Advanced Inspection Technologies Inc.: Transforming Inspections

Advanced Inspection Technologies Inc. stands at the forefront of revolutionizing inspection practices across industries. The company’s innovative approach leverages cutting-edge technologies to enhance safety, efficiency, and productivity, setting a new […]

Advanced Inspection Technologies Inc. stands at the forefront of revolutionizing inspection practices across industries. The company’s innovative approach leverages cutting-edge technologies to enhance safety, efficiency, and productivity, setting a new standard for asset integrity and risk mitigation.

With a deep understanding of industry needs, Advanced Inspection Technologies Inc. develops and deploys a comprehensive suite of solutions tailored to address specific challenges. From non-destructive testing to advanced data analytics, their expertise spans a wide range of applications, empowering clients to make informed decisions and optimize their operations.

Advanced Inspection Technologies Inc. Overview

![]()

Advanced Inspection Technologies Inc. (AIT) is a leading provider of innovative inspection solutions, committed to delivering exceptional services and technological advancements to diverse industries.

Company History, Advanced inspection technologies inc

Founded in [Year], AIT has a rich history of innovation and growth. The company began as a small operation specializing in [Initial Area of Expertise]. Through consistent dedication to research and development, AIT expanded its service offerings to encompass a wider range of inspection technologies and industries.

Mission, Vision, and Core Values

AIT’s mission is to provide comprehensive inspection solutions that enhance safety, reliability, and efficiency for our clients. Our vision is to be the trusted partner for all inspection needs, delivering cutting-edge technologies and unparalleled expertise. The company’s core values guide its operations and interactions with clients, employees, and partners:

- Integrity: AIT operates with honesty and transparency in all its endeavors.

- Innovation: The company continuously strives to develop and implement new technologies and solutions.

- Customer Focus: AIT is dedicated to exceeding client expectations by providing tailored solutions and exceptional service.

- Teamwork: AIT fosters a collaborative work environment that encourages open communication and shared success.

Key Services and Areas of Expertise

AIT offers a comprehensive suite of inspection services, catering to various industries. The company’s expertise spans a wide range of technologies and applications:

- Non-Destructive Testing (NDT): AIT utilizes various NDT techniques, including ultrasonic testing, radiographic inspection, magnetic particle testing, and eddy current testing, to evaluate the integrity of materials and structures without causing damage.

- Remote Visual Inspection: AIT employs advanced robotic systems and specialized cameras to conduct inspections in hazardous or inaccessible environments, ensuring safety and efficiency.

- Corrosion Inspection: AIT provides comprehensive corrosion assessments and mitigation strategies for various industries, minimizing asset degradation and extending service life.

- Structural Integrity Analysis: AIT utilizes advanced modeling and simulation techniques to assess the structural integrity of assets, ensuring safety and reliability.

Target Markets and Customer Base

AIT’s target markets include a wide range of industries, including:

- Energy: Oil and gas, power generation, renewable energy

- Infrastructure: Bridges, tunnels, pipelines, buildings

- Manufacturing: Aerospace, automotive, shipbuilding

- Transportation: Rail, aviation, maritime

AIT serves a diverse customer base, ranging from large corporations to small businesses. The company’s commitment to providing customized solutions and exceptional service has earned it a reputation for reliability and trust among its clients.

