Aircraft Engineering and Aerospace Technology: A Journey of Innovation

Aircraft engineering and aerospace technology represent a captivating blend of science, engineering, and innovation. This field has shaped our world, enabling travel across continents, pushing the boundaries of human exploration, […]

Aircraft engineering and aerospace technology represent a captivating blend of science, engineering, and innovation. This field has shaped our world, enabling travel across continents, pushing the boundaries of human exploration, and revolutionizing communication. From the Wright brothers’ pioneering flights to the marvels of modern aviation, the story of aerospace technology is a testament to human ingenuity and the relentless pursuit of progress.

This exploration delves into the intricate world of aircraft design, propulsion, materials, and systems. We will examine the fundamental principles that govern flight, the cutting-edge technologies driving innovation, and the challenges and opportunities that lie ahead in this dynamic field.

Introduction to Aircraft Engineering and Aerospace Technology

Aircraft engineering and aerospace technology encompass the design, development, construction, operation, and maintenance of aircraft and spacecraft. It is a fascinating field that combines principles of physics, mathematics, and engineering to push the boundaries of human exploration and innovation.

Historical Evolution of Aircraft Engineering and Aerospace Technology

The history of aircraft engineering and aerospace technology is a story of continuous innovation and advancement. From the early experiments with gliders and balloons to the development of supersonic jets and space exploration, this field has witnessed remarkable progress.

- Early Pioneers: The Wright brothers’ successful flight in 1903 marked the beginning of the modern era of aviation. Their pioneering work laid the foundation for future advancements in aircraft design and technology.

- World Wars and Technological Advancements: The First and Second World Wars spurred significant advancements in aircraft engineering, driven by the need for more efficient and powerful aircraft for military purposes. The development of jet engines, radar, and other technologies during this period revolutionized aviation.

- Post-War Era and Commercial Aviation: After the Second World War, commercial aviation experienced rapid growth. The development of passenger jets, such as the Boeing 707 and the Douglas DC-8, made air travel accessible to a wider population.

- Space Exploration: The space race between the United States and the Soviet Union in the 1950s and 1960s led to the development of powerful rockets and spacecraft. The launch of Sputnik 1 in 1957 and the Apollo 11 mission to the moon in 1969 were significant milestones in space exploration.

- Modern Era and Advancements: Today, aircraft engineering and aerospace technology continue to evolve at a rapid pace. Advancements in materials science, computational design, and automation are driving the development of more fuel-efficient, environmentally friendly, and technologically advanced aircraft and spacecraft.

Fundamental Principles of Aircraft Engineering

Aircraft engineering is based on a set of fundamental principles that govern the behavior of aircraft in flight.

- Aerodynamics: Aerodynamics is the study of how air flows around objects. It is a crucial aspect of aircraft design, as it determines the forces that act on the aircraft, such as lift, drag, and thrust.

- Propulsion: Propulsion systems provide the force that propels an aircraft through the air. Common propulsion systems include jet engines, turboprop engines, and piston engines.

- Structural Design: The structural design of an aircraft ensures that it can withstand the stresses and loads encountered during flight. It involves the selection of materials, the shape and configuration of the aircraft, and the design of the various components.

Diverse Fields within Aerospace Technology

Aerospace technology encompasses a wide range of fields, each playing a vital role in the development and operation of aircraft and spacecraft.

- Aircraft Design: Aircraft designers are responsible for creating the shape, size, and configuration of aircraft. They use computer-aided design (CAD) software and advanced simulation tools to optimize aircraft performance and safety.

- Manufacturing: Aircraft manufacturing involves the production of aircraft components and the assembly of the final product. Advanced manufacturing techniques, such as composites and additive manufacturing, are increasingly being used in aircraft production.

- Testing: Aircraft testing is essential to ensure that aircraft meet safety and performance standards. This involves ground tests, flight tests, and simulations.

- Operations: Aircraft operations involve the management and execution of flights. This includes air traffic control, flight planning, and crew training.

Aircraft Propulsion Systems

Aircraft propulsion systems are the heart of any aircraft, responsible for generating the thrust needed for flight. These systems convert energy from various sources into mechanical power, which is then used to propel the aircraft through the air. Different aircraft types require different propulsion systems based on their size, speed, and mission requirements.

