 7890A Gas Chromatograph stands as a cornerstone of modern analytical chemistry, offering unparalleled precision and versatility for a wide range of applications. This instrument, renowned for its robust design and advanced capabilities, has become an indispensable tool in industries such as pharmaceuticals, environmental monitoring, and food safety.

The 7890A operates on the fundamental principles of gas chromatography, separating and analyzing volatile compounds based on their boiling points and interactions with a stationary phase. Its modular design allows for customization with various detectors, columns, and injection techniques, catering to specific analytical needs. This adaptability, combined with its user-friendly interface and comprehensive data analysis software, makes the 7890A a powerful instrument for both research and routine analysis.

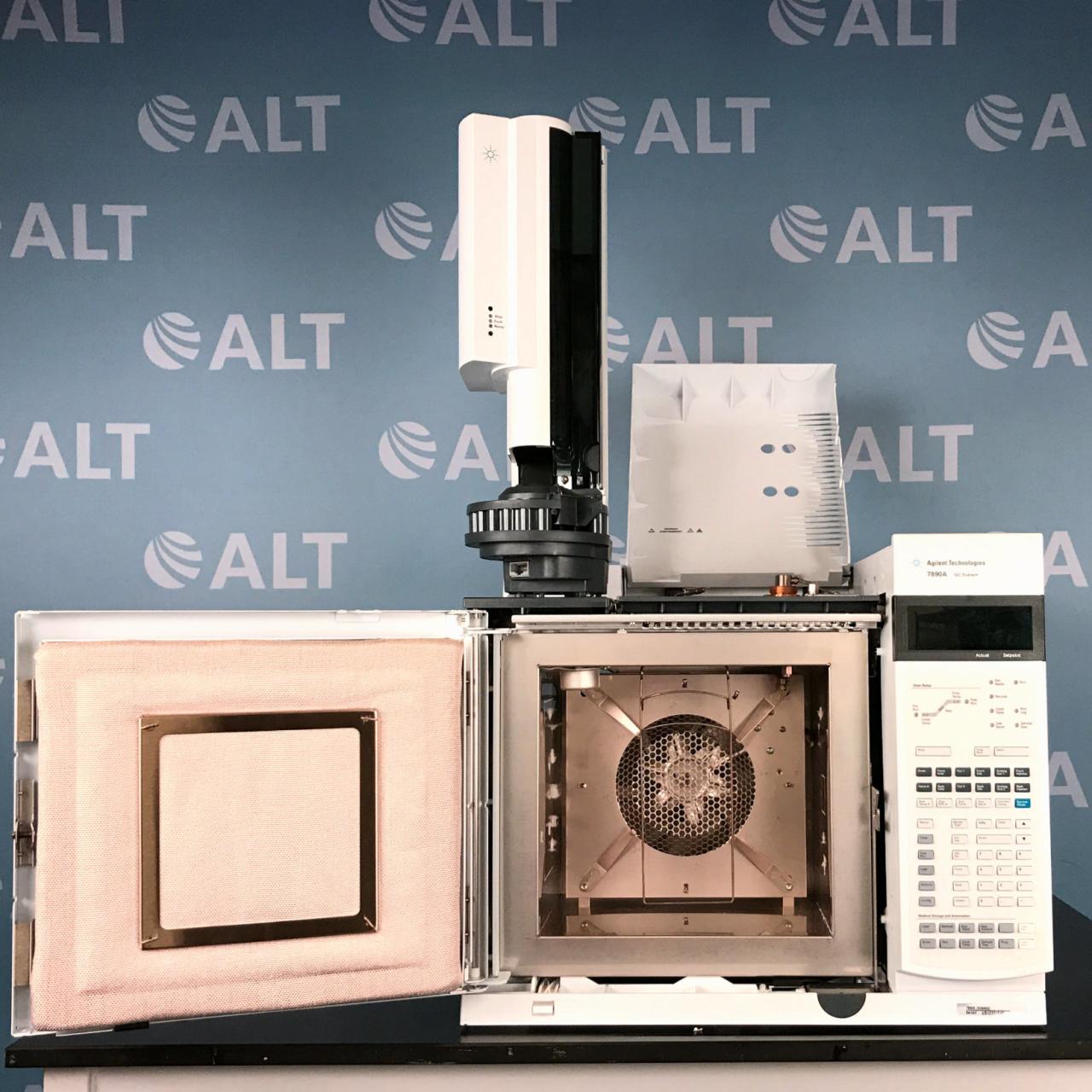

Agilent Technologies 7890A Gas Chromatograph Overview

The Agilent Technologies 7890A Gas Chromatograph (GC) is a robust and versatile analytical instrument designed for separating and quantifying volatile components in complex mixtures. It is widely used in various industries, including pharmaceuticals, environmental monitoring, and food safety, for its high sensitivity, accuracy, and reliability.

Fundamental Principles of Gas Chromatography

Gas chromatography (GC) is a separation technique that separates components of a mixture based on their different volatilities. In GC, the sample is injected into a heated, inert carrier gas stream that transports the sample through a column. The column is packed with a stationary phase, which can be either a solid or a liquid, and the components of the sample interact with the stationary phase to varying degrees. The more volatile components spend less time in the stationary phase and travel faster through the column, while the less volatile components spend more time in the stationary phase and travel slower. This difference in travel time results in the separation of the components, which are then detected by a detector.

Agilent Technologies 7890A Gas Chromatograph Operation

The Agilent Technologies 7890A GC system consists of several key components:

- Injector: The injector is where the sample is introduced into the carrier gas stream. The 7890A offers various injection techniques, including split, splitless, and on-column injection, to optimize sample introduction for different applications.

- Column: The column is the heart of the GC system, where the separation of the components takes place. The 7890A supports a wide range of columns, including packed columns and capillary columns, with different stationary phases to achieve the desired separation.

