GOL Pump Technology: Efficient Energy Solutions

GOL pump technology, a revolutionary advancement in energy efficiency, has emerged as a game-changer in various industries. This technology harnesses the power of electromagnetism to create highly efficient pumps, offering […]

GOL pump technology, a revolutionary advancement in energy efficiency, has emerged as a game-changer in various industries. This technology harnesses the power of electromagnetism to create highly efficient pumps, offering a sustainable alternative to traditional pumping systems.

GOL pumps function by utilizing a rotating magnetic field to propel a liquid, eliminating the need for mechanical components like gears or impellers. This unique design results in reduced friction, minimizing energy loss and maximizing efficiency. Moreover, GOL pumps are remarkably durable and require minimal maintenance, making them a cost-effective solution in the long run.

Introduction to GOL Pump Technology

GOL pump technology, also known as Gas Operated Liquid pump technology, is a unique and efficient method of pumping liquids using the energy of compressed gas. This technology finds applications in various industries, including oil and gas, chemical processing, and water treatment.

GOL pumps function based on the principle of gas expansion and pressure transfer. Compressed gas, typically nitrogen or air, is introduced into a chamber containing the liquid to be pumped. As the gas expands, it creates a pressure differential, forcing the liquid out of the pump. The expansion of the gas is controlled by a piston or diaphragm, which regulates the flow rate and pressure of the liquid.

History and Evolution of GOL Pump Technology

The development of GOL pump technology dates back to the early 20th century. Early GOL pumps were primarily used in the oil and gas industry for extracting crude oil from wells. Over the years, the technology has undergone significant advancements, resulting in more efficient, reliable, and versatile pumps.

GOL pumps have evolved to incorporate various features and functionalities, including:

* Improved materials: The use of advanced materials like stainless steel and high-performance polymers has enhanced the durability and corrosion resistance of GOL pumps.

* Enhanced efficiency: Advancements in design and manufacturing techniques have led to improved efficiency, reducing energy consumption and increasing the overall performance of the pumps.

* Increased versatility: Modern GOL pumps are designed to handle a wider range of liquids, including corrosive, viscous, and abrasive fluids.

These advancements have expanded the applications of GOL pump technology, making it a viable solution for various industries.

Applications of GOL Pump Technology

GOL pump technology, with its unique capabilities, finds diverse applications across various industries. This technology’s ability to efficiently handle high-pressure, high-volume fluids opens up opportunities in sectors like water pumping, energy storage, and industrial processes.

Water Pumping

GOL pumps are particularly well-suited for water pumping applications due to their high efficiency and ability to handle large volumes of water. They are often used in:

- Municipal water supply: GOL pumps can be used to move large volumes of water from reservoirs to treatment plants and then to distribution networks.

- Irrigation: GOL pumps can be used to efficiently pump water from rivers, lakes, or wells to irrigate crops.

- Industrial water supply: GOL pumps are used in various industries, including manufacturing, power generation, and mining, to supply water for cooling, processing, and other purposes.

The high efficiency of GOL pumps reduces energy consumption, making them a cost-effective option for water pumping applications. Additionally, their ability to handle high pressures allows them to pump water over long distances and to higher elevations.

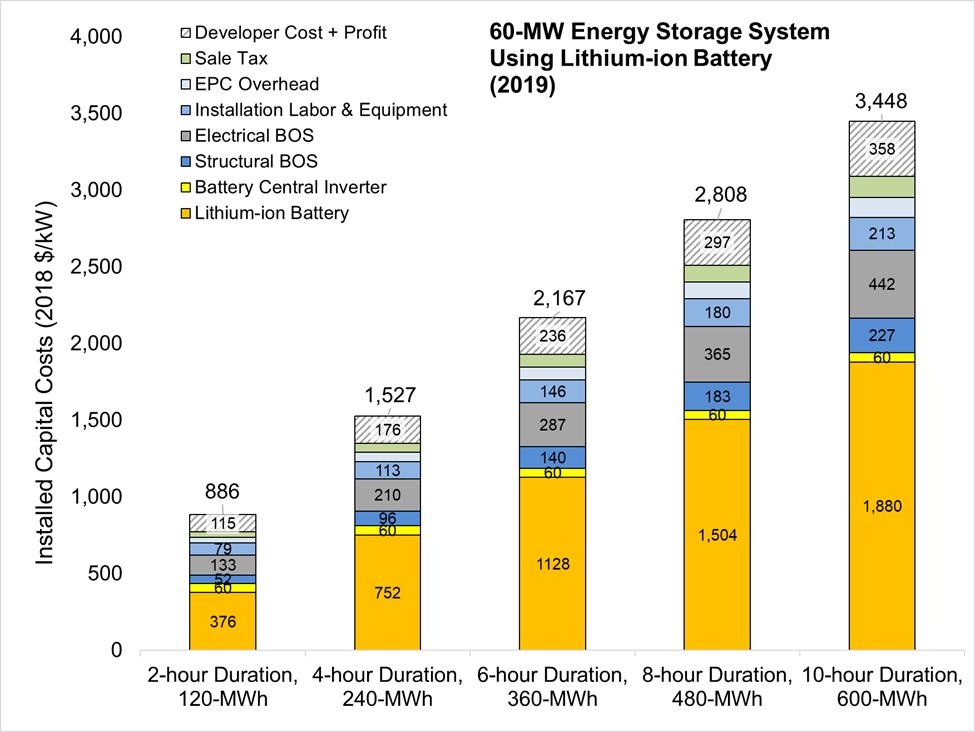

Energy Storage

GOL pump technology can be utilized for energy storage by using pumped hydro storage (PHS). In this system, water is pumped uphill to a reservoir during periods of low energy demand, and then released downhill through a turbine to generate electricity when demand is high.

- Pumped hydro storage: GOL pumps are used to pump water uphill to a reservoir during periods of low energy demand. This stored energy can then be released through a turbine to generate electricity when demand is high. This process allows for the efficient storage and release of energy, providing a reliable and scalable source of energy.

GOL pumps are well-suited for PHS due to their high efficiency and ability to handle large volumes of water. They can be used to pump water over long distances and to higher elevations, making them ideal for creating PHS systems in various geographical locations.

Industrial Processes

GOL pump technology is employed in various industrial processes where high-pressure, high-volume fluid handling is crucial.

- Chemical processing: GOL pumps are used to transport corrosive and abrasive fluids in chemical processing plants, ensuring efficient and safe operation.

- Oil and gas extraction: GOL pumps are utilized in oil and gas extraction to move fluids from wells to processing facilities, enabling efficient production.

- Mining: GOL pumps are employed in mining operations to transport slurries and other materials, facilitating efficient mineral extraction.

GOL pumps offer advantages in industrial processes due to their reliability, durability, and ability to handle high-pressure and high-volume fluids. They are also designed to operate in harsh environments, making them suitable for various industrial applications.

Epilogue

GOL pump technology has revolutionized pumping systems by offering a more efficient, reliable, and environmentally friendly approach. With its diverse applications across industries, GOL pumps are poised to play a pivotal role in shaping the future of energy consumption. As research and development continue, we can expect even greater advancements in GOL pump technology, further enhancing its potential to address global energy challenges.

Gol pump technology is all about maximizing efficiency and reliability. The right pump can make a big difference in your operation, and it’s important to choose the model that best fits your needs. For example, when considering an Atlas SE, it’s worth looking into the differences between the “with technology” and “SEL” models.

This comparison can help you make an informed decision, just as understanding the various aspects of gol pump technology can help you optimize your entire system.