Adhesive Systems Technology: Bonding the Future

Adhesive systems technology, a seemingly simple concept, has revolutionized countless industries and continues to shape our world in profound ways. From the construction of towering skyscrapers to the delicate assembly […]

Adhesive systems technology, a seemingly simple concept, has revolutionized countless industries and continues to shape our world in profound ways. From the construction of towering skyscrapers to the delicate assembly of intricate electronics, adhesives have become the invisible glue that holds our modern world together. This journey into the fascinating world of adhesives explores their history, their diverse applications, and the cutting-edge innovations that are pushing the boundaries of what’s possible.

Adhesives, far from being mere bonding agents, are sophisticated materials that have evolved over centuries. Their development has been driven by the need for stronger, more durable, and more versatile bonding solutions. This has led to a wide array of adhesive types, each with unique properties and applications. Whether it’s the epoxy that binds together aircraft parts or the pressure-sensitive adhesive that holds a bandage in place, each adhesive plays a crucial role in our daily lives.

Introduction to Adhesive Systems Technology

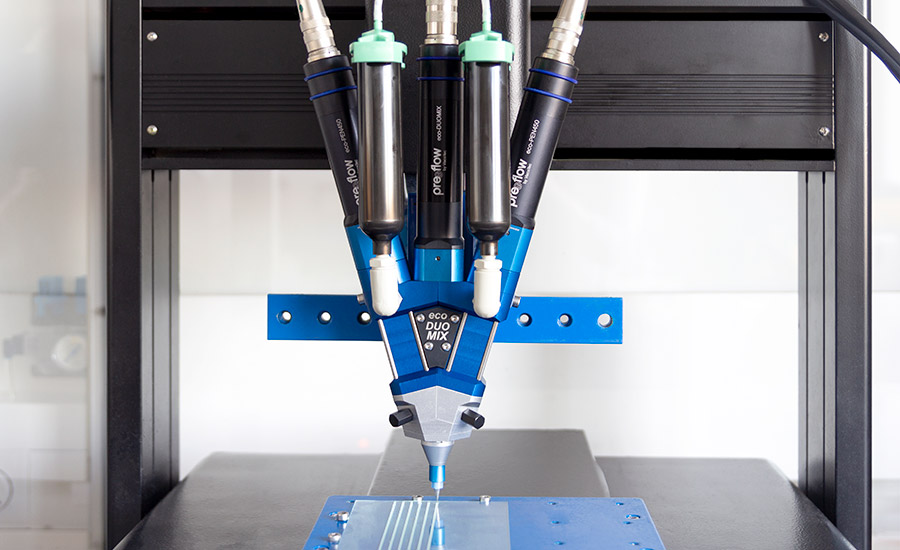

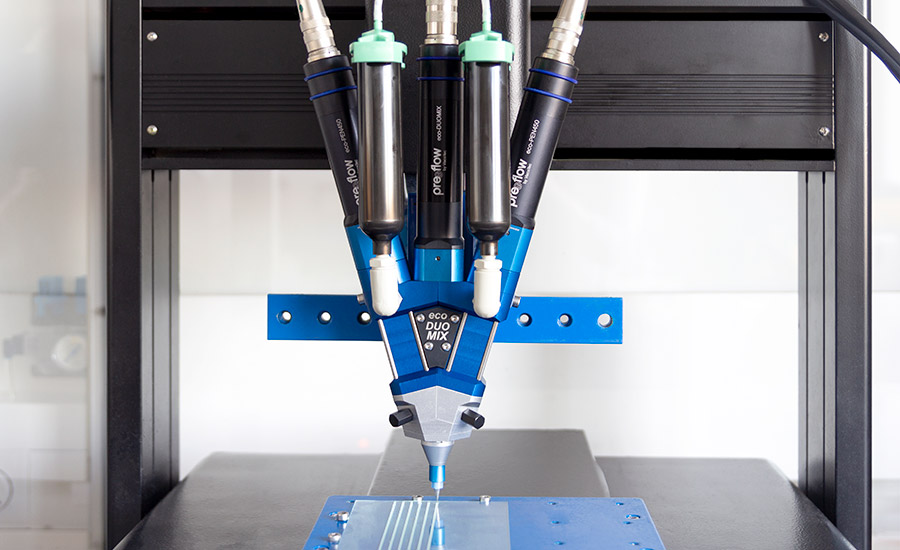

Adhesive systems technology is a crucial aspect of modern manufacturing and engineering, playing a vital role in countless applications across various industries. Adhesives are materials that create a bond between two or more surfaces, holding them together through a combination of physical and chemical forces. They offer numerous advantages over traditional mechanical fasteners, such as screws or rivets, including enhanced aesthetics, improved weight distribution, and the ability to bond dissimilar materials. This technology has evolved significantly over the years, with advancements in materials, formulations, and application techniques.