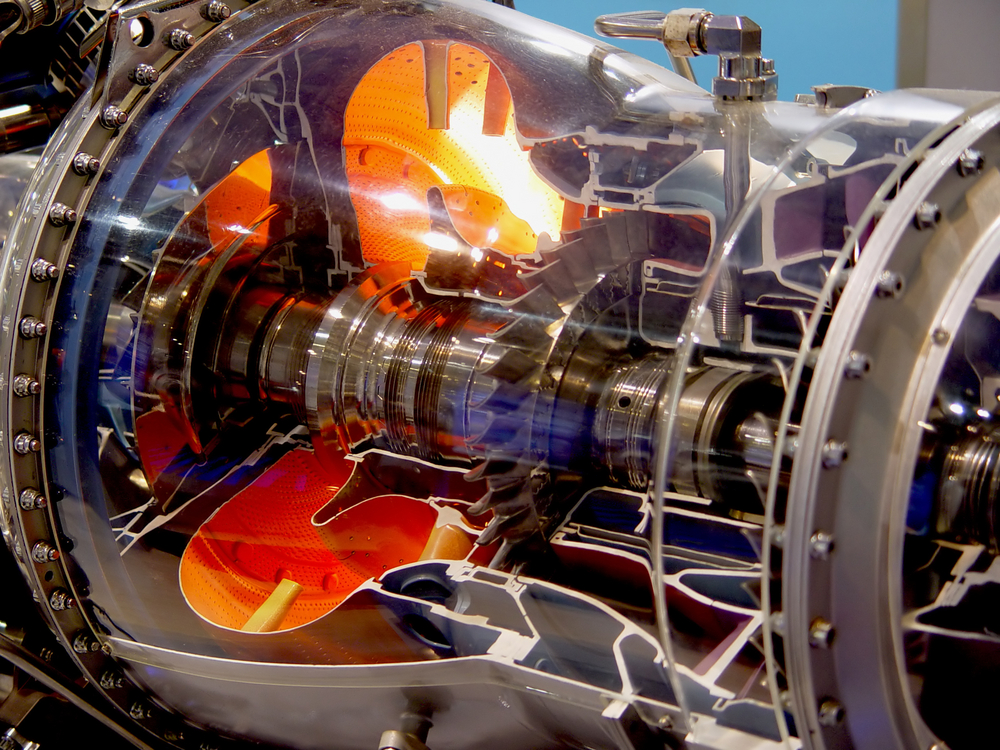

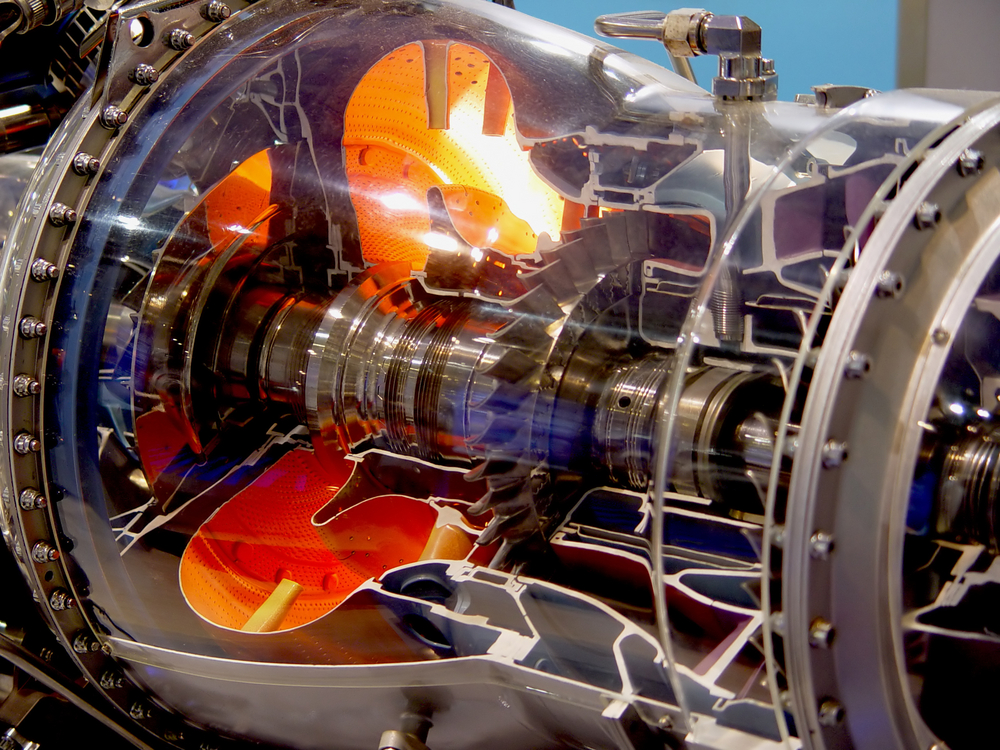

Jet Engines

Jet engines are the most common type of propulsion system for modern aircraft, particularly for high-speed and long-range flights. These engines work on the principle of jet propulsion, where air is compressed, heated, and then expanded through a nozzle, generating thrust. Jet engines are categorized into various types, including:

- Turbojet engines: These engines are simple and efficient at high speeds but are less fuel-efficient at lower speeds. They are commonly used in military aircraft and supersonic jets.