- Oven: The oven controls the temperature of the column, which is critical for achieving optimal separation. The 7890A oven offers precise temperature control and rapid heating and cooling rates to ensure reproducible results.

- Detector: The detector is responsible for detecting the separated components as they exit the column. The 7890A offers a variety of detectors, including flame ionization detector (FID), electron capture detector (ECD), and mass spectrometer (MS), each with specific sensitivities and applications.

- Data System: The data system collects and processes the signals from the detector, generating chromatograms that show the separated components and their relative amounts.

Applications of Agilent Technologies 7890A Gas Chromatograph

The Agilent Technologies 7890A GC system is used in a wide range of applications, including:

- Pharmaceuticals: Quality control of raw materials, intermediates, and finished products; analysis of impurities and degradation products; and drug discovery and development.

- Environmental Monitoring: Analysis of air, water, and soil samples for pollutants, such as volatile organic compounds (VOCs) and pesticides.

- Food Safety: Analysis of food products for contaminants, such as pesticides, herbicides, and mycotoxins; and determination of the authenticity and origin of food products.

- Chemical Industry: Analysis of raw materials, intermediates, and finished products; process monitoring and control; and research and development.

- Forensic Science: Analysis of evidence samples, such as blood, urine, and hair, for drugs and other substances.

7890A System Components and Configuration

The Agilent Technologies 7890A Gas Chromatograph is a sophisticated analytical instrument comprised of several interconnected components, each playing a crucial role in the overall GC analysis process. Understanding the functions and configuration options of these components is essential for optimizing GC performance and achieving accurate and reliable analytical results.

Injector

The injector is responsible for introducing the sample into the GC system. It is typically heated to a specific temperature to ensure that the sample is vaporized and injected into the carrier gas stream. The injector configuration can significantly impact the quality of the GC analysis.

- Split/Splitless Injection: This technique allows for a controlled injection of the sample into the GC system. In split injection, a portion of the sample is vented to the atmosphere, while the remaining portion enters the column. Splitless injection, on the other hand, introduces the entire sample into the column, maximizing sensitivity. This choice depends on the sample concentration and the desired analytical outcome.

