Zipper Technology: A History and Future

Zipper technology, a seemingly simple invention, has revolutionized the way we dress, travel, and even build. From its humble beginnings as a novel closure system, the zipper has become an […]

Zipper technology, a seemingly simple invention, has revolutionized the way we dress, travel, and even build. From its humble beginnings as a novel closure system, the zipper has become an indispensable part of modern life, impacting various industries and shaping our daily experiences.

This exploration delves into the fascinating history of zipper technology, tracing its evolution from early prototypes to the sophisticated designs we see today. We’ll uncover the ingenious mechanics behind these ubiquitous fasteners, examining the components that make them work and the diverse applications that have made them so versatile.

Zipper Manufacturing and Production: Zipper Technology

Zipper manufacturing is a complex process that involves numerous steps, from the initial preparation of raw materials to the final assembly of the zipper. This process requires specialized machinery and skilled labor to ensure the production of high-quality zippers that meet industry standards.

Raw Material Preparation

The zipper manufacturing process begins with the preparation of raw materials. These include metal strips, nylon or polyester tapes, and other components. The metal strips are typically made of brass, steel, or aluminum and are cut to the desired length and width. The nylon or polyester tapes are used to create the zipper teeth and slider.

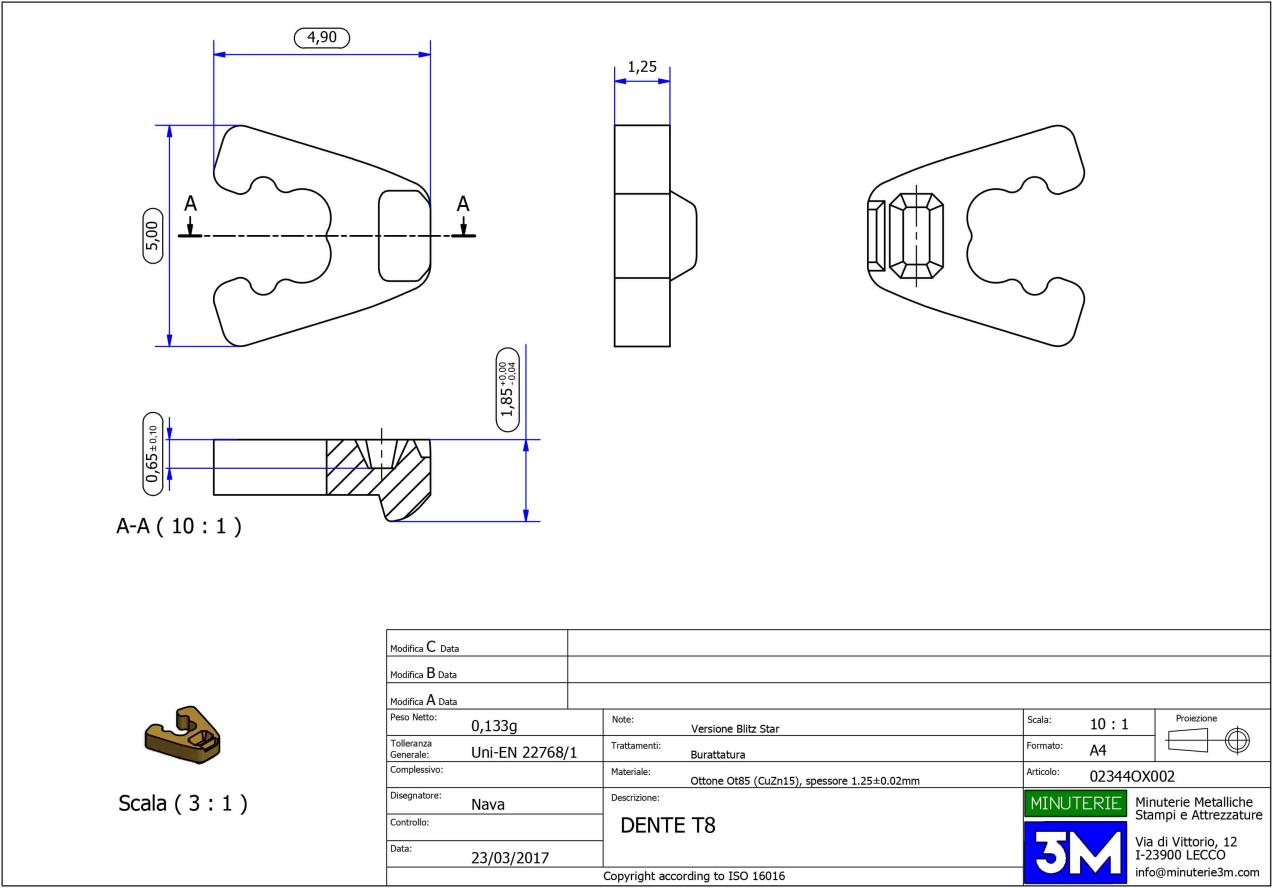

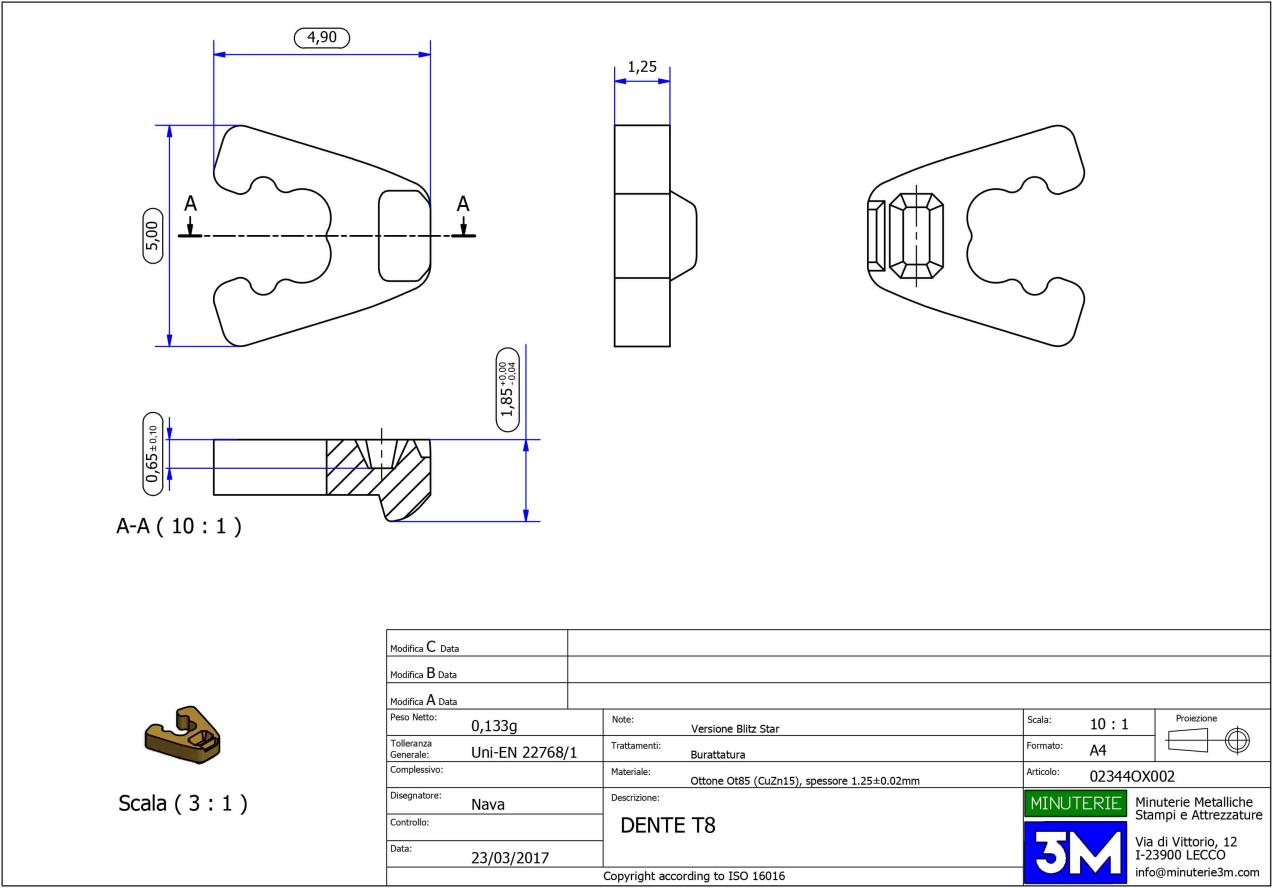

Zipper Teeth Production

The metal strips are then fed into a machine that forms the zipper teeth. This machine uses a series of dies to punch out the teeth from the metal strip. The teeth are then carefully inspected for any defects.

Slider Production

The slider is the part of the zipper that allows it to be opened and closed. It is typically made of plastic or metal and is molded or machined to the desired shape. The slider is then attached to the zipper tape.

Zipper Tape Assembly, Zipper technology

The zipper teeth and slider are then assembled onto the zipper tape. This process involves feeding the zipper tape through a machine that aligns the teeth and slider. The tape is then sewn or glued to the slider to create a secure bond.

Quality Control