- Turbofan engines: These engines are more efficient than turbojets at lower speeds and are widely used in commercial airliners. They utilize a large fan to bypass a portion of the air around the core engine, increasing efficiency and reducing noise.

- Turboprop engines: These engines combine a gas turbine with a propeller, providing high efficiency at lower speeds. They are commonly used in smaller regional aircraft and some military aircraft.

- Turbo-shaft engines: These engines are designed to produce shaft power rather than thrust. They are commonly used in helicopters and other rotary-wing aircraft.

Piston Engines

Piston engines were the primary propulsion system for early aircraft and are still used in some smaller aircraft, especially general aviation aircraft. These engines operate on the principle of converting chemical energy from fuel into mechanical energy through the combustion of fuel in cylinders. Piston engines are known for their simplicity and relatively low cost but are less efficient than jet engines at higher speeds.

Comparison of Propulsion Systems

| Characteristic | Jet Engine | Turboprop Engine | Piston Engine |

|---|---|---|---|

| Speed | High | Medium | Low |

| Efficiency | High at high speeds | High at low speeds | Low at high speeds |

| Noise | High | Medium | Low |

| Cost | High | Medium | Low |

| Maintenance | High | Medium | Low |

| Applications | Commercial airliners, military aircraft, supersonic jets | Regional aircraft, some military aircraft | General aviation aircraft, some light military aircraft |

Thrust Generation

Thrust is the force that propels an aircraft forward. In jet engines, thrust is generated by the acceleration of air through the engine. The principle of thrust generation can be understood by the following equation:

Thrust = Mass flow rate x Velocity change

The mass flow rate is the amount of air that flows through the engine per unit time, and the velocity change is the difference in velocity between the air entering the engine and the air exiting the nozzle.

Factors Influencing Engine Efficiency

Engine efficiency is a measure of how effectively an engine converts fuel energy into thrust. Several factors influence engine efficiency, including:

- Compression ratio: Higher compression ratios generally lead to higher efficiency.

- Turbine efficiency: Efficient turbines extract more energy from the hot gases, improving efficiency.

- Bypass ratio: In turbofan engines, a higher bypass ratio results in increased efficiency.

- Fuel type: The type of fuel used can affect efficiency. Jet fuels with higher energy content are more efficient.

- Operating conditions: Altitude, temperature, and humidity can all affect engine efficiency.