- On-Column Injection: This method involves injecting the sample directly onto the GC column. This technique is often used for volatile samples, as it minimizes the risk of sample degradation or loss.

- Programmable Temperature Vaporizing (PTV) Injection: This technique allows for precise temperature control of the injection process. The PTV injector is typically used for complex samples that require careful vaporization to prevent sample degradation.

Column Oven

The column oven houses the GC column, which is a long, narrow tube packed with a stationary phase. The stationary phase is a material that interacts with the components of the sample, separating them based on their volatility and affinity to the stationary phase. The column oven temperature is precisely controlled to optimize the separation process.

- Temperature Programming: The column oven temperature can be programmed to change over time, allowing for the separation of complex mixtures with a wide range of boiling points. This technique is crucial for achieving optimal separation of different components within the sample.

- Column Selection: The choice of GC column is crucial for successful separation. Various column types are available, each with different stationary phases and dimensions, offering a wide range of selectivity and separation capabilities. Choosing the right column depends on the nature of the sample and the analytical goals.

Detector

The detector is responsible for detecting the separated components as they elute from the GC column. The detector converts the presence of each component into a measurable signal, which is then recorded by the data system.

- Flame Ionization Detector (FID): This is a universal detector that responds to most organic compounds. It is highly sensitive and is commonly used in a wide range of applications, including environmental analysis, food safety, and pharmaceutical analysis.

- Electron Capture Detector (ECD): This detector is highly sensitive to compounds containing electronegative atoms, such as halogens and phosphorus. It is commonly used in pesticide analysis, environmental monitoring, and pharmaceutical analysis.

- Nitrogen-Phosphorus Detector (NPD): This detector is highly sensitive to compounds containing nitrogen and phosphorus. It is commonly used in food safety, environmental analysis, and pharmaceutical analysis.

- Mass Spectrometer (MS): This detector identifies and quantifies individual components in a sample by measuring their mass-to-charge ratio. MS is a powerful tool for identifying unknown compounds and providing detailed information about the chemical composition of a sample.

Data System, Agilent technologies 7890a

The data system collects, processes, and analyzes the signals generated by the detector. It allows for the visualization, integration, and interpretation of the GC data.

- Chromatogram Display: The data system displays the chromatogram, which is a graph showing the detector response as a function of time. This allows for the identification and quantification of the individual components in the sample.

- Data Analysis: The data system provides tools for data analysis, including peak identification, quantification, and library searching. This allows for the identification of unknown compounds and the determination of their concentrations in the sample.

Configuration Options

The 7890A offers a wide range of configuration options, allowing for customization to meet specific analytical needs.

- Detector Selection: The 7890A can be configured with a variety of detectors, including FID, ECD, NPD, and MS. The choice of detector depends on the specific application and the type of compounds being analyzed.

- Column Selection: A wide range of GC columns are available, offering different stationary phases, dimensions, and selectivity. The choice of column depends on the nature of the sample and the desired separation.

- Injection Techniques: The 7890A supports various injection techniques, including split/splitless, on-column, and PTV injection. The choice of injection technique depends on the sample volatility and the desired sensitivity.

7890A Operation and Maintenance

The Agilent Technologies 7890A Gas Chromatograph is a sophisticated analytical instrument that requires careful operation and regular maintenance to ensure optimal performance and reliable results. This section will cover the procedures for operating the 7890A system, including sample preparation, injection, data acquisition, and analysis. It will also discuss the routine maintenance tasks required to maintain the instrument’s accuracy and longevity.

Sample Preparation

Proper sample preparation is crucial for obtaining accurate and reproducible results from GC analysis. The following steps Artikel the general procedures for preparing samples for analysis on the 7890A:

- Sample Selection and Collection: The first step is to select and collect the appropriate sample for analysis. The choice of sample depends on the specific application and the analytes of interest. Ensure the sample is representative of the material being analyzed.

- Sample Preparation: Depending on the sample type and the analytical method, further preparation may be necessary. This can include:

- Filtration: Removing particulate matter from the sample to prevent clogging the GC system.

