Belding Tank Technologies: A Comprehensive Guide

Belding tank technologies have revolutionized industries, offering efficient and reliable solutions for various applications. These tanks, known for their robust construction and versatility, play a vital role in water treatment, […]

Belding tank technologies have revolutionized industries, offering efficient and reliable solutions for various applications. These tanks, known for their robust construction and versatility, play a vital role in water treatment, chemical processing, and oil and gas sectors. Their ability to handle diverse fluids, withstand demanding environments, and ensure safe storage makes them indispensable across numerous industries.

This guide delves into the fascinating world of Belding tanks, exploring their history, design, types, applications, and future trends. We will examine the key considerations for choosing the right Belding tank, ensuring optimal performance, and adhering to safety regulations.

Introduction to Belding Tanks

Belding tanks, also known as surge tanks or surge suppressors, are essential components in fluid systems designed to absorb and dampen pressure fluctuations. Their primary function is to mitigate pressure surges and oscillations that can occur due to sudden changes in flow rate or system conditions.

Belding tanks have a rich history, dating back to the early 20th century. Initially used in hydroelectric power plants, their importance has expanded to various industries, including water treatment, chemical processing, and oil and gas extraction. Their evolution has been driven by the need for reliable and efficient fluid handling, particularly in systems with high pressure gradients or rapid flow variations.

Significance of Belding Tanks in Various Industries

Belding tanks play a crucial role in maintaining system stability and preventing damage in numerous industries. Their significance stems from their ability to:

- Protect Equipment from Pressure Surges: Sudden changes in flow rate, such as valve closures or pump start-ups, can create pressure surges that can damage pipes, pumps, and other equipment. Belding tanks act as a buffer, absorbing the excess energy and preventing these damaging pressure spikes.

- Ensure Consistent Flow Rates: By dampening pressure fluctuations, Belding tanks help maintain consistent flow rates, which is essential for processes that require precise fluid delivery. This is particularly important in applications such as water distribution systems, where consistent water pressure is crucial for efficient delivery.

- Improve System Efficiency: Belding tanks can reduce energy consumption by minimizing pressure losses caused by pressure surges. This is achieved by storing excess energy during periods of high flow and releasing it during periods of low flow, resulting in smoother and more efficient operation.

- Enhance Safety: By mitigating pressure surges, Belding tanks enhance safety by reducing the risk of system failures, leaks, and potential accidents. This is especially important in industries where hazardous materials are handled, as it helps prevent catastrophic events.

Types of Belding Tanks

Belding tanks, also known as surge tanks, are essential components in various hydraulic systems, playing a crucial role in managing pressure fluctuations and ensuring consistent water flow. These tanks come in various designs, each tailored to specific applications and operational requirements.

Classifications of Belding Tanks

Understanding the different types of Belding tanks is essential for selecting the most appropriate option for a given application. The following table provides a comprehensive overview of the various types, their characteristics, and typical applications.

| Type | Description | Materials | Typical Applications |

|---|---|---|---|

| Simple Belding Tank | A basic tank with a single opening connected to the pipeline. It absorbs pressure surges by temporarily storing excess water. | Steel, concrete, or fiberglass | Small-scale water systems, irrigation systems, and fire suppression systems |

| Standpipe Belding Tank | A tall, vertical tank with a standpipe connected to the pipeline. It provides additional head pressure and helps maintain a consistent flow rate. | Steel, concrete, or fiberglass | High-rise buildings, water distribution systems, and industrial applications |

| Surge Tank with Air Chamber | A Belding tank equipped with an air chamber to absorb pressure surges. The air chamber acts as a cushion, reducing the impact of pressure fluctuations. | Steel, concrete, or fiberglass | Pumping stations, hydropower plants, and water treatment facilities |

| Differential Belding Tank | A tank with two chambers, one for water and the other for air. It allows for more precise control of pressure fluctuations and can be used for both pressure and flow regulation. | Steel, concrete, or fiberglass | High-pressure systems, industrial processes, and water distribution networks |

| Variable-Volume Belding Tank | A tank with a variable volume that can be adjusted to accommodate different flow rates and pressure demands. | Steel, concrete, or fiberglass | Water distribution systems, irrigation systems, and industrial applications |

Advantages and Disadvantages of Different Belding Tank Types

Each type of Belding tank offers distinct advantages and disadvantages, making it crucial to carefully consider the specific requirements of the application.