Technologies and Solutions

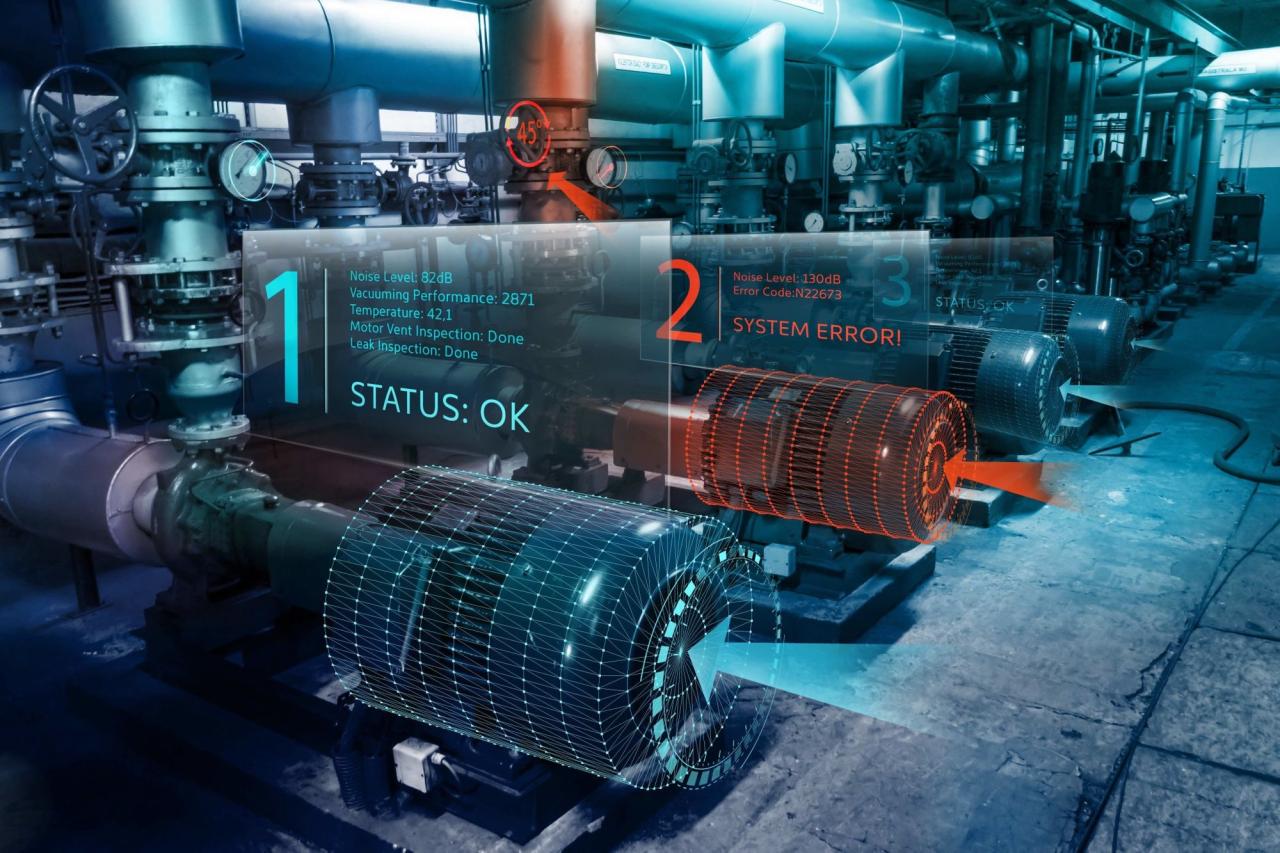

Advanced Inspection Technologies Inc. (AIT) is a leading provider of innovative inspection solutions, utilizing cutting-edge technologies to enhance safety, efficiency, and productivity across various industries. AIT’s expertise lies in developing and deploying advanced inspection technologies that enable clients to identify potential issues before they become major problems.

Advanced Inspection Technologies

AIT offers a comprehensive suite of advanced inspection technologies, each designed to address specific challenges and provide detailed insights into the condition of assets. These technologies encompass a range of modalities, including:

- Non-Destructive Testing (NDT): AIT employs a variety of NDT techniques, such as ultrasonic testing (UT), radiographic testing (RT), eddy current testing (ECT), and magnetic particle testing (MT), to assess the integrity of materials and structures without causing damage. NDT methods are crucial for identifying flaws, cracks, corrosion, and other defects in pipelines, bridges, aircraft, and other critical infrastructure.

- Remote Visual Inspection (RVI): RVI utilizes robotic systems equipped with high-resolution cameras and sensors to inspect hard-to-reach or hazardous areas. This technology is particularly valuable for inspecting pipelines, tanks, and other confined spaces, minimizing the need for human entry and reducing safety risks.

- 3D Laser Scanning: AIT’s 3D laser scanning technology creates highly accurate and detailed digital models of structures and assets. This technology is used for asset management, facility planning, and construction monitoring, enabling precise measurements and visualizations for informed decision-making.