- Extraction: Isolating the analytes of interest from the sample matrix.

- Derivatization: Chemically modifying the analytes to improve their volatility or detectability.

- Sample Dilution: If the analyte concentration is too high, it may be necessary to dilute the sample to ensure it falls within the linear range of the detector.

- Sample Storage: Store the prepared samples in appropriate containers under suitable conditions to prevent degradation or contamination.

Injection Techniques

The 7890A offers various injection techniques, each suited for different sample types and analytical needs.

- Split Injection: This technique is commonly used for analyzing volatile samples. A portion of the sample is injected into the GC system, and the rest is vented to the atmosphere. This reduces the amount of sample entering the column, improving peak resolution and reducing the risk of overloading the column.

- Splitless Injection: This technique is ideal for analyzing trace components in complex matrices. The entire sample is injected into the GC system, allowing for the detection of even low concentrations of analytes. However, this technique can lead to broader peaks and decreased resolution.

- On-Column Injection: This technique is used for analyzing thermally labile compounds. The sample is injected directly onto the GC column, minimizing the risk of degradation.

- Programmed Temperature Vaporization (PTV) Injection: This technique combines the advantages of split and splitless injection. The sample is initially injected into a heated chamber, where it is vaporized and then transferred to the GC column. This allows for the analysis of both volatile and non-volatile compounds.

Data Acquisition and Analysis

The 7890A is equipped with a powerful data acquisition and analysis system.

- Chromatographic Data: The GC separates the components of the sample based on their volatility, generating a chromatogram. The chromatogram displays the signal intensity of the detector as a function of time.

- Peak Identification and Quantification: The data acquisition system can identify and quantify the peaks in the chromatogram. This involves determining the retention time of each peak, its area, and its height.

- Data Processing: The system can perform various data processing tasks, such as baseline correction, peak integration, and calibration.

- Reporting: The data can be exported in various formats for further analysis and reporting.

7890A System Configuration

The 7890A can be configured with a wide range of components to meet specific analytical requirements.

- Inlet System: The inlet system is responsible for introducing the sample into the GC column. Different inlet systems are available, including split/splitless, on-column, and PTV inlets.

- GC Column: The GC column is the heart of the system, where the separation of the sample components takes place. The choice of column depends on the analytes of interest and the separation requirements.

- Detector: The detector is used to detect the separated components as they elute from the GC column. The 7890A offers a variety of detectors, including flame ionization detector (FID), electron capture detector (ECD), nitrogen-phosphorus detector (NPD), and mass spectrometer (MS).

- Data System: The data system acquires and processes the chromatographic data, providing a comprehensive analysis of the sample.

Routine Maintenance

Regular maintenance is essential for ensuring the optimal performance and longevity of the 7890A.

- Cleaning: Clean the instrument regularly to remove dust, debris, and contaminants. This includes cleaning the inlet system, column, detector, and other components.

- Calibration: Calibrate the instrument regularly to ensure accurate measurements. This involves using standard samples to determine the response of the system to known concentrations of analytes.

- Troubleshooting: Identify and resolve any issues that may arise during operation. This may involve checking for leaks, replacing consumables, or adjusting system parameters.

- Preventive Maintenance: Perform regular preventive maintenance tasks to minimize the risk of breakdowns and ensure optimal performance. This includes replacing consumables, inspecting components, and checking for wear and tear.

Applications and Case Studies

The Agilent Technologies 7890A Gas Chromatograph is a versatile instrument with a wide range of applications across various industries. Its high sensitivity, precision, and reliability make it an ideal choice for a wide range of analytical challenges.

This section will explore real-world examples of the 7890A’s applications, showcasing its capabilities and benefits in diverse fields. We will also examine case studies demonstrating the effectiveness of the 7890A in solving specific analytical problems. Finally, we will discuss how the 7890A contributes to improving product quality, process efficiency, and regulatory compliance.