Fundamental Principles of Adhesion

Adhesion is a complex phenomenon involving the interactions between molecules at the interface of two surfaces. Understanding the fundamental principles of adhesion is essential for designing and optimizing adhesive systems. The strength of an adhesive bond depends on several factors, including:

* Surface Energy: The ability of a surface to attract and hold molecules.

* Intermolecular Forces: The attractive forces between molecules, such as Van der Waals forces, hydrogen bonding, and dipole-dipole interactions.

* Wetting: The ability of the adhesive to spread over the surface and displace air.

* Surface Preparation: The cleanliness and roughness of the surfaces to be bonded.

The strength of an adhesive bond is directly proportional to the surface area of contact and the strength of the intermolecular forces between the adhesive and the surfaces.

Historical Development of Adhesive Systems

Adhesive systems have a long history, dating back to ancient civilizations. Early adhesives were primarily natural materials, such as animal glues, resins, and gums. The development of synthetic polymers in the 20th century revolutionized the field, leading to the creation of a wide range of high-performance adhesives.

* Ancient Times: Natural adhesives like animal glues, resins, and gums were used for bonding wood, leather, and other materials.

* 19th Century: The discovery of rubber and its adhesive properties opened new possibilities.

* 20th Century: The development of synthetic polymers, such as epoxy resins, acrylics, and silicones, significantly expanded the range of adhesive applications.

* Present Day: Continued research and development focus on creating adhesives with enhanced properties, such as high strength, durability, and environmental friendliness.

Applications of Adhesive Systems

Adhesive systems are widely used across various industries, including:

* Construction: Bonding structural elements, such as beams, columns, and walls.

* Automotive: Assembly of car bodies, interiors, and exterior components.

* Aerospace: Bonding lightweight and high-performance materials for aircraft and spacecraft.

* Electronics: Attaching components to circuit boards and other electronic devices.

* Medical: Bonding medical devices, prosthetics, and tissue grafts.

* Packaging: Sealing food containers, bags, and boxes.

* Consumer Products: Bonding components in furniture, appliances, and toys.

Types of Adhesives

Adhesives are substances that can bond two or more surfaces together through a chemical or physical process. They are widely used in various industries, including construction, manufacturing, aerospace, and automotive, to join materials like metals, plastics, ceramics, and wood. The choice of adhesive depends on the specific application and the properties required for the bond.

Adhesives are classified based on their chemical composition and bonding mechanisms. The most common types of adhesives are:

Epoxy Adhesives

Epoxy adhesives are two-part systems that consist of a resin and a hardener. When mixed, the resin and hardener undergo a chemical reaction that forms a strong, durable bond. Epoxy adhesives are known for their excellent adhesion to a wide range of materials, high strength, and good chemical and temperature resistance. They are commonly used in structural applications, such as bonding metal parts, repairing cracks in concrete, and creating high-performance composites.

- Characteristics: Epoxy adhesives are known for their high strength, good chemical resistance, and excellent adhesion to a variety of materials. They can be used in a wide range of temperatures and are often chosen for structural applications.

- Advantages:

- High strength and durability

- Excellent adhesion to a variety of materials

- Good chemical and temperature resistance

- Versatile and can be used in a wide range of applications

- Limitations:

- Can be difficult to apply and require precise mixing ratios

- Limited open time (time before the adhesive starts to cure)

- May require specialized equipment for application

Acrylic Adhesives

Acrylic adhesives are single-component systems that cure by reacting with moisture in the air. They are known for their fast curing time, good adhesion to a variety of materials, and flexibility. Acrylic adhesives are often used in applications where a fast bond is required, such as bonding plastics, wood, and metal.

