Wilspec Technologies Pressure Switch: A Comprehensive Guide

Wilspec Technologies pressure switch sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset. […]

Wilspec Technologies pressure switch sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset. Wilspec Technologies is a leading provider of pressure switch solutions, specializing in the design, manufacture, and distribution of high-quality pressure switches for a wide range of applications. The company is known for its commitment to innovation, quality, and customer satisfaction. This comprehensive guide delves into the world of Wilspec pressure switches, exploring their technology, applications, and benefits.

From the fundamentals of pressure switch operation to the intricate details of Wilspec’s product offerings, this guide provides a clear and concise understanding of this essential technology. We’ll examine the various types of pressure switches available, their unique features, and how they are used in diverse industries. We’ll also explore the factors to consider when selecting a Wilspec pressure switch, ensuring that you choose the right solution for your specific needs. This guide will also delve into the installation and maintenance aspects of Wilspec pressure switches, equipping you with the knowledge to ensure their optimal performance and longevity.

Wilspec Pressure Switches

Wilspec pressure switches are essential components in various industries, playing a crucial role in controlling fluid pressure levels. They are designed to activate or deactivate electrical circuits based on pressure changes within a system. This functionality makes them vital for safety, efficiency, and performance in a wide range of applications.

Applications of Wilspec Pressure Switches, Wilspec technologies pressure switch

Wilspec pressure switches are categorized based on their intended applications, ensuring they meet the specific requirements of each industry. Here’s a breakdown of the most common categories:

- Industrial Applications: Wilspec pressure switches are widely used in industrial settings for tasks such as:

- Monitoring and controlling pressure in hydraulic and pneumatic systems

- Protecting equipment from overpressure or underpressure conditions

- Activating alarms or shutdown procedures in case of pressure fluctuations

- Regulating fluid flow in various processes

- Automotive Applications: Wilspec pressure switches are integral to automotive systems, performing functions like:

- Monitoring engine oil pressure

- Controlling fuel pump operation

- Activating warning lights for low tire pressure

- Regulating air conditioning systems

- HVAC Applications: Wilspec pressure switches are essential in HVAC systems, where they are used to:

- Monitor and control refrigerant pressure

- Protect compressors from overpressure

- Regulate fan operation based on pressure changes

- Ensure optimal performance and energy efficiency

Features and Benefits of Wilspec Pressure Switches

Wilspec pressure switches are renowned for their unique features and benefits that set them apart from competitors. These features contribute to their reliability, durability, and performance:

- High Accuracy and Sensitivity: Wilspec pressure switches are designed with precision, ensuring accurate pressure readings and reliable switching actions. This is essential for critical applications where precise pressure control is crucial.

- Durability and Robust Construction: Wilspec pressure switches are built to withstand harsh environments and demanding applications. They are constructed with high-quality materials and robust designs, ensuring long-term reliability and minimal maintenance requirements.

- Wide Operating Range: Wilspec pressure switches are available in a wide range of pressure ratings, allowing them to be used in various applications with different pressure requirements. This versatility makes them suitable for a broad spectrum of industrial and commercial settings.

- Customizable Options: Wilspec offers customizable options for their pressure switches, allowing users to tailor them to their specific needs. This includes options for different pressure settings, electrical connections, and mounting configurations.

- Cost-Effectiveness: Wilspec pressure switches offer a balance of performance and affordability, making them a cost-effective solution for various applications. Their durability and long service life contribute to their overall value proposition.

Real-World Applications of Wilspec Pressure Switches

Wilspec pressure switches find application in numerous real-world scenarios, demonstrating their versatility and importance across industries:

- Industrial Manufacturing: Wilspec pressure switches are used in manufacturing processes to monitor and control pressure in hydraulic presses, pneumatic systems, and other machinery. They ensure safe and efficient operation by detecting pressure fluctuations and activating safety mechanisms if necessary.

- Power Generation: In power generation plants, Wilspec pressure switches are used to monitor pressure in boilers, turbines, and other critical systems. They help ensure efficient and reliable power generation by detecting pressure changes and activating control systems to maintain optimal performance.

- Oil and Gas Industry: Wilspec pressure switches play a vital role in the oil and gas industry, monitoring pressure in pipelines, wells, and processing facilities. They help prevent leaks, optimize production, and ensure safety by detecting pressure changes and triggering alarms or shutdown procedures.

- Water Treatment Plants: Wilspec pressure switches are used in water treatment plants to monitor and control pressure in filtration systems, pumps, and other equipment. They ensure efficient water treatment by regulating pressure levels and preventing overpressure or underpressure conditions.

- Automotive Industry: In the automotive industry, Wilspec pressure switches are used in various systems, including engine oil pressure monitoring, fuel pump control, and tire pressure monitoring. They contribute to vehicle safety and performance by detecting pressure changes and activating warning lights or control systems as needed.