Applications in Various Industries

The Agilent Technologies 7890A Gas Chromatograph finds applications in various industries, including:

- Environmental Monitoring: The 7890A is used to analyze air, water, and soil samples for pollutants such as volatile organic compounds (VOCs), pesticides, and herbicides. This helps ensure environmental compliance and protect public health.

- Food Safety: The 7890A plays a crucial role in food safety analysis by identifying and quantifying contaminants, such as pesticides, mycotoxins, and residues of antibiotics, in food products. This helps ensure the safety and quality of food products.

- Pharmaceutical Analysis: The 7890A is used for the analysis of pharmaceutical products to ensure their purity, potency, and stability. This includes the analysis of raw materials, intermediates, and finished products.

- Petrochemical Industry: The 7890A is used to analyze petroleum products, such as gasoline, diesel, and kerosene, to determine their composition and quality. This helps ensure the quality and performance of fuels and lubricants.

- Chemical Manufacturing: The 7890A is used to analyze chemical products to ensure their purity, composition, and quality. This helps ensure the safety and effectiveness of chemical products.

Case Studies

Here are some case studies that highlight the effectiveness of the Agilent Technologies 7890A Gas Chromatograph in addressing specific analytical challenges:

- Case Study 1: Environmental Monitoring

A leading environmental consulting firm used the 7890A to analyze soil samples for volatile organic compounds (VOCs) near a former industrial site. The 7890A’s high sensitivity and precision enabled the firm to identify and quantify low levels of VOCs, helping them determine the extent of contamination and develop a remediation plan. - Case Study 2: Food Safety

A food processing company used the 7890A to analyze their raw materials for pesticide residues. The 7890A’s accurate and reliable results helped the company ensure the safety of their products and maintain compliance with food safety regulations. - Case Study 3: Pharmaceutical Analysis

A pharmaceutical company used the 7890A to analyze the purity and potency of their active pharmaceutical ingredients (APIs). The 7890A’s precise and accurate results helped the company ensure the quality and effectiveness of their products and meet regulatory requirements.

Benefits of Using the 7890A

The Agilent Technologies 7890A Gas Chromatograph offers numerous benefits, including:

- High Sensitivity and Precision: The 7890A provides exceptional sensitivity and precision, allowing for the detection and quantification of even trace amounts of analytes.

- Reliability and Durability: The 7890A is known for its reliability and durability, ensuring consistent and accurate results over time.

- Versatility: The 7890A is a versatile instrument that can be configured to meet a wide range of analytical needs. It offers a variety of detectors, columns, and accessories, making it suitable for various applications.

- Ease of Use: The 7890A is designed for ease of use, with intuitive software and a user-friendly interface. This makes it easy for operators to learn and operate the instrument, minimizing training time and errors.

- Data Integrity and Compliance: The 7890A is designed to ensure data integrity and compliance with regulatory requirements. It features advanced data management capabilities and supports electronic signatures and audit trails.

Advancements and Future Trends

The Agilent Technologies 7890A Gas Chromatograph, a robust and versatile instrument, has been at the forefront of analytical chemistry for decades. However, the field of analytical chemistry is constantly evolving, driven by the need for faster, more sensitive, and more automated analytical solutions. The 7890A has benefited from these advancements and continues to be a powerful tool for researchers and analysts. Here we will explore some of the key advancements in GC technology and their impact on the 7890A, as well as emerging trends that are shaping the future of GC analysis.

Advancements in GC Technology

The 7890A has benefited from significant advancements in GC technology over the years. These advancements have improved the performance, versatility, and user-friendliness of the instrument. Here are some of the key advancements:

- Enhanced Detector Sensitivity: Advancements in detector technology, such as the development of more sensitive flame ionization detectors (FIDs) and mass spectrometers (MS), have significantly improved the detection limits of the 7890A. This allows for the analysis of trace-level analytes, providing greater accuracy and precision in complex samples.

- Improved Column Technology: The development of new stationary phases and column materials has expanded the range of analytes that can be separated and analyzed using the 7890A. This includes the development of columns with improved thermal stability, inertness, and selectivity, enabling the analysis of a wider range of compounds, including volatile organic compounds (VOCs), pesticides, and pharmaceuticals.