- Thermography: Thermographic imaging captures heat signatures, allowing inspectors to identify areas of thermal anomalies. This technology is used to detect overheating components, insulation defects, and other potential problems in electrical systems, mechanical equipment, and building structures.

- Advanced Analytics and Data Visualization: AIT’s solutions leverage data analytics and visualization tools to extract meaningful insights from inspection data. This enables clients to track asset performance, identify trends, and optimize maintenance strategies for improved efficiency and cost savings.

Applications in Various Industries

AIT’s advanced inspection technologies find widespread application across a variety of industries, including:

- Oil and Gas: Inspection of pipelines, tanks, and other critical infrastructure to ensure safety and prevent leaks, corrosion, and other potential failures.

- Power Generation: Inspection of turbines, boilers, and other power plant equipment to detect wear and tear, corrosion, and other issues that could affect plant performance and reliability.

- Aerospace: Inspection of aircraft components, engines, and structures to ensure safety and maintain airworthiness.

- Infrastructure: Inspection of bridges, tunnels, and other critical infrastructure to assess structural integrity and identify potential safety hazards.

- Manufacturing: Inspection of production lines, machinery, and equipment to ensure quality control and identify potential defects.

- Construction: Monitoring of construction projects to ensure compliance with design specifications and identify potential safety risks.

Proprietary Solutions

AIT has developed a range of proprietary solutions that leverage its advanced inspection technologies to provide tailored solutions for specific industry needs. These solutions include:

- Pipeline Integrity Management System (PIMS): This comprehensive solution utilizes a combination of NDT, RVI, and data analytics to assess the integrity of pipelines and optimize maintenance strategies. PIMS helps clients identify potential issues before they become major problems, reducing the risk of leaks, spills, and other costly incidents.

- Asset Performance Management (APM) Platform: This platform integrates data from various inspection technologies to provide a holistic view of asset health. APM enables clients to track asset performance, identify trends, and optimize maintenance strategies for improved efficiency and cost savings.

- Remote Inspection and Monitoring (RIM) System: This system utilizes RVI and other remote sensing technologies to enable continuous monitoring of critical infrastructure. RIM provides real-time data on asset health, allowing for early detection of potential problems and proactive maintenance planning.

| Technology | Capabilities | Industry Applications |

|---|---|---|

| Non-Destructive Testing (NDT) | Identifies flaws, cracks, corrosion, and other defects in materials and structures without causing damage. | Pipelines, bridges, aircraft, infrastructure, manufacturing, construction. |

| Remote Visual Inspection (RVI) | Inspects hard-to-reach or hazardous areas using robotic systems equipped with cameras and sensors. | Pipelines, tanks, confined spaces, power generation, aerospace, infrastructure. |

| 3D Laser Scanning | Creates highly accurate and detailed digital models of structures and assets for asset management, facility planning, and construction monitoring. | Infrastructure, construction, manufacturing, power generation, oil and gas. |

| Thermography | Captures heat signatures to identify areas of thermal anomalies, such as overheating components, insulation defects, and other potential problems. | Electrical systems, mechanical equipment, building structures, power generation, manufacturing. |

| Advanced Analytics and Data Visualization | Extracts meaningful insights from inspection data, enabling clients to track asset performance, identify trends, and optimize maintenance strategies. | All industries, including oil and gas, power generation, aerospace, infrastructure, manufacturing, and construction. |

Industry Impact and Applications

Advanced Inspection Technologies Inc. is revolutionizing various industries by providing cutting-edge inspection solutions that enhance safety, efficiency, and productivity. The company’s advanced technologies are transforming traditional inspection methods, leading to significant improvements in asset management, operational reliability, and overall business performance.

Impact on Various Industries

The impact of Advanced Inspection Technologies Inc. extends across diverse industries, including:

- Energy: Advanced inspection technologies are crucial for ensuring the safety and reliability of energy infrastructure, including pipelines, power plants, and oil rigs. These technologies enable early detection of defects, reducing the risk of catastrophic failures and minimizing downtime.

- Transportation: In the transportation sector, advanced inspection technologies are used to inspect bridges, tunnels, and aircraft, ensuring structural integrity and preventing accidents. This improves safety for passengers and reduces maintenance costs.