Quality control is a crucial part of the zipper manufacturing process. Each zipper is inspected at various stages of production to ensure that it meets the required specifications. This includes checking for defects in the teeth, slider, and tape.

Types of Machinery Used in Zipper Production

Zipper production relies on specialized machinery to perform various tasks, including:

- Metal Strip Cutting Machines: These machines are used to cut the metal strips to the desired length and width.

- Zipper Teeth Forming Machines: These machines use dies to punch out the zipper teeth from the metal strips.

- Slider Molding Machines: These machines are used to mold the plastic or metal sliders.

- Zipper Tape Assembly Machines: These machines align the zipper teeth and slider and attach them to the zipper tape.

- Sewing Machines: These machines are used to sew the zipper tape to the slider.

- Inspection Machines: These machines are used to inspect the zippers for defects.

Quality Control Measures

Quality control measures are essential in ensuring the production of high-quality zippers. These measures include:

- Visual Inspection: Zippers are visually inspected at various stages of production to identify any defects in the teeth, slider, or tape.

- Dimensional Inspection: The dimensions of the zippers are measured to ensure that they meet the required specifications.

- Strength Testing: Zippers are subjected to strength tests to ensure that they can withstand the expected wear and tear.

- Corrosion Testing: Zippers are tested for corrosion resistance to ensure that they can withstand exposure to the elements.

Final Review

Zipper technology, a testament to human ingenuity, continues to evolve, driven by innovation and a desire for greater efficiency and durability. As we look to the future, we can expect to see even more remarkable advancements in zipper design, opening up new possibilities for applications across diverse industries.

Zipper technology, a seemingly simple invention, has revolutionized countless industries. From clothing to luggage, zippers provide a secure and convenient way to fasten and unfasten items. PAC Technologies, a leading provider of automation solutions , has played a significant role in advancing zipper manufacturing processes, ensuring efficiency and quality in production.

The evolution of zipper technology continues, with innovative designs and materials emerging, further enhancing its versatility and durability.