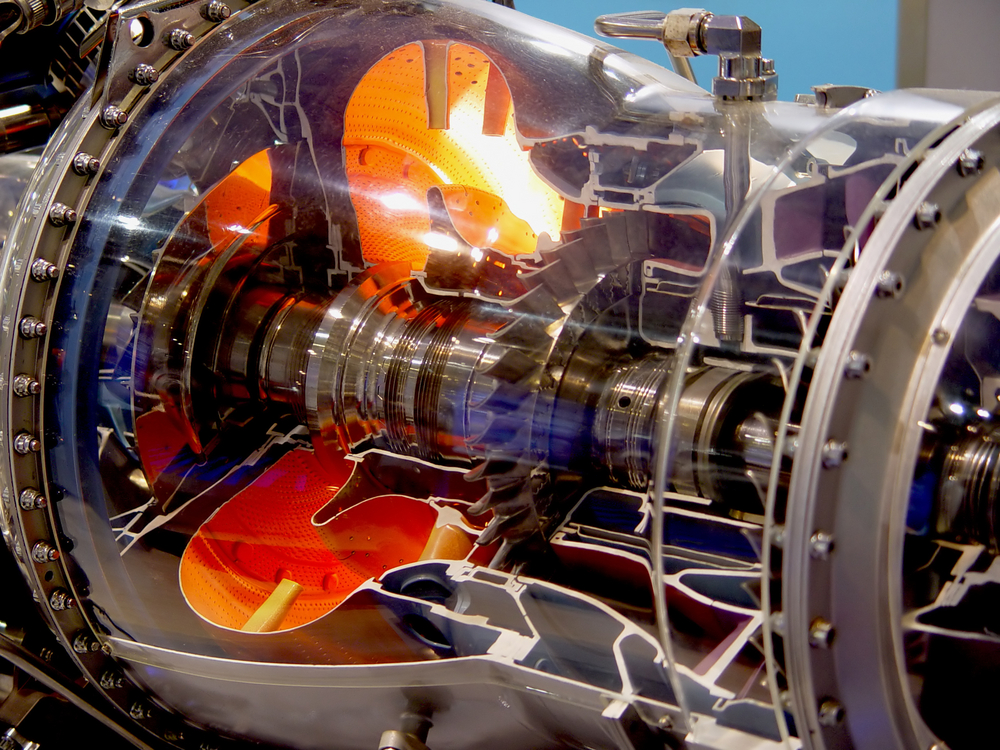

Aerospace Materials and Manufacturing

The design and construction of aircraft rely heavily on advanced materials and manufacturing processes. These technologies play a crucial role in achieving the demanding performance requirements of aerospace applications, including lightweight, high strength, and resistance to extreme environments.

Advanced Aerospace Materials

Aerospace materials are meticulously chosen for their exceptional properties, enabling aircraft to withstand the rigors of flight. Key categories include:

- Composites: Composites combine two or more materials, often a reinforcing fiber embedded in a matrix, to achieve enhanced properties. Examples include carbon fiber reinforced polymer (CFRP) and glass fiber reinforced polymer (GFRP).

- Carbon Fiber Reinforced Polymer (CFRP): Renowned for its high strength-to-weight ratio, stiffness, and resistance to fatigue, CFRP is extensively used in aircraft structures, such as fuselages, wings, and tail sections.

- Glass Fiber Reinforced Polymer (GFRP): While not as strong as CFRP, GFRP offers excellent cost-effectiveness and is employed in non-critical aircraft components, like fairings and interior panels.

- Ceramics: Ceramics possess exceptional heat resistance, wear resistance, and electrical insulation properties. They find applications in high-temperature components, such as turbine blades, rocket nozzles, and thermal protection systems.

- Silicon Carbide (SiC): SiC ceramics exhibit high melting points and excellent thermal shock resistance, making them suitable for components operating at elevated temperatures.

- Zirconia (ZrO2): Zirconia ceramics are known for their high fracture toughness and are utilized in applications requiring wear resistance, such as engine seals and bearings.

- Metallic Alloys: Metallic alloys are created by combining different metals to enhance specific properties. Examples include aluminum alloys, titanium alloys, and nickel-based superalloys.

- Aluminum Alloys: Lightweight and corrosion-resistant, aluminum alloys are widely used in aircraft structures, such as fuselages, wings, and landing gear.

- Titanium Alloys: Titanium alloys offer excellent strength-to-weight ratio, high temperature resistance, and corrosion resistance. They are employed in critical components, such as engine parts, landing gear, and fasteners.

- Nickel-Based Superalloys: These alloys exhibit exceptional high-temperature strength and creep resistance, making them suitable for components operating at extreme temperatures, such as turbine blades and combustors.

Aerospace Manufacturing Processes

The manufacturing processes used in aerospace production are highly specialized, ensuring the precision and quality required for flight safety. Common methods include:

- Forging: Forging involves shaping metal by hammering or pressing it into a desired form. This process enhances the material’s strength and toughness, making it suitable for critical aircraft components, such as engine shafts and landing gear components.

- Casting: Casting involves pouring molten metal into a mold to create a specific shape. This method is used for complex components, such as engine casings and turbine blades, where intricate geometries are required.

- Additive Manufacturing (3D Printing): Additive manufacturing builds components layer by layer from a digital design. This technology offers significant advantages in creating complex geometries, reducing material waste, and enabling customized designs.

- Powder Bed Fusion: A common additive manufacturing process, powder bed fusion uses a laser or electron beam to melt and fuse powdered material, creating the desired shape.

- Directed Energy Deposition: This process involves melting and depositing material layer by layer using a focused energy source, such as a laser or electron beam.

Challenges and Innovations

The pursuit of lighter, stronger, and more sustainable aircraft presents ongoing challenges in materials and manufacturing.

- Lightweight Materials: The constant drive to reduce aircraft weight requires the development of even lighter materials, such as advanced composites and metallic alloys with enhanced strength-to-weight ratios.

- High-Performance Materials: Meeting the demands of high-speed flight and extreme environments requires materials with superior strength, stiffness, and temperature resistance.

- Sustainable Manufacturing: The aerospace industry is increasingly focusing on reducing its environmental impact. This involves exploring sustainable manufacturing processes, using recycled materials, and minimizing waste generation.

Space Exploration and Aerospace Technology

Space exploration is a testament to human ingenuity and our relentless pursuit of knowledge. Aerospace technology plays a pivotal role in enabling us to venture beyond Earth, pushing the boundaries of what we can achieve. From the design of spacecraft to the development of advanced propulsion systems and communication networks, aerospace technology is the backbone of space exploration.