Installation and Maintenance: Wilspec Technologies Pressure Switch

Proper installation and regular maintenance are crucial for ensuring the longevity and optimal performance of Wilspec pressure switches. By following these guidelines, you can maximize the lifespan of your pressure switch and minimize the risk of malfunctions.

Installation

The installation process involves connecting the pressure switch to the water system and wiring it to the control circuit. The following steps provide a general guide for installing Wilspec pressure switches:

- Safety Precautions:

- Always disconnect the power supply before working on the pressure switch.

- Wear appropriate safety gear, including gloves and eye protection.

- Ensure the water supply is turned off before making any connections.

- Location:

- Choose a location that is easily accessible for maintenance and troubleshooting.

- Avoid installing the pressure switch in areas with extreme temperatures or humidity.

- Ensure the pressure switch is mounted securely to prevent vibrations or movement.

- Plumbing Connections:

- Connect the pressure switch to the water supply line using the appropriate fittings and pipe sizes.

- Ensure all connections are tight and leak-free.

- Use Teflon tape or pipe sealant on threaded connections to prevent leaks.

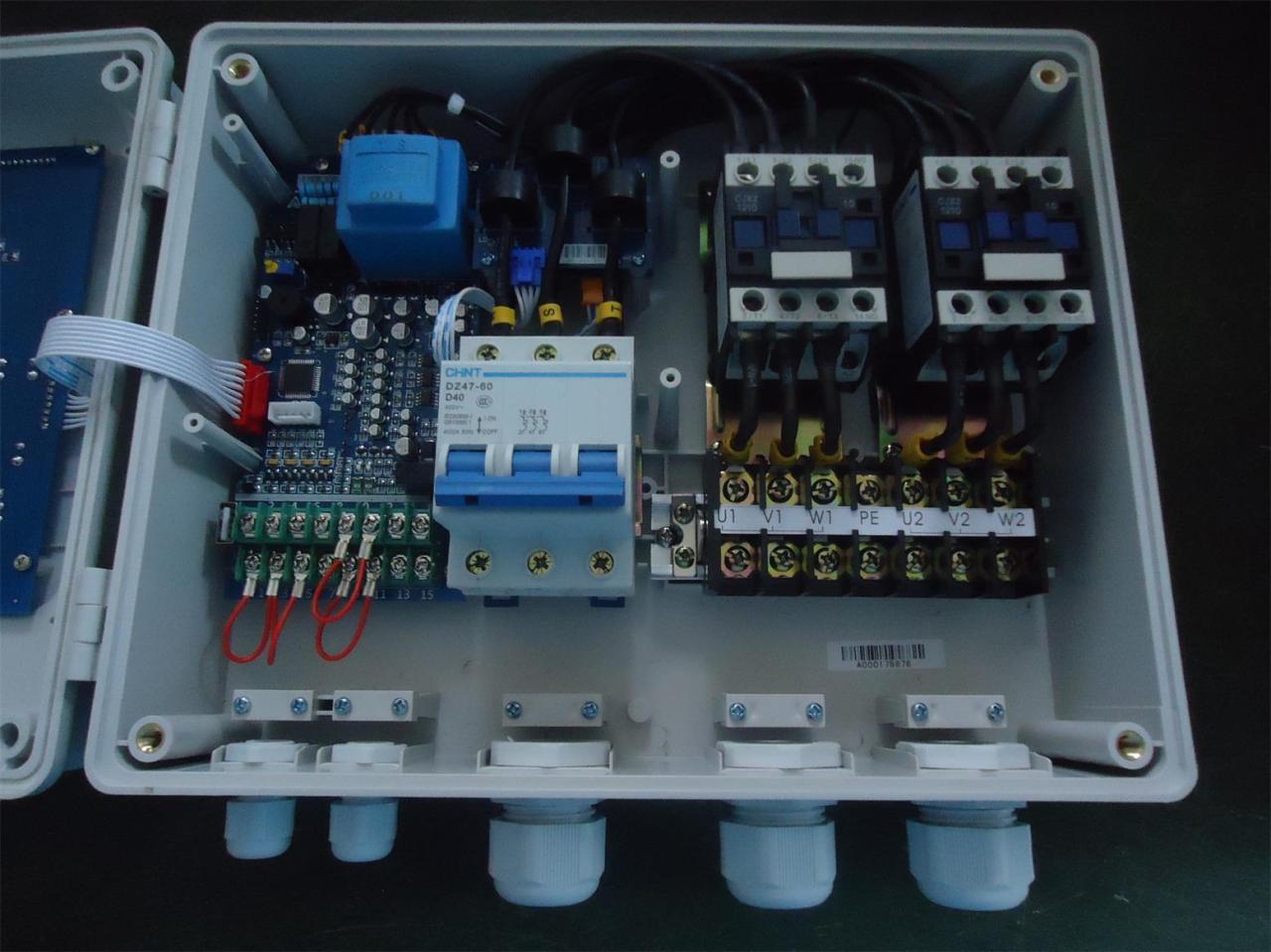

- Electrical Connections:

- Connect the pressure switch to the control circuit using the appropriate wiring and terminals.