- Manufacturing: Advanced inspection technologies are essential for quality control in manufacturing processes, enabling manufacturers to identify defects early and improve product quality. This leads to increased productivity and reduced waste.

- Construction: Advanced inspection technologies play a vital role in ensuring the safety and durability of buildings and infrastructure. They enable engineers and contractors to identify potential problems before they become major issues, saving time and money.

Examples of Improved Safety, Efficiency, and Productivity

Advanced Inspection Technologies Inc. has a proven track record of delivering tangible benefits to its clients:

- Reduced Downtime: In the energy sector, a major oil pipeline operator implemented Advanced Inspection Technologies Inc.’s pipeline inspection system, which identified a critical flaw in the pipeline before it could cause a leak or rupture. This early detection prevented a potential environmental disaster and saved millions of dollars in downtime and remediation costs.

- Enhanced Safety: A bridge inspection project using Advanced Inspection Technologies Inc.’s drone-based inspection system identified structural weaknesses in a bridge that were not visible during traditional inspections. This early detection allowed for timely repairs, ensuring the safety of commuters and preventing a potential collapse.

- Improved Efficiency: A manufacturing company using Advanced Inspection Technologies Inc.’s automated inspection system significantly reduced inspection time, leading to faster production cycles and increased output. The system also eliminated human error, improving product quality and reducing scrap rates.

Comparison with Traditional Inspection Methods

Traditional inspection methods often rely on manual labor, which can be time-consuming, expensive, and prone to human error. Advanced inspection technologies offer several advantages over traditional methods:

- Increased Accuracy: Advanced inspection technologies provide more accurate and detailed data, leading to more reliable assessments and better decision-making.

- Improved Speed: Advanced inspection technologies can inspect assets much faster than traditional methods, reducing downtime and increasing efficiency.

- Enhanced Safety: Advanced inspection technologies often involve remote or automated inspection, reducing the risk of human injury during hazardous inspections.

- Cost Savings: While the initial investment in advanced inspection technologies may be higher, the long-term cost savings from reduced downtime, improved safety, and enhanced efficiency often outweigh the initial investment.

Value Proposition of Advanced Inspection Technologies

Advanced Inspection Technologies Inc. offers a compelling value proposition for businesses across various industries:

“By embracing advanced inspection technologies, businesses can unlock significant improvements in safety, efficiency, and productivity, ultimately leading to increased profitability and a competitive edge.”

Case Studies and Success Stories

Advanced Inspection Technologies Inc. has a proven track record of delivering innovative solutions that enhance asset integrity and minimize risks across various industries. Our success stories showcase the real-world impact of our advanced inspection technologies, highlighting the challenges addressed, solutions implemented, and the positive outcomes achieved.

Case Study: Enhancing Pipeline Integrity in the Energy Sector

This case study demonstrates how Advanced Inspection Technologies Inc. played a pivotal role in ensuring the safety and reliability of a major oil and gas pipeline network. The challenge was to identify and assess potential corrosion and defects within the pipeline infrastructure, which could lead to leaks, spills, and environmental damage.

Advanced Inspection Technologies Inc. deployed a combination of advanced inspection technologies, including:

- Inline inspection: Utilizing intelligent pigs equipped with advanced sensors, we conducted a comprehensive inspection of the pipeline’s internal condition, identifying areas of corrosion, pitting, and other anomalies.

- Remote visual inspection: Employing robotic crawlers with high-definition cameras, we inspected hard-to-reach areas and provided detailed visual assessments of the pipeline’s external condition.

- Advanced data analysis: Our team of experts analyzed the inspection data using sophisticated algorithms to identify critical areas requiring immediate attention and develop targeted repair strategies.

The outcome of this project was a significant improvement in pipeline integrity, reducing the risk of leaks and spills. The implementation of our solutions enabled the energy company to:

- Extend the lifespan of their pipeline infrastructure: By identifying and addressing potential issues early, we helped the company avoid costly repairs and downtime.

- Minimize environmental risks: The timely identification and mitigation of corrosion and defects significantly reduced the risk of oil and gas spills, protecting the environment.

- Improve operational efficiency: The enhanced pipeline integrity enabled the company to operate their pipeline network more reliably and efficiently, reducing maintenance costs and downtime.