Role of Aerospace Technology in Space Exploration

Aerospace technology is instrumental in every aspect of space exploration, from the initial launch to the operations and communication of spacecraft in orbit or beyond. The following are key areas where aerospace technology makes space exploration possible:

- Spacecraft Design: Spacecraft are designed to withstand the extreme conditions of space, including vacuum, radiation, and temperature fluctuations. Aerospace engineers utilize advanced materials, structural analysis, and thermal management techniques to ensure the reliability and longevity of spacecraft.

- Propulsion Systems: Propulsion systems are essential for launching spacecraft into orbit and maneuvering them in space. Rocket engines, ion propulsion, and solar sails are examples of propulsion systems used in space exploration. The development of these systems requires a deep understanding of physics, chemistry, and materials science.

- Communication Networks: Communication networks are vital for maintaining contact with spacecraft and receiving data from them. Ground stations, satellites, and deep-space networks enable the transmission of information between Earth and spacecraft, facilitating scientific research and mission control.

Challenges and Opportunities in Space Exploration

Space exploration presents numerous challenges and opportunities, driving innovation and pushing the limits of aerospace technology. These challenges and opportunities are intertwined, creating a dynamic field where progress in one area often unlocks possibilities in others.

- Reusable Launch Vehicles: Developing reusable launch vehicles is a key challenge and opportunity in space exploration. Reusable vehicles reduce the cost of space travel by allowing for multiple launches and landings. Companies like SpaceX and Blue Origin are leading the way in this area, with their respective Falcon 9 and New Shepard rockets.

- Space-Based Infrastructure: Establishing space-based infrastructure, such as space stations and lunar bases, is essential for long-duration space missions and scientific research. This requires the development of advanced life support systems, power generation, and resource utilization technologies.

Recent Advancements in Space Exploration, Aircraft engineering and aerospace technology

Recent advancements in space exploration have significantly impacted aerospace technology, leading to new capabilities and possibilities. Here are some notable examples:

- The James Webb Space Telescope: The James Webb Space Telescope (JWST) is a powerful infrared telescope that was launched in 2021. It is designed to observe the early universe, study exoplanets, and investigate the formation of stars and galaxies. The JWST’s advanced optics, sunshield, and cryogenic systems are a testament to the capabilities of modern aerospace technology.

- Private Space Exploration: Private companies, such as SpaceX and Blue Origin, are playing an increasingly important role in space exploration. They are developing innovative technologies, reducing launch costs, and opening up access to space for a wider range of applications.

- Mars Exploration: The Perseverance rover, launched by NASA in 2020, is exploring Mars and searching for signs of past life. The rover’s advanced instruments, including a laser-based spectrometer and a drill, are enabling scientists to gather valuable data about the Red Planet.

Future Trends in Aircraft Engineering and Aerospace Technology

The field of aircraft engineering and aerospace technology is constantly evolving, driven by advancements in technology, changing societal needs, and growing environmental concerns. Emerging trends are shaping the future of flight, pushing the boundaries of what is possible and redefining the way we travel and explore the skies.

Electric Propulsion

Electric propulsion is rapidly gaining traction as a viable alternative to traditional jet engines. Electric motors offer several advantages over combustion engines, including higher efficiency, lower emissions, and reduced noise pollution. The development of high-energy-density batteries and efficient electric motors is paving the way for the widespread adoption of electric aircraft, particularly in the short-haul and regional markets.

For example, the Eviation Alice, a nine-passenger electric aircraft, is designed for short-haul flights and is expected to enter service in 2024. Larger electric aircraft, such as the Airbus E-Fan X, are also under development and could potentially revolutionize long-haul air travel in the future.

Closure

As we conclude our journey through the world of aircraft engineering and aerospace technology, it is clear that this field continues to evolve at an unprecedented pace. From the development of electric aircraft and unmanned aerial vehicles to the exploration of space, the future holds boundless possibilities. By embracing innovation, fostering collaboration, and addressing the challenges of sustainability, we can unlock the full potential of aerospace technology to create a brighter and more interconnected future.

Aircraft engineering and aerospace technology are fields that push the boundaries of innovation, constantly seeking ways to improve efficiency and safety. From the intricate design of wings to the powerful engines that propel them, these industries are constantly evolving.

This drive for advancement can be seen even in seemingly unrelated areas, like the development of automatic technology australia garage door opener , which uses similar principles of automation and precision control to enhance convenience and security. The lessons learned from aerospace engineering can often be applied to other fields, demonstrating the interconnected nature of technological innovation.