Simple Belding Tank

Advantages:

- Simple design and construction

- Cost-effective for small-scale applications

- Easy to maintain

Disadvantages:

- Limited capacity for absorbing pressure surges

- May not be suitable for high-pressure or high-flow applications

Standpipe Belding Tank

Advantages:

- Provides additional head pressure

- Helps maintain consistent flow rate

- Suitable for high-rise buildings and water distribution systems

Disadvantages:

- Higher construction costs compared to simple tanks

- Requires more space for installation

Surge Tank with Air Chamber

Advantages:

- Effectively absorbs pressure surges

- Reduces the impact of pressure fluctuations

- Suitable for high-pressure and high-flow applications

Disadvantages:

- More complex design and construction

- Requires regular maintenance to ensure proper air pressure

Differential Belding Tank

Advantages:

- Provides precise control of pressure fluctuations

- Can be used for both pressure and flow regulation

- Suitable for high-pressure and high-flow systems

Disadvantages:

- Most complex design and construction

- Higher initial cost compared to other types

Variable-Volume Belding Tank

Advantages:

- Adaptable to different flow rates and pressure demands

- Optimizes performance for varying operating conditions

Disadvantages:

- More complex design and control system

- Higher initial cost compared to fixed-volume tanks

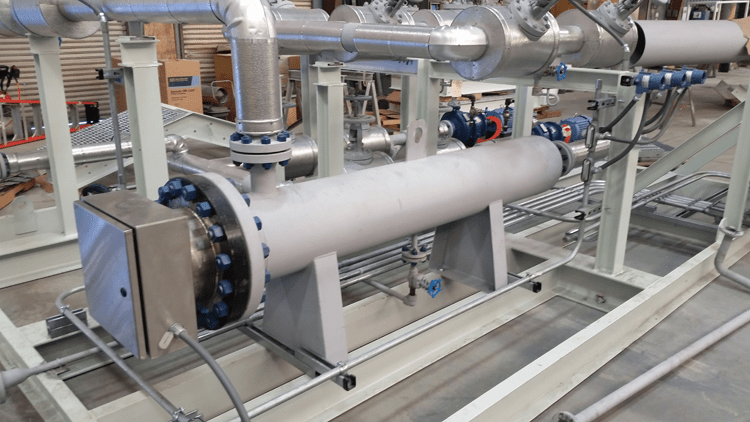

Design and Construction of Belding Tanks: Belding Tank Technologies

Belding tanks, also known as baffled tanks, are specifically designed for the efficient separation of solid particles from liquids. The design and construction of these tanks are crucial for optimal performance and longevity. Several key principles and considerations guide the construction of Belding tanks, ensuring effective separation and minimizing operational challenges.

Design Principles and Considerations, Belding tank technologies

The design of a Belding tank involves careful consideration of various factors, including the specific application, the properties of the liquid and solid phases, and the desired level of separation efficiency. These considerations determine the tank’s dimensions, baffle arrangement, and overall configuration.

Flow Patterns and Baffle Design

The design of the baffles is crucial for controlling the flow patterns within the tank, which directly impacts the separation process. Baffles are strategically positioned to create turbulence and induce a swirling motion, effectively promoting the settling of solid particles. The spacing and orientation of baffles are determined based on the characteristics of the liquid and solid phases, ensuring efficient separation without excessive pressure drops.

Tank Dimensions and Capacity

The dimensions of a Belding tank are determined by the volume of liquid to be processed and the desired residence time for effective separation. The tank’s diameter and height are carefully chosen to accommodate the flow rate and provide sufficient settling space for the solid particles.

Materials Selection

The materials used in Belding tank construction are critical for ensuring durability, corrosion resistance, and compatibility with the processed fluids. Common materials include:

- Stainless Steel: Highly resistant to corrosion, making it suitable for handling various chemicals and liquids. Its strength and durability make it a popular choice for Belding tanks.

- Carbon Steel: A cost-effective option for handling non-corrosive liquids. However, it may require coatings or linings for protection against corrosion in certain applications.

- Fiberglass Reinforced Plastic (FRP): Lightweight and corrosion-resistant, making it suitable for handling acidic or corrosive liquids. However, it may have limitations in terms of temperature and pressure resistance.

- Concrete: Used for larger-scale Belding tanks, particularly for wastewater treatment applications. Concrete offers durability and cost-effectiveness, but requires careful design and construction to ensure proper sealing and corrosion resistance.

Design Features and their Impact on Tank Performance

Various design features can enhance the performance of Belding tanks. Some examples include:

- Inclined Baffles: These baffles create a spiral flow pattern, promoting efficient settling and minimizing short-circuiting. This configuration is particularly effective for handling high flow rates or high-density solids.

- Multiple Settling Zones: Tanks can be designed with multiple settling zones, each optimized for specific particle sizes or densities. This approach improves overall separation efficiency by allowing for more targeted settling of different particle types.

- Sludge Removal Systems: Efficient sludge removal systems are essential for maintaining the tank’s performance. This can include mechanisms like bottom drain valves, screw conveyors, or other specialized equipment, depending on the specific application.

Conclusive Thoughts

As we conclude our exploration of Belding tank technologies, it becomes evident that these versatile structures are crucial for modern industries. Their ability to meet evolving demands, adapt to diverse environments, and ensure safe operations makes them an essential component of numerous processes. From water treatment to chemical processing, Belding tanks continue to play a vital role in driving innovation and efficiency across various sectors.

Belding Tank Technologies is a leading provider of innovative tank solutions for various industries. Their commitment to quality and efficiency has earned them a reputation for excellence. You can learn more about their services and products by visiting their location at 2055 Technology Pkwy, Mechanicsburg, PA 17050.

Belding Tank Technologies’ dedication to innovation and customer satisfaction makes them a valuable partner for any project requiring reliable and efficient tank solutions.