- Refer to the wiring diagram provided with the pressure switch for specific connections.

- Use wire nuts or terminal blocks for secure connections.

- Ensure all wires are properly insulated and protected from damage.

- Testing and Calibration:

- After installation, test the pressure switch to ensure it is operating correctly.

- Calibrate the pressure switch to the desired settings using the adjustment screw or knob.

- Refer to the manufacturer’s instructions for specific calibration procedures.

Maintenance

Regular maintenance is essential for keeping your Wilspec pressure switch functioning reliably. This includes:

- Visual Inspection:

- Regularly inspect the pressure switch for any signs of damage, corrosion, or leaks.

- Check for loose connections, worn wires, or cracked components.

- Replace any damaged or worn parts promptly.

- Pressure Calibration:

- Recalibrate the pressure switch periodically to ensure accurate operation.

- Use a pressure gauge to verify the set points and adjust them as needed.

- Refer to the manufacturer’s instructions for calibration procedures.

- Cleaning:

- Clean the pressure switch regularly to remove any dirt, debris, or mineral deposits.

- Use a soft cloth or brush and a mild detergent to clean the switch.

- Avoid using harsh chemicals or abrasive cleaners.

- Troubleshooting:

- If the pressure switch malfunctions, troubleshoot the issue to identify the cause.

- Check for loose connections, power supply problems, or blocked water lines.

- Refer to the manufacturer’s troubleshooting guide for specific solutions.

Best Practices

- Regular Maintenance: Establish a regular maintenance schedule for your pressure switch, such as monthly or quarterly inspections.

- Proper Storage: When not in use, store the pressure switch in a clean, dry environment to prevent corrosion and damage.

- Professional Assistance: For complex installations or troubleshooting, consult a qualified electrician or plumber.

- Manufacturer’s Instructions: Always refer to the manufacturer’s instructions and safety guidelines for specific installation and maintenance procedures.

Industry Trends and Innovations

The pressure switch industry is constantly evolving, driven by technological advancements, emerging applications, and stricter regulations. Wilspec Technologies is actively engaged in understanding and adapting to these trends to remain at the forefront of the industry.

Emerging Applications and Market Segments

The demand for pressure switches is expanding across various industries, driven by the need for precise pressure control and automation.

- Renewable Energy: Pressure switches play a crucial role in wind turbines, solar power systems, and other renewable energy applications, ensuring efficient and reliable operation.

- Industrial Automation: The increasing adoption of automation in manufacturing, process control, and other industrial sectors is driving the demand for reliable and durable pressure switches.

- Medical Devices: Pressure switches are essential components in medical devices such as infusion pumps, ventilators, and other critical equipment, where accuracy and safety are paramount.

- Aerospace and Defense: Pressure switches are used in various aerospace and defense applications, including aircraft systems, missile guidance systems, and other critical equipment.

Impact of Industry Regulations and Standards

Pressure switch manufacturers must comply with stringent industry regulations and standards to ensure product safety, reliability, and performance.

- UL and CSA Standards: These standards set specific requirements for pressure switch design, testing, and performance, ensuring safety and reliability in various applications.

- IEC Standards: International Electrotechnical Commission (IEC) standards provide global guidelines for pressure switch design and performance, promoting interoperability and consistency.

- ATEX Certification: For applications in potentially explosive atmospheres, pressure switches must comply with ATEX certification requirements, ensuring safety in hazardous environments.

Technological Advancements in Pressure Switch Technology

The pressure switch industry is witnessing significant technological advancements, leading to improved performance, reliability, and efficiency.

- Smart Pressure Switches: These switches integrate sensors, electronics, and communication capabilities, enabling real-time monitoring, data logging, and remote control.

- Miniaturization and Compact Designs: Advancements in materials and manufacturing processes allow for smaller and more compact pressure switches, suitable for space-constrained applications.

- Increased Accuracy and Precision: Technological advancements have resulted in pressure switches with higher accuracy and precision, enabling more precise pressure control in critical applications.

- Improved Durability and Reliability: Advances in materials science and manufacturing techniques have led to pressure switches with enhanced durability and reliability, capable of withstanding harsh operating conditions.

Closing Summary

Wilspec Technologies pressure switches are a testament to innovation and reliability, providing a critical component in countless applications. By understanding the technology, applications, and selection process, you can harness the power of Wilspec pressure switches to optimize your systems and achieve superior performance. As the industry continues to evolve, Wilspec remains at the forefront, developing cutting-edge pressure switch solutions that meet the ever-changing demands of the modern world. Whether you’re a seasoned professional or just starting your journey with pressure switch technology, this guide provides the essential knowledge to navigate the world of Wilspec pressure switches with confidence.

Wilspec Technologies’ pressure switches are a key component in many medical devices, including those used in chiropractic technology. These switches ensure precise control over the application of force, allowing for targeted adjustments and therapies. Understanding the role of pressure switches in chiropractic technology helps to appreciate the importance of Wilspec’s contribution to this field.