- Characteristics: Acrylic adhesives are known for their fast curing time, good adhesion to a variety of materials, and flexibility. They are often used in applications where a fast bond is required.

- Advantages:

- Fast curing time

- Good adhesion to a variety of materials

- Flexible and can withstand some stress

- Easy to apply

- Limitations:

- Lower strength compared to epoxy adhesives

- Limited temperature resistance

- Can be susceptible to moisture and UV degradation

Polyurethane Adhesives

Polyurethane adhesives are single-component or two-component systems that cure by reacting with moisture in the air or by mixing a resin and a hardener. They are known for their high strength, flexibility, and good adhesion to a variety of materials, including porous surfaces. Polyurethane adhesives are often used in construction, automotive, and furniture applications.

- Characteristics: Polyurethane adhesives are known for their high strength, flexibility, and good adhesion to a variety of materials, including porous surfaces.

- Advantages:

- High strength and durability

- Good adhesion to a variety of materials, including porous surfaces

- Flexible and can withstand some stress

- Can be used in a wide range of temperatures

- Limitations:

- Can be sensitive to moisture and UV degradation

- May have a longer curing time compared to acrylic adhesives

- Can be more expensive than other types of adhesives

Silicone Adhesives, Adhesive systems technology

Silicone adhesives are single-component systems that cure by reacting with moisture in the air. They are known for their high temperature resistance, flexibility, and water resistance. Silicone adhesives are often used in applications where high temperatures or exposure to moisture is expected, such as sealing windows and doors, bonding silicone materials, and sealing electronic components.

- Characteristics: Silicone adhesives are known for their high temperature resistance, flexibility, and water resistance.

- Advantages:

- High temperature resistance

- Excellent water resistance

- Flexible and can withstand some stress

- Easy to apply

- Limitations:

- Lower strength compared to other types of adhesives

- Limited adhesion to some materials, such as polyethylene and polypropylene

- Can be more expensive than other types of adhesives

Hot Melt Adhesives

Hot melt adhesives are solid materials that are heated to a liquid state and then applied to the surfaces to be bonded. As the adhesive cools, it solidifies and forms a strong bond. Hot melt adhesives are known for their fast curing time, good adhesion to a variety of materials, and low cost. They are often used in packaging, bookbinding, and furniture applications.

- Characteristics: Hot melt adhesives are solid materials that are heated to a liquid state and then applied to the surfaces to be bonded. As the adhesive cools, it solidifies and forms a strong bond.

- Advantages:

- Fast curing time

- Good adhesion to a variety of materials

- Low cost

- Easy to apply

- Limitations:

- Lower strength compared to other types of adhesives

- Limited temperature resistance

- May require specialized equipment for application

Pressure-Sensitive Adhesives

Pressure-sensitive adhesives are materials that adhere to a surface upon the application of pressure. They are commonly used in tapes, labels, and other applications where a quick and easy bond is required. Pressure-sensitive adhesives are known for their low cost, ease of application, and versatility.

- Characteristics: Pressure-sensitive adhesives are materials that adhere to a surface upon the application of pressure.

- Advantages:

- Low cost

- Easy to apply

- Versatile and can be used in a wide range of applications

- Limitations:

- Lower strength compared to other types of adhesives

- Limited temperature resistance

- Can be susceptible to moisture and UV degradation

Conclusive Thoughts: Adhesive Systems Technology

As we move forward, the future of adhesive systems technology holds immense promise. With ongoing research and development in areas like bio-based adhesives, smart adhesives, and self-healing materials, the possibilities for innovation are boundless. These advancements have the potential to create more sustainable, efficient, and even self-repairing bonding solutions. From reducing our environmental impact to improving the performance of everyday products, adhesive systems technology is poised to play an even greater role in shaping our future.

Adhesive systems technology plays a vital role in many industries, from construction to manufacturing. One area where it’s particularly important is in the design of comfortable and supportive mattresses. Take, for example, the Sealy Performance with Posturepedic technology , which utilizes advanced adhesive systems to ensure that the layers of the mattress stay securely together, providing optimal comfort and support.

This type of technology allows for greater flexibility and durability in mattress construction, ultimately leading to a more satisfying sleep experience.