- Automated Sample Handling: The 7890A can be integrated with automated sample handling systems, such as autosamplers and robotic systems, which streamline the analytical process and reduce the risk of human error. This is particularly beneficial for high-throughput applications, where multiple samples need to be analyzed efficiently.

- Improved Data Analysis Software: The 7890A is equipped with powerful data analysis software that provides comprehensive tools for peak identification, quantification, and reporting. The software allows for advanced data processing, including baseline correction, peak deconvolution, and library searching, facilitating more accurate and reliable results.

Miniaturization and Microfluidic GC

Miniaturization of GC systems has gained significant traction in recent years, driven by the need for portable, on-site analysis. Microfluidic GC systems, which integrate all components onto a single chip, offer several advantages, including reduced size, lower power consumption, and faster analysis times. These systems have the potential to revolutionize GC analysis, enabling on-site monitoring of environmental pollutants, food safety testing, and medical diagnostics. While the 7890A is not a microfluidic GC system, it has paved the way for the development of these technologies through its robust design and advanced capabilities.

Automation and High-Throughput Analysis

Automation is another major trend in GC analysis, particularly in industrial settings where high-throughput analysis is required. The 7890A can be integrated with robotic systems and automated sample handling systems, allowing for the analysis of hundreds or even thousands of samples per day. This automation reduces manual labor, improves accuracy, and enhances efficiency in production monitoring, quality control, and environmental monitoring.

Integration with Other Analytical Techniques

GC is often used in conjunction with other analytical techniques, such as mass spectrometry (MS), to provide comprehensive information about the composition of samples. The 7890A can be coupled with various MS systems, enabling the identification and quantification of compounds with high sensitivity and selectivity. This integration provides valuable insights into complex mixtures, such as those found in environmental samples, biological samples, and pharmaceutical formulations.

Future Directions and Applications

The 7890A is a versatile instrument that is well-suited for a wide range of applications. As the field of analytical chemistry continues to evolve, the 7890A will likely play an increasingly important role in addressing emerging challenges. Here are some potential future directions and applications:

- Analysis of Emerging Pollutants: The 7890A can be used to analyze emerging pollutants, such as microplastics and pharmaceuticals, which pose significant environmental and health risks. Advanced GC techniques, such as comprehensive two-dimensional gas chromatography (GCxGC), can be employed to separate and identify these complex pollutants.

- Point-of-Care Diagnostics: The 7890A can be adapted for point-of-care diagnostics, enabling rapid and accurate analysis of biological samples. This could revolutionize healthcare, allowing for faster diagnoses and personalized treatment plans.

- Food Safety and Quality Control: The 7890A can be used to analyze food samples for contaminants, such as pesticides, heavy metals, and mycotoxins, ensuring food safety and quality. Automated GC systems can be deployed for high-throughput analysis, ensuring efficient monitoring of food products.

- Environmental Monitoring: The 7890A is a valuable tool for environmental monitoring, enabling the analysis of air, water, and soil samples for pollutants. The instrument can be used to track changes in environmental conditions, assess the impact of human activities, and guide environmental protection efforts.

Last Point

From its sophisticated components to its wide array of applications, the Agilent Technologies 7890A Gas Chromatograph exemplifies the cutting edge of analytical science. Its ability to deliver accurate and reliable results, coupled with its versatility and ease of use, has cemented its status as a leading instrument in the field. As advancements in GC technology continue to evolve, the 7890A remains a valuable tool, poised to play a pivotal role in shaping the future of analytical chemistry.

The Agilent Technologies 7890A gas chromatograph is a powerful tool for analyzing complex samples, but finding the right accessories can be crucial for optimal performance. For those looking for reliable and high-quality components, union technology corp is a trusted source.

They offer a wide range of compatible parts, ensuring your 7890A operates at peak efficiency and delivers accurate results. Whether you need injectors, detectors, or columns, Union Technology Corp. has you covered.