Case Study: Ensuring Structural Integrity in the Aerospace Industry

In this case study, Advanced Inspection Technologies Inc. was tasked with inspecting and assessing the structural integrity of an aging aircraft fleet for a major airline. The challenge was to identify potential fatigue cracks, corrosion, and other defects in the aircraft’s fuselage, wings, and other critical components, ensuring continued airworthiness and passenger safety.

We implemented a multi-pronged approach, utilizing a combination of technologies:

- Non-destructive testing (NDT): We employed various NDT techniques, including eddy current testing, ultrasonic testing, and X-ray inspection, to detect hidden defects and assess their severity.

- 3D laser scanning: We captured detailed 3D models of the aircraft’s structure, allowing for precise measurements and analysis of any deviations or anomalies.

- Data visualization and analysis: Our team of engineers analyzed the inspection data using specialized software to identify critical areas requiring repair or replacement.

The outcome of this project was a significant improvement in aircraft safety and reliability. The airline was able to:

- Extend the service life of their aircraft: By identifying and addressing potential issues early, the airline avoided premature retirement of their fleet and saved significant costs.

- Enhance passenger safety: The thorough inspection and repair of critical components ensured the continued airworthiness of the aircraft, protecting passengers and crew.

- Improve operational efficiency: The enhanced aircraft integrity enabled the airline to operate their fleet more reliably and efficiently, reducing maintenance costs and delays.

Table of Key Case Studies

| Project | Industry | Challenge | Solution | Outcome |

|---|---|---|---|---|

| Pipeline Integrity Enhancement | Energy | Corrosion and defects in pipeline infrastructure | Inline inspection, remote visual inspection, advanced data analysis | Improved pipeline integrity, reduced risk of leaks and spills, extended lifespan, minimized environmental risks |

| Aircraft Structural Integrity Assessment | Aerospace | Fatigue cracks, corrosion, and defects in aircraft structure | Non-destructive testing, 3D laser scanning, data visualization and analysis | Enhanced aircraft safety and reliability, extended service life, improved operational efficiency |

| Bridge Inspection and Maintenance | Infrastructure | Corrosion, cracks, and structural deterioration in bridge components | Drone inspection, advanced imaging techniques, structural analysis | Improved bridge safety and reliability, extended lifespan, reduced maintenance costs |

Future Trends and Innovations

The landscape of advanced inspection technologies is constantly evolving, driven by advancements in artificial intelligence (AI), robotics, and data analytics. This dynamic environment presents a plethora of opportunities for innovation and the development of more sophisticated inspection solutions.

The Role of Artificial Intelligence and Machine Learning

AI and machine learning are revolutionizing the way inspections are conducted, enabling faster, more accurate, and more efficient analysis of data. These technologies are transforming traditional inspection processes by automating tasks, improving defect detection, and providing predictive insights.

- Automated Defect Detection: AI algorithms can analyze vast amounts of data from various inspection sources, including images, videos, and sensor readings, to identify anomalies and potential defects with high accuracy. This automation significantly reduces human error and allows for faster inspection cycles.

- Predictive Maintenance: AI-powered systems can analyze historical inspection data and identify patterns that indicate potential equipment failures. This predictive capability enables proactive maintenance strategies, minimizing downtime and maximizing asset lifespan.

- Real-Time Monitoring and Analysis: AI algorithms can continuously monitor critical infrastructure and provide real-time alerts for any potential issues. This allows for immediate response and mitigation of risks, ensuring safety and operational efficiency.

Last Recap: Advanced Inspection Technologies Inc

As industries continue to evolve and demand more sophisticated inspection methods, Advanced Inspection Technologies Inc. remains committed to pushing the boundaries of innovation. Their unwavering focus on research and development ensures that they remain at the cutting edge, delivering solutions that anticipate future needs and empower clients to navigate the complexities of the modern world.

Advanced Inspection Technologies Inc. specializes in cutting-edge solutions for various industries. Their commitment to innovation is evident in their partnerships with companies like concord financial technologies , a leading provider of financial technology solutions. This collaboration allows Advanced Inspection Technologies Inc.

to leverage the latest advancements in financial technology, ensuring their clients receive the most comprehensive and efficient inspection services.